Patents

Literature

30results about How to "Improve performance and life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

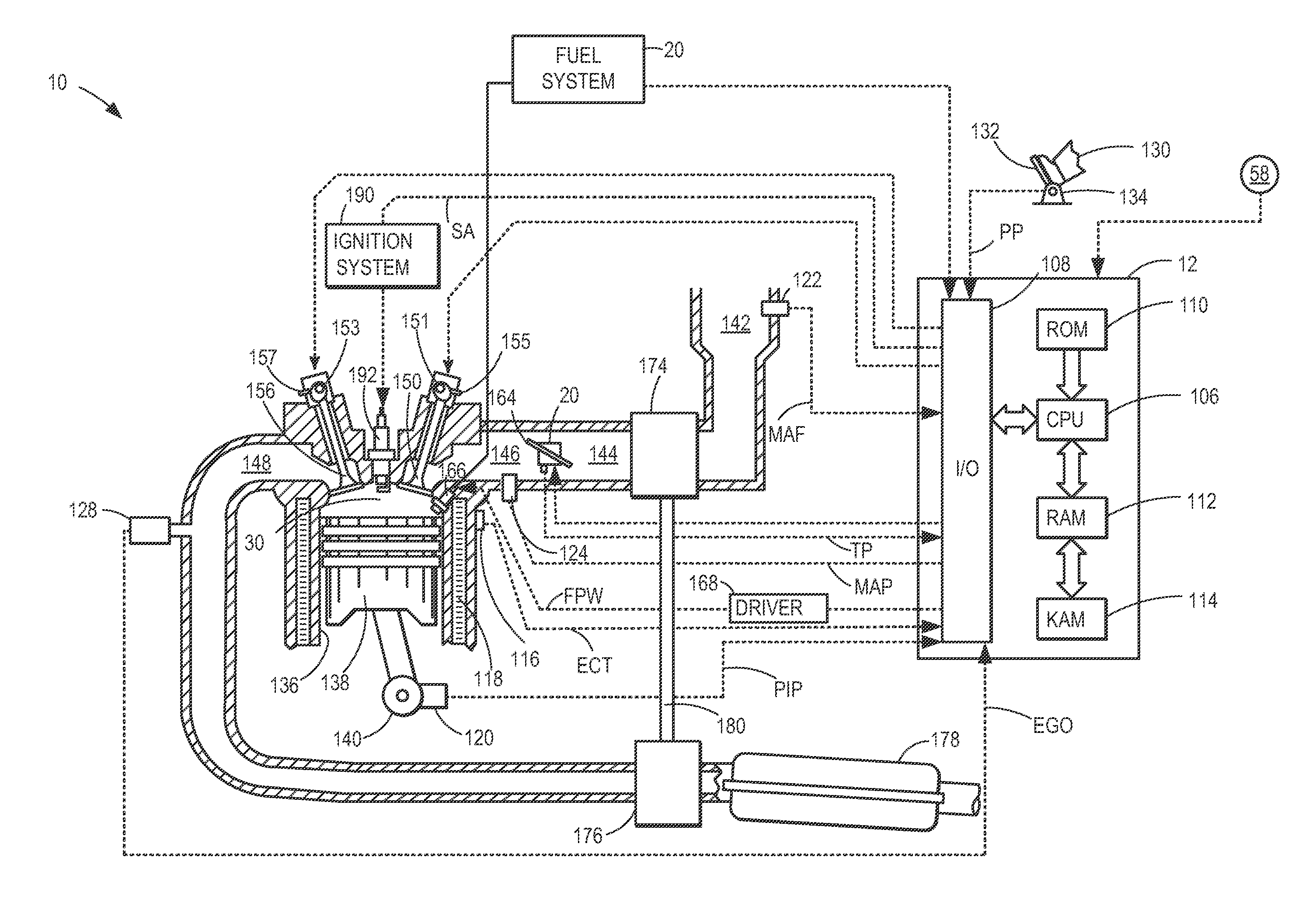

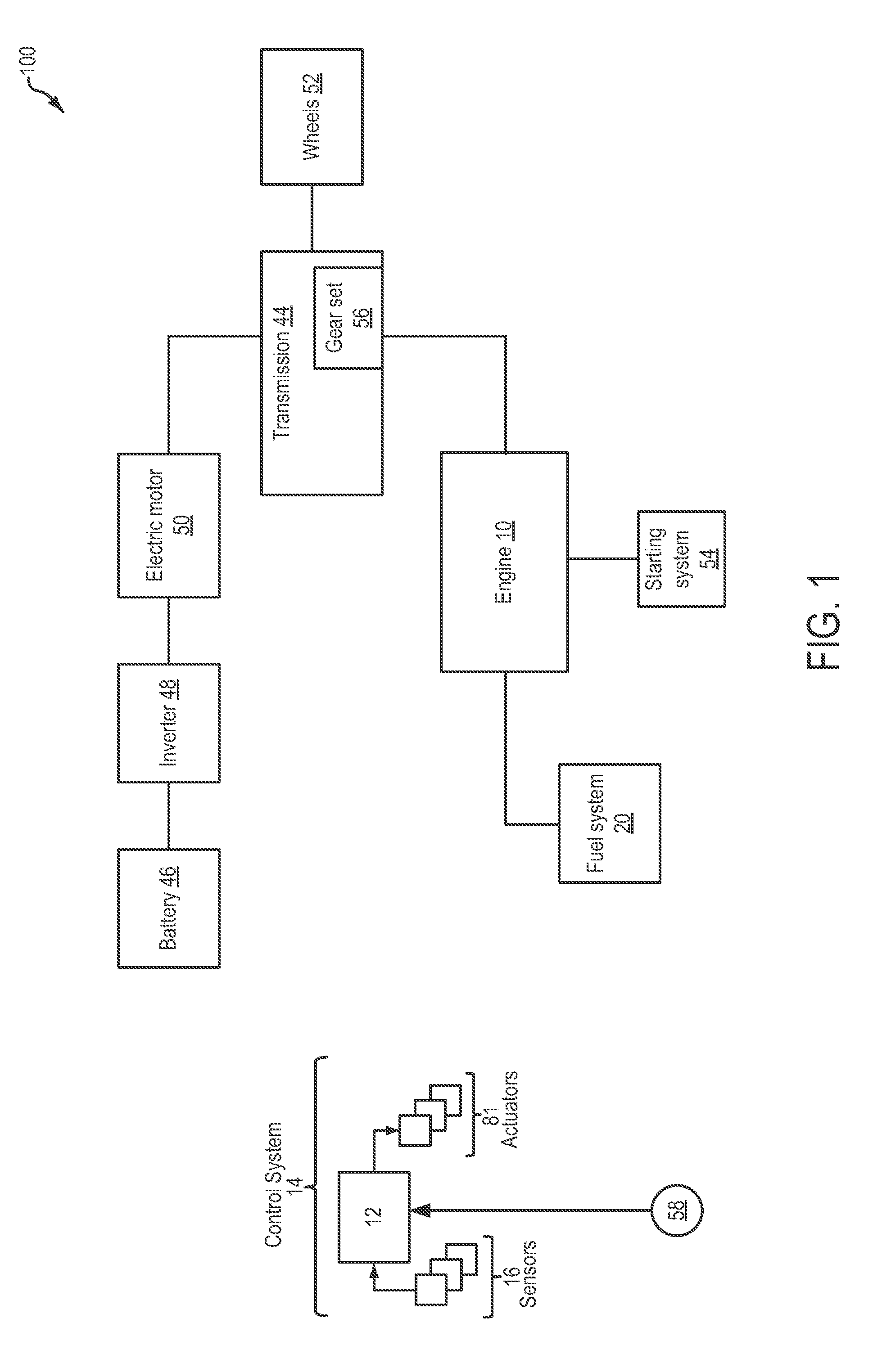

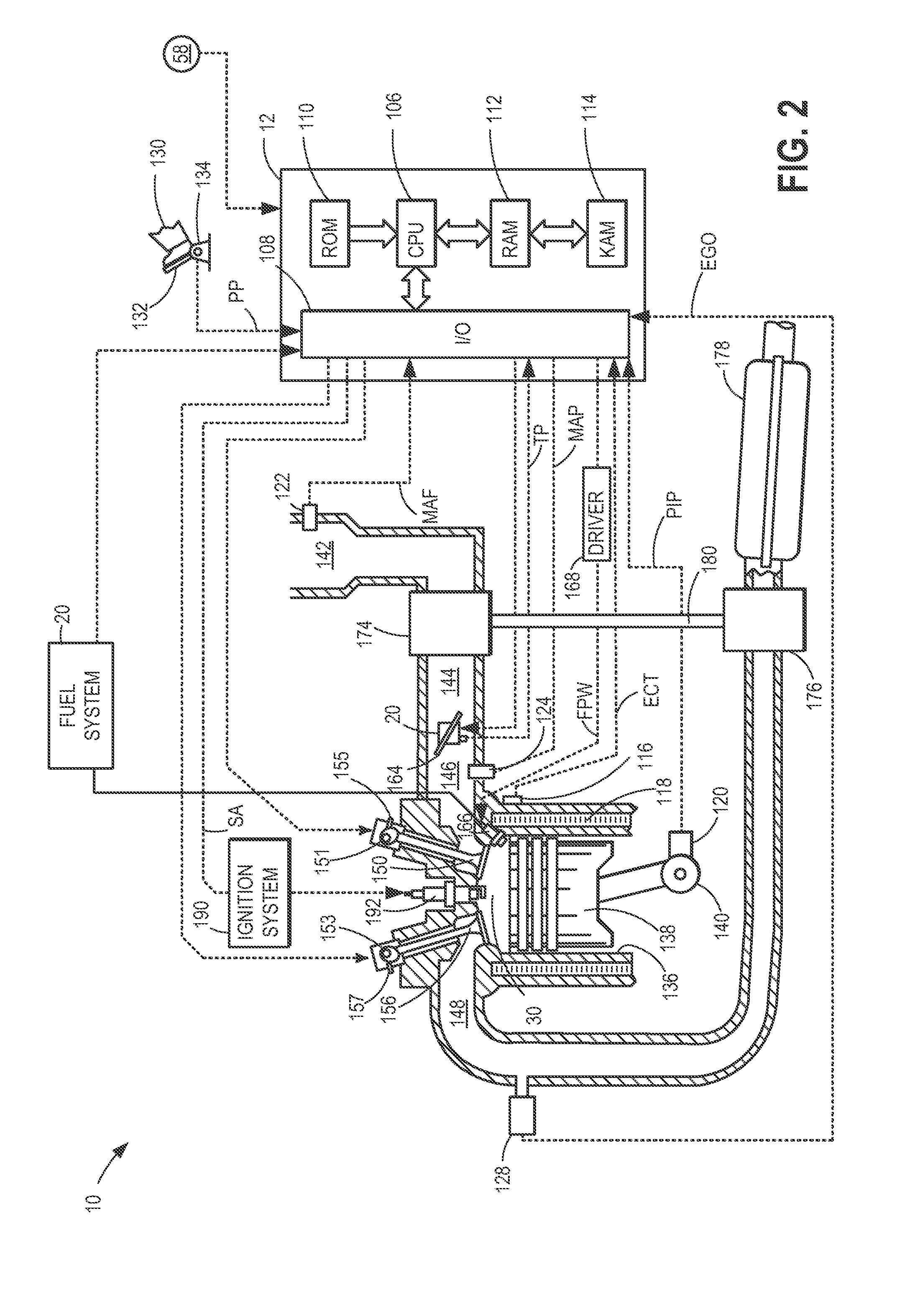

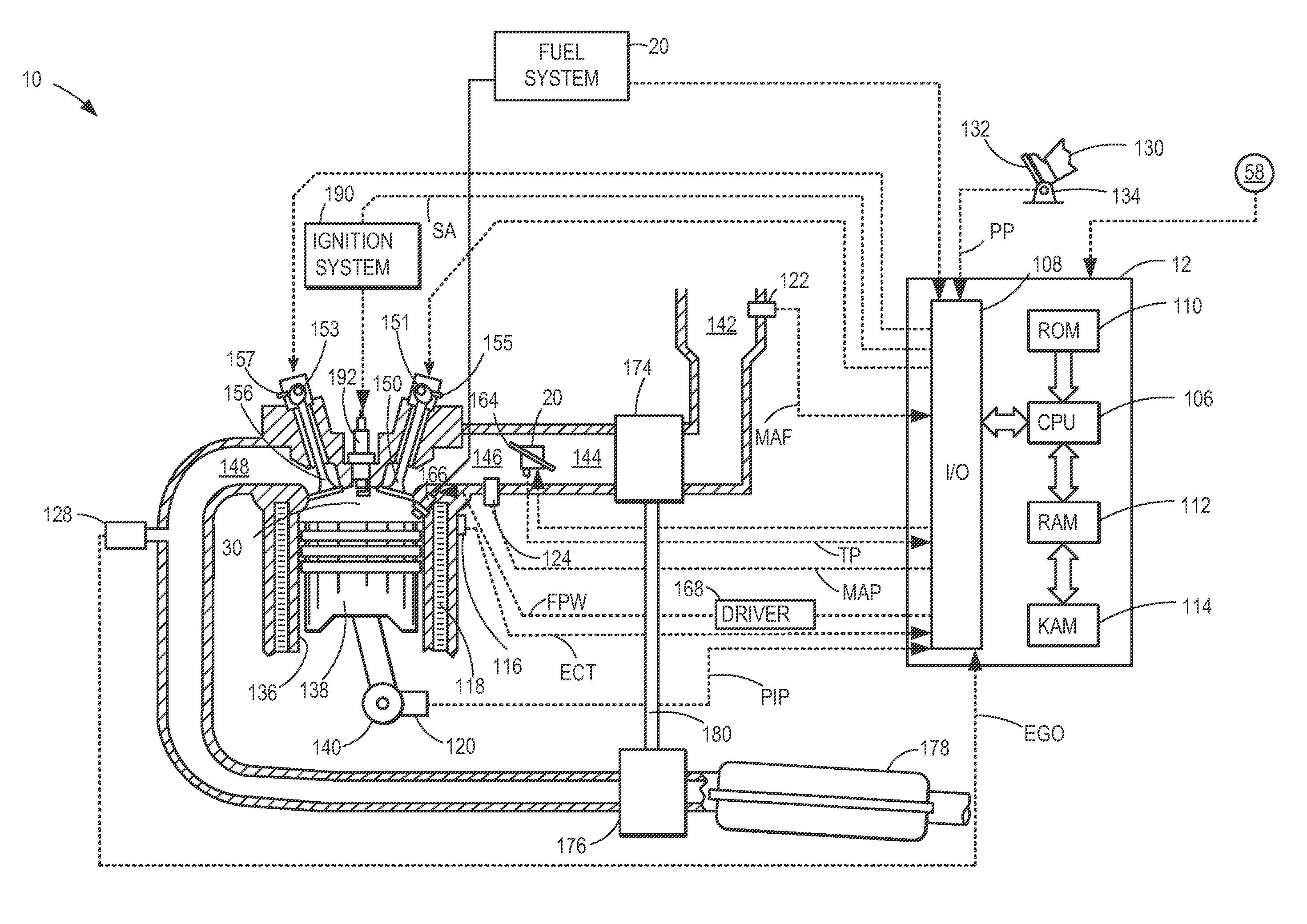

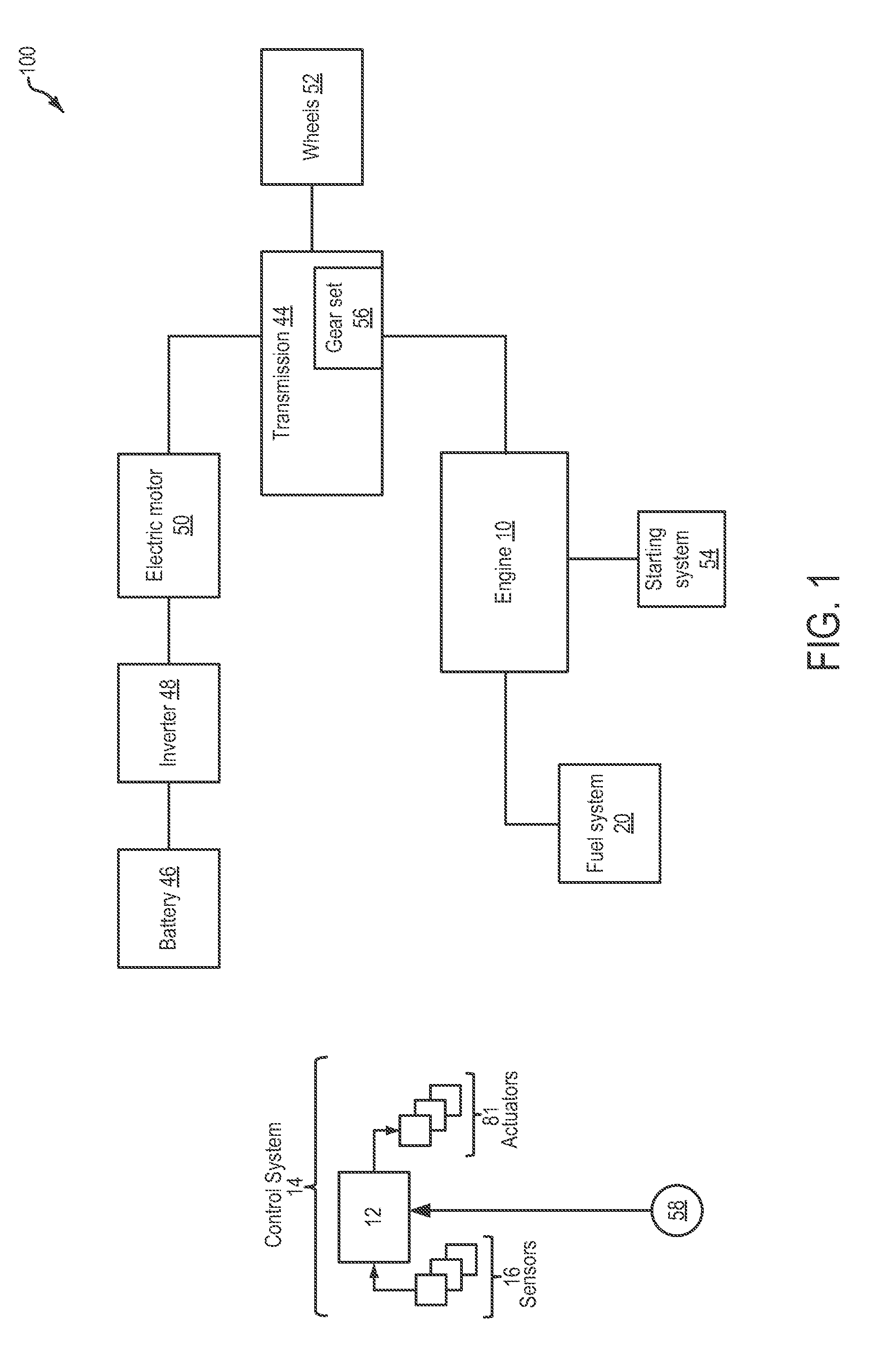

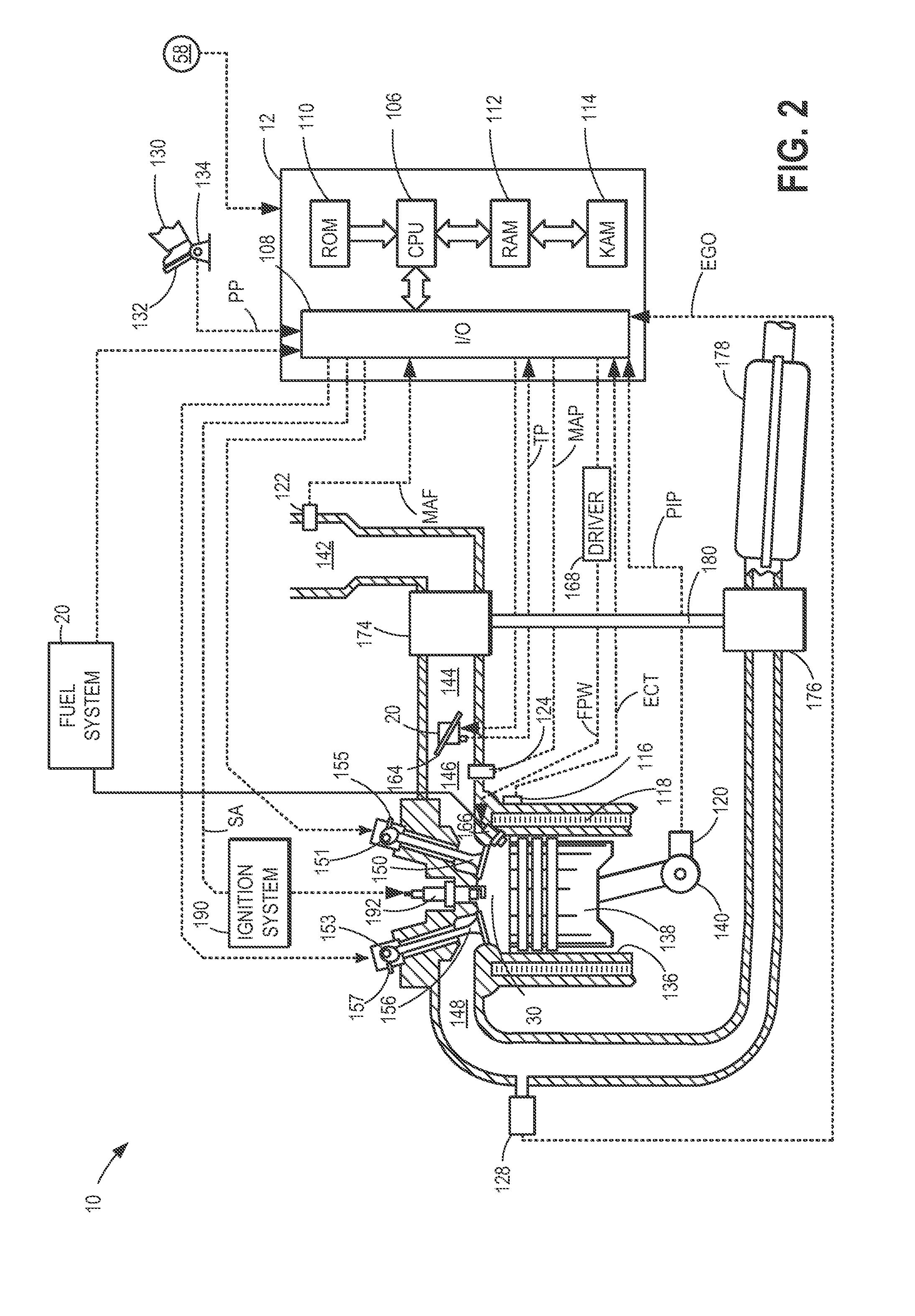

Method and system for vehicle speed control

ActiveUS20130066493A1Prolong lifeImprove performanceHybrid vehiclesDigital data processing detailsBrake torqueRegenerative brake

Methods are provided for controlling a vehicle speed during a downhill travel. Based on the estimated grade of the downhill travel and further based on an input received from the operator, different combinations of an engine braking torque and a regenerative braking torque are used to maintain the vehicle speed during the downhill travel. A battery rate of charging is also adjusted based on the duration or distance of the downhill travel, as indicated by the operator input.

Owner:FORD GLOBAL TECH LLC

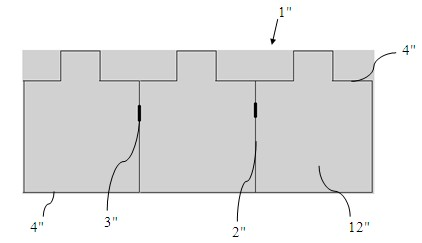

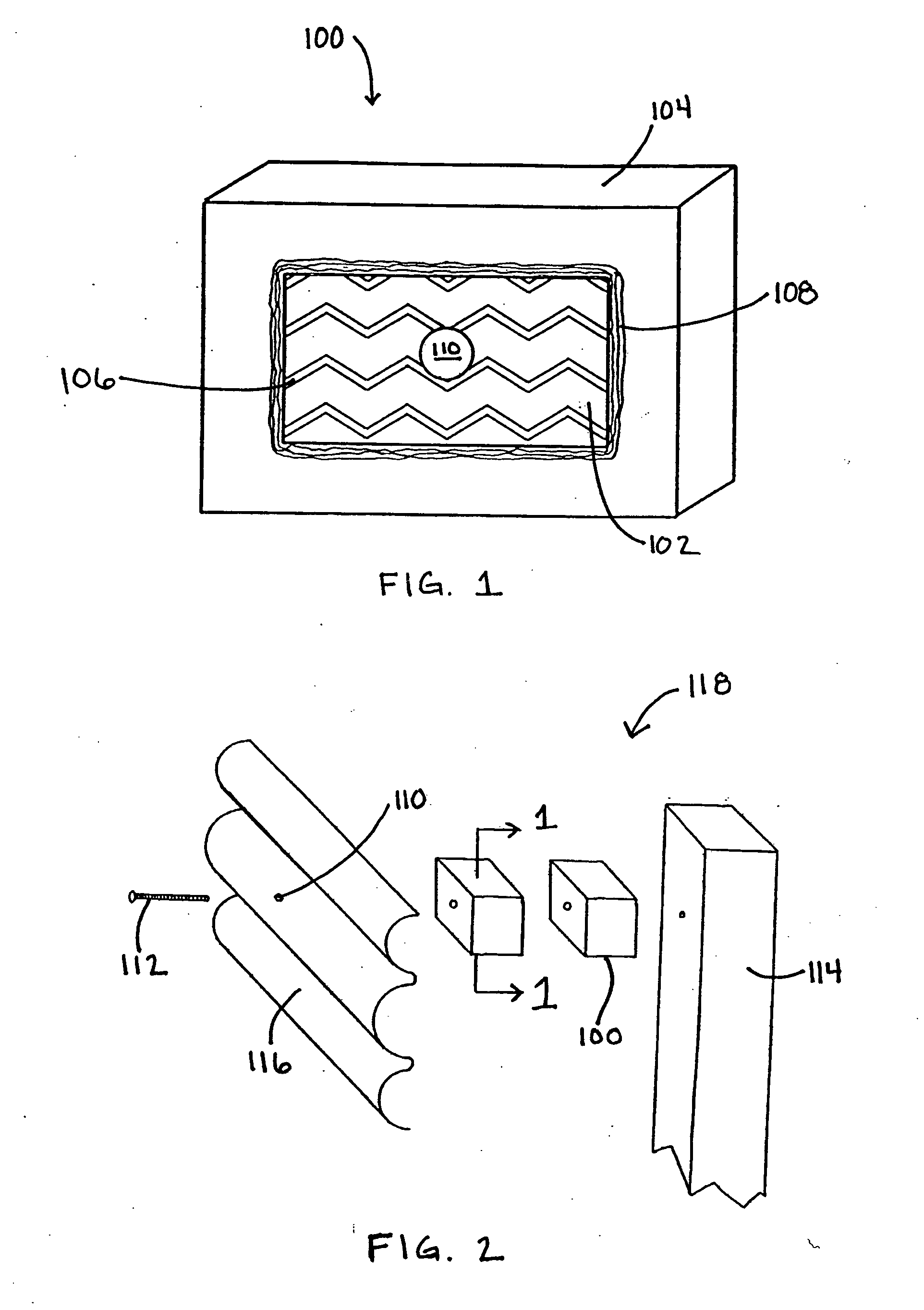

Floor or wall covering

A metal-stone floor or wall covering, more particularly a “hard surface” floor covering is created in plant by stamping large panels from sheet metal with an interlocking reversing notched edge. This allows each large panel to lock into additional panel sufficient to cover a floor area, whereupon the sheet metal in plant is covered with cross linking polymer cement mixed with crushed powdered stone and the resulting slurry is applied over the surface of the sheet metal in a thin layer and allowed to harden. Grout line grooves are carved into the mixed overlay and filled with a latex grout which is then allowed to harden after which, the tile is colorized, and then sealed with a clear coat, dried and shipped to site for bonding in place by beads of a foamed adhesive which allow some flexing of the floor as an integral structure.

Owner:DOMBOWSKY MICHAEL

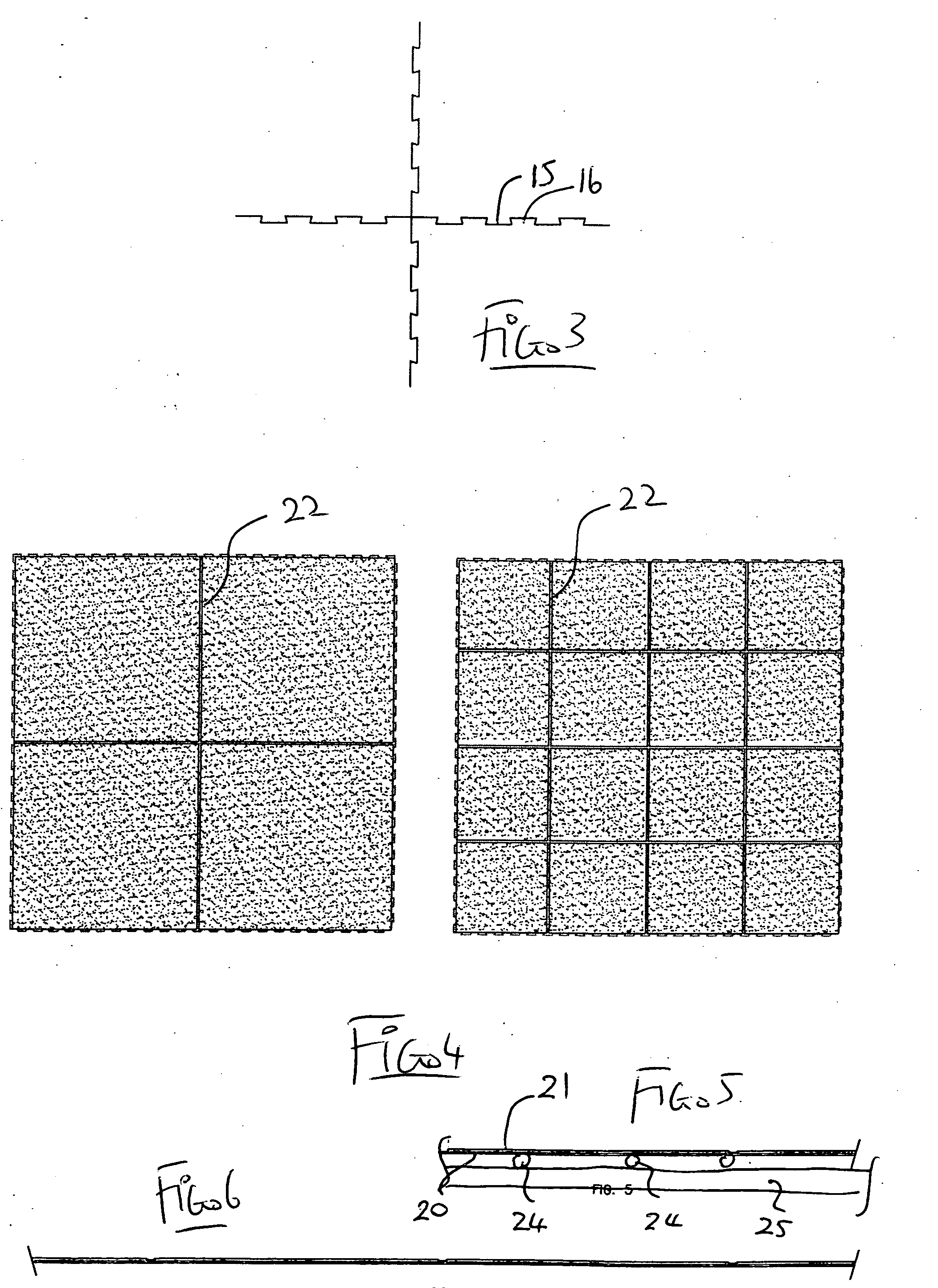

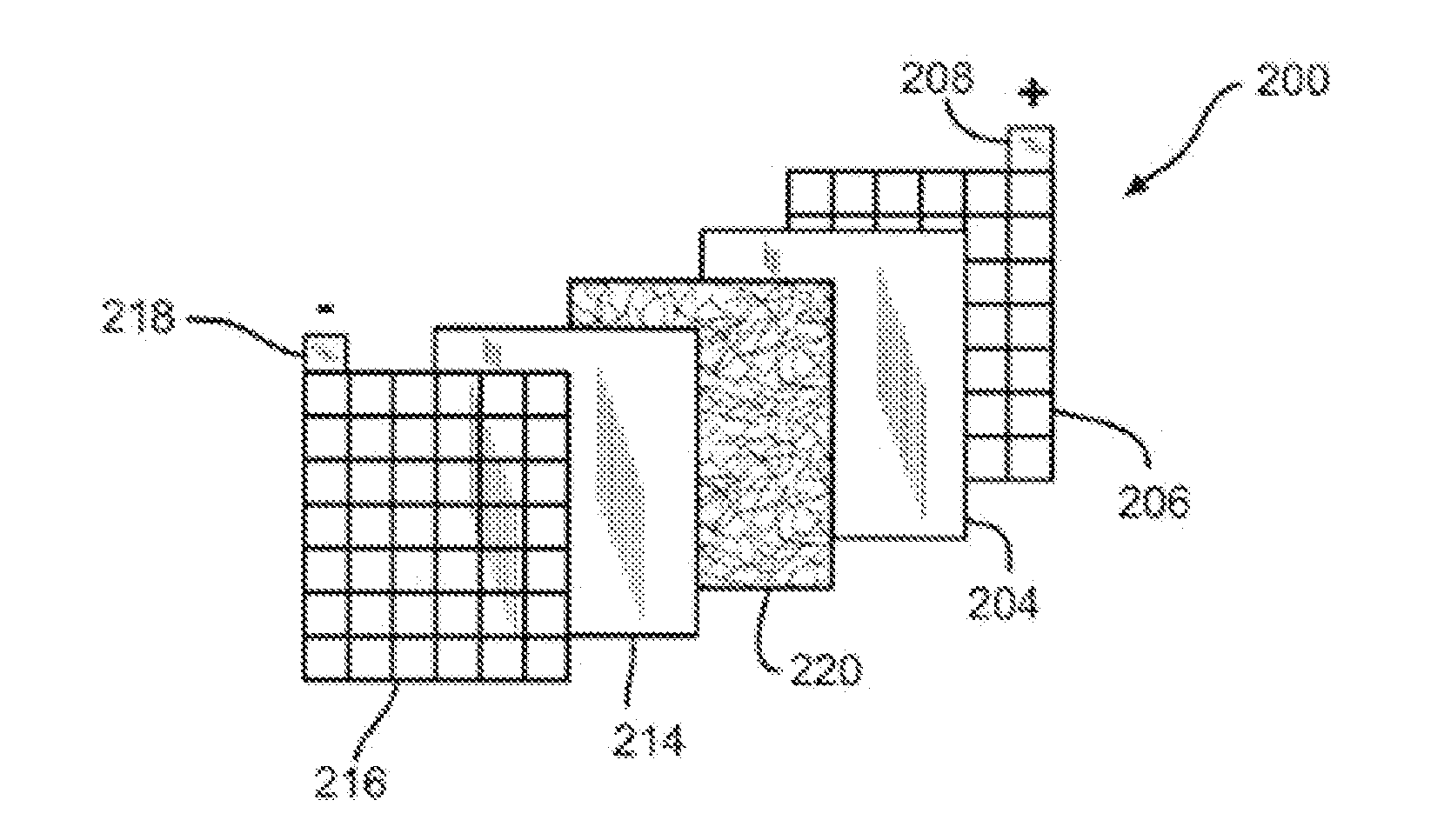

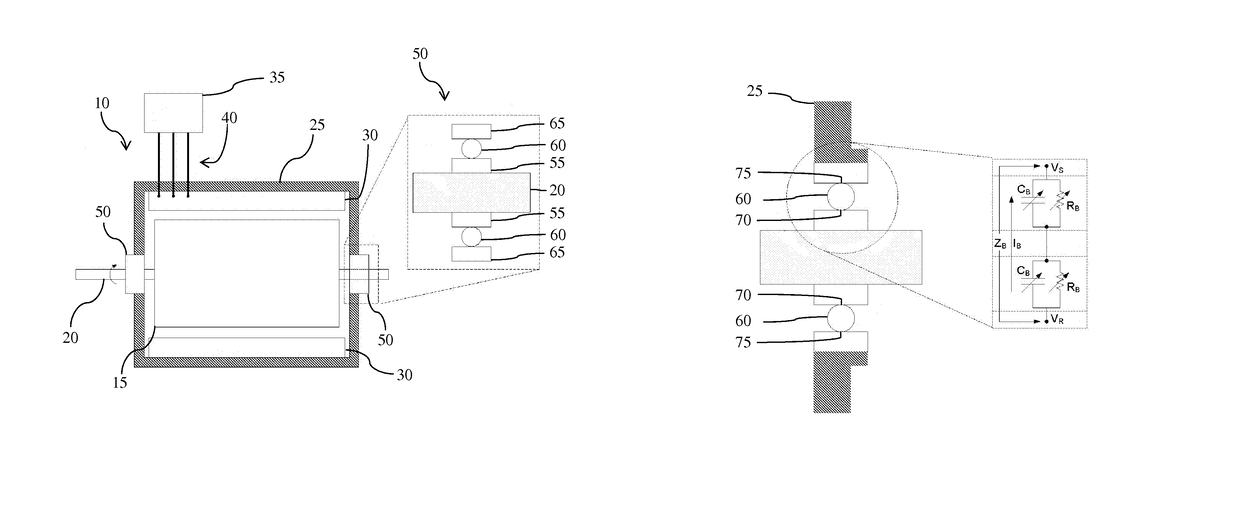

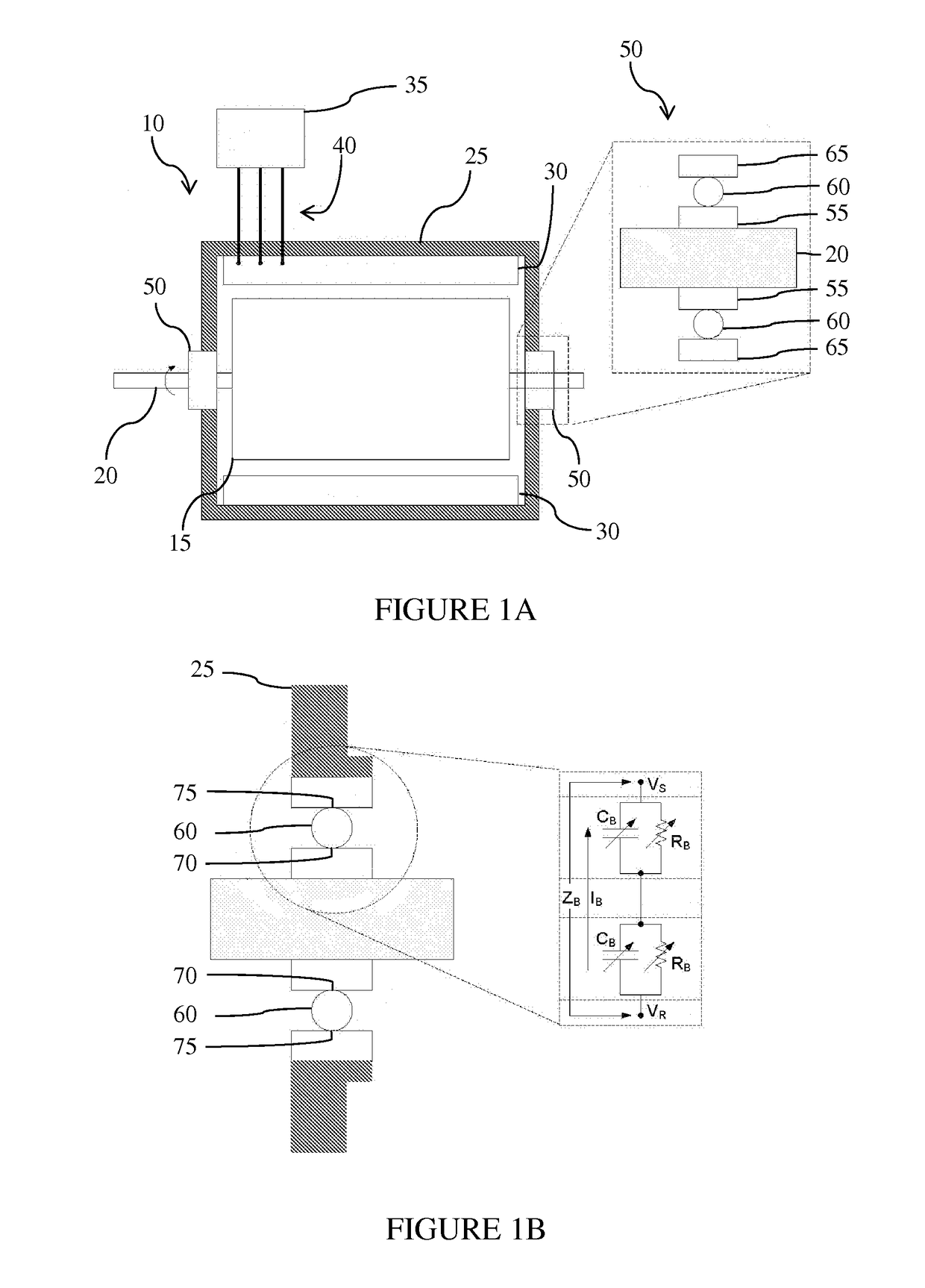

Rotary capacitor for shunting high frequency bearing currents and reducing EMI in electric machinery

ActiveUS20160329780A1Reducing and mitigating flowImprove performance and lifeAssociation with grounding devicesElectric machineryDynamo

Rotary capacitor assemblies divert or mitigate high-frequency electrical currents and voltages in bearings of electric machinery (e.g., motors and generators) without direct contact with the bearings. The assemblies include rotating capacitors, in which surfaces in close proximity are free to rotate with respect to another while maintaining relative surface area and separation distance. A lubricant (such as air or oil) facilitates capacitive surfaces hydrodynamically “floating” on each other. A shunt body is connected electrically in parallel with the bearings of the machine, providing a non-contact or nearly non-contact electrical pathway for damaging high-frequency currents an voltages to be shunted around the mechanical load carrying bearings.

Owner:C MOTIVE TECHNOLOGIES INC

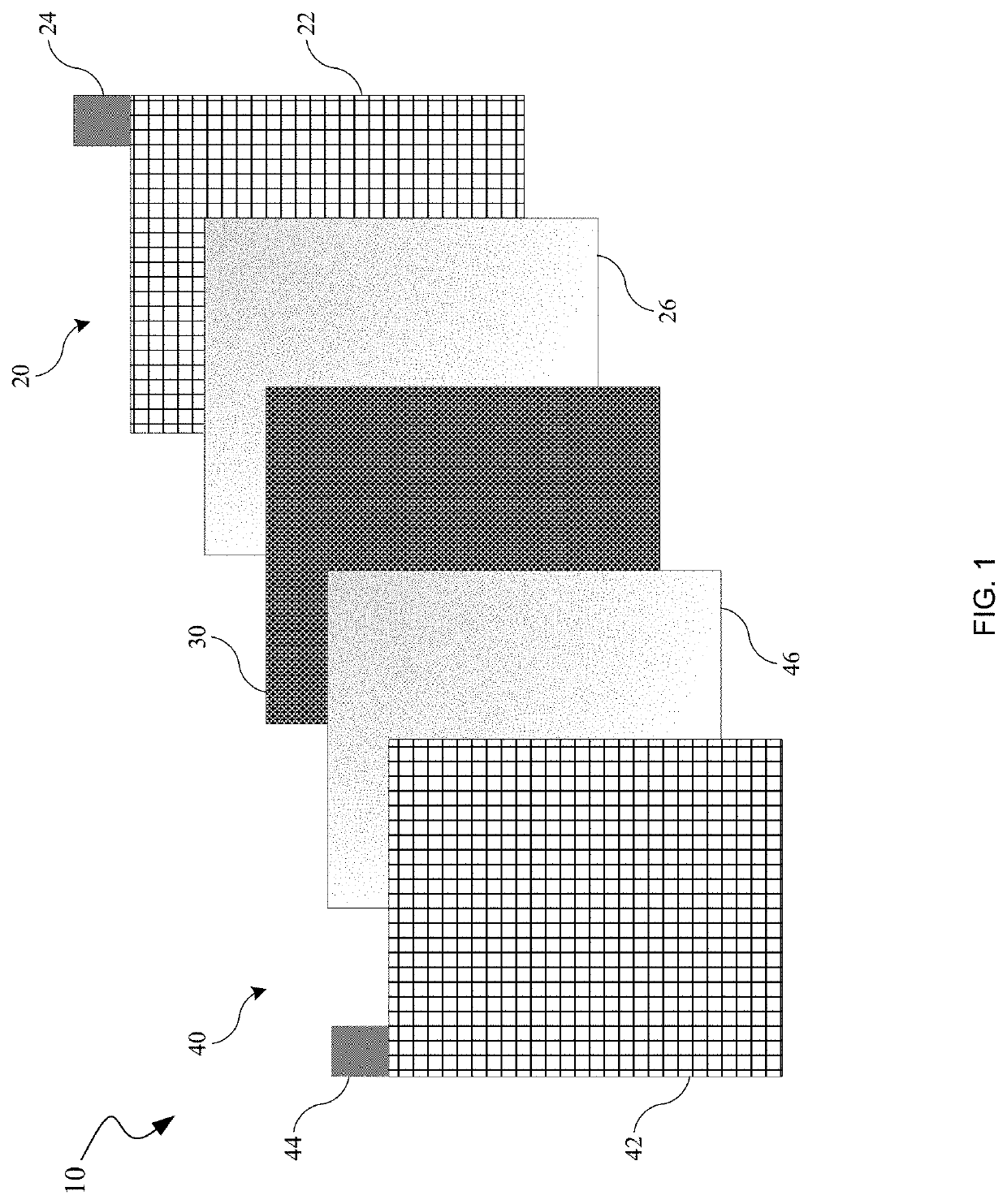

Small pore size nonwoven mat with hydrophilic/acid resistant filler used in lead acid batteries and applications therefor

ActiveUS20160268567A1Reduce air permeabilitySmall average pore sizeLead-acid accumulatorsCell component detailsFiberGlass fiber

According to one embodiment, a nonwoven fiber mat includes between 10% and 50% by weight of a plurality of first glass fibers having an average diameter of less than 5 μm and between 50% and 90% by weight of a plurality of second glass fibers having an average diameter of greater than 6 μm. The nonwoven fiber mat also includes an acid resistant binder that binds the first and second glass fibers together. The nonwoven fiber mat has an average pore size of between 1 and 100 μm and exhibits an air permeability of below 100 cubic feet per minute per square foot (cfm / ft2) as measured by the Frazier test at 125 Pa according to ASTM Standard Method D737.

Owner:JOHNS MANVILLE CORP

Method and system for vehicle speed control

ActiveUS8634939B2Maintain speedImprove performance and lifeAuxillary drivesVehicle fittingsBrake torqueRegenerative brake

Methods are provided for controlling a vehicle speed during a downhill travel. Based on the estimated grade of the downhill travel and further based on an input received from the operator, different combinations of an engine braking torque and a regenerative braking torque are used to maintain the vehicle speed during the downhill travel. A battery rate of charging is also adjusted based on the duration or distance of the downhill travel, as indicated by the operator input.

Owner:FORD GLOBAL TECH LLC

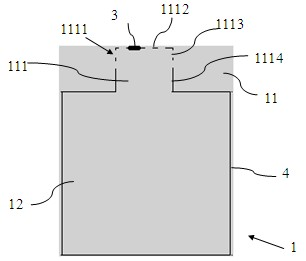

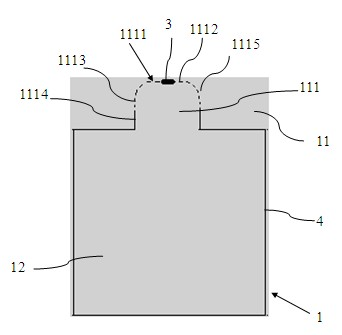

Manufacturing method for electrode sheet cutting, electrode sheet using the same, and secondary battery using the same

InactiveCN102427125APrevent puncture or punctureImprove performance and lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryBiomedical engineering

The present invention provides a manufacturing method for electrode sheet cutting, an electrode sheet using the manufacturing method, and a secondary battery using the manufacturing method. The manufacturing method comprises the following steps that: (1) one end of an electrode sheet substrate is provided with an electrode lug reservation position for cutting to form a plurality of electrode lugs, the other end of the electrode sheet substrate is provided with a material coating area, the electrode lug reservation position is provided with a starting position, a cutting tool is adopted to carry out cutting from the starting position; (2) the cutting tool cuts along the cutting line, and finally returns to the starting position to form the electrode sheet with the electrode lugs; (3) the cut electrode sheet is separated. The method of present invention has the following advantages that: the cutting treatment is started from the electrode lug reservation position, such that the burr generating or the tearing mark generating on the edge of the material coating area is avoided so as to prevent the isolation membrane from perforation or puncture, therefore, the use performance and the service life of the battery are enhanced.

Owner:SUZHOU GOLDEN CROWN NEW ENERGY +1

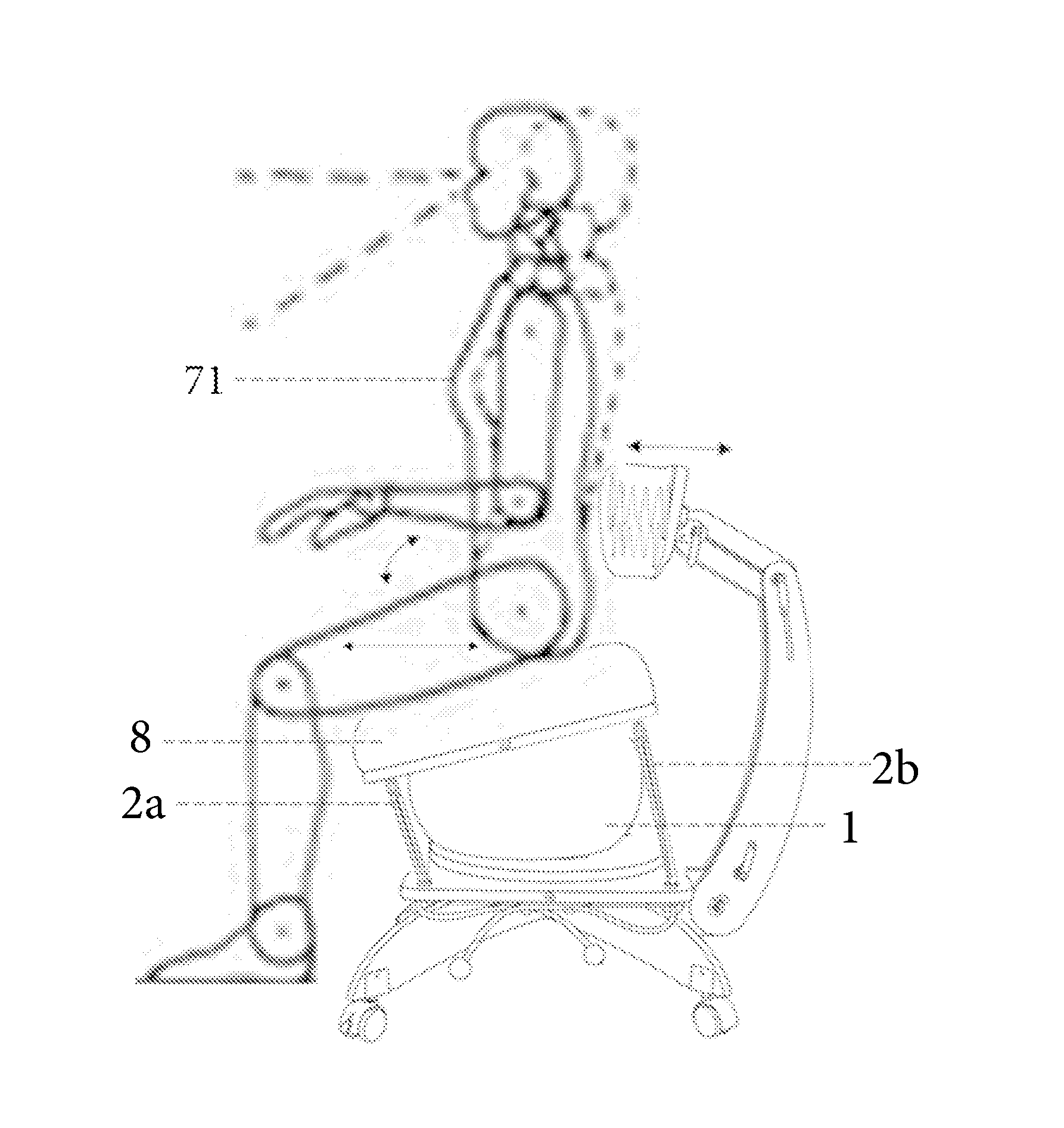

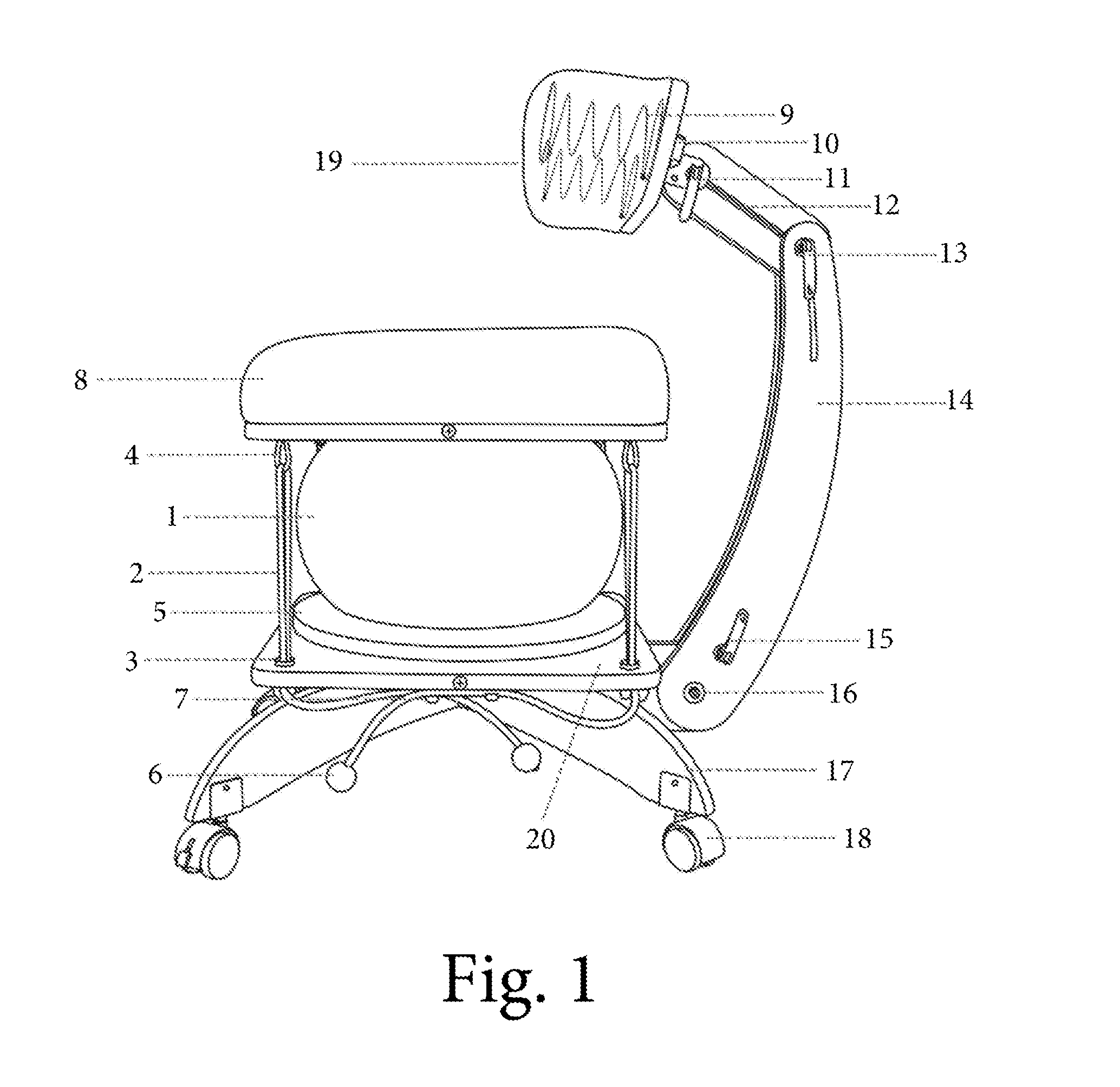

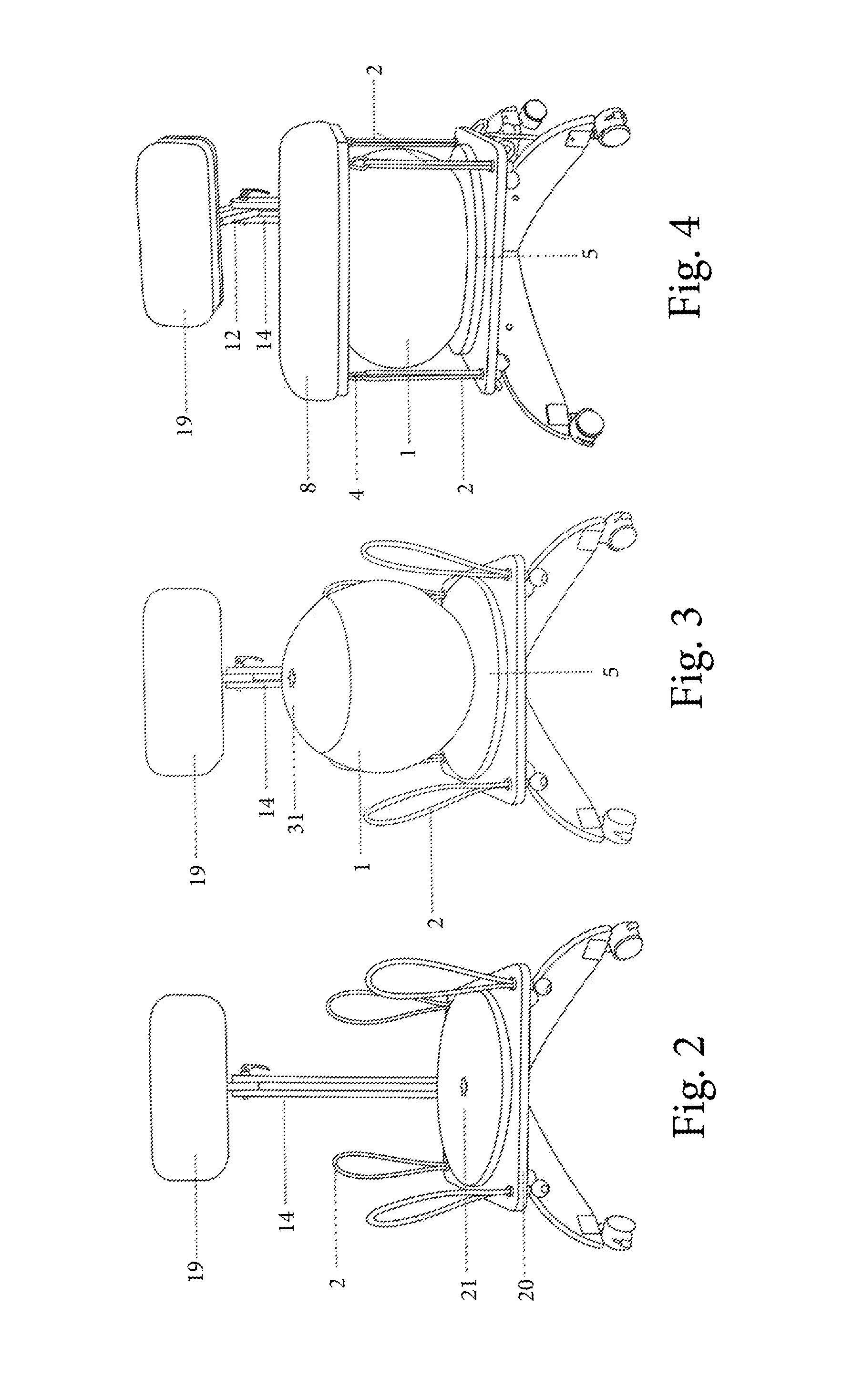

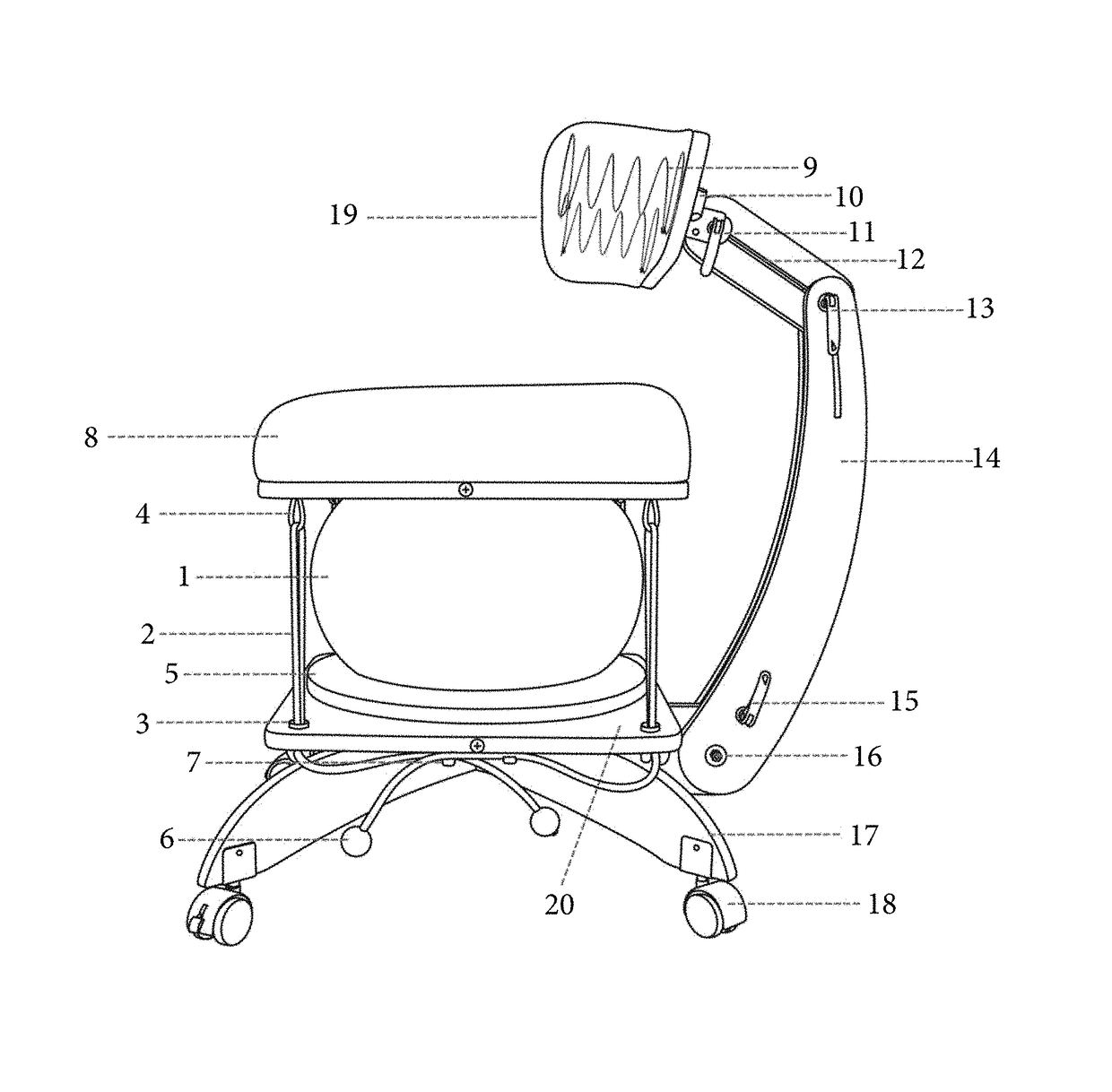

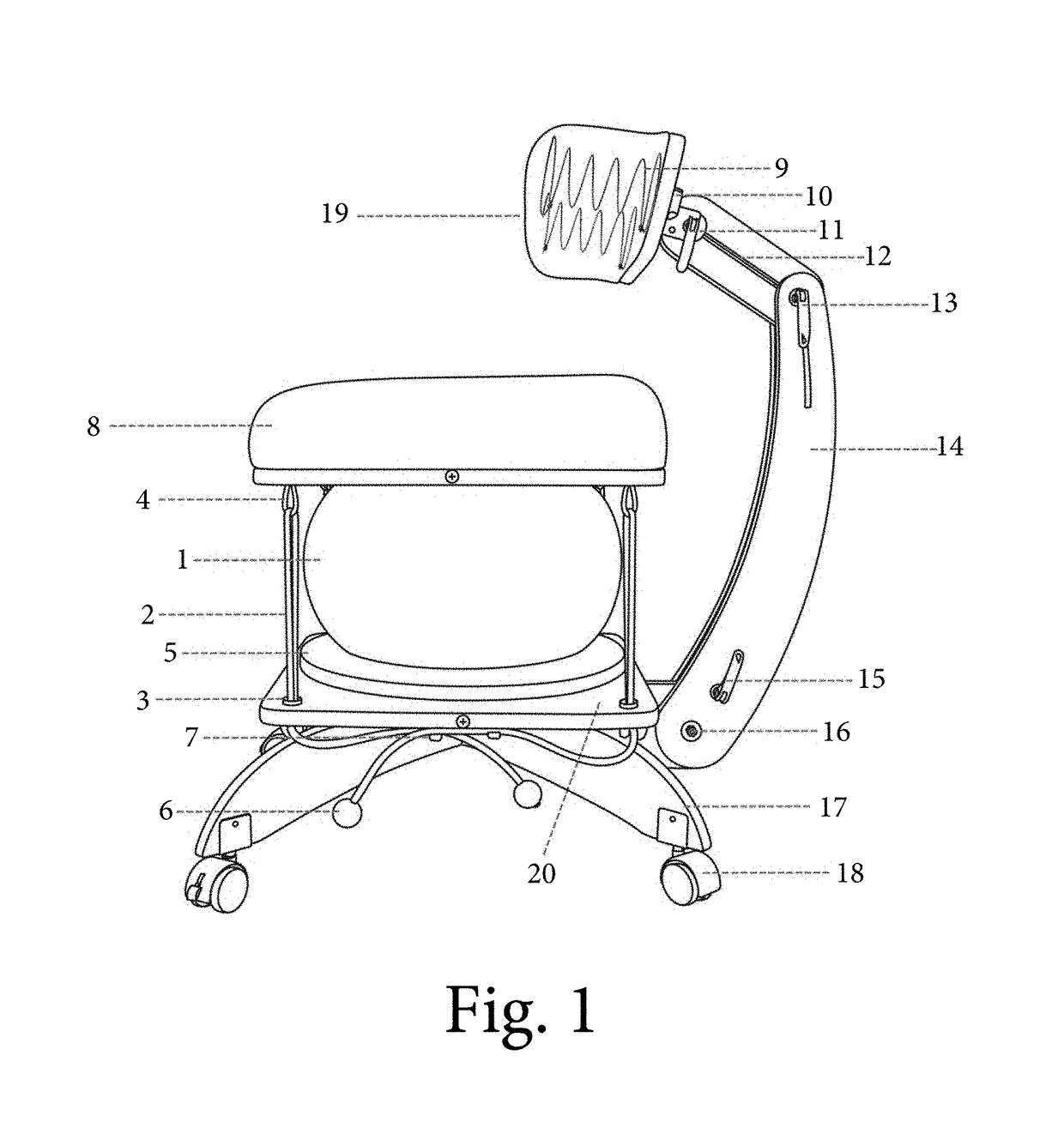

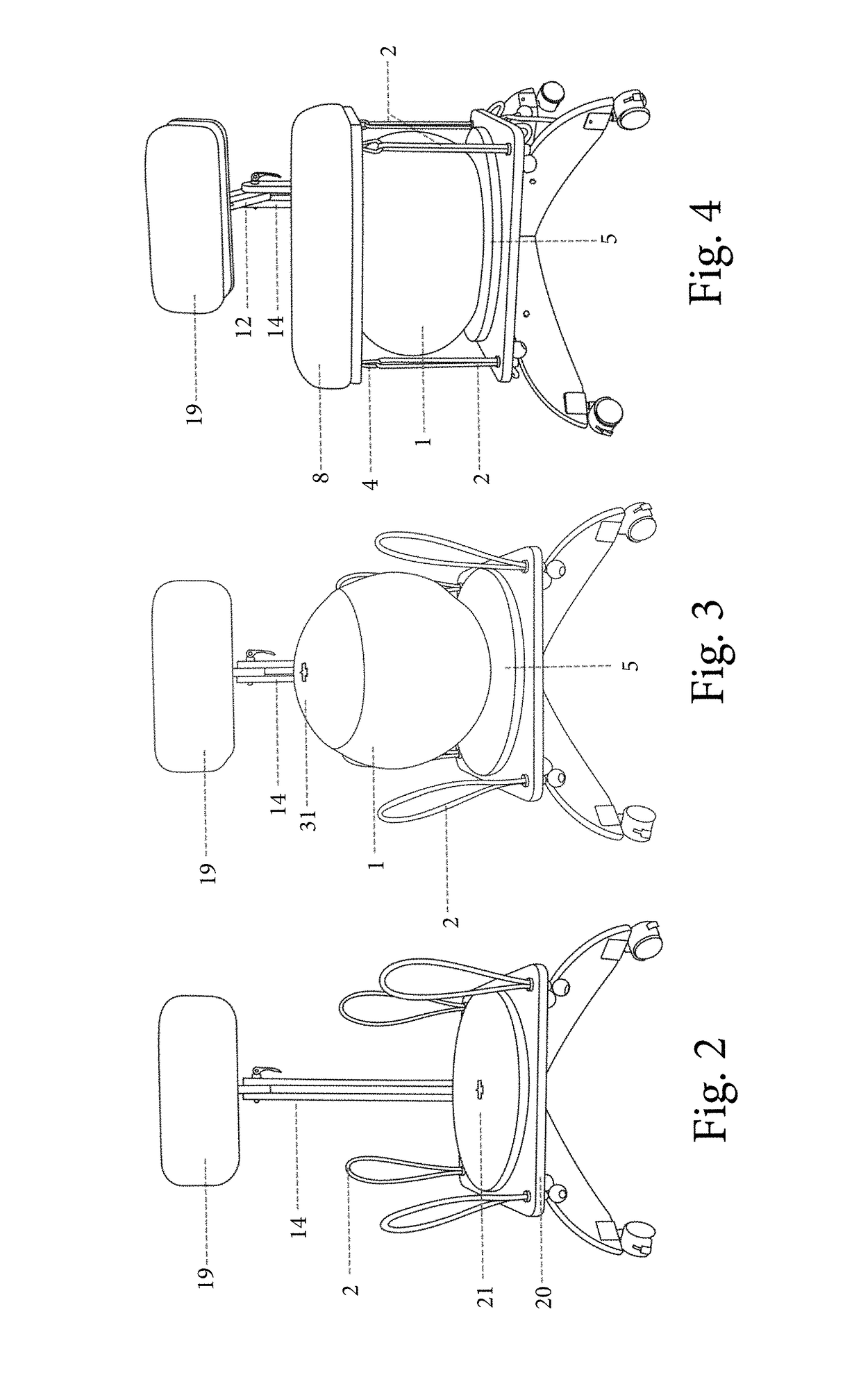

Ergonomic Chair

A chair having a contoured seat cushion mounted on top of an exercise ball with four tension-adjustable elastic cords such as bungee cords is provided. The shock absorbing cords may attach to the underside of the seat cushion by looping through spring-eye carabiner type hooks, and may pass through grooved locking tubes with v-channels for adjusting the cord tension. The ball may sit on top of a swivel plate, so that dynamic motion and counterbalancing are attainable for a variety of ergonomically beneficial seating styles.

Owner:MARK DARREN WILLIAM

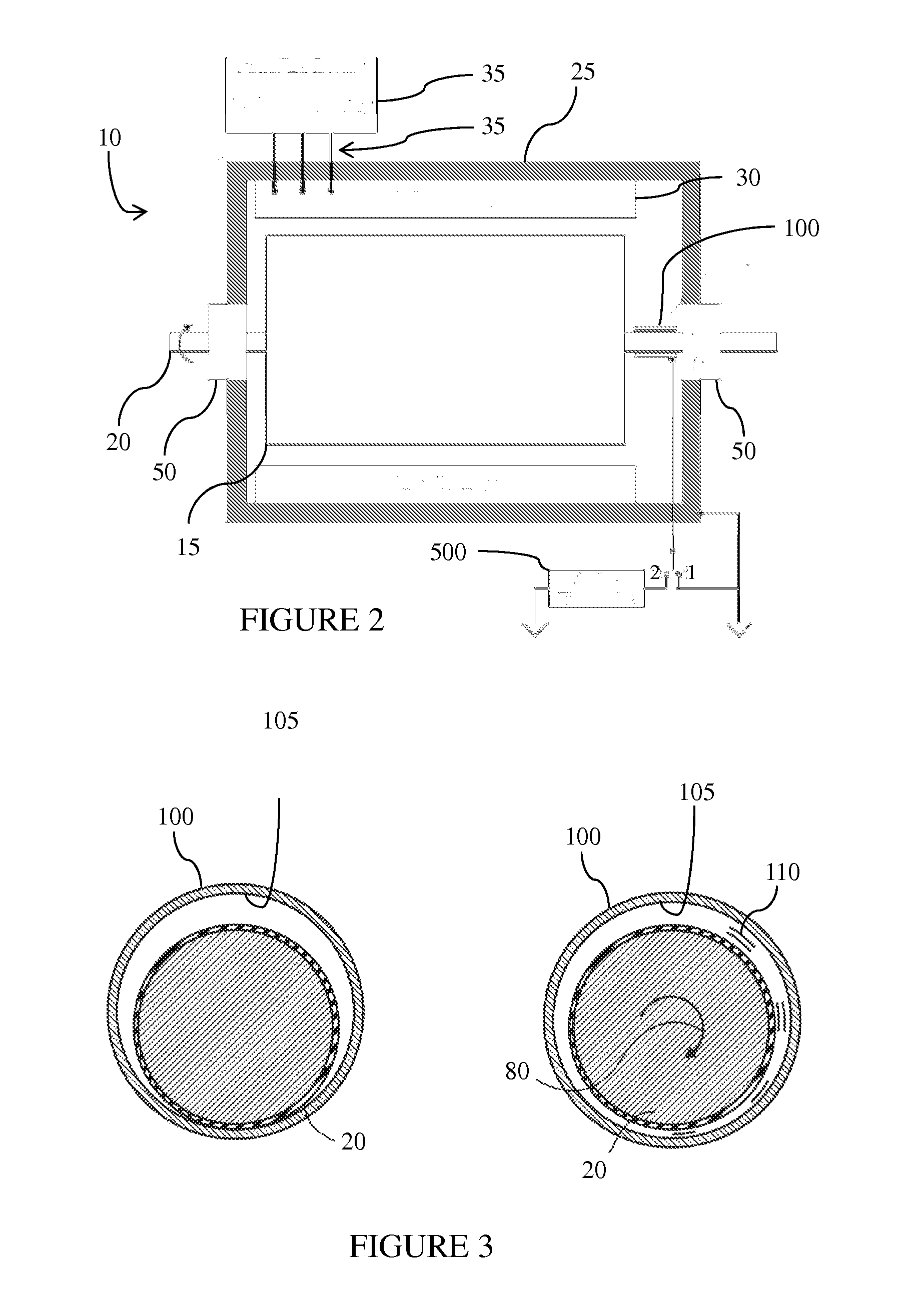

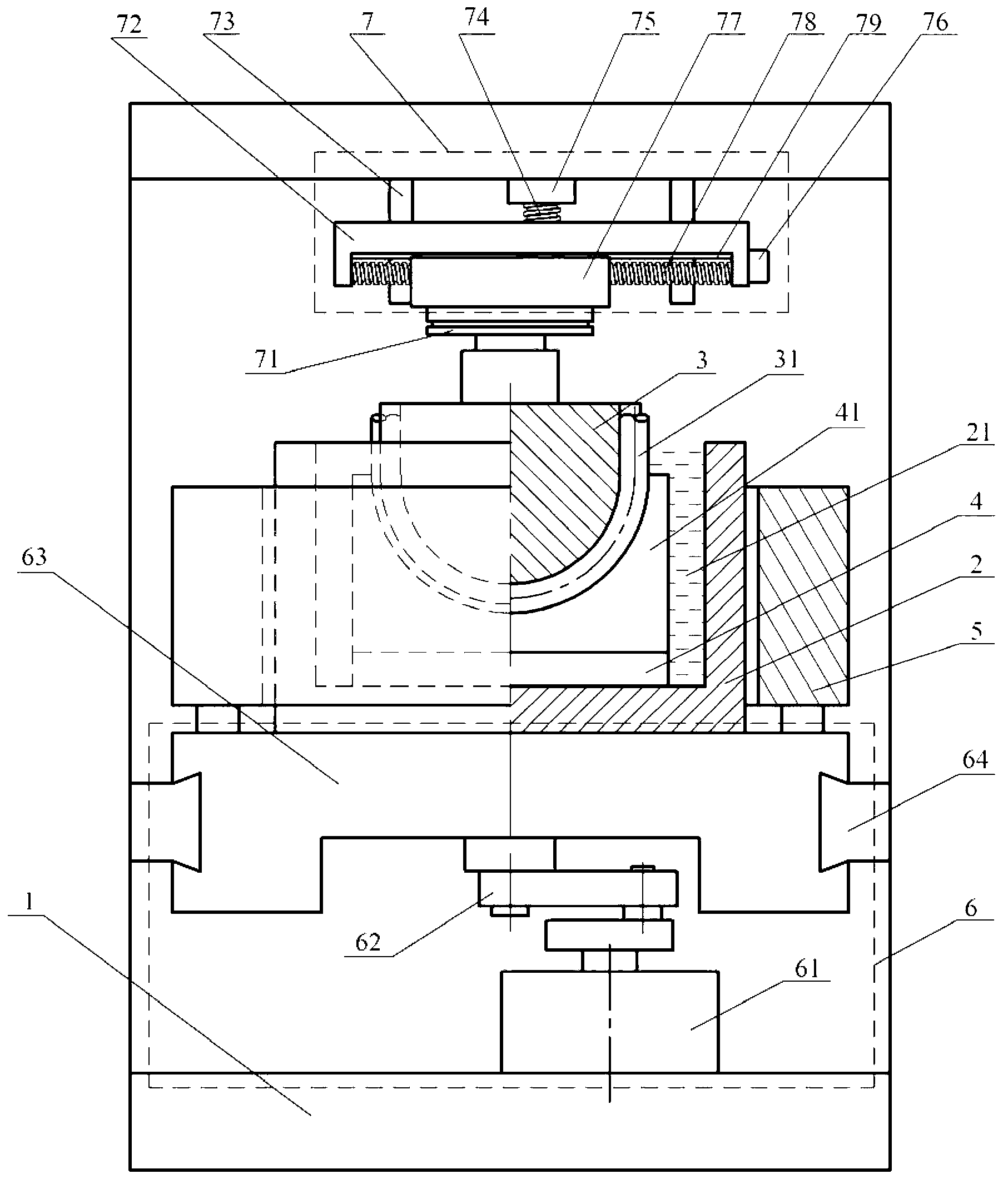

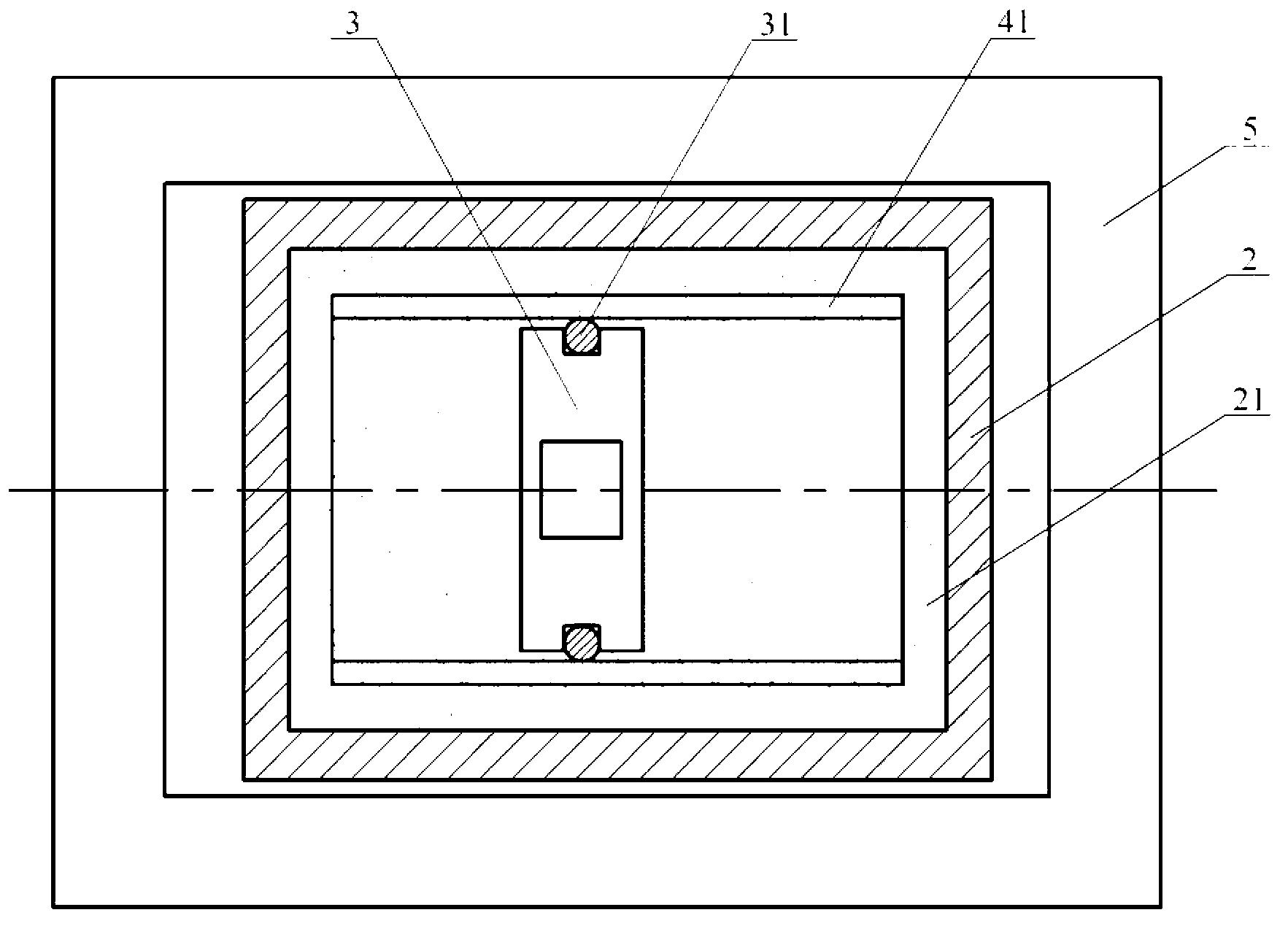

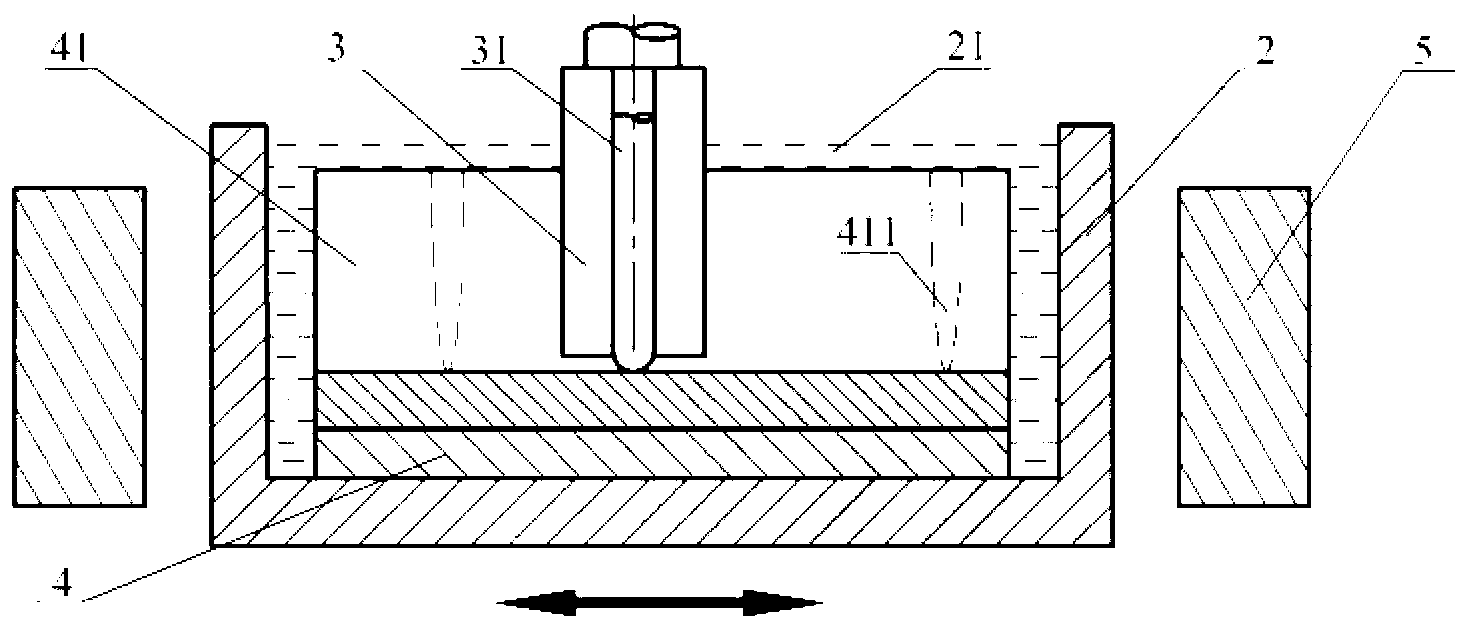

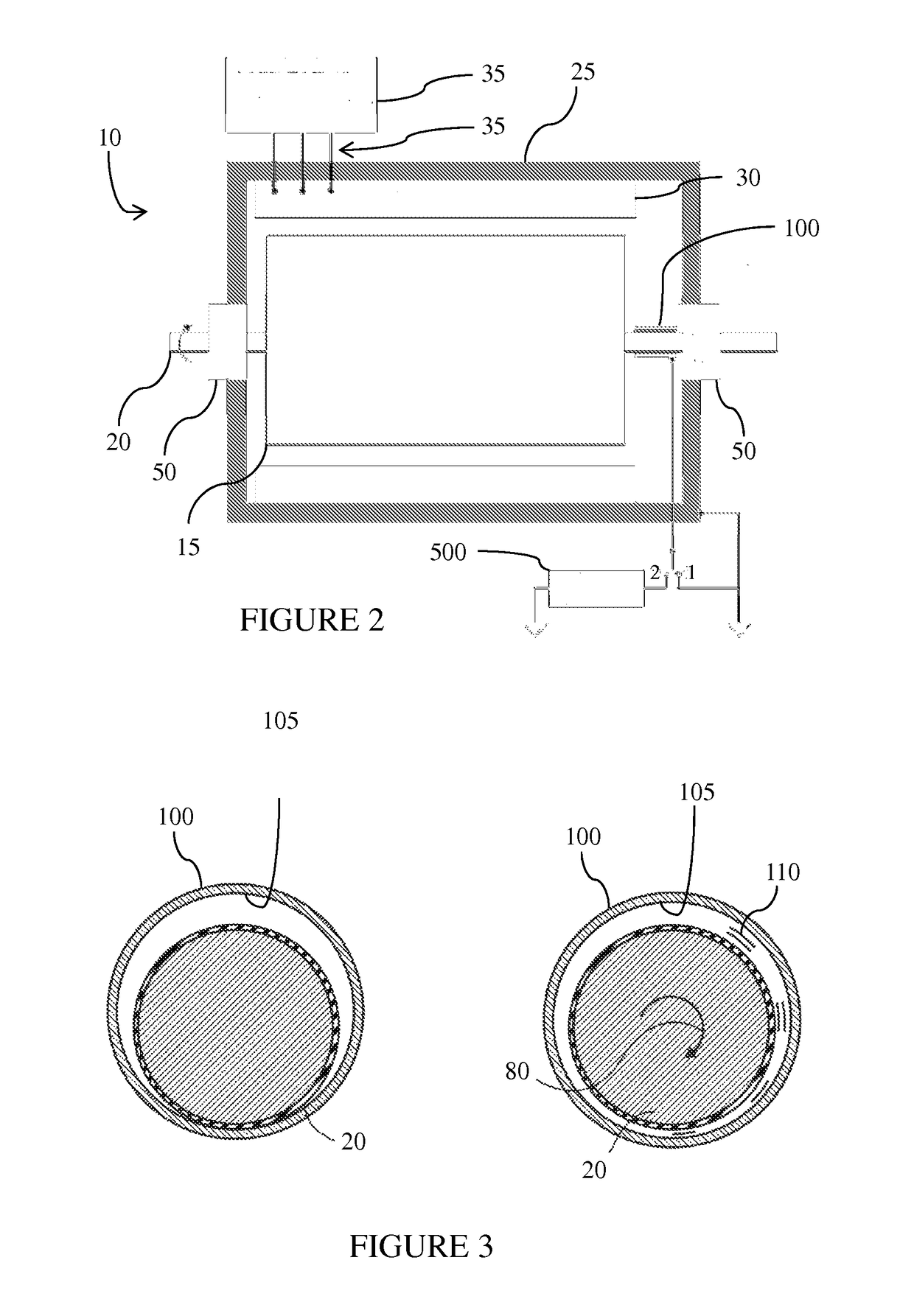

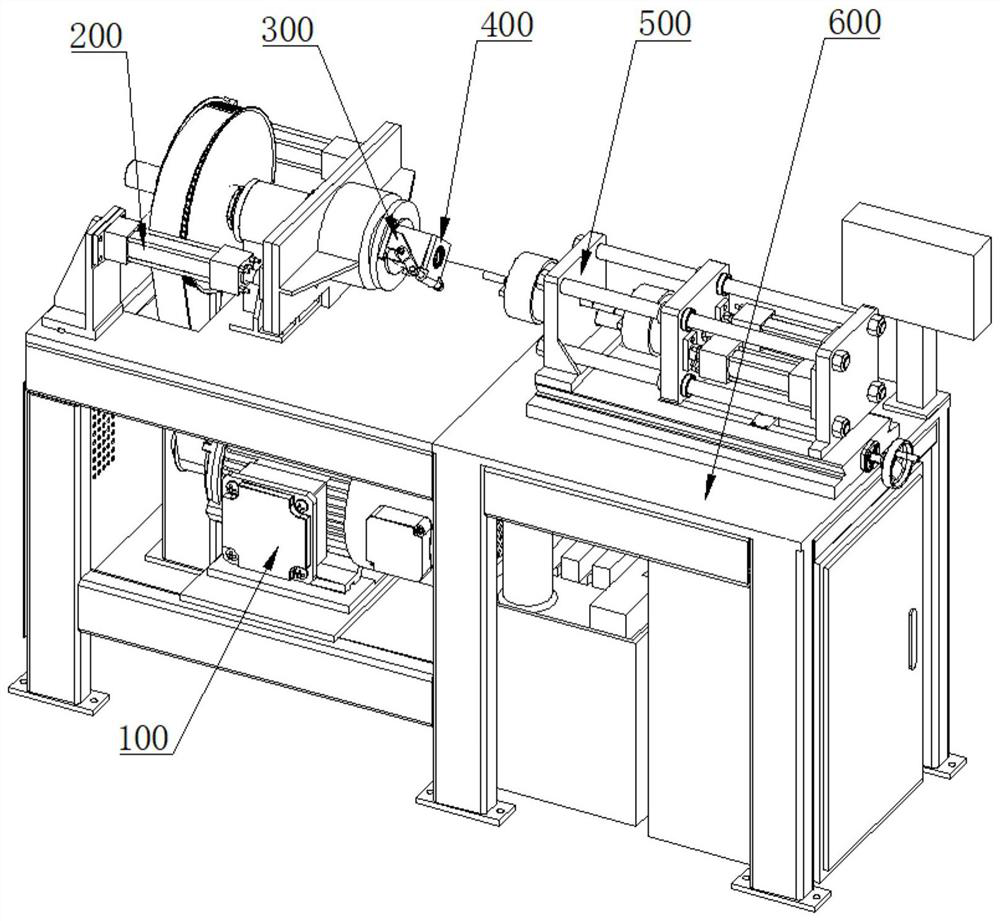

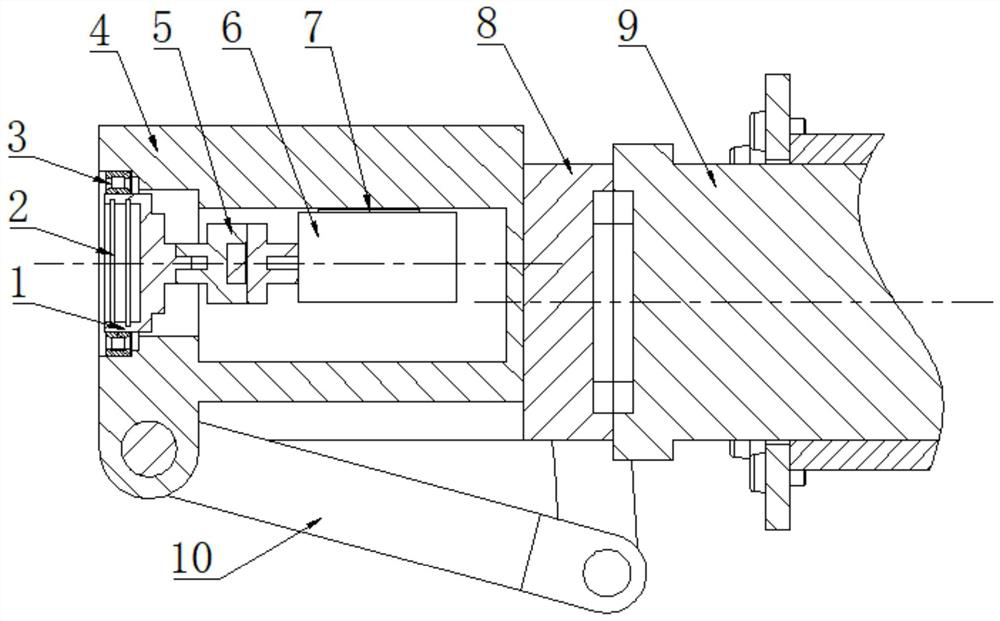

Frictional wear test method and test device for sealing ring

ActiveCN103308410AReduce excessive wearImprove performance and lifeInvestigating abrasion/wear resistanceElectricityEngineering

The invention discloses a frictional wear test method and a frictional wear test device for a sealing ring. The method comprises the following steps of: 1) fixing a lower test piece on a lower clamp; 2) embedding an upper test piece into a cambered accommodating slot, and adjusting an adjustment bolt to control the axial compression rate of the upper test piece; 3) adding a test medium into a medium slot, and setting test temperature, a normal load and a friction frequency; and 4) controlling a bidimensional adjustable mobile table and a horizontal reciprocating motion device, and calculating a friction coefficient between the upper test piece and the lower test piece. The device comprises a machine seat, the medium slot, an upper clamp, a lower clamp, a temperature control console, a horizontal reciprocating motion device, the bidimensional adjustable mobile table and a data acquisition control system, wherein the bidimensional adjustable mobile table, the horizontal reciprocating motion device and the temperature control console are electrically connected with the data acquisition control system. The frictional wear test method and the frictional wear test device have the beneficial effects that a working condition of the sealing ring is really simulated; in a test process, the friction is synchronously and dynamically acquired; and the friction interface damage evolution property and the influence rule of the sealing ring are accurately analyzed.

Owner:菏泽建数智能科技有限公司

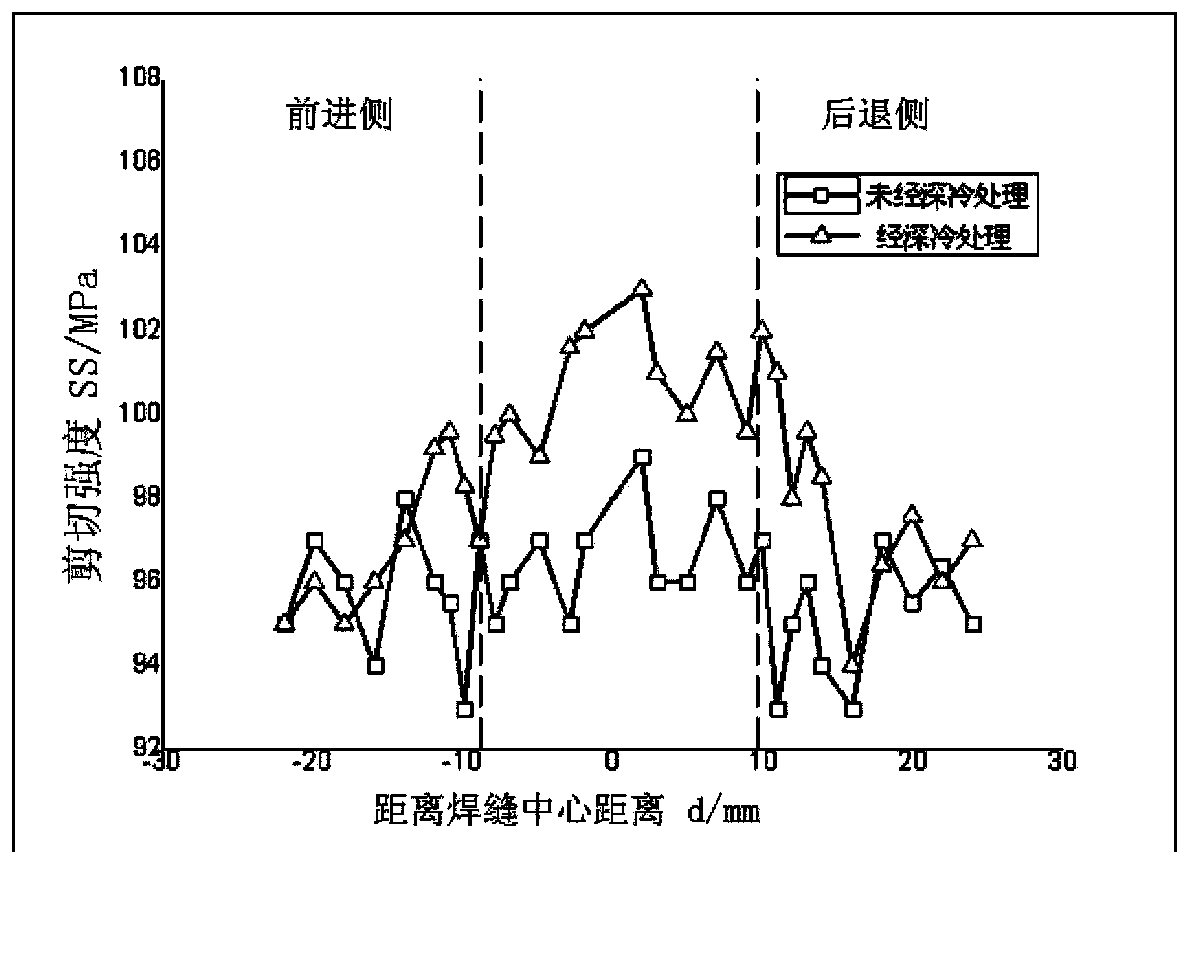

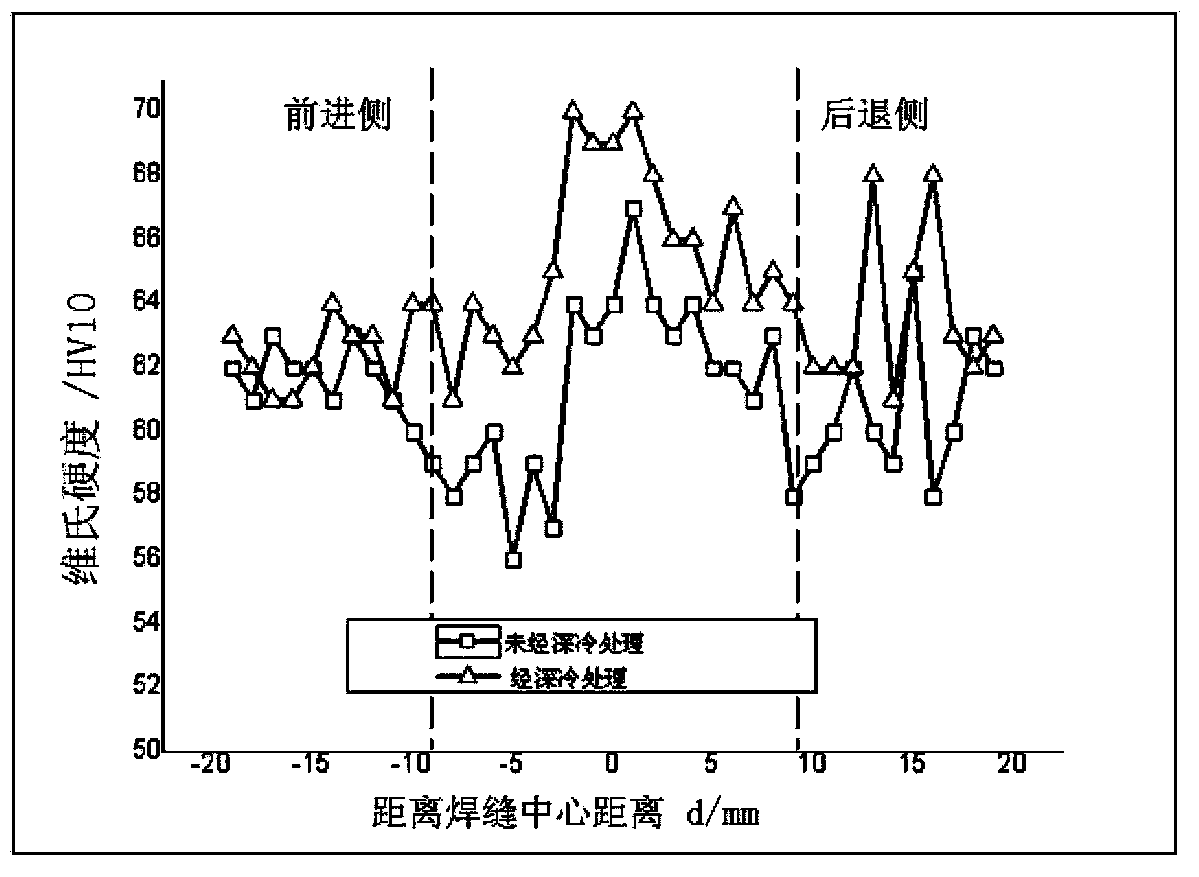

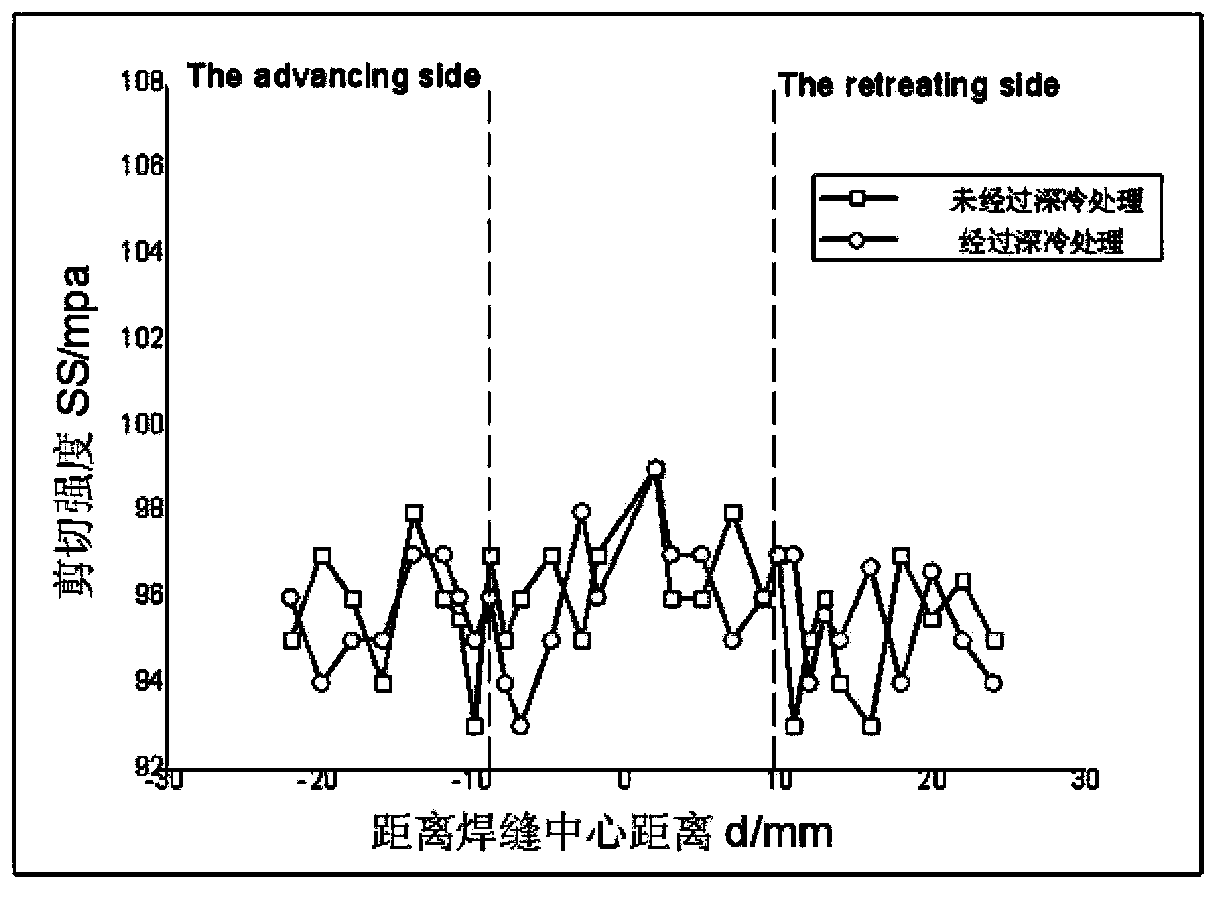

Treatment process method for improving performance of 5052 aluminum alloy friction stir welding joint

InactiveCN103421943AHigh strengthImprove performance and lifeFurnace typesHeat treatment furnacesFriction stir weldingFriction welding

The invention discloses a treatment process method for improving the performance of a 5052 aluminum alloy friction stir welding joint. According to the method, no preheating treatment is required, and final treatment is directly performed on the 5052 aluminum alloy friction stir welding joint; the final treatment comprises the step that a welded structure is directly subjected to subzero treatment at minus 160 DEG C to minus 190 DEG C for 5-24 hours. With adoption of the method disclosed by the invention, the strength (rigidity) of the 5052 aluminum alloy friction stir welding joint can be improved as compared with that of a conventional friction stir welding joint. The mechanical property of the 5052 aluminum alloy friction stir welding joint is improved for certain degree.

Owner:SOUTHWEST JIAOTONG UNIV

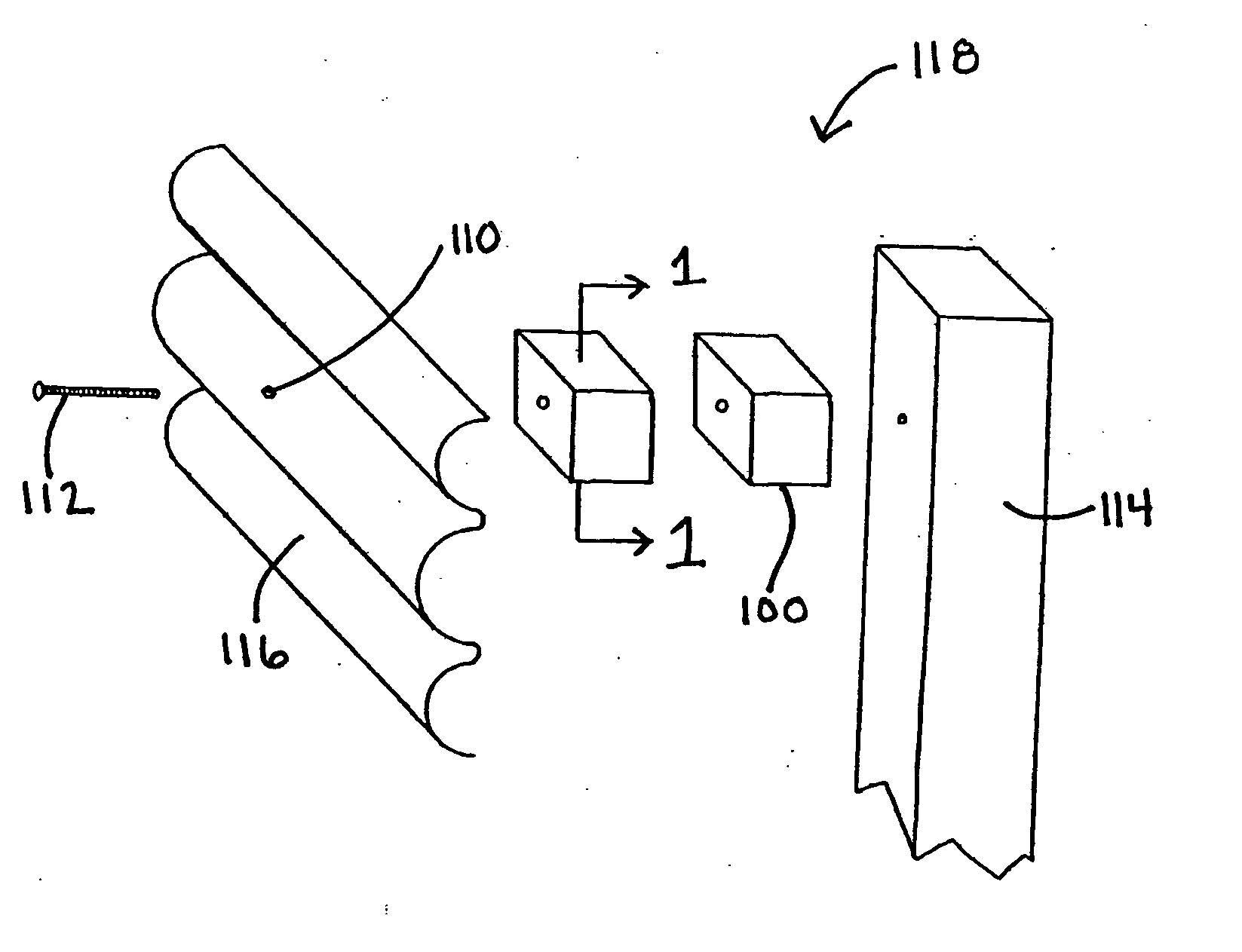

Blocks for absorption of collision energy

InactiveUS20050196233A1Improve abilitiesImprove protectionLoading/unloadingTraffic restrictionsGlass fiberElastomer

An energy-absorbing block is described for use as (or in conjunction with) bumpers and similar objects used to receive and dissipate large amounts of impact energy. The block includes an inner core at least partially formed of elastomeric materials, such as rubber from discarded vehicle tires, with the core being at least substantially surrounded by an outer shell which is preferably at least partially formed of a rigid thermoplastic material. The block may also contain a reinforcing layer of material, such as glass fiber or fabric, positioned between the core and the shell or interspersed within the shell. The block may be mounted to a bumper such as a guardrail, and / or to a mounting structure such as a guardrail post or loading dock, via a fastener inserted through a mounting bore in the block.

Owner:WEST VIRGINIA UNIVERSITY

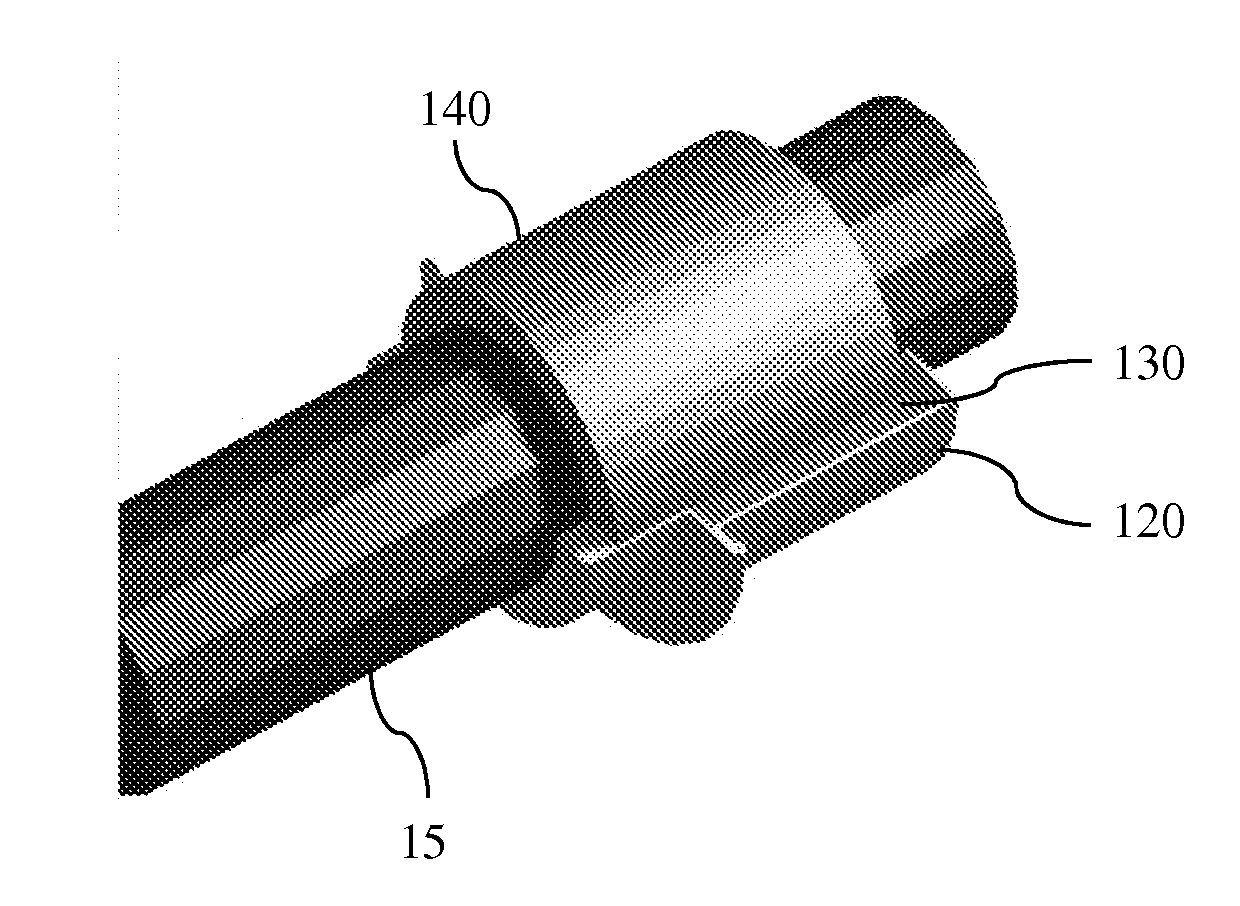

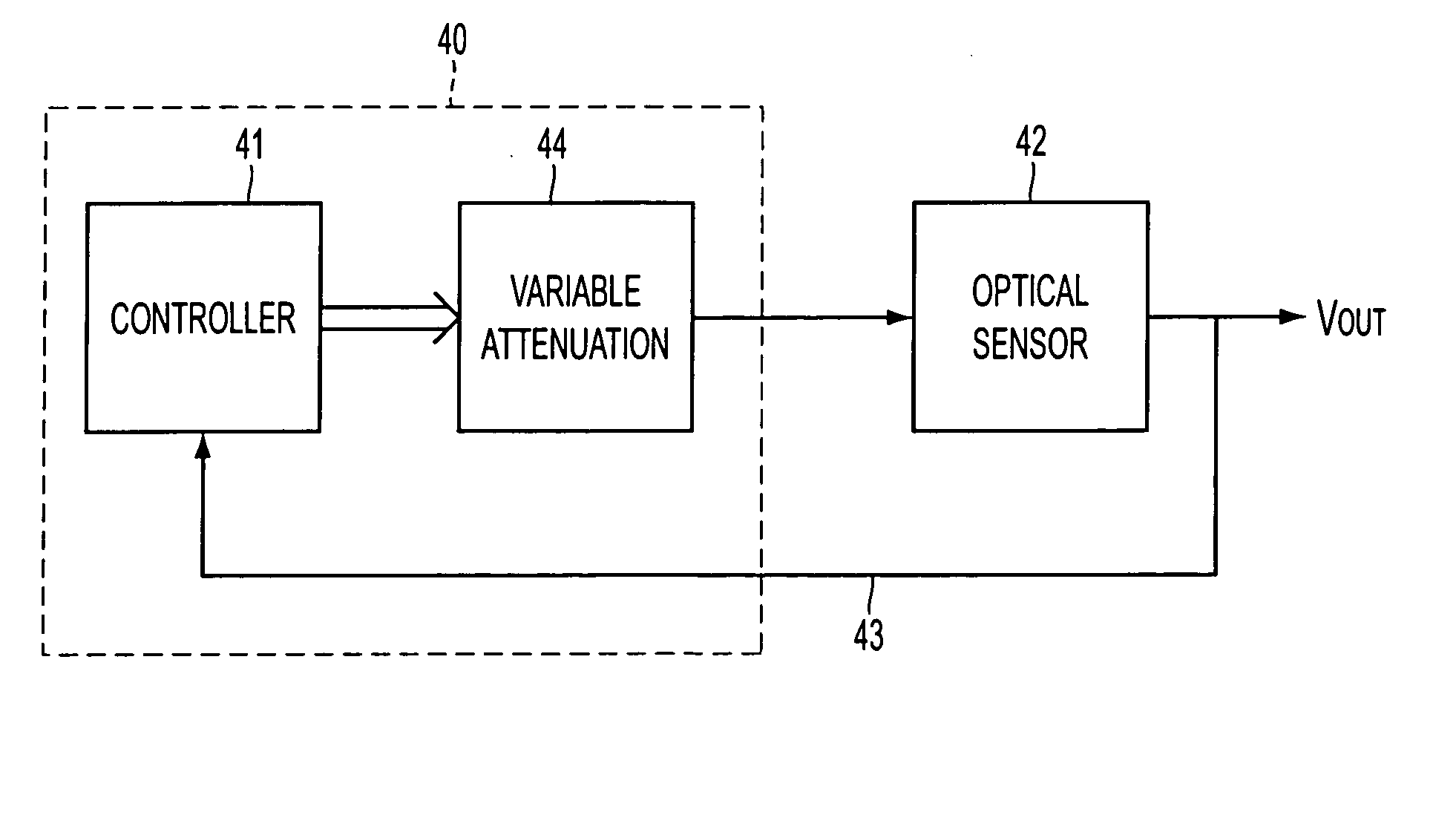

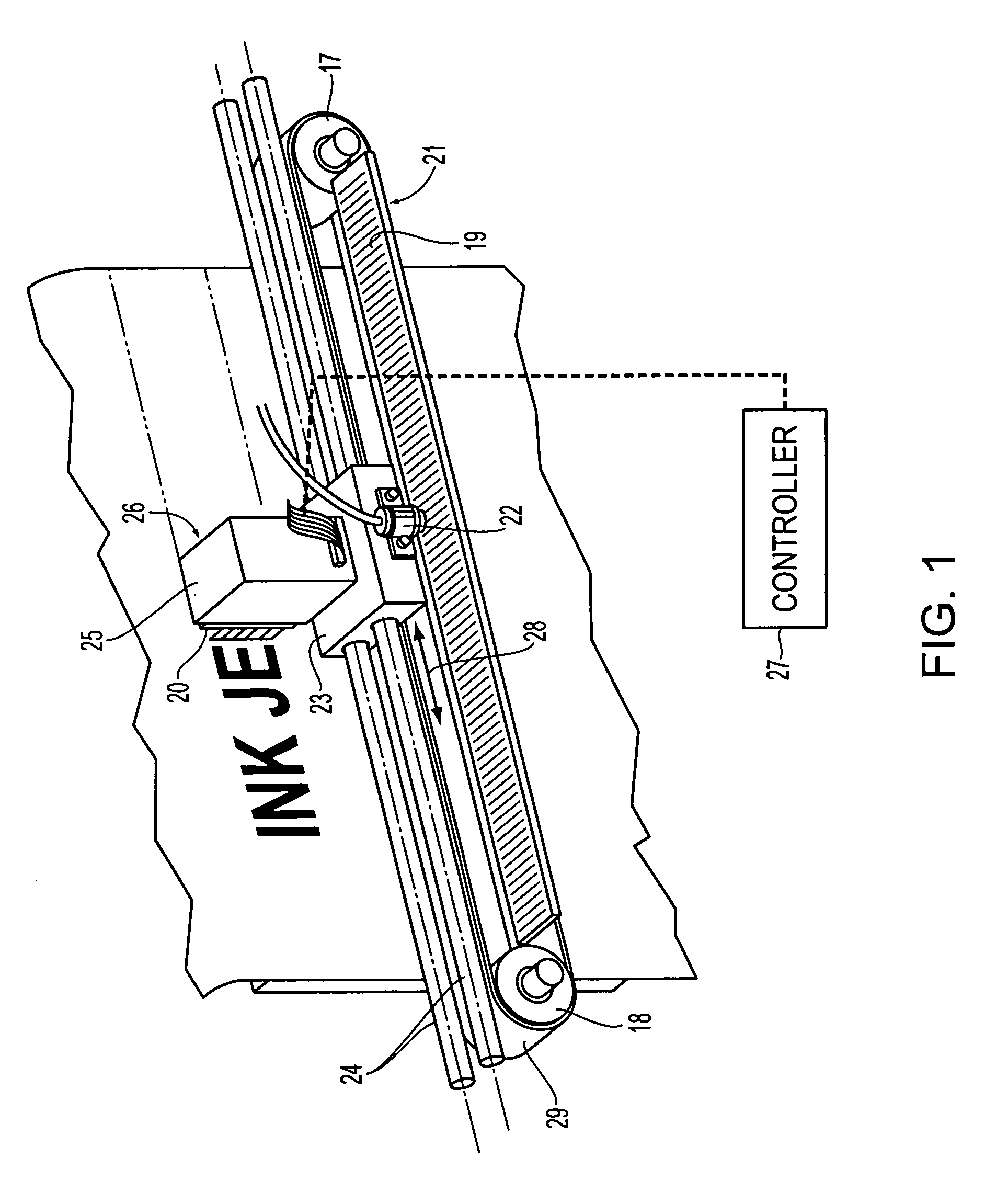

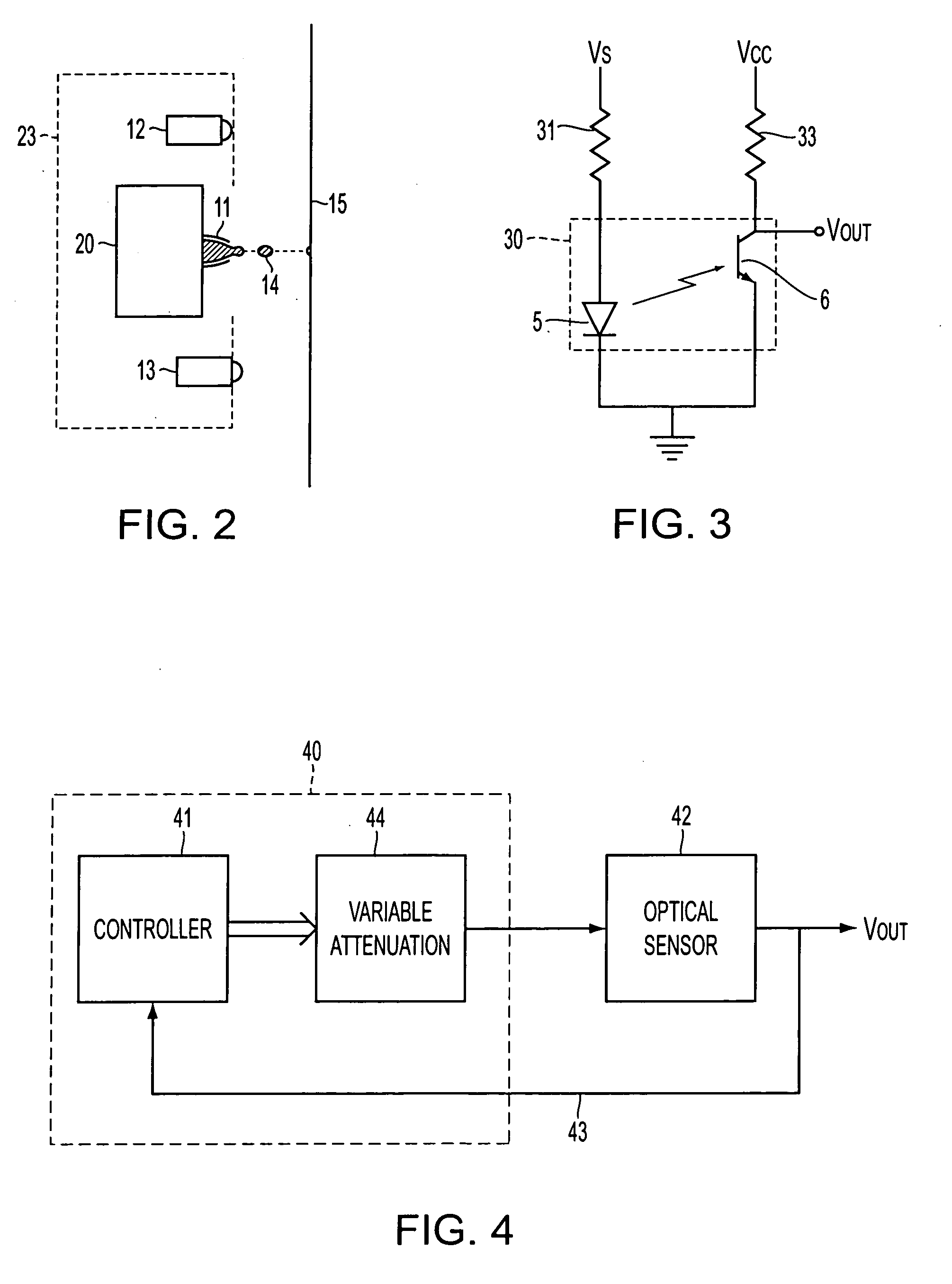

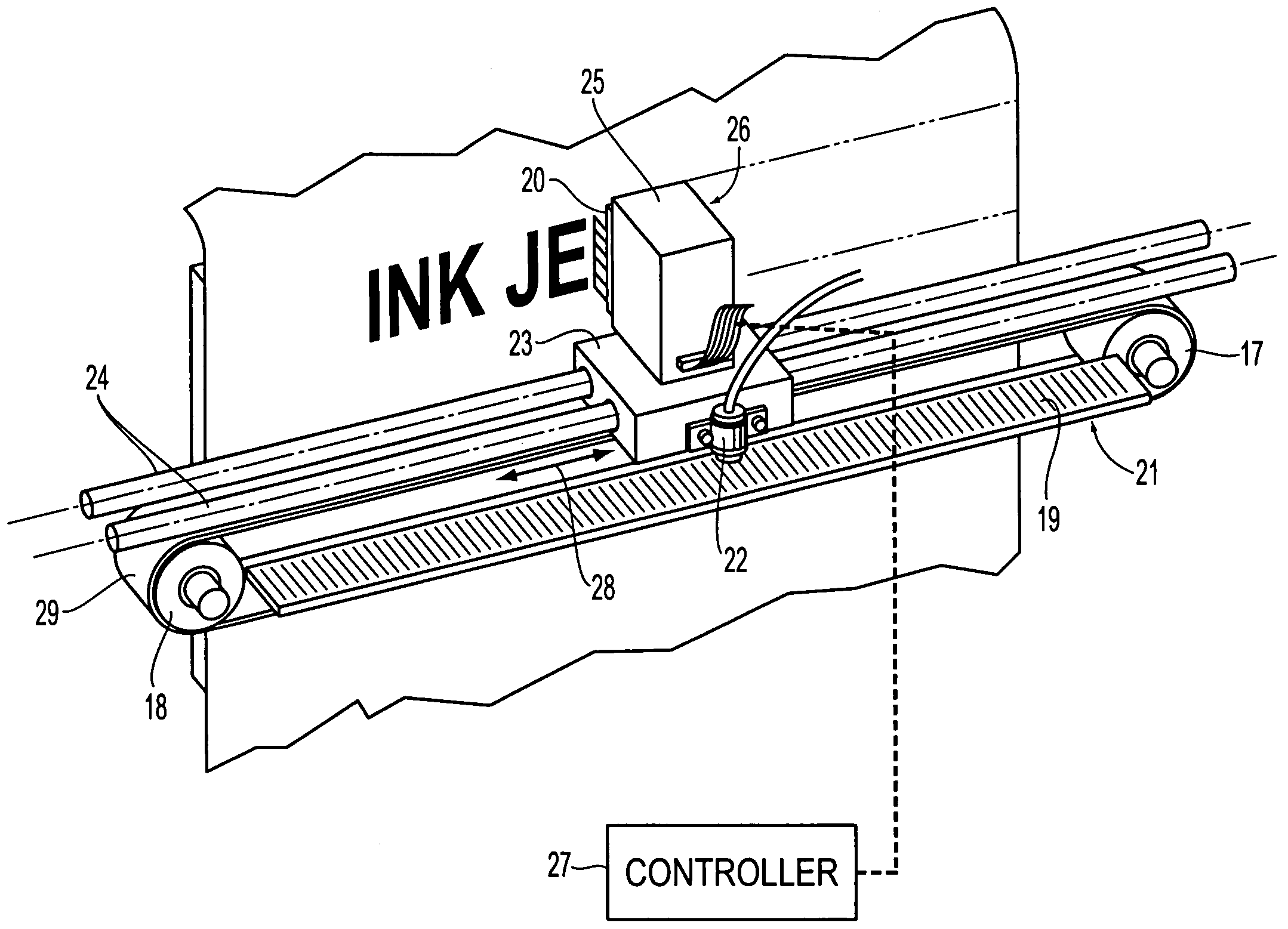

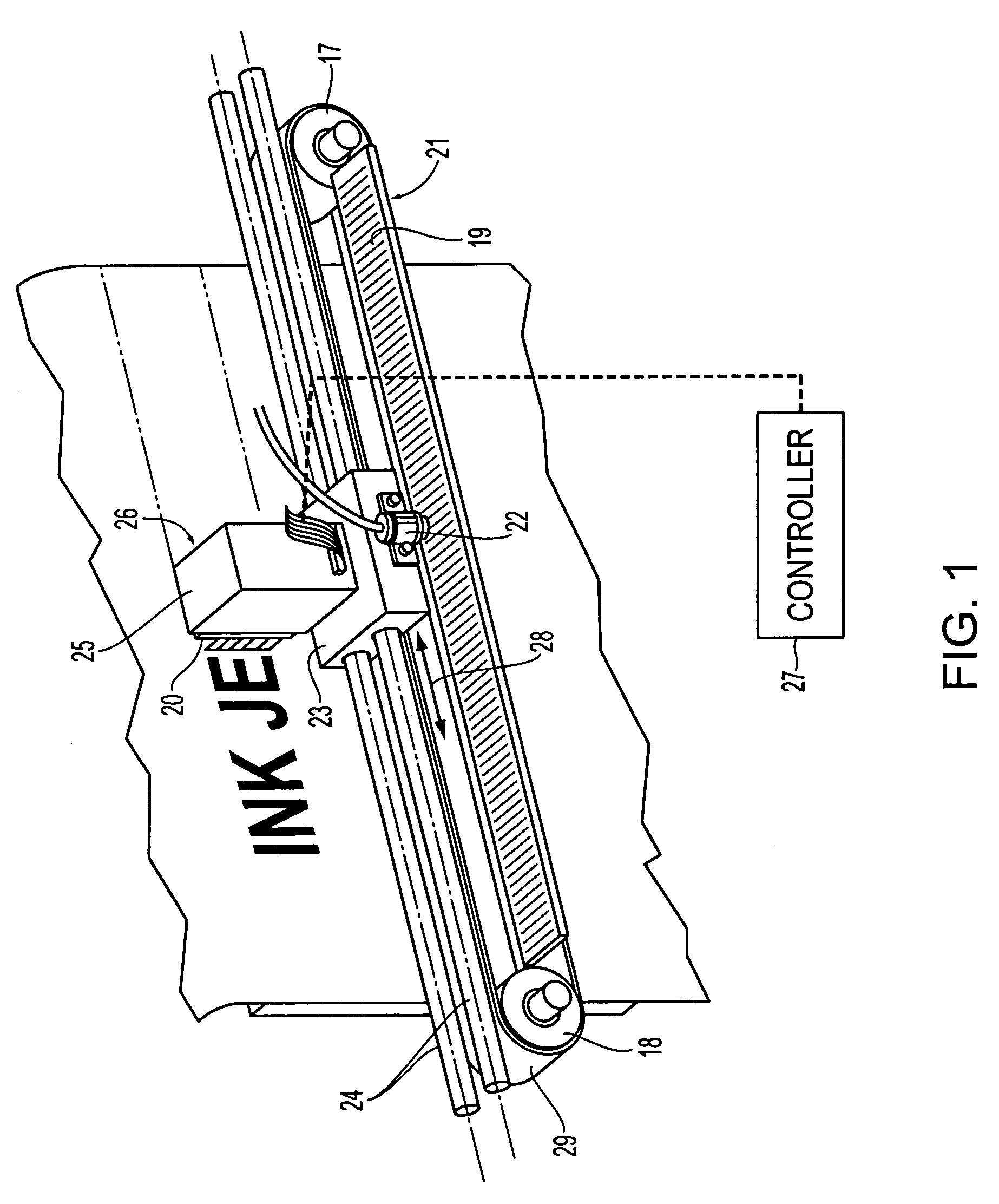

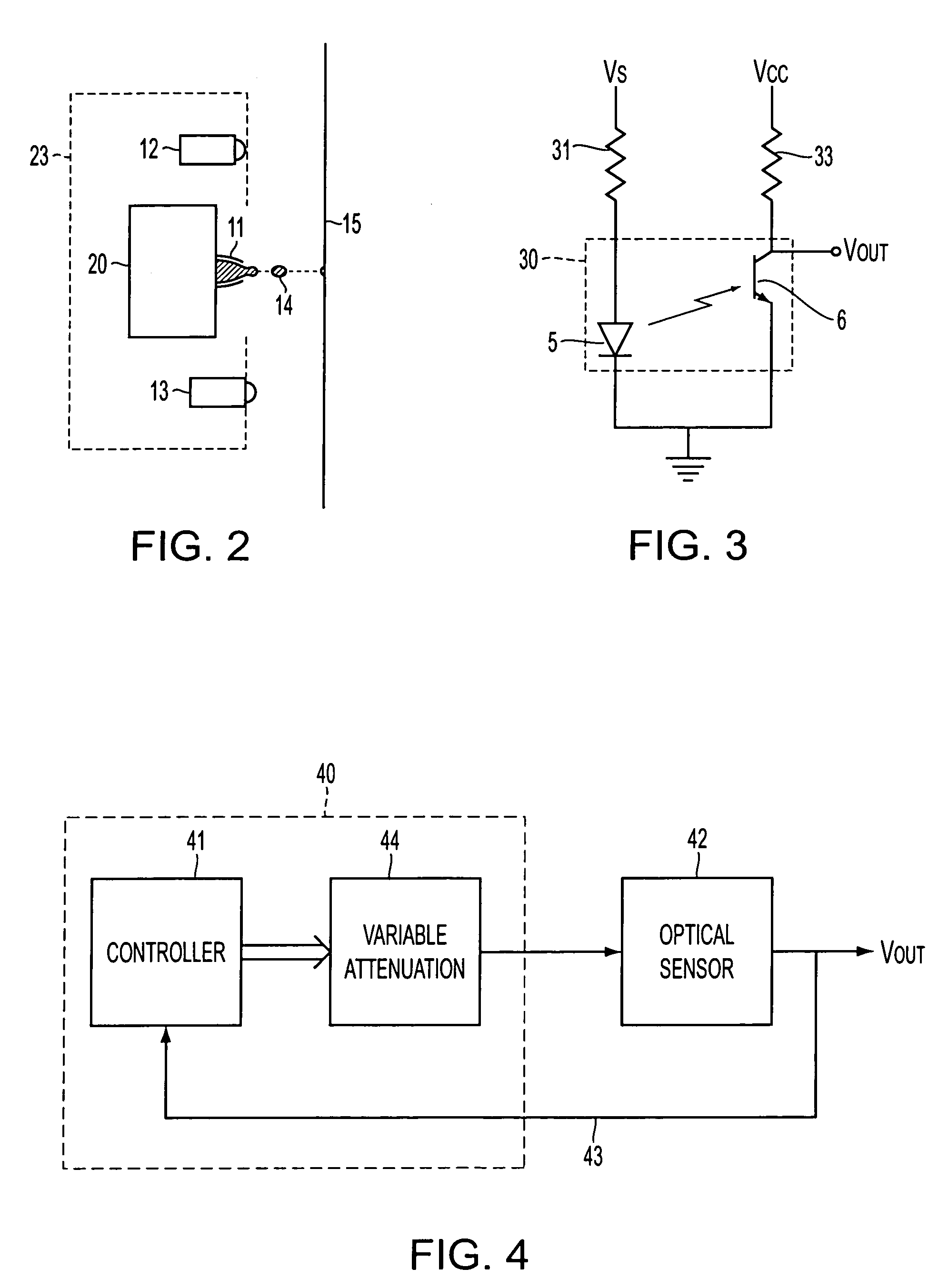

Method and device for optical sensor compensation, and apparatus incorporating the same

InactiveUS20050110984A1Lower costImprove performance and lifePhotometry using reference valueSpacing mechanismsOptical detectorsVIT signals

An optical sensor has a sensor compensation to compensate for sensor degradation due to airborne contaminations in the operating environment. For example, in a thermal ink jet printing environment, the thermal ink jet operation produces misting or splashing of the thermal ink jet droplets, causing a gradual degradation of the sensor sensitivity due to a surface accumulation of the ink jet droplets. The optical sensor device includes an optical emitter emitting an optical signal according to an emitter input, an optical detector disposed to detect the optical signal and output a detector output having an output level according to the detected optical signal, a variable attenuator having an adjustable attenuation setting, and a controller adjusting the attenuation setting of the variable attenuator. During an adjustment operation, the controller determines the attenuation setting at which the output level of the detector output exceeds a predetermined value, and accordingly sets the variable attenuator to operate the detector output at an output level exceeding the predetermined value by a margin. Compensations for the optical emitter and the optical detector are disclosed, including the use of a variable pulse-width modulated signal.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Method for preparing high-temperature wear resistant lining plate by plasma arc cladding

InactiveCN102912339AImprove performance and lifeExcellent high hardnessMetallic material coating processesEmulsionCeramic particle

The invention discloses a method for preparing a high-temperature wear resistant lining plate by plasma arc cladding. The method comprises the steps as follows: removing rust, greasy dirt and oxide skin on the surface of a metal base; preparing metal-based ceramic particle reinforced alloy powder according to the metal base and the work requirement; mixing mixed alloy powder with white emulsion; uniformly coating the mixed alloy powder onto the surface of the metal base; controlling the thickness of a precoating layer to be 0.8-2 mm; naturally drying; fixing the metal base with the precoating layer to a machine tool of plasma arc cladding equipment; conducting single-pass scan on the precoating layer on the surface of the metal base by plasma arc; and uniformly cladding the surface of the metal base along with the movement of the plasma arc so as to obtain a cladding layer with the cladding thickness of 0.3-1.5 mm. The high temperature resistant compound lining plate prepared by the method is low in cost and stable in quality, is suitable for large-scale production, can meet the requirements of field high-temperature wear condition and can be effectively prolonged in service life.

Owner:QINHUANGDAO GERUIDE ENERGY SAVING TECH SERVICE

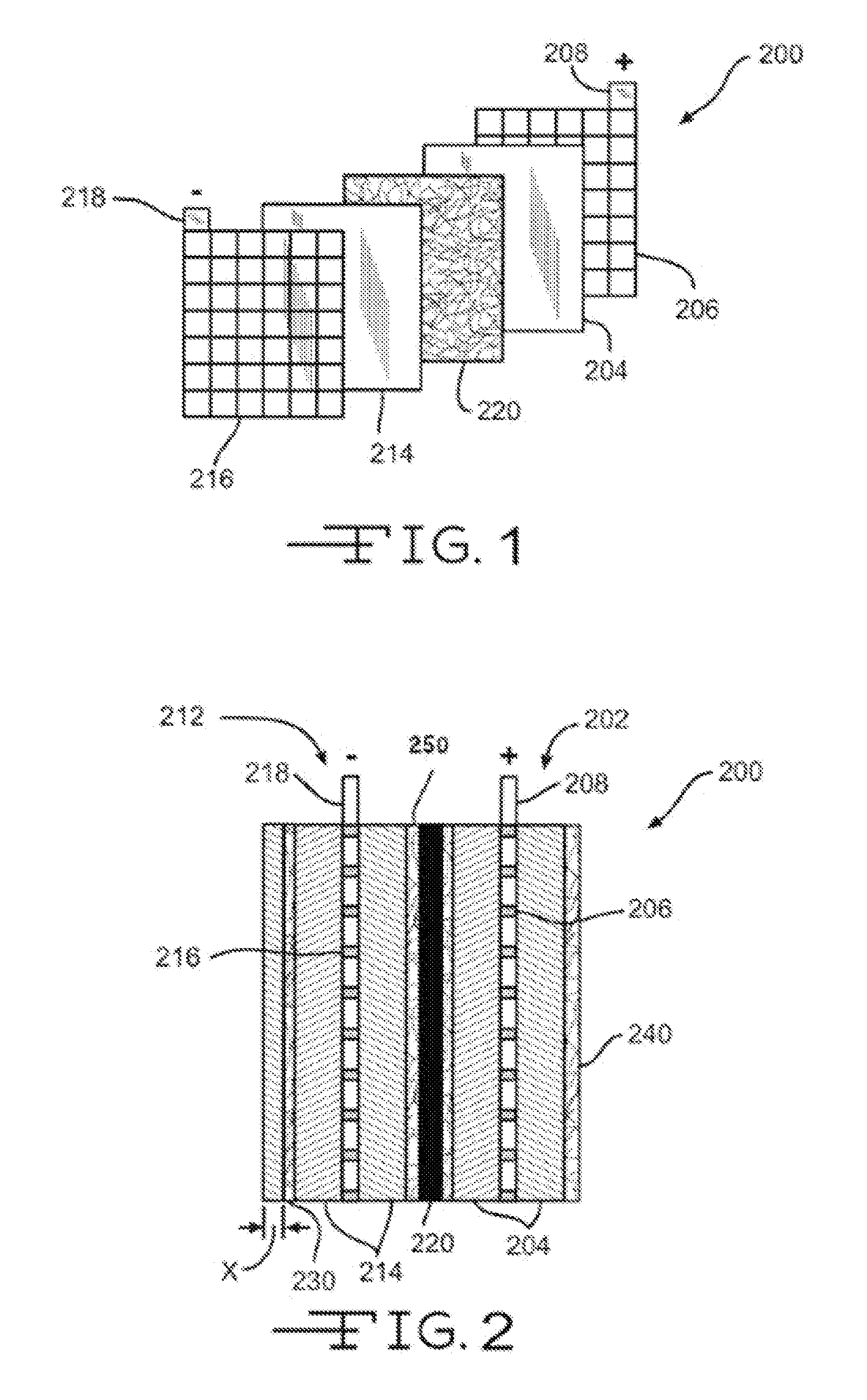

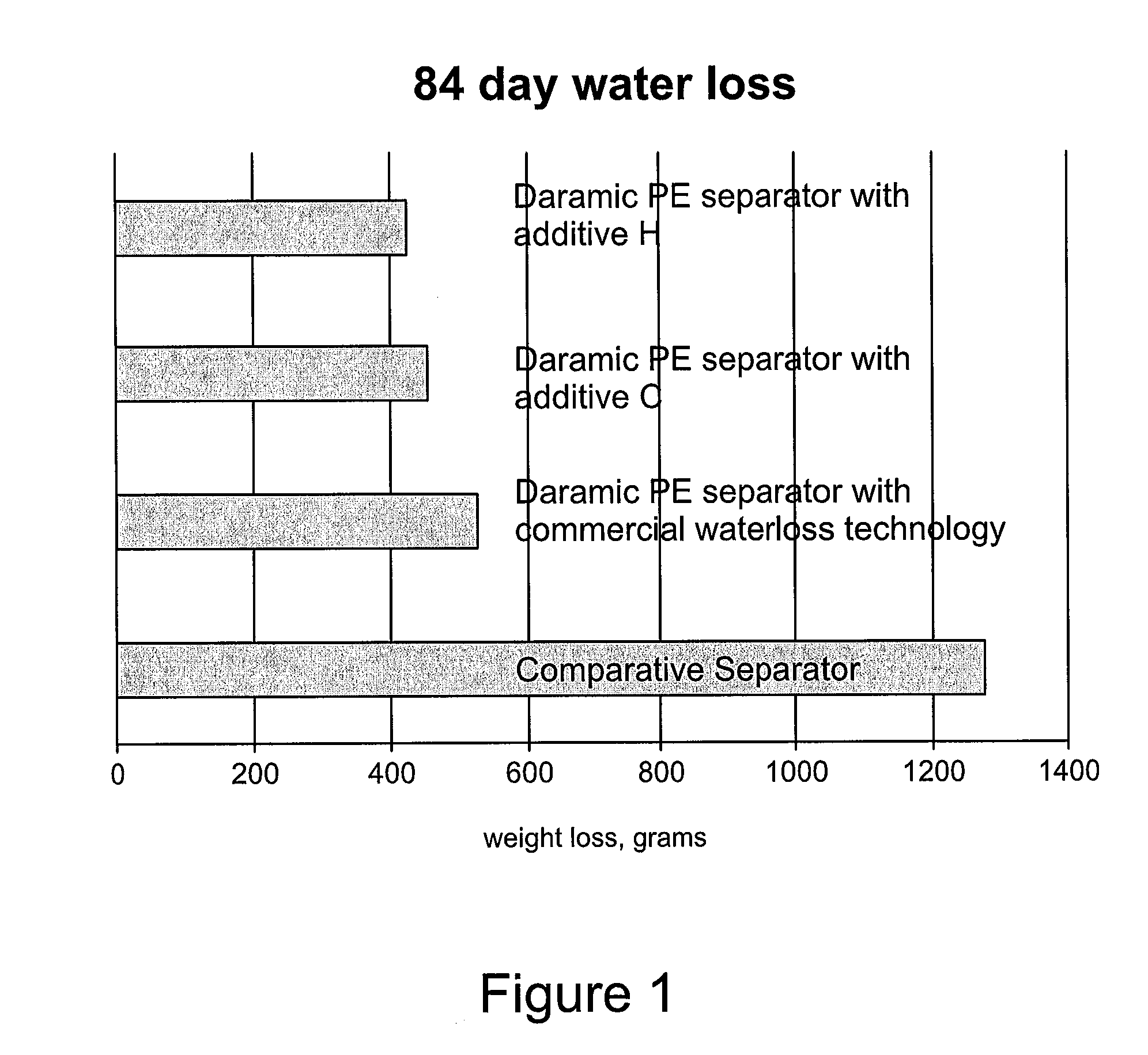

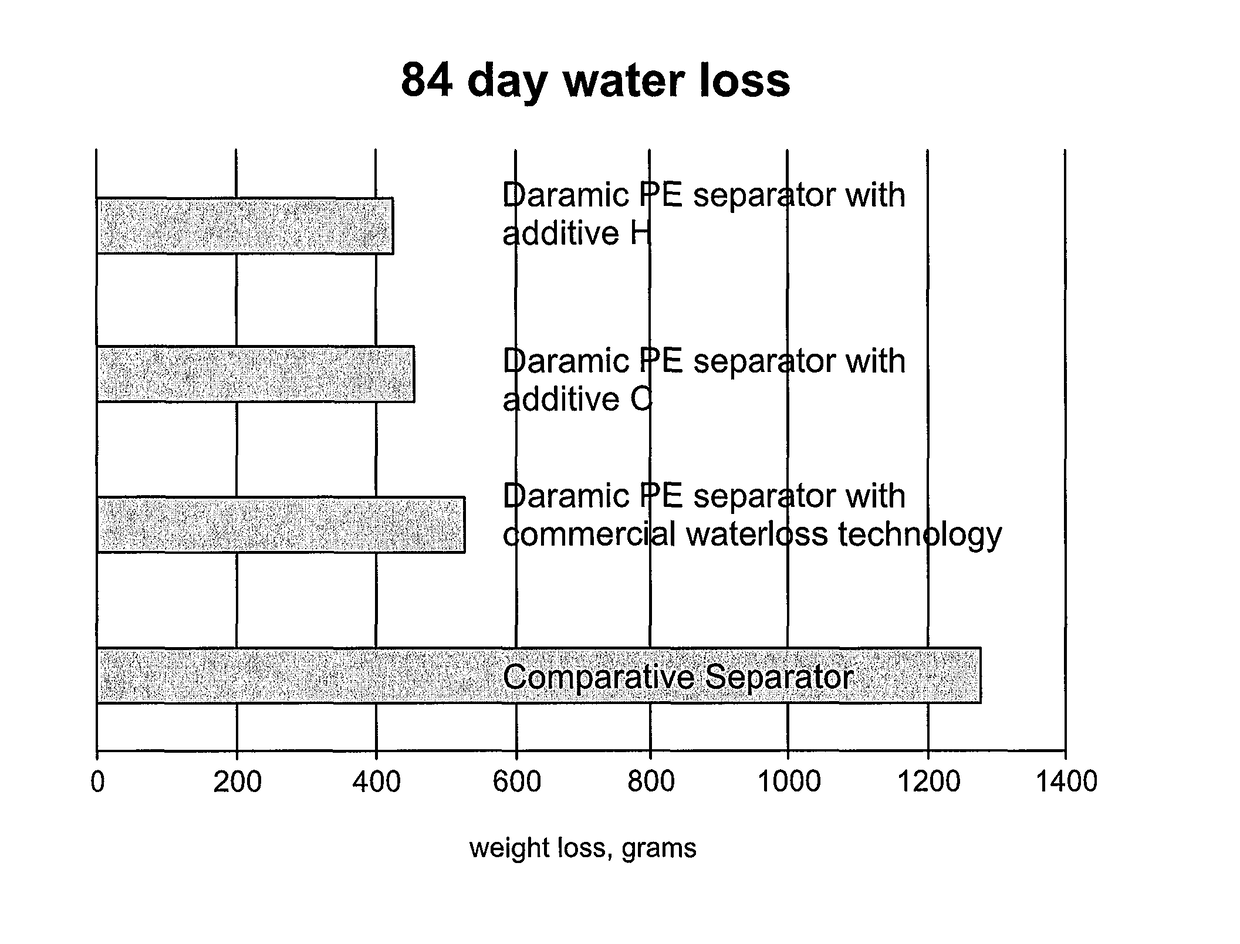

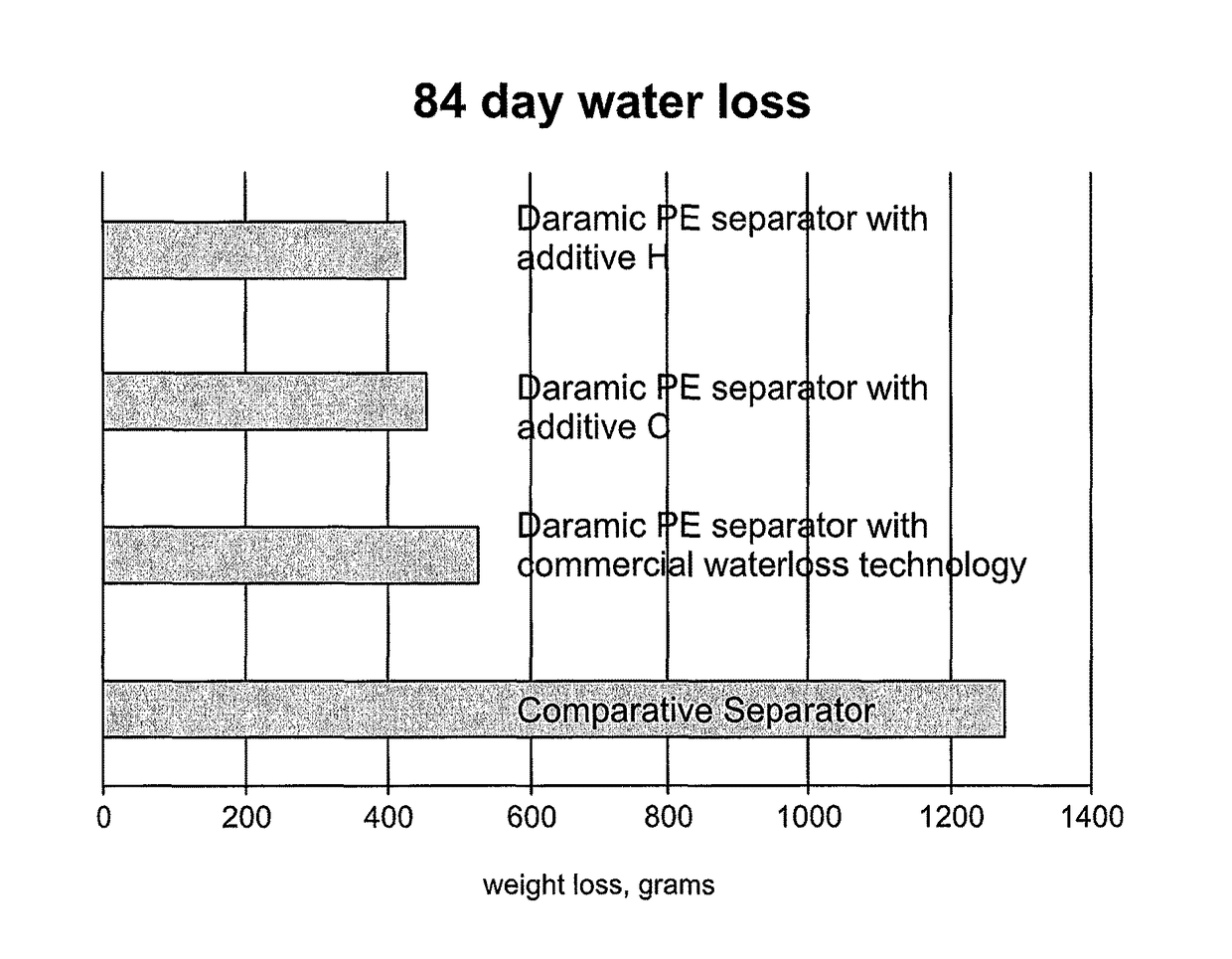

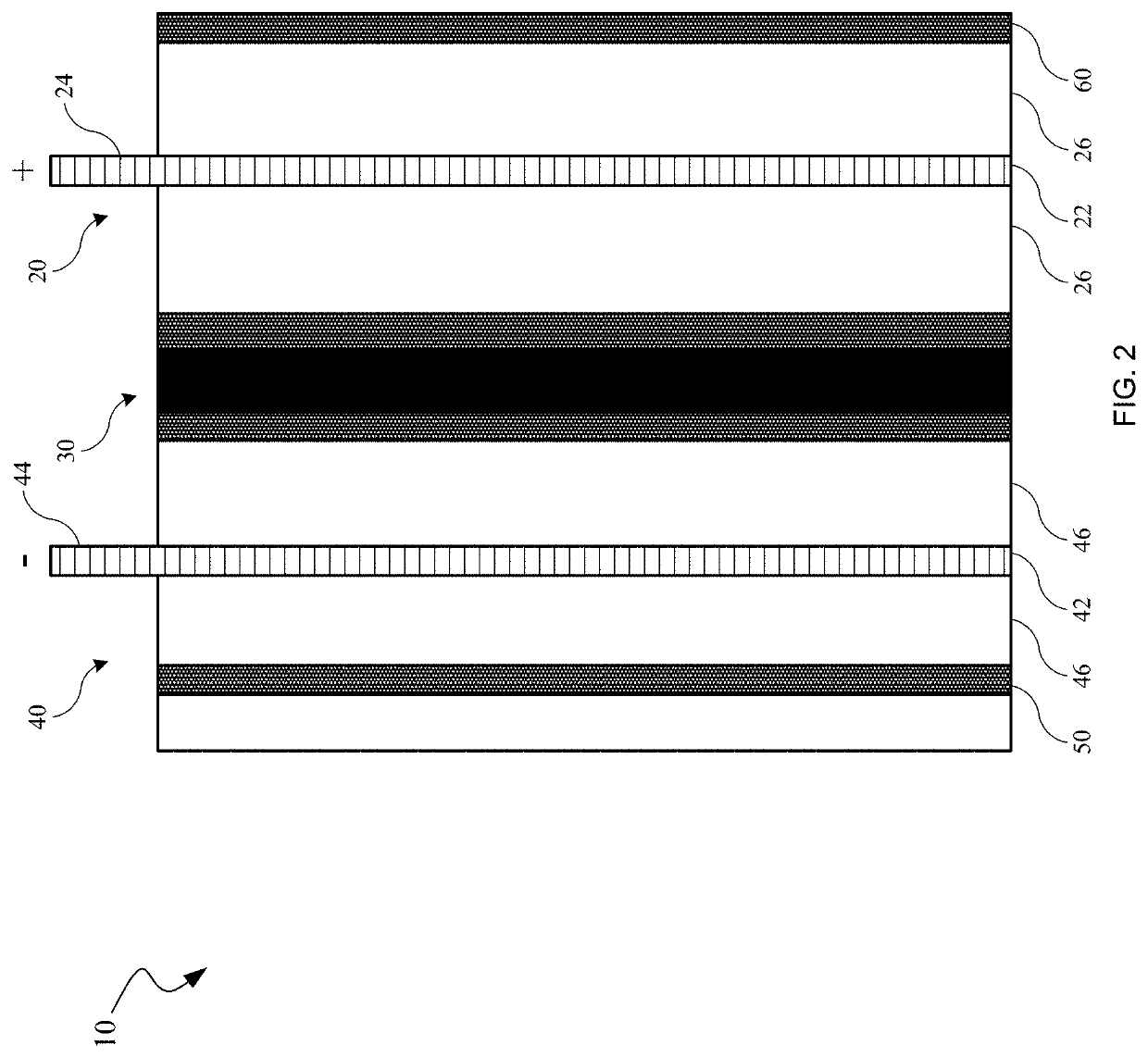

Water loss separators used with lead acid batteries, systems for improved water loss performance, and methods of manufacture and use thereof

ActiveUS20160254573A1Improve performanceProlong lifeCell seperators/membranes/diaphragms/spacersCell electrodesEngineeringMethods of production

In at least select embodiments, the instant disclosure is directed to new or improved battery separators, components, materials, additives, surfactants, lead acid batteries, systems, vehicles, and / or related methods of production and / or use. In at least certain embodiments, the instant disclosure is directed to surfactants or other additives for use with a battery separator for use in a lead acid battery, to battery separators with a surfactant or other additive, and / or to batteries including such separators. In at least certain select embodiments, the instant disclosure relates to new or improved lead acid battery separators and / or systems including improved water loss technology and / or methods of manufacture and / or use thereof. In at least select embodiments, the instant disclosure is directed toward a new or improved lead acid battery separator or system with one or more surfactants and / or additives, and / or methods for constructing lead acid battery separators and batteries with such surfactants and / or additives for improving and / or reducing water loss from the battery.

Owner:DARAMIC LLC

Preparation method for powder metallurgical steel collar ring of ring-twisting frame

A preparation method for a powder metallurgical steel collar ring of a ring-twisting frame comprises the following steps: after mixing No.20 industrial engine oil and reduced iron powder, and adding natural flake graphite powder, molybdenum powder and tungsten powder in sequence, wherein the material mixing time is 45 to 60 minutes; using a screen mesh of 80 meshes to screen the mixture prepared at the second step; forming a part blank with the mixture under the pressure of 5.5-6.0 T / cm<2>, with the density of 6.25-6.35 g / cm<3>; sintering the formed steel collar ring blank on a silicon nitride base plate; then cooling and discharging the steel collar ring blank; carrying out the heat treatment and surface polishing to the steel collar ring according to the technical requirements of the part so as to reach design requirements. According to the powder metallurgical steel collar ring of the ring-twisting frame, provided by the invention, the specific principal element material graininess component and the special material prescription are adopted, the heat treatment surface hardness of the steel collar ring is HRA50 to 60, the friction coefficient is 0.03 to 0.04 Mu, the permeability Phi is equal to 500-800*10-12, and the usability and the service life are improved greatly.

Owner:陕西华夏粉末冶金有限责任公司

Method and device for optical sensor compensation, and apparatus incorporating the same

InactiveUS7077492B2Improve performance and lifeProlong lifePhotometry using reference valueSpacing mechanismsUltrasound attenuationEngineering

An optical sensor has a sensor compensation to compensate for sensor degradation due to airborne contaminations in the operating environment. For example, in a thermal ink jet printing environment, the thermal ink jet operation produces misting or splashing of the thermal ink jet droplets, causing a gradual degradation of the sensor sensitivity due to a surface accumulation of the ink jet droplets. The optical sensor device includes an optical emitter emitting an optical signal according to an emitter input, an optical detector disposed to detect the optical signal and output a detector output having an output level according to the detected optical signal, a variable attenuator having an adjustable attenuation setting, and a controller adjusting the attenuation setting of the variable attenuator. During an adjustment operation, the controller determines the attenuation setting at which the output level of the detector output exceeds a predetermined value, and accordingly sets the variable attenuator to operate the detector output at an output level exceeding the predetermined value by a margin. Compensations for the optical emitter and the optical detector are disclosed, including the use of a variable pulse-width modulated signal.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Ergonomic chair

ActiveUS10021983B2Improves strength and endurance and flexibilityIncrease loopStoolsAdjustable chairsDynamic motionEngineering

A chair having a contoured seat cushion mounted on top of an exercise ball with four tension-adjustable elastic cords such as bungee cords is provided. The shock absorbing cords may attach to the underside of the seat cushion by looping through spring-eye carabiner type hooks, and may pass through grooved locking tubes with v-channels for adjusting the cord tension. The ball may sit on top of a swivel plate, so that dynamic motion and counterbalancing are attainable for a variety of ergonomically beneficial seating styles.

Owner:MARK DARREN WILLIAM

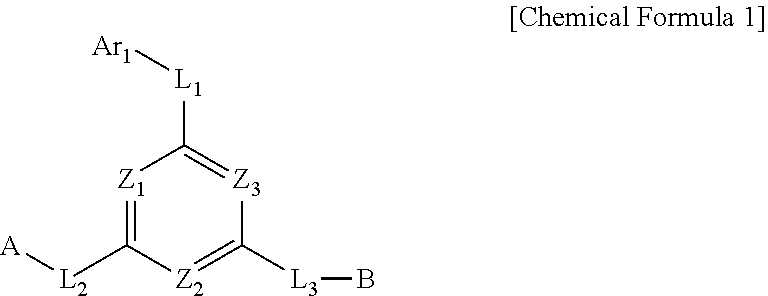

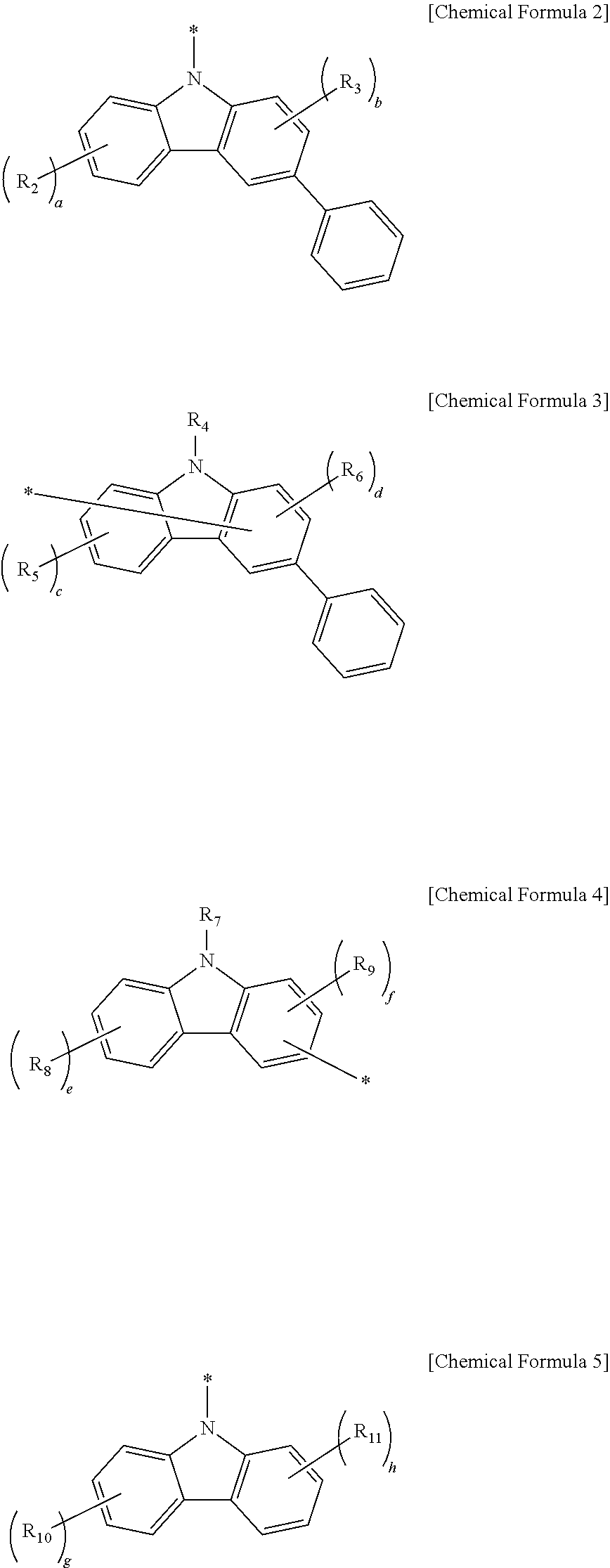

Organic compound and organic electroluminescent device using the same

ActiveUS20210135118A1Improve luminous performanceReduce the driving voltageOrganic chemistrySolid-state devicesSimple Organic CompoundsOrganic electroluminescence

The present disclosure relates to a novel organic compound which has excellent thermal stability, electron transporting ability, and light emitting ability, and to an organic EL device containing the same. As the organic compound is used in an organic material layer of the organic EL device, the thermal stability, luminous efficiency, driving voltage, and life of the device can be improved.

Owner:SOLUS ADVANCED MATERIALS CO LTD

Small pore size nonwoven mat with hydrophilic/acid resistant filler used in lead acid batteries and applications therefor

ActiveUS9755205B2Reduce penetrationSmall sizeElectrode carriers/collectorsLead-acid accumulator electrodesGlass fiberFiber

According to one embodiment, a nonwoven fiber mat includes between 10% and 50% by weight of a plurality of first glass fibers having an average diameter of less than 5 μm and between 50% and 90% by weight of a plurality of second glass fibers having an average diameter of greater than 6 μm. The nonwoven fiber mat also includes an acid resistant binder that binds the first and second glass fibers together. The nonwoven fiber mat has an average pore size of between 1 and 100 μm and exhibits an air permeability of below 100 cubic feet per minute per square foot (cfm / ft2) as measured by the Frazier test at 125 Pa according to ASTM Standard Method D737.

Owner:JOHNS MANVILLE CORP

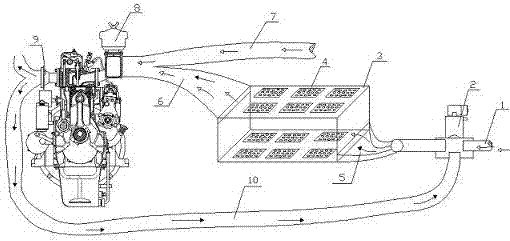

Battery thermal management system based on oil-electricity hybrid electric vehicle

PendingCN107093782AImprove performance and lifeAvoid thermal runawayInternal combustion piston enginesExhaust apparatusThermal runawayElectrical battery

Disclosed is a battery thermal management system based on an oil-electricity hybrid electric vehicle. By means of a natural aspiration principle of an internal combustion engine, air sucked into a combustion chamber flows through a power battery box to cool a power battery, high temperature waste gas introduced into the combustion chamber is made to flow through the power battery by means of the working principle of a waste gas recycling system to heat the power battery, and finally the actual temperature of the working power battery is controlled within the best working temperature region. The system can achieve control according to the difference between the current actual working temperature and the ideal working temperature of the power battery on the condition that the power, oil consumption and discharge performance of the internal combustion engine are not affected, so that cooling or heating treatment is performed on the power battery. The using performance of the whole power battery pack is improved, and the service life of the whole power battery pack is prolonged; thermal runaway of the battery is avoided, the power battery safety accident rate is lowered, and the battery thermal management system is low in cost, efficient and capable of saving energy.

Owner:NANCHANG UNIV

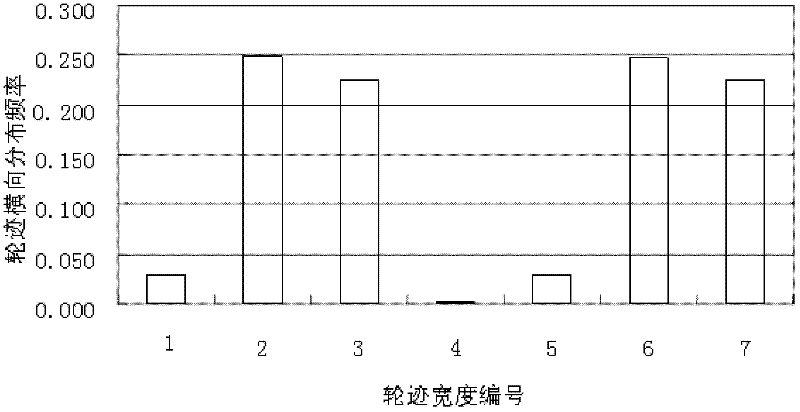

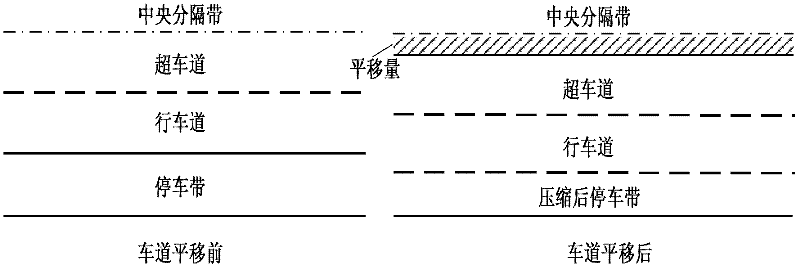

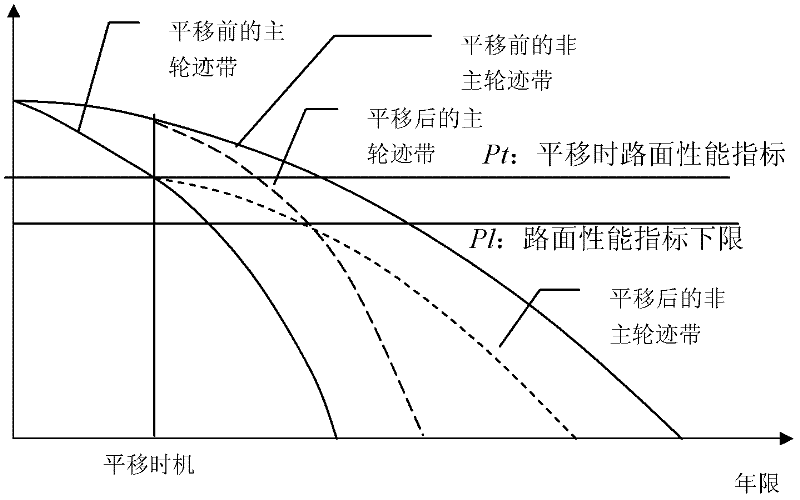

Method for prolonging service life of pavement

InactiveCN102312411AImprove performance and lifeReduce maintenance costsTraffic signalsRoad signsDecay functionAutomotive engineering

The invention discloses a method for prolonging service life of a pavement. When lane accumulated axle load reaches Nt or an pavement performance index reaches Pt, old traffic marker lines of a road are shoveled off, lanes are translated for 50-150cm and new marker lines are drawn, wherein the Nt and the Pt are respectively determined by the following formulas: Pl=f (Nt.az+NS.azl)= f (Nt.azf+Ns.az), and Pt=f (Nt.az), wherein: Pl denotes the lower limit of the pavement performance index, the f (.) denotes to a decay function of pavement performance with times of accumulated axle load, the Nt denotes the lane accumulated axle load during lane translation, the Ns denotes the lane accumulated axle load after translation, the az denotes main wheel path axle load frequency, azl denotes the original main wheel path axle load frequency after lane translation and the azf denotes the axle load frequency of translated new main wheel paths before translation. By adopting the method of regularly translating the lanes, the space distribution of the load in the service life of the road is effectively kept to be even, the service performance and the service life of the road are greatly improved and the maintenance cost of the road is saved.

Owner:HEBEI UNIV OF TECH

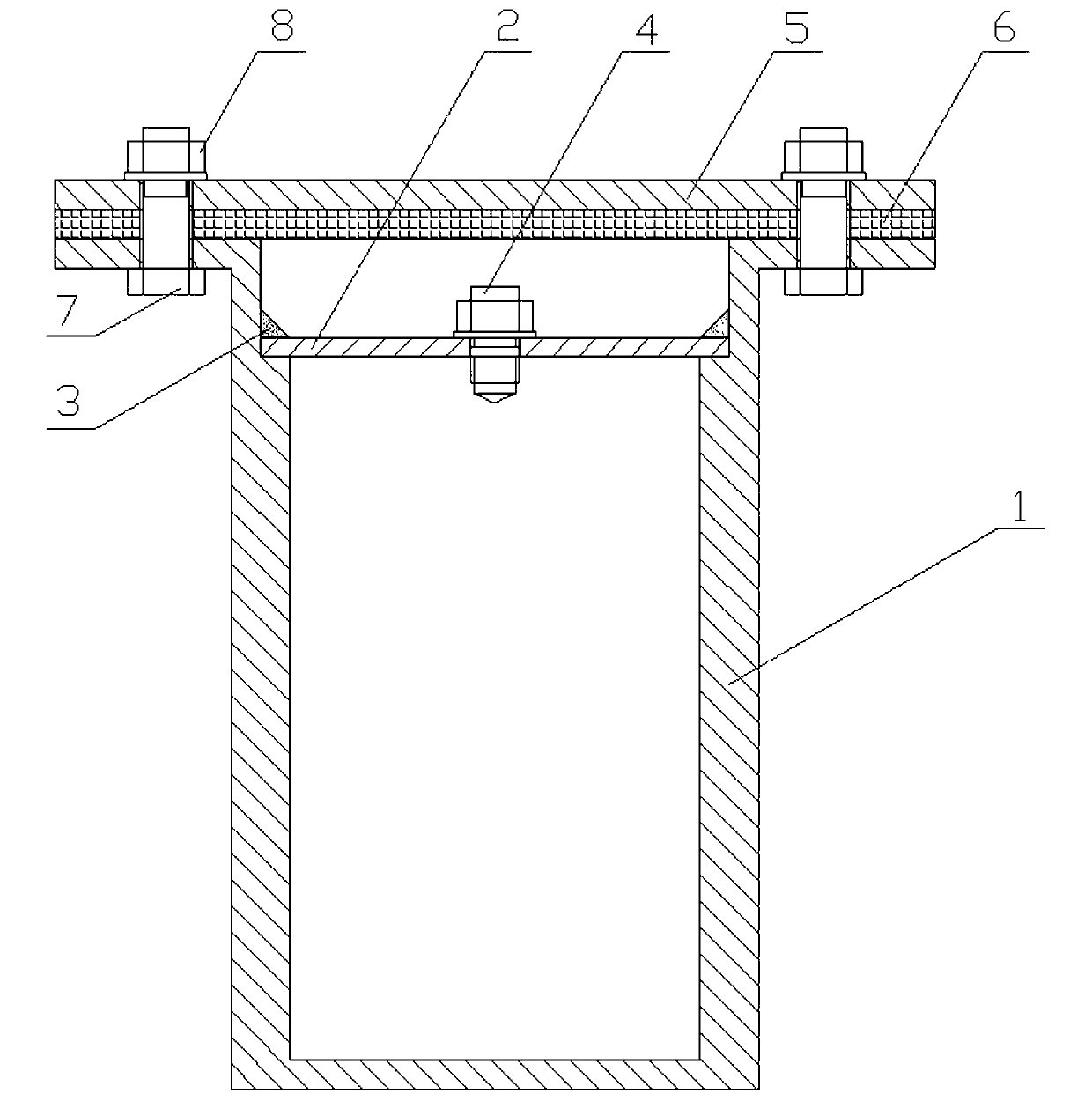

Low-temperature pack boronizing steel part surface-strengthening treatment device and method

InactiveCN102766839AImprove sealingImprove performance and lifeSolid state diffusion coatingSodium silicateJoint surface

The invention discloses a low-temperature pack boronizing steel part surface-strengthening treatment device and a method. The device comprises a barrel-shaped boronizing tank, and an internal cover is matched with the boronizing tank; an asbestos board and an external cover are sequentially fitted on a fixed flange arranged on the upper end of the boronizing tank, and at least three fixing holders are evenly arranged along the circumference of the boronizing tank between the external cover and the fixed flange. When the device is in used, pack boronizing agent and a workpiece are loaded into the device, and the internal cover is closed; sodium silicate mastic is prepared and applied on the circumference of the joint surface between the edge of the internal cover and the inner wall of the boronizing tank for sealing; and the asbestos board and the external cover are sequentially closed, and are tightly fixed by the fixing holders. The invention is implemented by adopting the internal cover and external cover sealing method, the sodium silicate mastic is adopted to seal the internal cover, the thick asbestos board is clamped between the external cover and a furnace shell, moreover, a plurality of evenly distributed fixing holders are used for sealing, and thereby the sealing property of the low-temperature pack boronizing steel part surface-strengthening treatment device is effectively enhanced.

Owner:上海市机械制造工艺研究所有限公司

Surface treatment method for metal stamping die

InactiveCN107937867AImproved thermal fatigue life and thermal wear resistanceImprove performance and lifeSolid state diffusion coatingFurnace typesOperational performanceSilicon nitride

The invention relates to the technical field of surface treatment of stamping dies, and discloses a surface treatment method for a metal stamping die. According to the surface treatment method, permeation treatment is carried out, penetrating fluid contains iron boride and silicon nitride, and therefore the thermal fatigue life of the die can be remarkably prolonged, and the thermal wear resistance of the die can be remarkably improved; and then heat treatment and surface strengthening treatment are carried out, different surface treatment modes are used for the die, and therefore the technical advantages of various surface treatment modes can be brought into play, and in addition, the obvious effects of the combined use can be achieved. The method has the advantages that the surface morphology, the chemical components, the structure and the stress state of the die are changed through a composite treatment technology, and therefore the operational performance of the die can be improved, and the service life of the die can be prolonged.

Owner:蚌埠市宏大制药机械有限公司

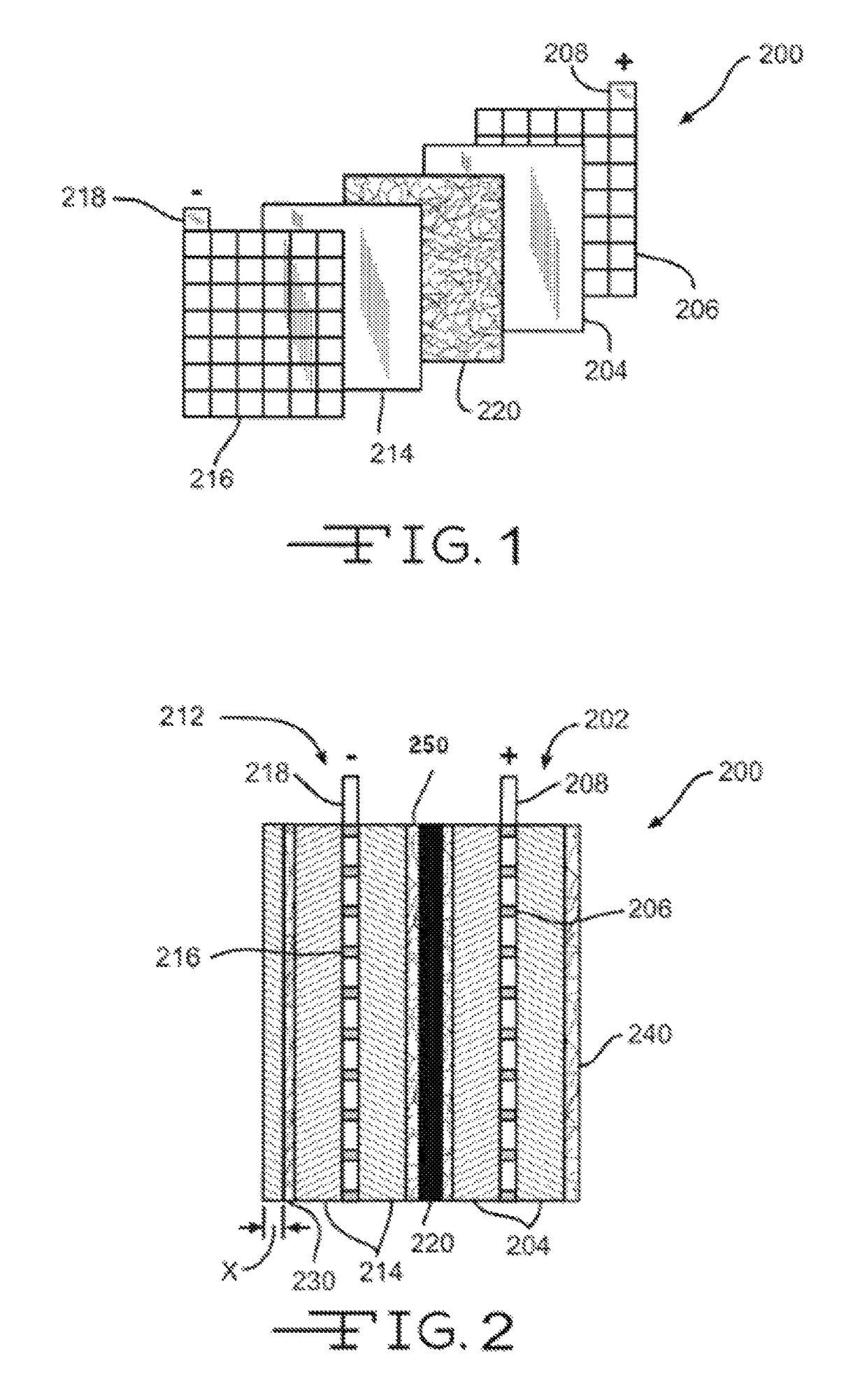

Rotary capacitor for shunting high frequency bearing currents and reducing EMI in electric machinery

ActiveUS9653970B2Reduce trafficImprove performance and lifeAssociation with grounding devicesElectricityElectric machinery

Rotary capacitor assemblies divert or mitigate high-frequency electrical currents and voltages in bearings of electric machinery (e.g., motors and generators) without direct contact with the bearings. The assemblies include rotating capacitors, in which surfaces in close proximity are free to rotate with respect to another while maintaining relative surface area and separation distance. A lubricant (such as air or oil) facilitates capacitive surfaces hydrodynamically “floating” on each other. A shunt body is connected electrically in parallel with the bearings of the machine, providing a non-contact or nearly non-contact electrical pathway for damaging high-frequency currents an voltages to be shunted around the mechanical load carrying bearings.

Owner:C MOTIVE TECHNOLOGIES INC

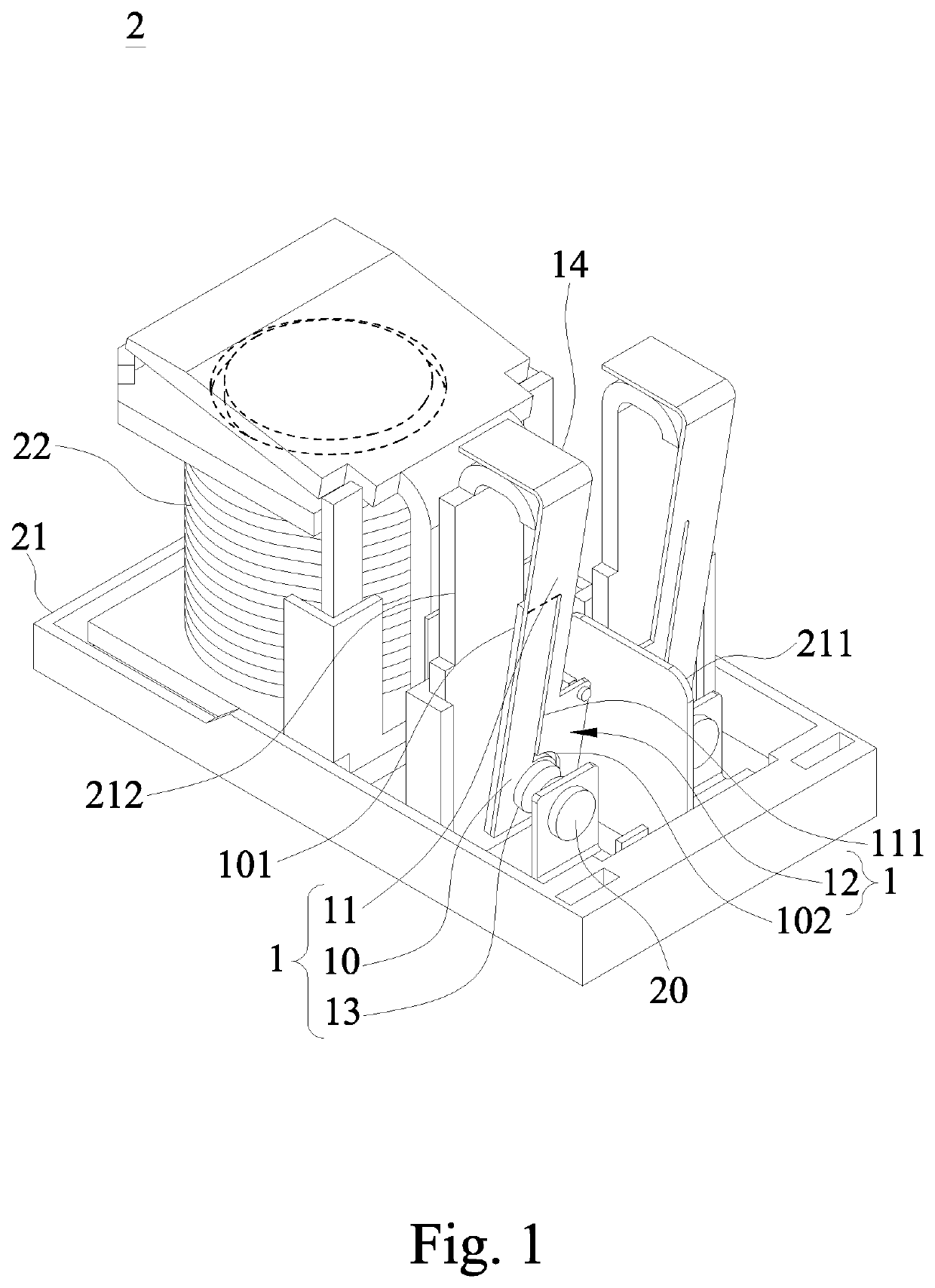

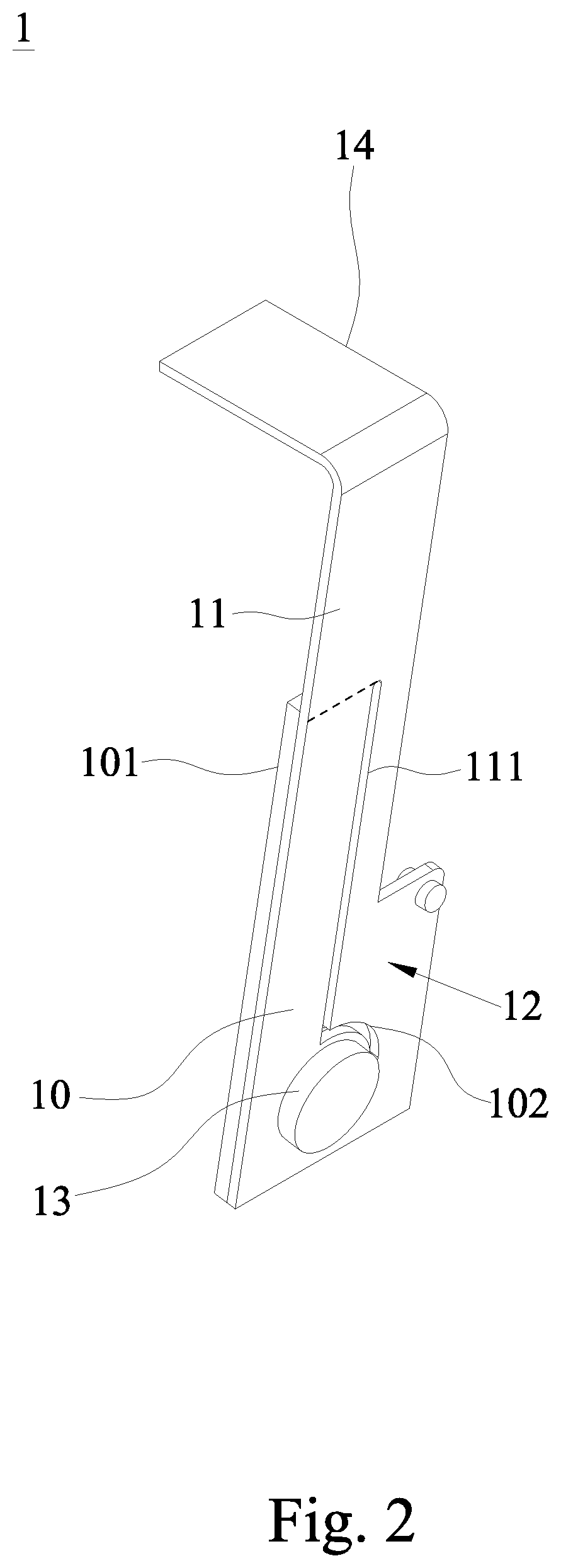

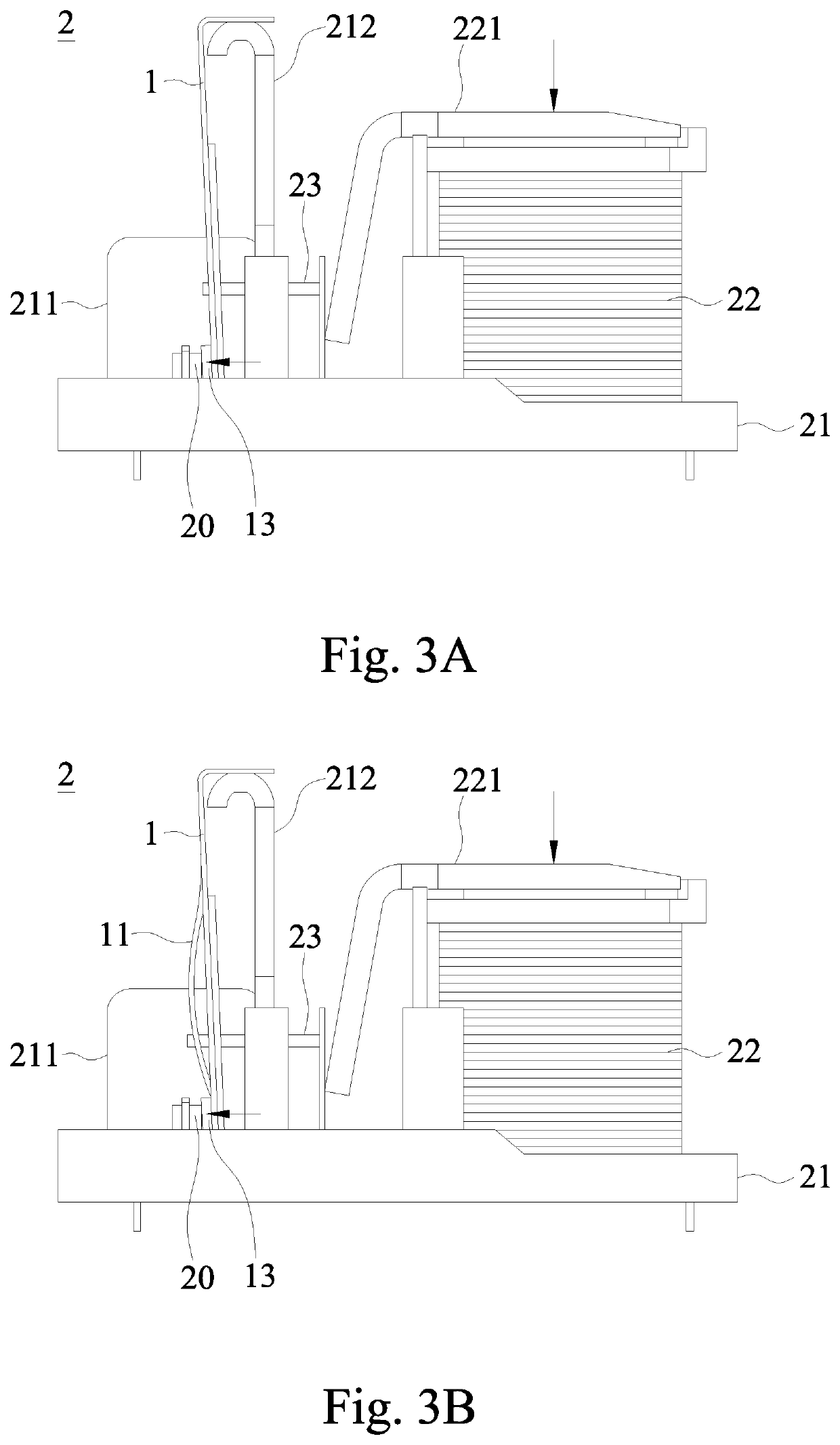

Movable spring plate and relay thereof

ActiveUS10522312B1Improve performance and lifeAvoid arcingElectromagnetic relay detailsNon-polarised relaysEngineeringClosed state

A movable spring plate structure for defining an open or closed state with respect to a fixed contact includes a rigid spring plate contact portion, a soft spring plate warp portion, a soft spring plate force-applying portion and a movable contact. The soft spring plate warp portion is coupled to the rigid spring plate contact portion, and a first deformation gap is formed between the rigid and soft spring plate contact portions. The rigid spring plate contact portion is harder than the soft spring plate warp portion. The soft spring plate force-applying portion is disposed at the soft spring plate warp portion, and the movable contact is disposed at the rigid spring plate contact portion. A force applied to the soft spring plate force-applying portion drives the movable and fixed contacts into a closed state.

Owner:SONG CHUAN PRECISION

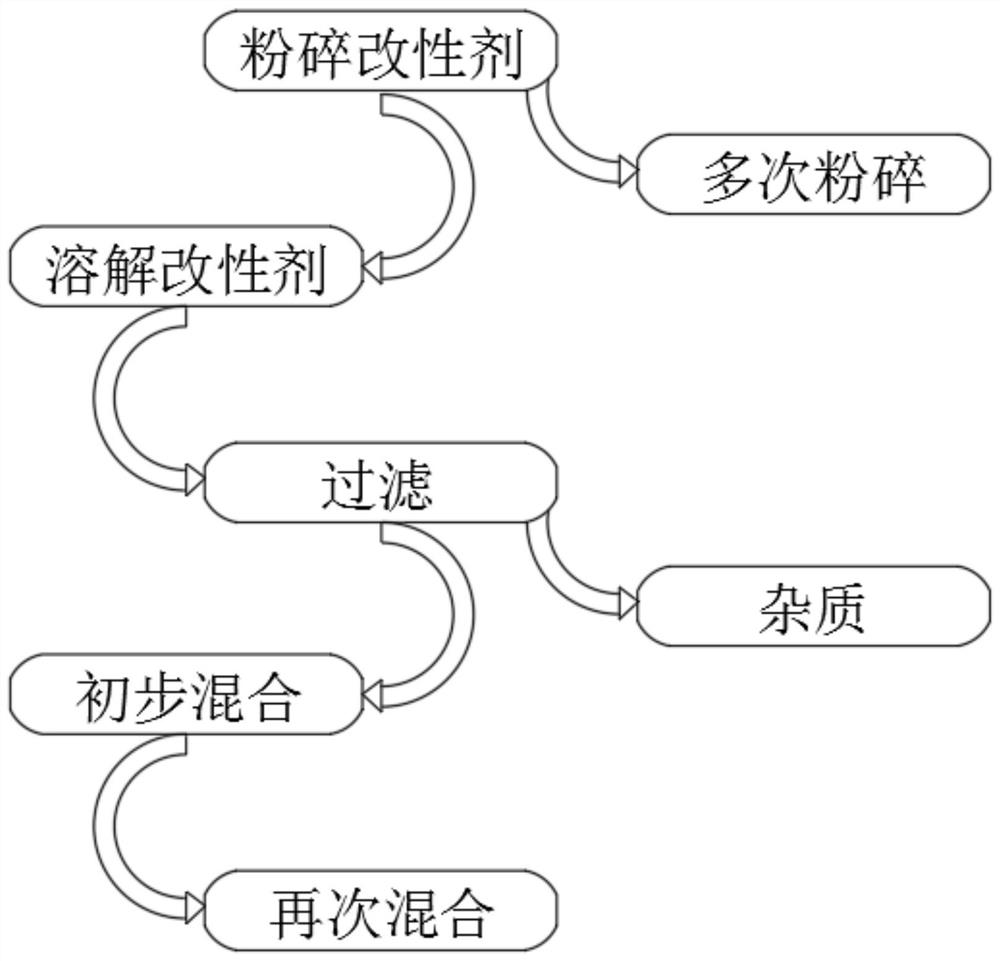

High-performance modified asphalt and manufacturing method thereof

PendingCN113717536AImprove viscosity and toughnessImprove performance and lifeBuilding insulationsProcess engineeringAsphalt

The invention relates to the technical field of asphalt preparation, and discloses high-performance modified asphalt. The high-performance modified asphalt is prepared from the following components in parts by weight: 15-30 parts of auxiliary materials, 10-18 parts of a modifier, 50-100 parts of raw asphalt and 2-25 parts of a solvent. The invention also discloses a manufacturing method of the high-performance modified asphalt. The manufacturing method comprises the following steps: S1, crushing of the modifier: putting the modifier into a crusher for crushing for 10-30 minutes, and then conducting screening with a 200-to-400-mesh sieve to obtain the crushed modifier; and S2, dissolving of the modifier: adding the crushed modifier and a solvent into a mixing tank, and carrying out stirring and mixing to obtain a mixed solution A. By adding the modifier, the viscosity and toughness, the softening point, the low-temperature cracking resistance and the elasticity of the modified asphalt can be effectively improved; and by doping an anti-stripping agent and an anti-aging agent, the use performance of a pavement material can be improved, and the service life of the pavement material can be prolonged.

Owner:镇江越辉新材料有限公司

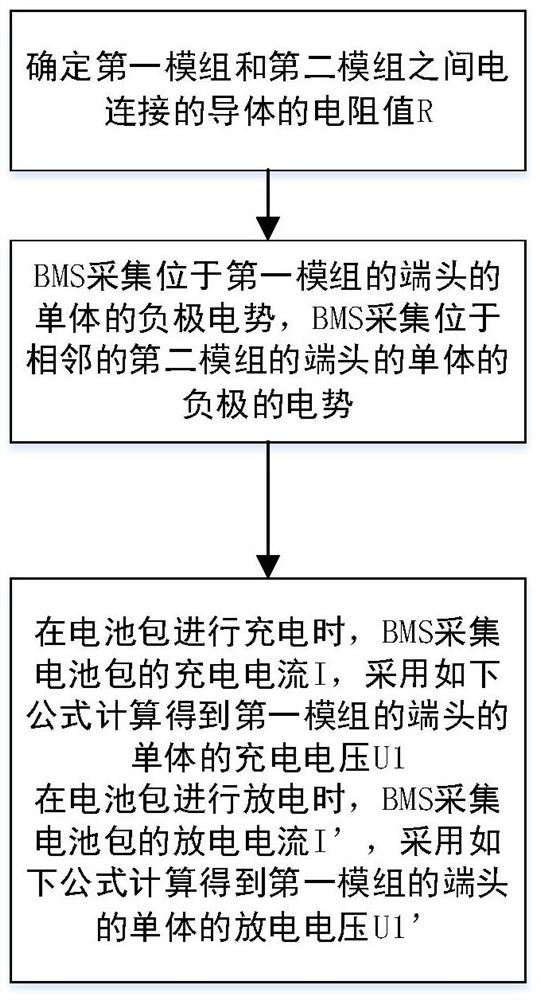

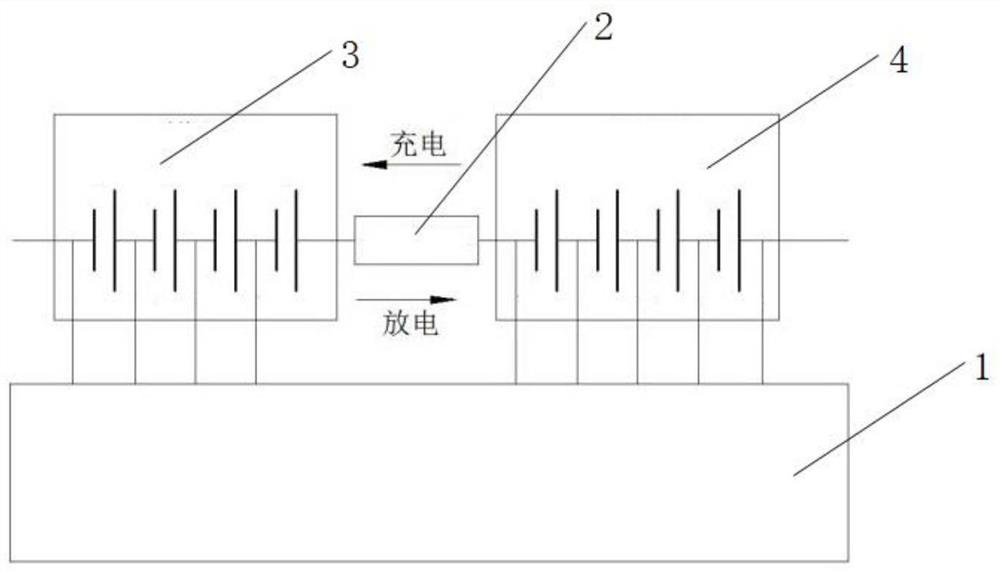

Voltage acquisition method of battery pack and electric vehicle

PendingCN113253127AImprove consistencyImprove performance and lifeElectrical testingAutomotive engineeringElectrical battery

The invention relates to the technical field of electric vehicles, in particular to a voltage acquisition method of a battery pack and an electric vehicle, and the acquisition method comprises the following steps that: S1, a resistance value R of a conductor electrically connected between a first module and a second module is determined; s2, a BMS collects the negative electrode potential of the single body located at the end of the first module, and the BMS collects the negative electrode potential of the single body located at the end of the adjacent second module; s3, when the battery pack is charged, the BMS collects the charging current I of the battery pack to obtain the charging voltage U1 of the single body at the end of the first module; and when the battery pack is discharged, the BMS collects the discharge current I' of the battery pack to obtain the discharge voltage U1' of the single body at the end of the first module. The sampling precision of the voltage of the single body can be improved, the consistency of the battery pack is improved, and therefore the use performance of the battery pack is improved, and the service life of the battery pack is prolonged.

Owner:宝能(广州)汽车研究院有限公司

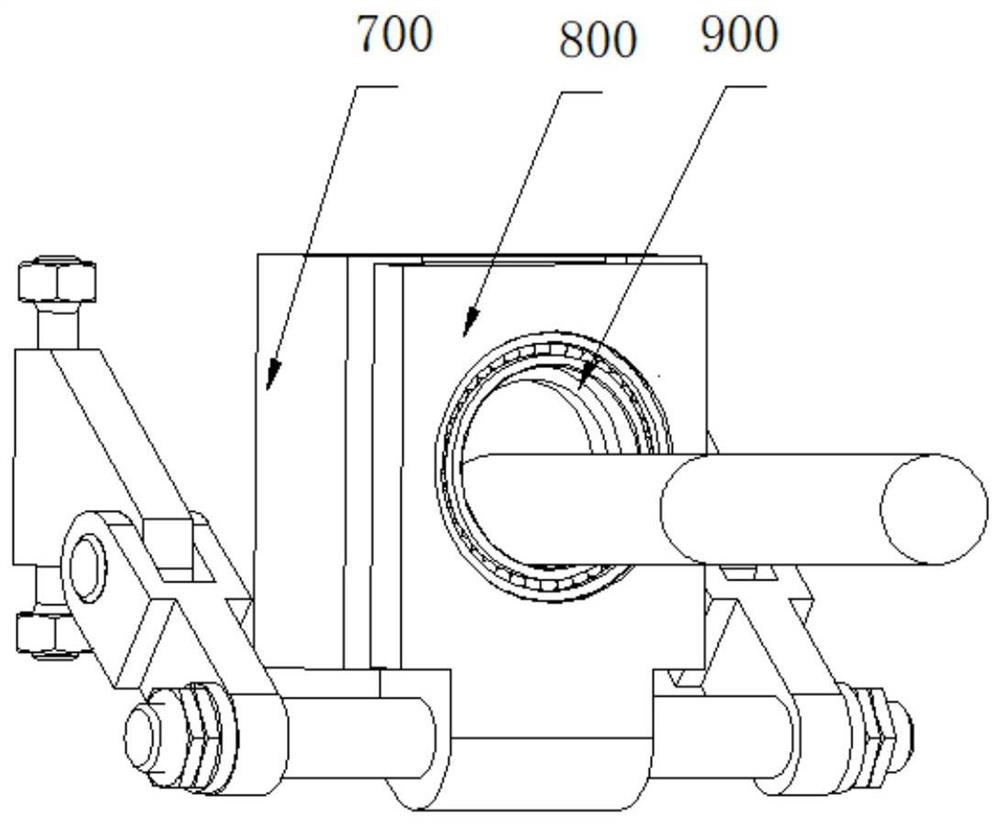

Low-stress discharging die and method in pure rolling contact with bar

ActiveCN112588937AEliminate friction and wearImprove performance and lifeBar stockIndustrial engineering

The invention relates to a low-stress discharging die and method in pure rolling contact with a bar, and belongs to the technical field of low-stress precise discharging. According to the low-stress discharging die and method in pure rolling contact with the bar, structural optimization design is carried out on the basis of an existing discharging die, an autorotation anti-attrition hammer head isarranged in an existing hammer head sliding block, so that sliding friction contact between the surface of the bar and the discharging die is converted into pure rolling contact, friction abrasion between the bar and the discharging die is greatly reduced or even eliminated, the use performance of a discharging machine is remarkably improved, the service life of the discharging machine is remarkably prolonged, and meanwhile the surface quality of the bar is greatly improved. The autorotation anti-attrition hammer head comprises an inner hammer head body in interference fit with an inner ringof a bearing; the inner hammer head body is connected with an inner hammer head motor through a coupler; an inner hammer head motor base of the inner hammer head motor is fixedly installed in an innercavity of the hammer head sliding block; the lower end of the hammer head sliding block is connected with a shaft head through a connecting rod; and a main shaft coincides with the axis of the bar.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Water loss separators used with lead acid batteries, systems for improved water loss performance, and methods of manufacture and use thereof

ActiveUS9979054B2Improve performance and lifeDelay water lossCell seperators/membranes/diaphragms/spacersCell electrodesEngineeringMethods of production

In at least select embodiments, the instant disclosure is directed to new or improved battery separators, components, materials, additives, surfactants, lead acid batteries, systems, vehicles, and / or related methods of production and / or use. In at least certain embodiments, the instant disclosure is directed to surfactants or other additives for use with a battery separator for use in a lead acid battery, to battery separators with a surfactant or other additive, and / or to batteries including such separators. In at least certain select embodiments, the instant disclosure relates to new or improved lead acid battery separators and / or systems including improved water loss technology and / or methods of manufacture and / or use thereof. In at least select embodiments, the instant disclosure is directed toward a new or improved lead acid battery separator or system with one or more surfactants and / or additives, and / or methods for constructing lead acid battery separators and batteries with such surfactants and / or additives for improving and / or reducing water loss from the battery.

Owner:DARAMIC LLC

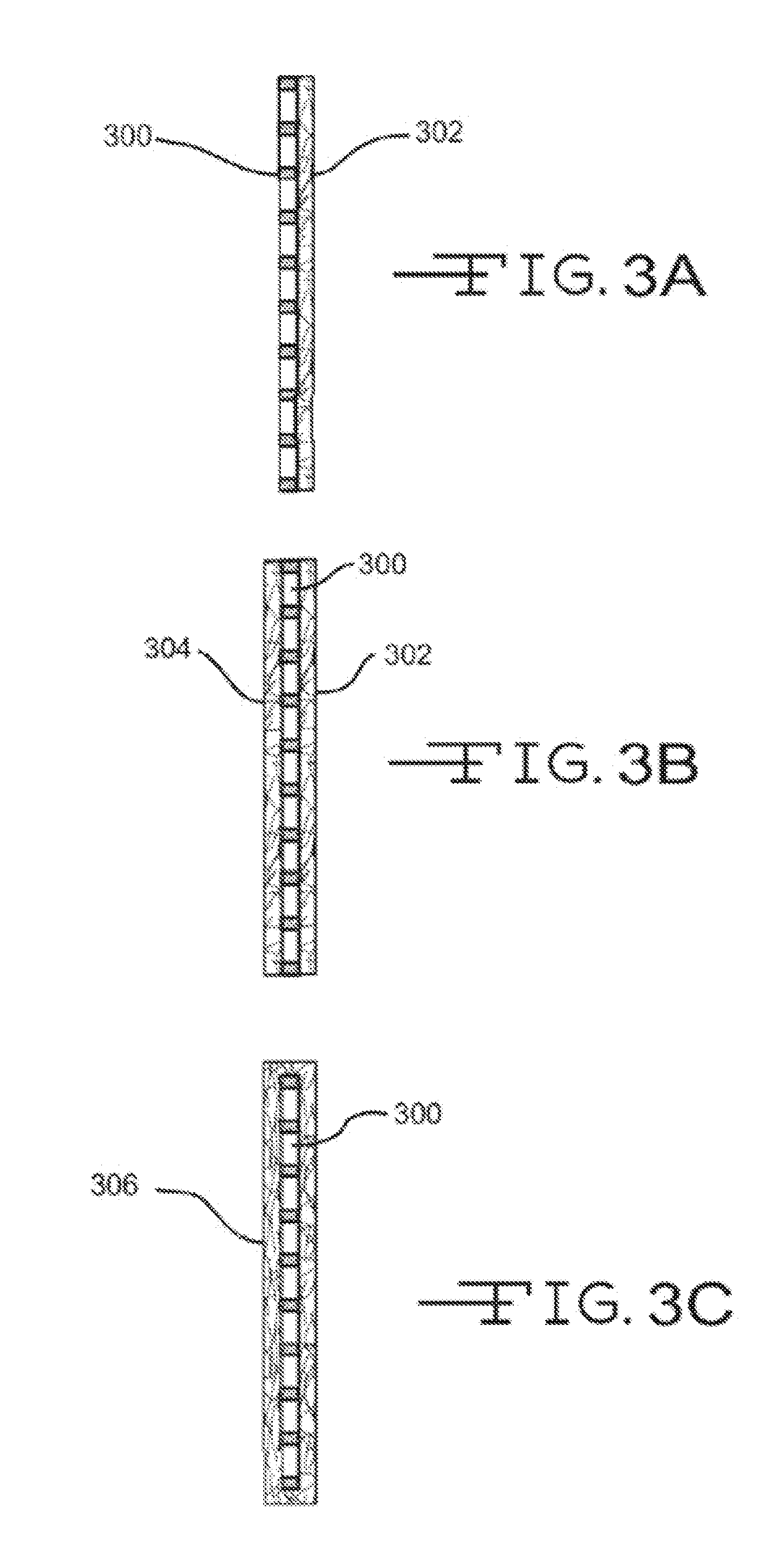

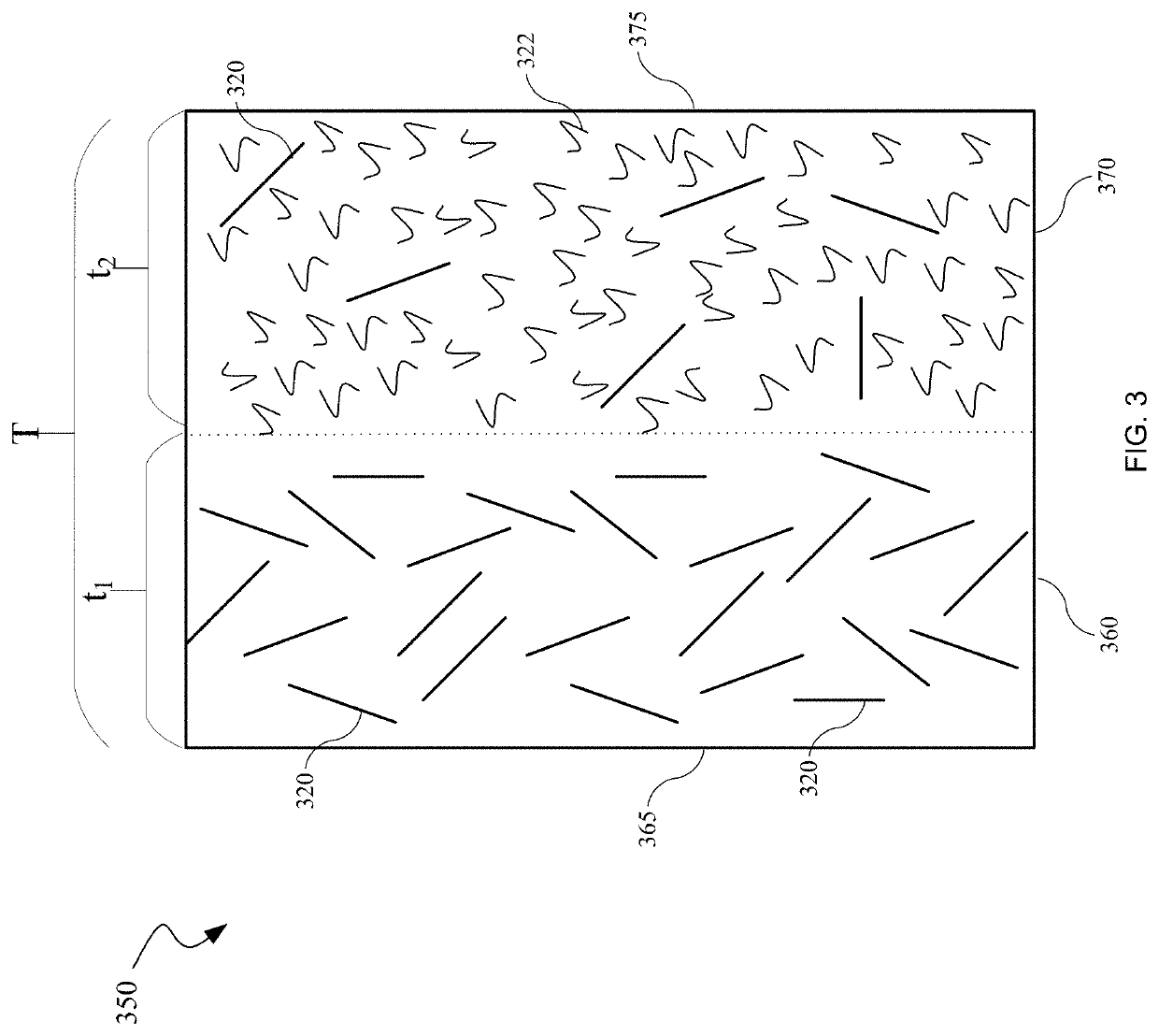

Multilayer non-woven mat for lead acid batteries and applications therefor

PendingUS20210376304A1Improve performance and lifeFunction increaseFinal product manufactureAdhesive articlesPhysical chemistryEngineering

A multilayer non-woven mat for a lead-acid battery includes a first layer of non-woven web of fibers including coarse fibers having an average fiber diameter from about 6 μm to about 25 μm and a second layer of non-woven web of fibers including microfibers having an average diameter from about 0.5 μm to about 5 μm. The multilayer non-woven mat includes a binder configured to simultaneously bind the coarse fibers in the first layer together, the microfibers in the second layer together, and at least some of the coarse fibers in the first layer to at least some of the microfibers in the second layer together. The first layer is configured to absorb an active material of an electrode of the lead acid battery, and the second layer is configured to block the active material of the electrode from passing through the non-woven glass mat.

Owner:JOHNS MANVILLE CORP

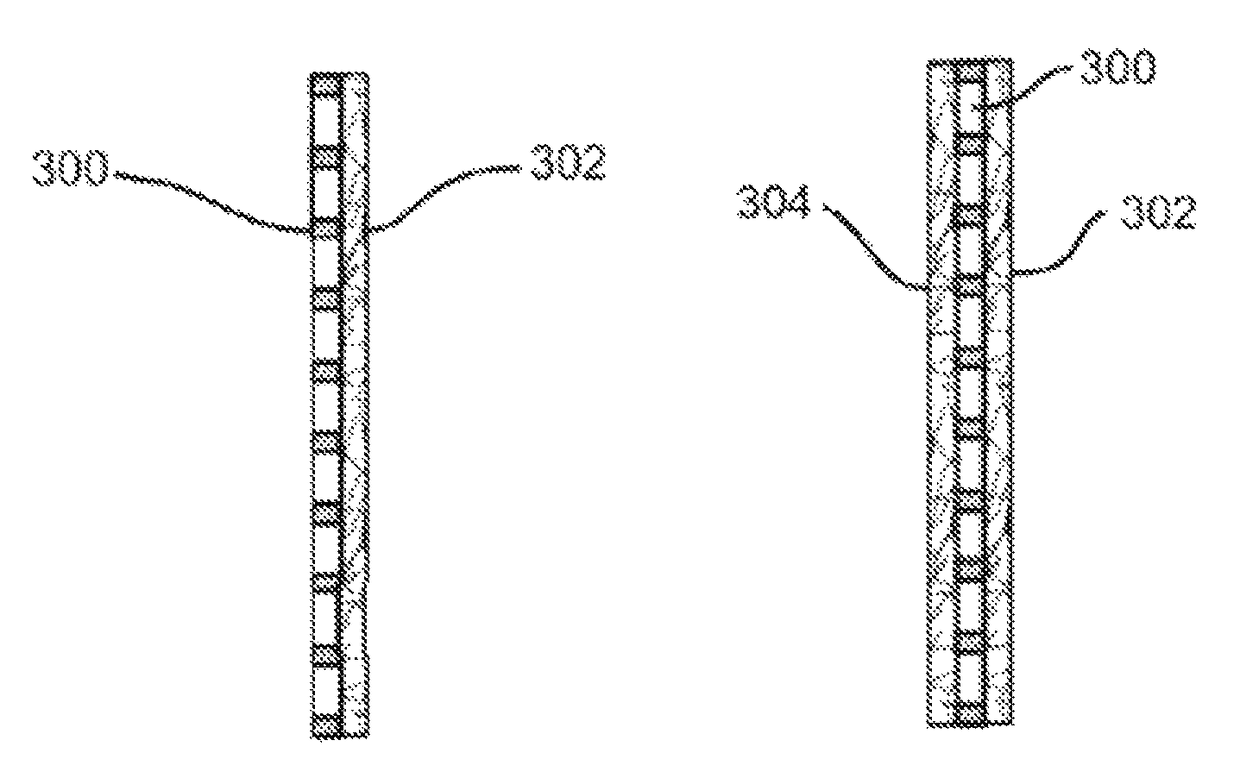

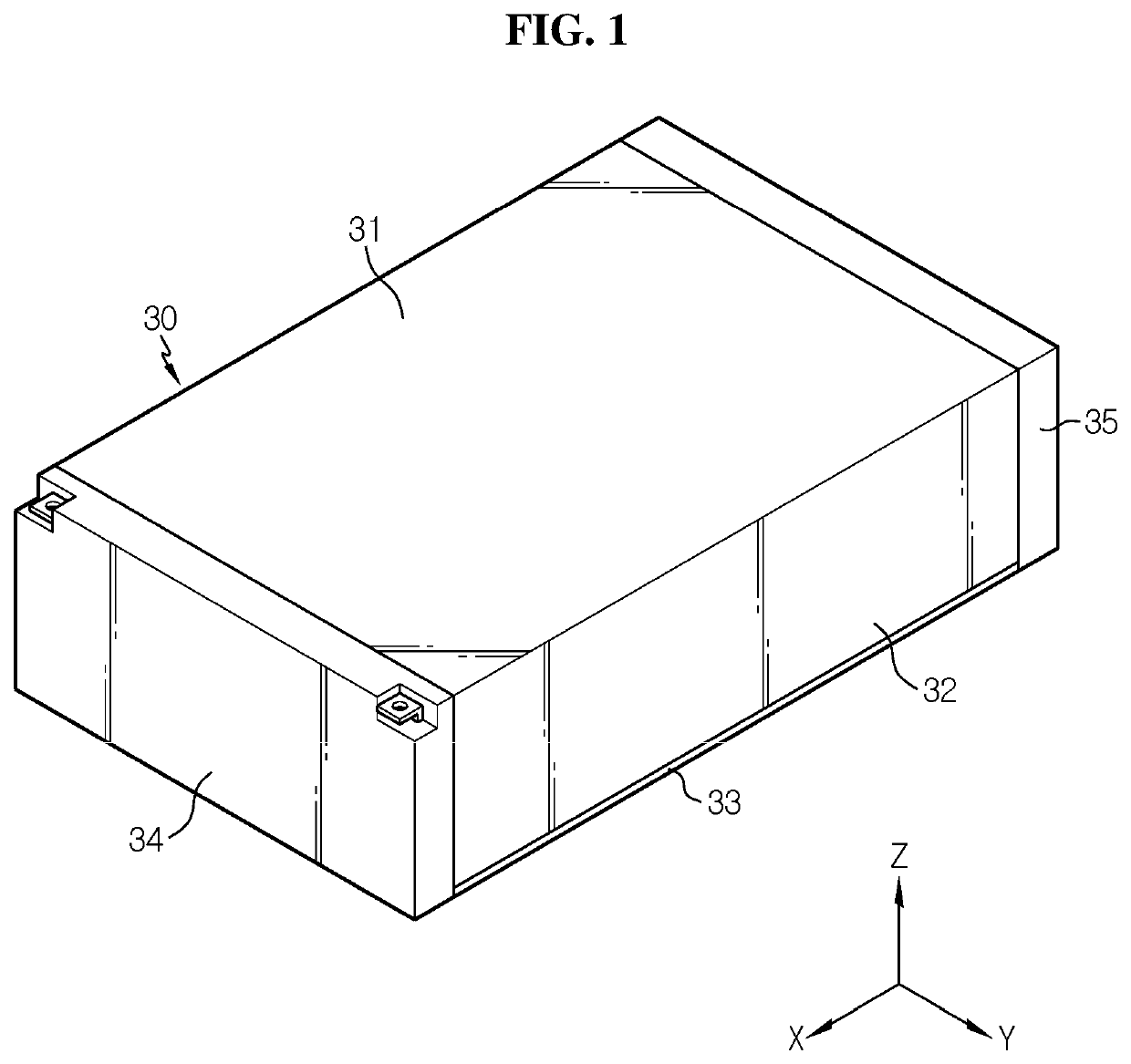

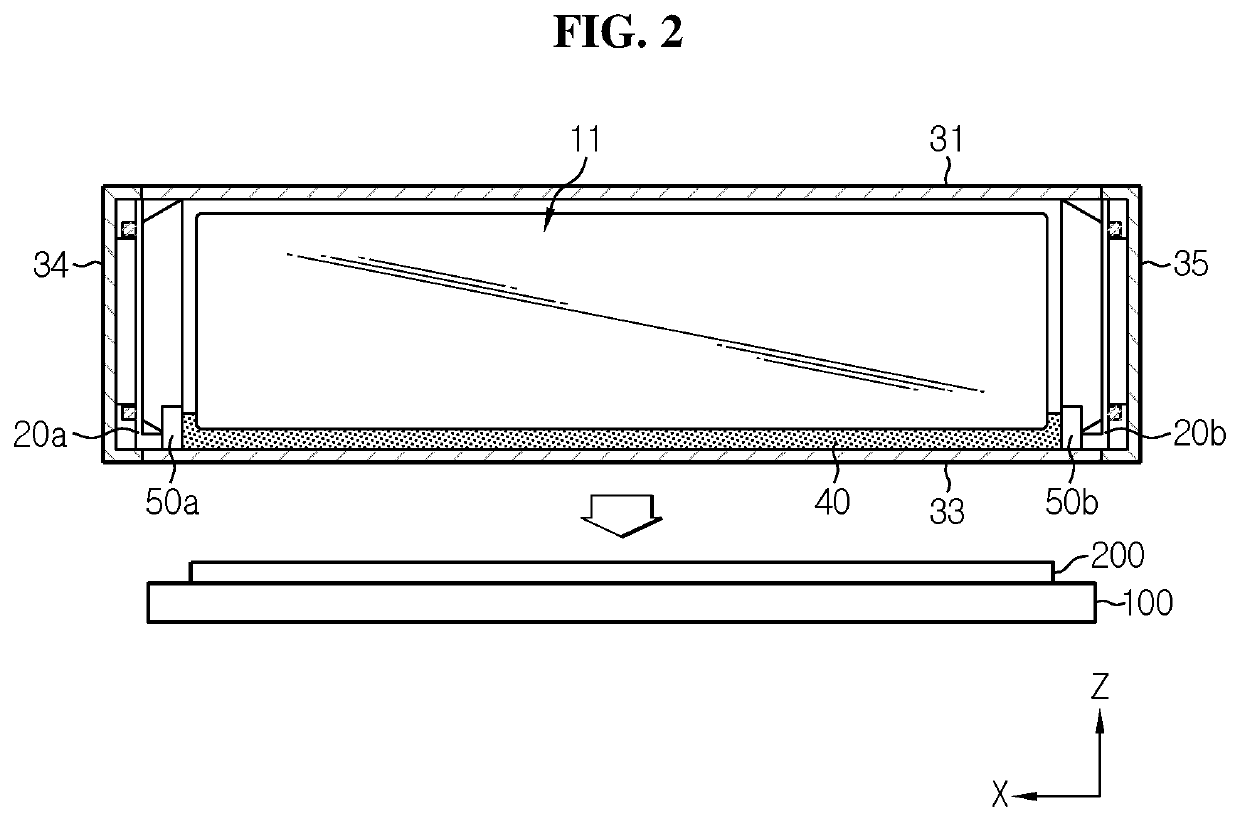

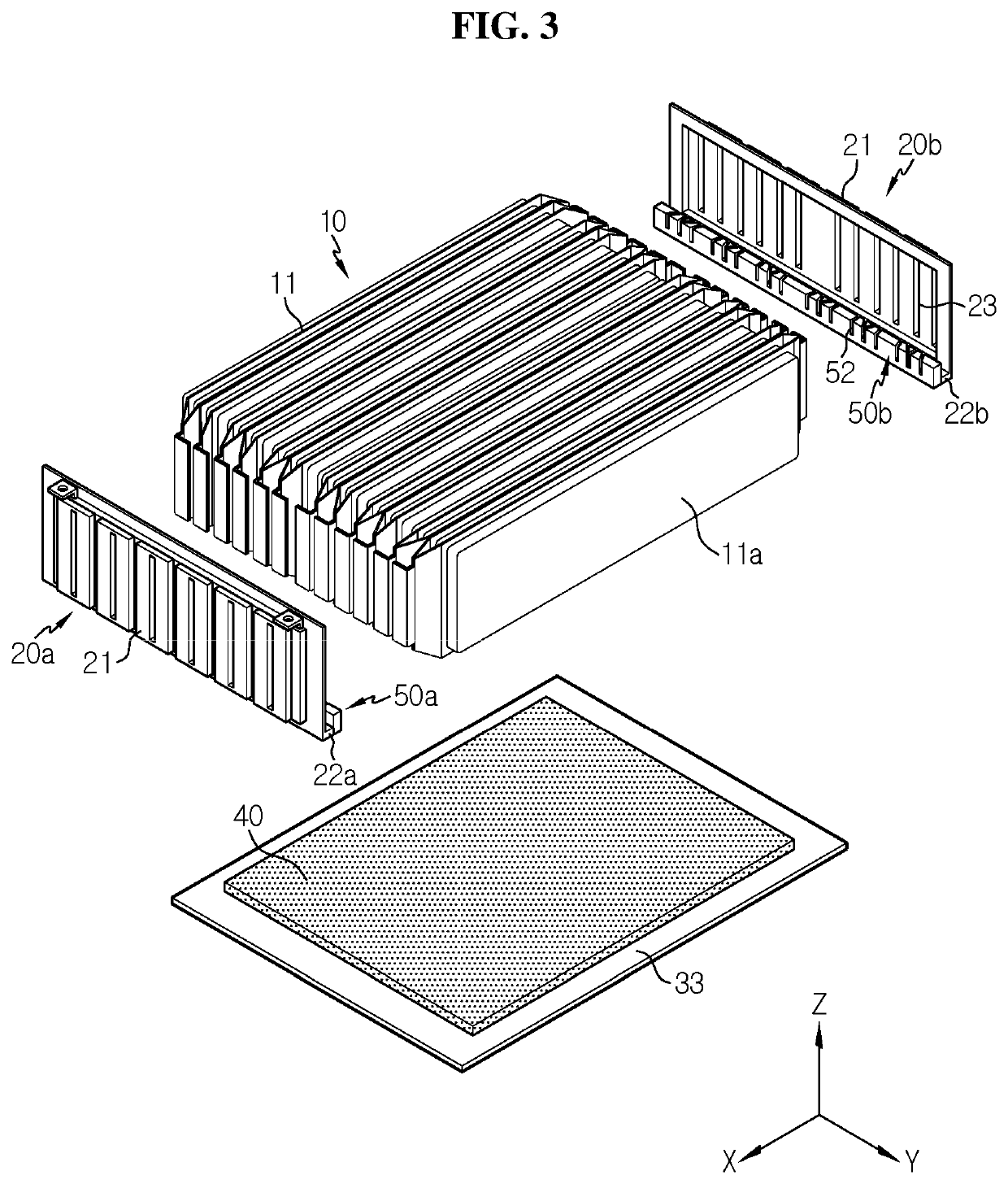

Battery Module

PendingUS20220109199A1Improve performance and lifeFix the cell stack betterSecondary cellsCell component detailsStructural engineeringMechanical engineering

A battery module includes a bottom plate to support a cell stack; a busbar frame having a lower end portion bent in an inward direction along an upper surface of the bottom plate and mounted on the front and rear sides of the cell stack; a thermally conductive resin applied to the upper surface of the bottom plate; and a fence member provided at an end of the lower end portion of the busbar frame and disposed on the upper surface of the bottom plate to prevent the leakage of the thermally conductive resin.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com