Numerical-control roller bending device used for step guide rail bending, molding and processing

A technology of bending forming and bending device, applied in the field of machinery, can solve the problems of low material utilization rate and uncontrollable cross-sectional size, and achieve the effect of preventing sideslip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

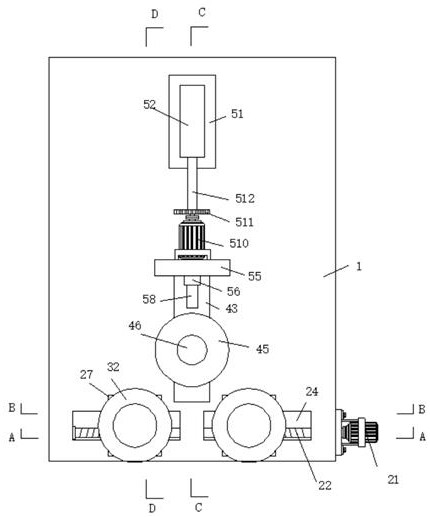

[0049]Assemble the required fixed mold 32 and movable mold 45, turn on the external power supply, place the ladder rails that need to be rolled in the grooves of the two fixed molds 32, start the hydraulic cylinder 52, and the hydraulic cylinder 52 pushes the hydraulic rod 512 to move , The hydraulic rod 512 pushes the vertical plate 55 to move, and the vertical plate 55 drives the vertical rod 54 and the limit slider 53 at the lower end to slide along the long groove 41 and the bottom groove 43, respectively, and the limit slider 53 and the bottom groove 43 can maintain the vertical The plate 55 slides steadily without tilting. The vertical plate 55 pushes the load-bearing screw 58 to run through the threads in the threaded long groove 57. The reinforcement block 56 increases the number of threads to make the thrust more stable. The load-bearing screw 58 pushes the mold 45 to move. The mold 45 drives the slide bar 42 and the bottom plate 44 to slide in the long groove 41 and the bo...

Embodiment 2

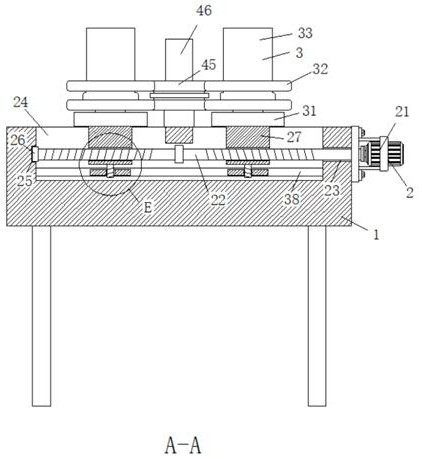

[0051]If the bending amplitude of the stairway guide rail needs to be increased in length, the first motor 21 is controlled to start, and the first motor 21 drives the two-way threaded rod 22 to rotate. The two ends of the two-way threaded rod 22 are in opposite directions, and the two slides are driven by the opposite threads. The block 27 slides to both ends. The first motor 21 adopts a servo motor. Through the control system, the number of turns and the angle of rotation are precisely controlled, and the two-way threaded rod 22 is driven to rotate by a fixed number of turns. The distance between the two sliders 27 can be precisely controlled. The distance between them is such that when rolling with the ladder rail parts, the supporting point of the bending force becomes larger, and the bending amplitude is correspondingly increased. The first motor 21 is controlled by the numerical control system to achieve precise adjustment. If the bending amplitude needs to be reduced, the fir...

Embodiment 3

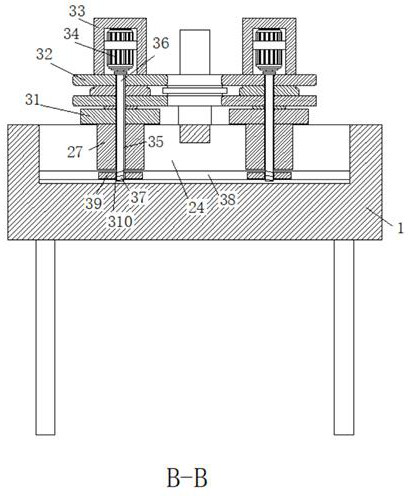

[0053]When rolling, the movable die 45 squeezes the ladder rail onto the fixed die 32. During the continuous extrusion, the ladder rail is bent, and the contact point between the curved ladder rail and the two fixed die 32 changes. , Resulting in a slight change in the force direction of the fixed mold 32, the two fixed molds 32 as backers, may slide along the direction of the chute 24 when bearing the roller pressure, start the second motor 34, the second motor 34 drives the rotating rod 36 rotates, the external thread 37 at the bottom of the rotating rod 36 drives the sliding plate 39 upward under the action of the threaded hole 310. The sliding plate 39 cannot move up in the limiting groove 38, so it tightly abuts on the upper surface of the limiting groove 38. The entire fixed mold mechanism 3 is fixed, and friction is generated during rolling to prevent side slip. Since the lateral extrusion force angle of the ladder rail against the fixed mold 32 is small, the force component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com