High-performance modified asphalt and manufacturing method thereof

A technology of modified asphalt and manufacturing method, which is applied in the direction of building structure, building components, building insulation materials, etc. It can solve the problems of general performance, complicated preparation process, and insufficient penetration ability, so as to improve flow performance and crushing efficiency , the effect of improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

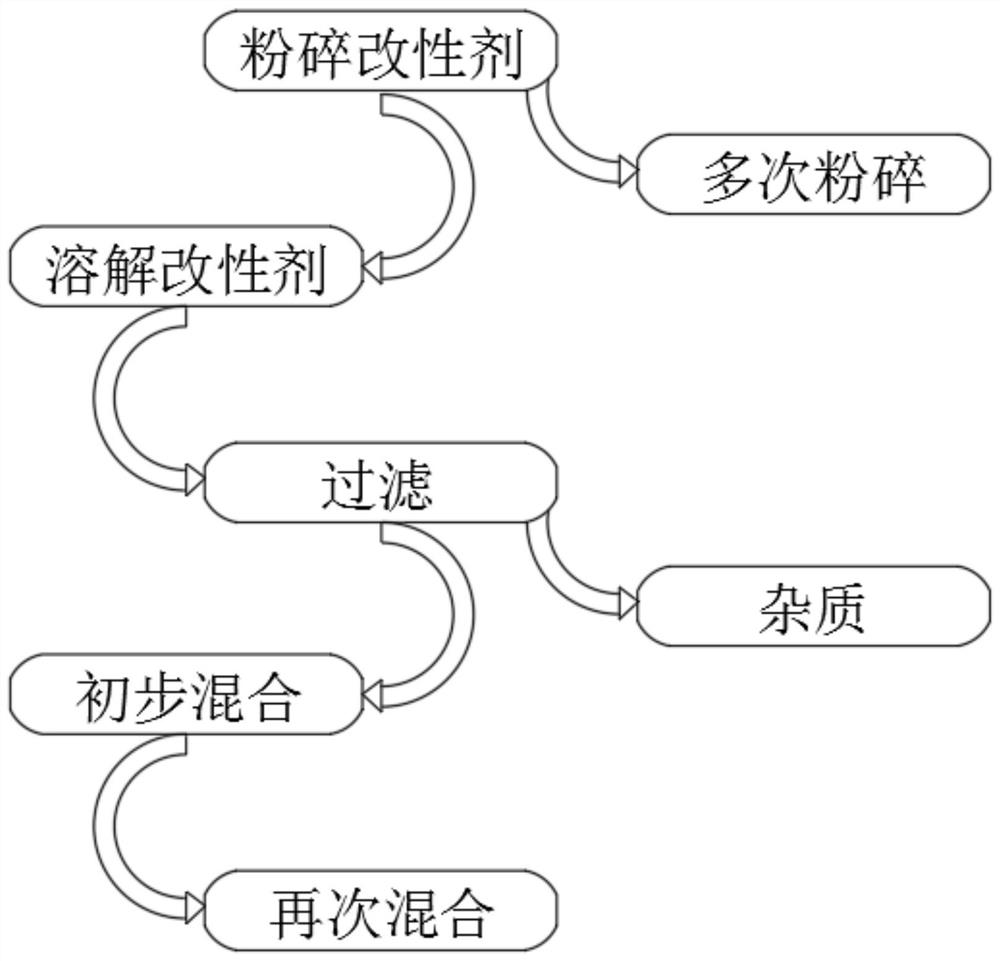

[0029] refer to figure 1 , a high-performance modified asphalt, its formula includes: 25 parts of auxiliary materials, 12 parts of modifiers, 80 parts of original asphalt, and 9 parts of solvent.

[0030] In the present invention, the original asphalt is a mixed asphalt formed by straight-run asphalt and oxidized asphalt, and its ratio is straight-run asphalt: oxidized asphalt=1:1.5, and the organic solvent is styrene, perchlorethylene, trichloroethylene, ethylene glycol Any one of ether and triethanolamine, the auxiliary materials are polyvinylpyrrolidone 4-6 block polyvinyl alcohol amide sodium compound and hydroxymethyl cellulose sodium compound, ethylene oxide-propylene oxide block copolymer polyoxyethylene ether , the formula also includes 2 parts of anti-peeling agent, 3 parts of anti-aging agent, mixed with anti-stripping agent and anti-aging agent, can improve the service performance and life of the pavement material, modifier is thermoplastic elastomer SBS, styrene-bu...

Embodiment 2

[0039] refer to figure 1 , a high-performance modified asphalt, its formula includes: 18 parts of auxiliary materials, 10 parts of modifiers, 90 parts of original asphalt, and 14 parts of solvent.

[0040] In the present invention, the original asphalt is a mixed asphalt formed by straight-run asphalt and oxidized asphalt, the ratio of which is straight-run asphalt: oxidized asphalt=1:2, and the organic solvent is styrene, perchlorethylene, trichlorethylene, ethylene glycol Any one of ether and triethanolamine, the auxiliary materials are polyvinylpyrrolidone 4-6 block polyvinyl alcohol amide sodium compound and hydroxymethyl cellulose sodium compound, ethylene oxide-propylene oxide block copolymer polyoxyethylene ether , the formula also includes 2 parts of anti-stripping agent, 4 parts of anti-aging agent, mixed with anti-stripping agent and anti-aging agent, can improve the service performance and life of the pavement material, and the modifying agent is thermoplastic elast...

Embodiment 3

[0049] refer to figure 1 , a high-performance modified asphalt, its formula includes: 25 parts of auxiliary materials, 12 parts of modifiers, 80 parts of original asphalt, and 9 parts of solvent.

[0050] In the present invention, the original asphalt is a mixed asphalt formed by straight-run asphalt and oxidized asphalt, and its ratio is straight-run asphalt: oxidized asphalt=1:1.5, and the organic solvent is styrene, perchlorethylene, trichloroethylene, ethylene glycol Any one of ether and triethanolamine, the auxiliary materials are polyvinylpyrrolidone 4-6 block polyvinyl alcohol amide sodium compound and hydroxymethyl cellulose sodium compound, ethylene oxide-propylene oxide block copolymer polyoxyethylene ether , the formula also includes 4 parts of anti-stripping agent, 5 parts of anti-aging agent, mixed with anti-stripping agent and anti-aging agent, can improve the service performance and life of the pavement material, modifier is thermoplastic elastomer SBS, styrene-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com