Metal grid flexible conductive film and manufacturing method thereof

A metal grid, flexible and conductive technology, applied in the field of conductive film, can solve the problems of insufficient lightness and flexibility of the finished product, and achieve the effect of stable product performance, reduced material usage, and excellent touch and vision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

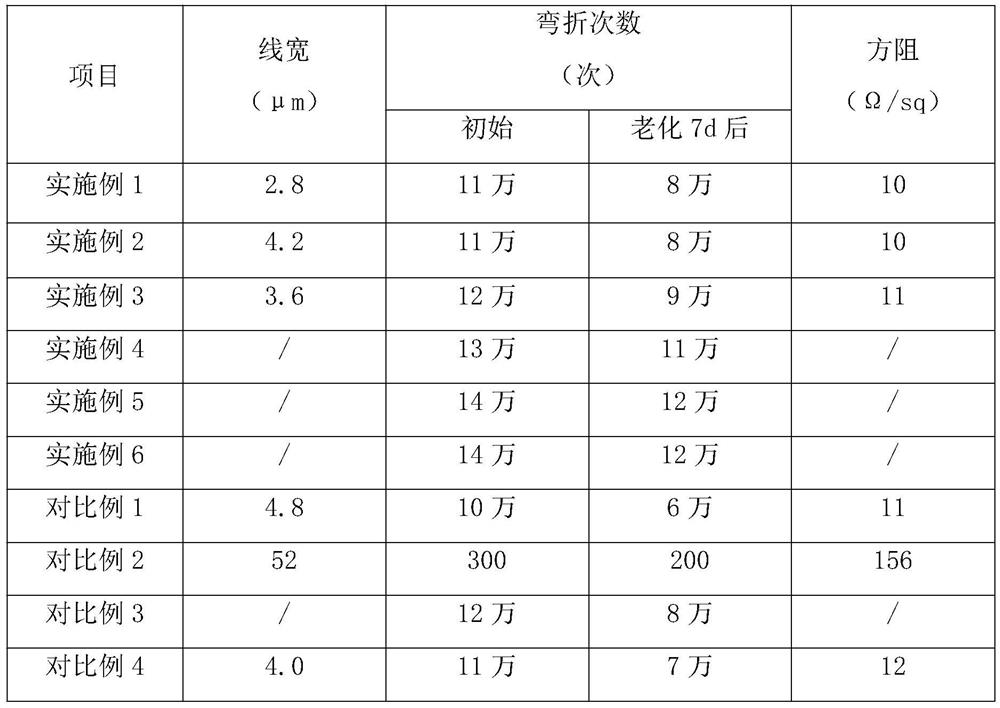

Examples

Embodiment 1

[0044] (1) Coating: The catalyst is prepared by mixing palladium catalyst, pure water, solvent and active agent, heating and stirring; take a flexible transparent substrate, coat the catalyst on both its upper and lower sides to form a catalyst layer, and coat the surface of the catalyst layer with Cloth photoresist, form photoresist coating layer, make substrate A;

[0045] (2) Exposure: Place substrate A obtained in step (1) under a photomask for exposure treatment, the wavelength of ultraviolet light is 314nm, and the exposure energy is 50mJ / cm 2 , the lighted area in the photoresist coating layer is cured to obtain the substrate B;

[0046] (3) Developing: Get the substrate B obtained in step (2) and place it in a developing solution for developing treatment, remove the unilluminated part in the photoresist coating layer, and form a photoresist layer with grooves. The catalyst layer is exposed to form a circuit pattern, and a substrate C is obtained; wherein the developin...

Embodiment 2

[0051] (1) Coating: The catalyst is prepared by mixing palladium catalyst, pure water, solvent and active agent, heating and stirring; take a flexible transparent substrate, coat the catalyst on both its upper and lower sides to form a catalyst layer, and coat the surface of the catalyst layer with Cloth photoresist, form photoresist coating layer, make substrate A;

[0052] (2) Exposure: the base material A obtained in step (1) is placed under a photomask for exposure treatment, the wavelength of ultraviolet light is 314nm, and the exposure energy is 65mJ / cm 2, the illuminated area in the photoresist coating layer is cured, and the Obtain substrate B;

[0053] (3) Developing: Get the substrate B obtained in step (2) and place it in a developing solution for developing treatment, remove the unilluminated part in the photoresist coating layer, and form a photoresist layer with grooves. The catalyst layer was exposed to form a circuit pattern, and the substrate C was obtained; ...

Embodiment 3

[0058] (1) Coating: The catalyst is prepared by mixing palladium catalyst, pure water, solvent and active agent, heating and stirring; take a flexible transparent substrate, coat the catalyst on both its upper and lower sides to form a catalyst layer, and coat the surface of the catalyst layer with Cloth photoresist, form photoresist coating layer, make substrate A;

[0059] (2) Exposure: the base material A obtained in step (1) is placed under a photomask for exposure treatment, the wavelength of ultraviolet light is 365nm, and the exposure energy is 80mJ / cm 2 , the illuminated area in the photoresist coating layer is cured, and the Obtain substrate B;

[0060] (3) Developing: Get the substrate B obtained in step (2) and place it in a developing solution for developing treatment, remove the unilluminated part in the photoresist coating layer, and form a photoresist layer with grooves. The catalyst layer is exposed to form a circuit pattern, and the substrate C is obtained; w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com