Blocks for absorption of collision energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

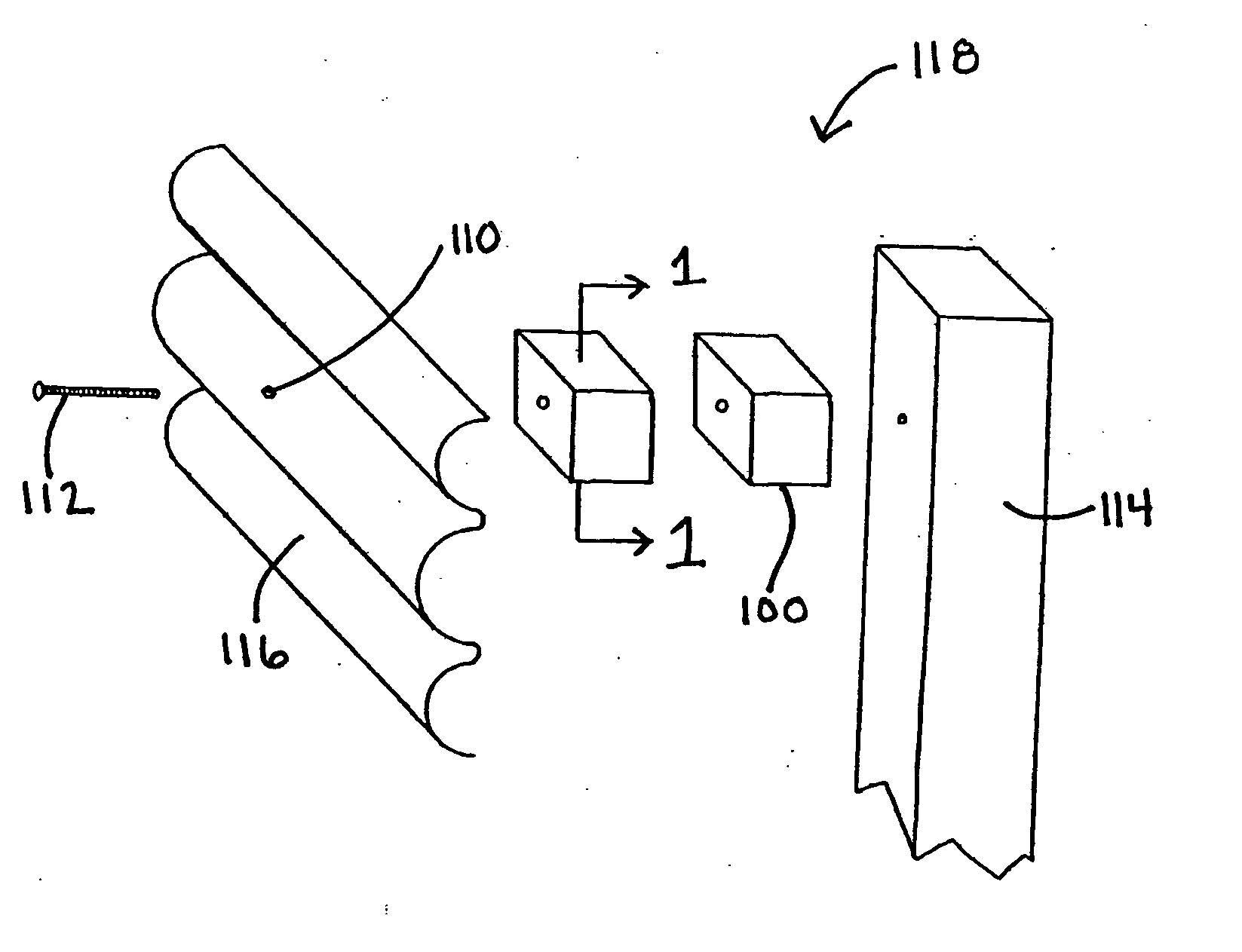

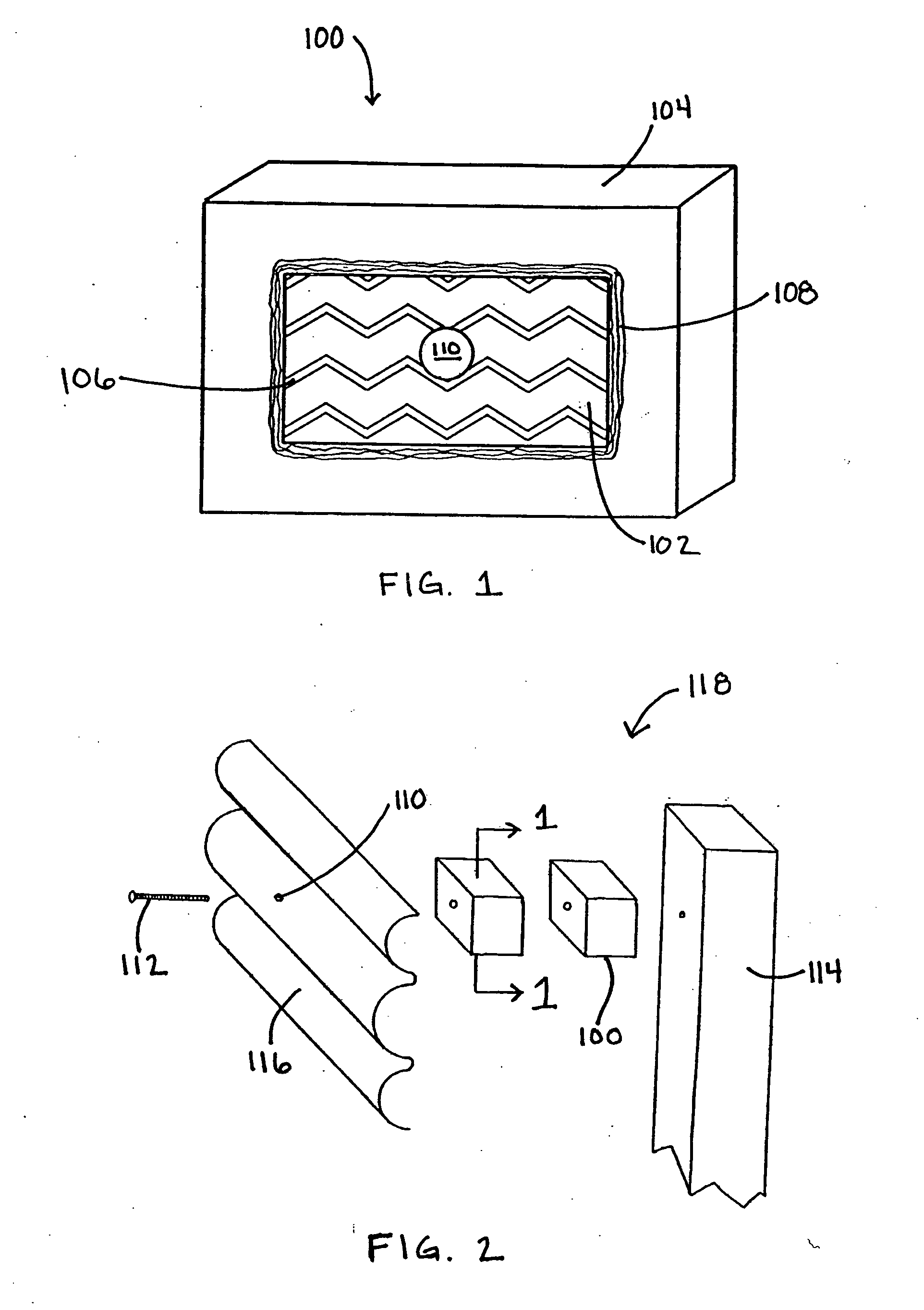

[0018]FIG. 1 shows an energy-absorbing block 100 having an elastomeric inner core 102 substantially surrounded by an outer shell 104. The core 102 is preferably made at least partially of recycled elastomeric materials, such as rubber from discarded tires. The outer shell 104 is preferably at least partially made of recycled thermoplastic materials, such as polymers from household waste, discarded computer / electronic housings, or other sources. The block 100 also preferably includes a reinforcing layer 108 of fibrous materials, e.g., individual or cabled strands, and / or woven or nonwoven fabrics. The reinforcing layer 108 may separate the inner core 102 from the outer shell 104, or it may be interspersed within the outer shell 104 when it is molded.

[0019] In a preferred version, the block 100 is made by compression molding recycled thermoplastic pellets about the core 102 to form a rigid outer shell 104. While compression molding is a preferred method for forming the outer shell 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com