Decorative aluminum-plastic plate forming machining method

A technology for forming and processing aluminum-plastic panels, which is used in metal processing equipment, feeding devices, positioning devices, etc., and can solve problems such as inability to punch and inconvenient production and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

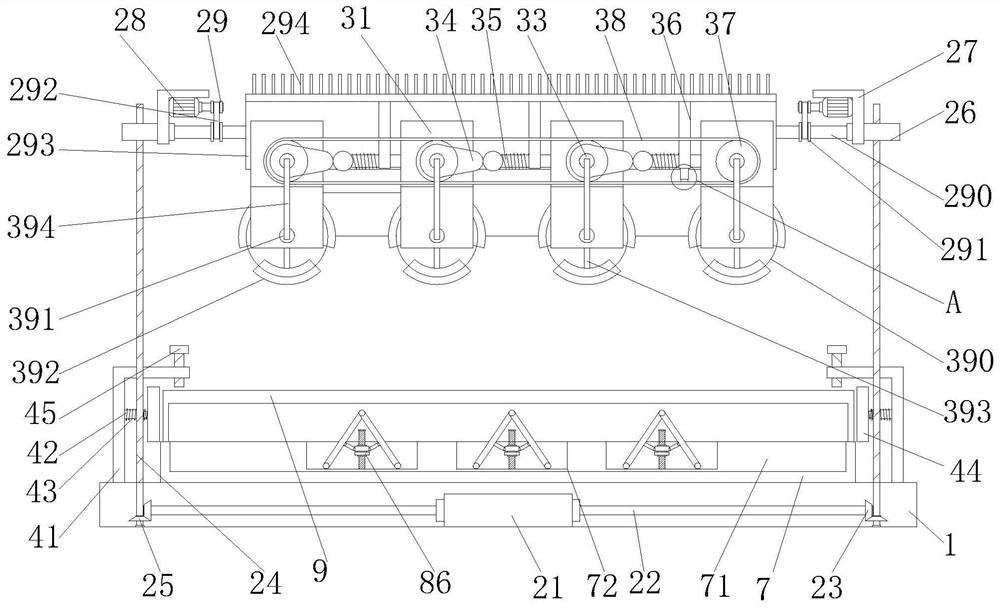

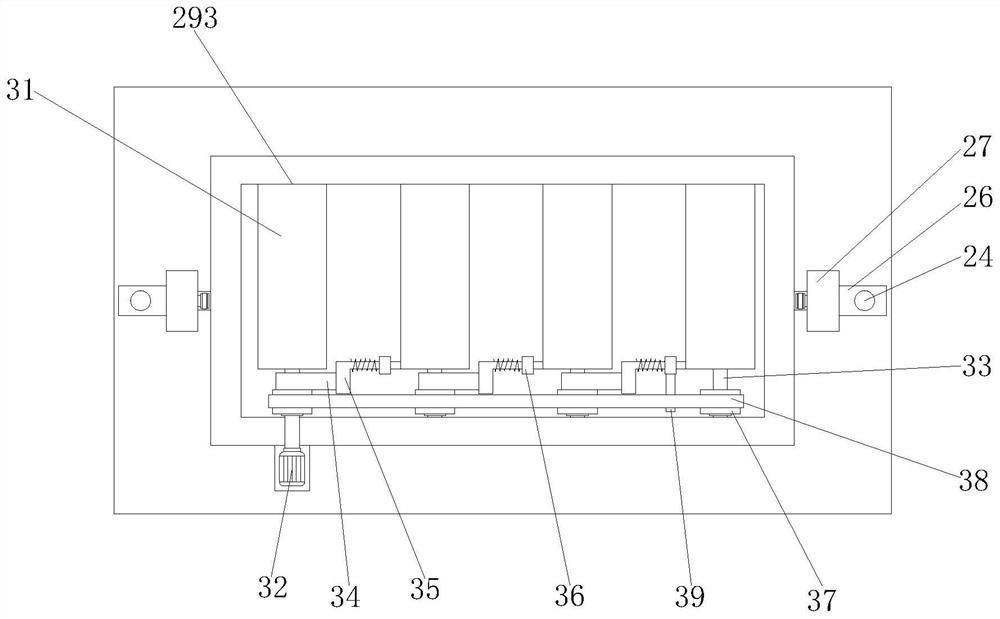

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

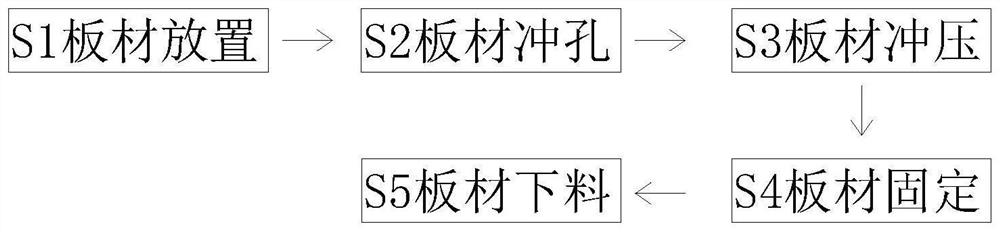

[0036] like Figure 1 to Figure 8 Shown is a decorative aluminum-plastic plate forming processing method, which uses a stamping forming equipment, the stamping forming equipment includes a base 1, a stamping device, an adjustment device, a clamping device, and a punching table 9, using the above-mentioned decorative aluminum plastic plate The specific method of plate forming processing method is as follows:

[0037] S1. Plate placement: manually place the unpunched aluminum-plastic plate on the surface of the punching table 9 for fixed clamping;

[0038] S2. Plate punching: Tongyan turns on the biaxial motor 21, so that the punching screws 24 on both sides rotate to drive the punching knife 294 to punch the surface of the aluminum-plastic plate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com