Construction method of special-shaped curved surface concrete roof

A technology of special-shaped curved surface and construction method, which is applied in the direction of roof engineering tools, roof, roof covering, etc., can solve problems such as holes and cracks, difficult construction, concrete collapse, etc., and achieve the effect of reducing quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

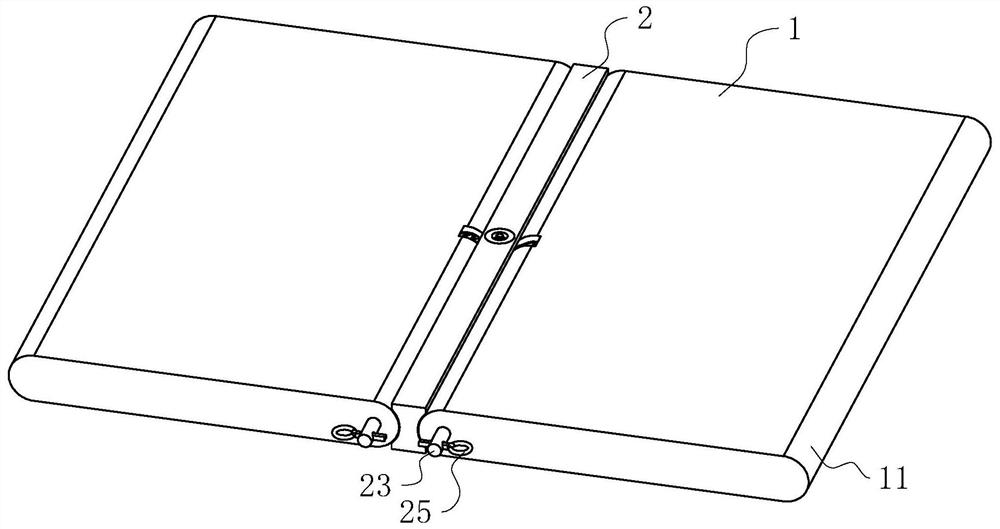

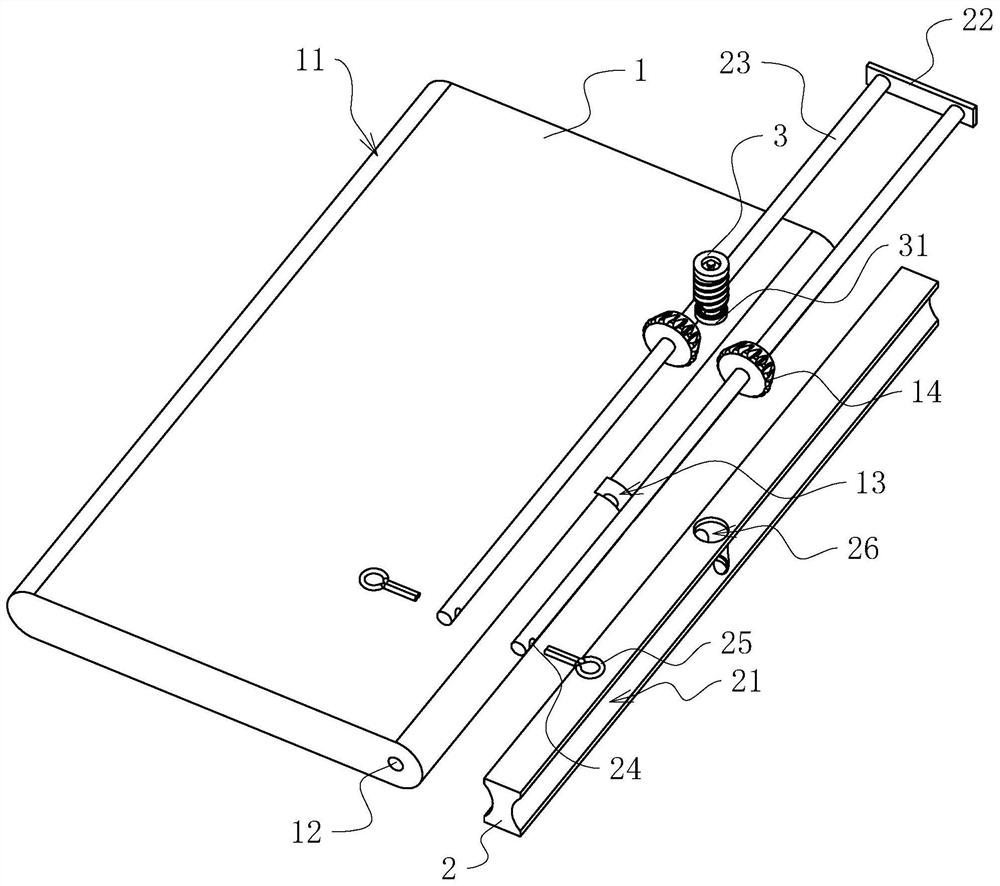

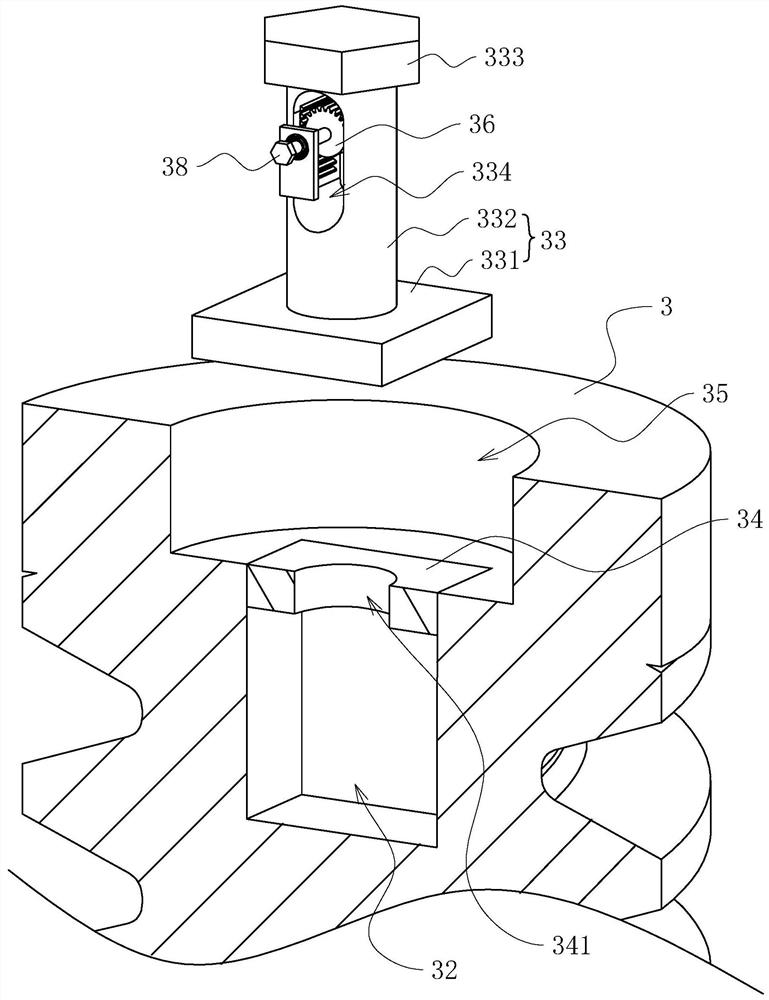

[0042] Attached below. Figure 1-4 This application will be further explained in detail.

[0043] The embodiment of the application discloses a construction method of a special-shaped curved concrete roof. A construction method of special-shaped curved concrete roof includes the following steps:

[0044] S1. Sectioning of curved roof sections: according to the design drawings, the curved roof is sectioned horizontally and longitudinally, and divided into several curved surfaces with the same size, and the curved roof is divided into a grid shape.

[0045] S2, computer pre-arranging: according to the divided curved surfaces, positioning the whole curved surface according to four points of each curved surface, and modeling the curved roof; Then, according to the three-dimensional model of the curved roof and the radian of each curved surface, the positioning coordinates and height of each steel pipe are calculated.

[0046] S3, positioning and setting-out: the curved roof is position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com