Manufacturing method for electrode sheet cutting, electrode sheet using the same, and secondary battery using the same

A manufacturing method and pole piece technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve problems such as battery performance impact, improve performance and life, and prevent puncture or puncture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

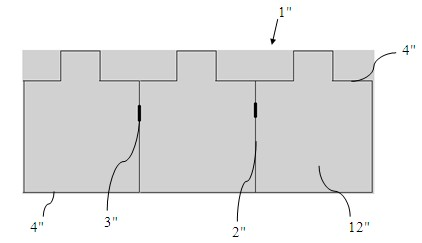

[0027] like figure 1 As shown in , the prior art pole piece cutting method is as follows: the pole piece substrate 1 "is cut, and the pole piece substrate 1 " includes a material coating area 12 ". During cutting, at least one cutter is used to start from one Start cutting at the starting position 3" of the side 2" of the material coating area 12" of the pole piece, and cut along the cutting line 4" to the start of the side 2" of the material coating area 12" of the other pole piece Position 3", cut the starting position 3" of the next pole piece material coating area 12" side 2" in turn, so, after cutting a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com