Patents

Literature

35results about How to "Improve viscosity and toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold mixing color asphalt mixture and preparation method

The invention discloses a cold mixing color asphalt mixture and a preparation method. The preparation method comprises the following steps: selecting aromatic hydrocarbon oil, rubber oil, petroleum resin, epoxy resin, a modifier, a plasticizer, a diluent, diatomite, a pigment and stabilizers, and mixing the materials according to the mass proportion, thus obtaining color asphalt cement; selecting an emulsifier, the stabilizers and a defoamer, and mixing the three materials with the color asphalt cement in proportion, thus obtaining emulsified color asphalt cement; and selecting an aggregate, a filler, cement, a waterborne curing agent, an expansive agent and the emulsified color asphalt cement, and mixing the materials in proportion, thus obtaining the cold mixing color asphalt mixture.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

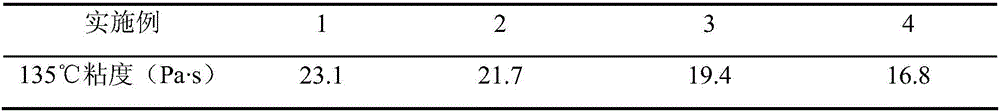

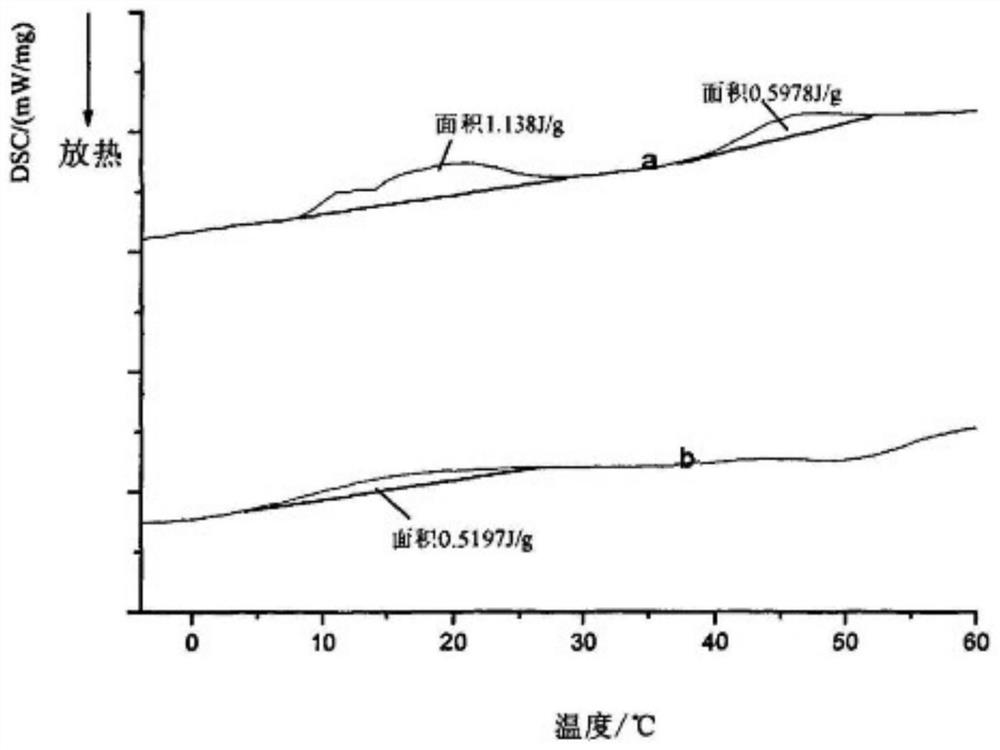

Polymer chemically-modified asphalt composition capable of being stably stored at high temperature and preparation method thereof

InactiveCN101613533AGood storage stability at high temperatureMeet usable requirementsBuilding insulationsElastomerViscous liquid

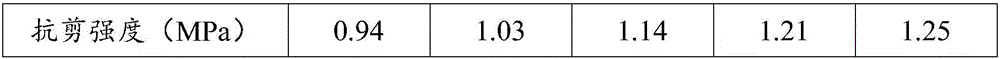

The invention relates to a high polymer chemically-modified asphalt composition and a preparation method thereof. The preparation method comprises the following steps: chemically modifying rubber, elastomer and base asphalt, and additionally matching stuffing and processing aids; premixing the materials by high polymer processing equipment to prepare the master batch of the modified asphalt; and fully dispersing the master batch into the asphalt by a high-speed shear mixer or by mechanical stirring. Or the modified asphalt material can be prepared by firstly pre-preparing a viscous liquid mixture of modified asphalt and then stirring and mixing the viscous liquid mixture of modified asphalt with the base asphalt. The modified asphalt material prepared by the invention has stable storage performance at high temperature, good performance at high temperature and low temperature, stable processing and preparation and simple and convenient method, and not only can be directly used in factory production but also can be used for road laying sites and in the construction of waterproofing materials.

Owner:NORTHWEST NORMAL UNIVERSITY

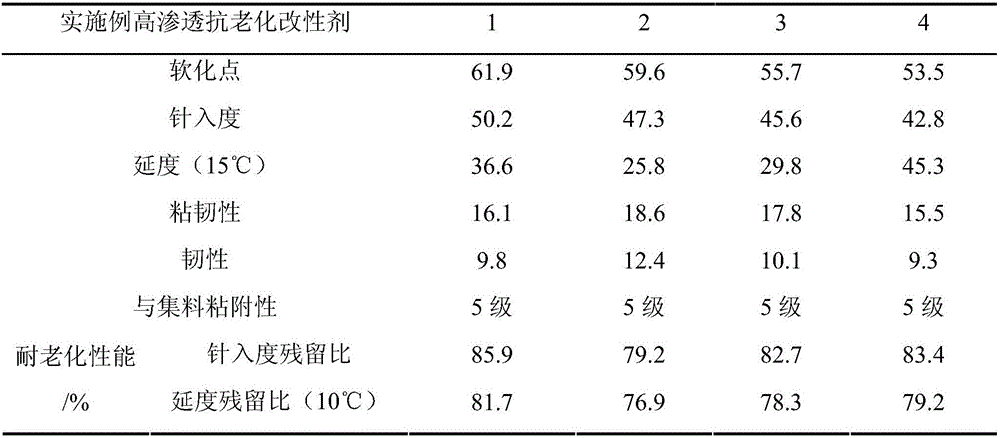

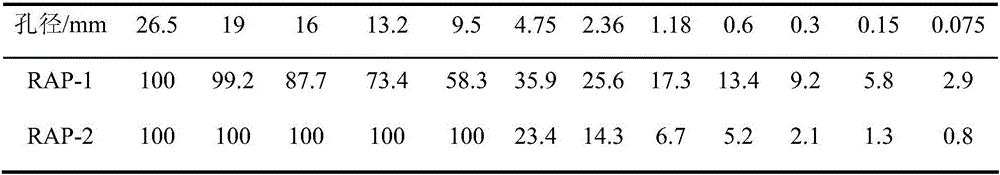

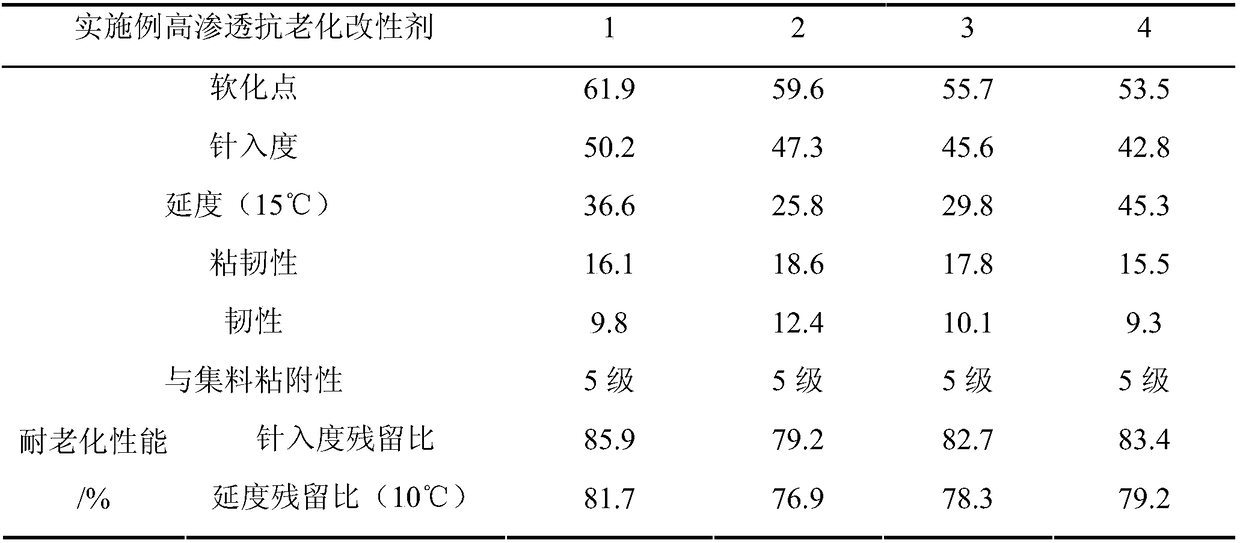

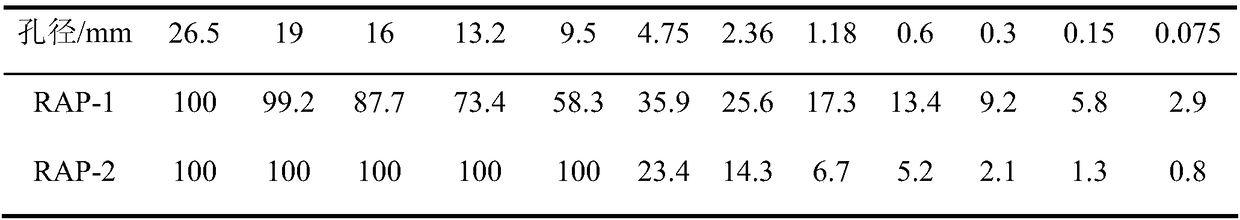

High-permeability anti-aging modifier and preparation method thereof

The invention is applied to the field of road engineering materials, and discloses a high-permeability anti-aging modifier which is prepared from the following raw materials in parts by mass: 35-45 parts of a light component, 4-6 parts of a permeation promoting component, 20-25 parts of a plastification component, 4-5 parts of a tolerance component, 5-10 parts of an anti-aging component, 4-8 parts of water and 18-25 parts of an SBS component. The permeation effect of the high-permeability anti-aging modifier on aged asphalt is improved by virtue of polarization treatment of the light component, the regeneration effect is improved, meanwhile secondary aging of regenerated alphabet in the mixing and service process, and moreover the adhesion and toughness property of alphabet is improved. The Marshall stability of an anti-aging regenerated alphabet mixed material is up to 12KN, the flexural-tensile strain of the anti-aging regenerated alphabet mixed material is up to 2568mu epsilon, the anti-aging property of the anti-aging regenerated alphabet mixed material is remarkably improved, and application of a high-volume regenerated alphabet mixed material in a road surface layer structure is possible.

Owner:WUHAN UNIV OF TECH +1

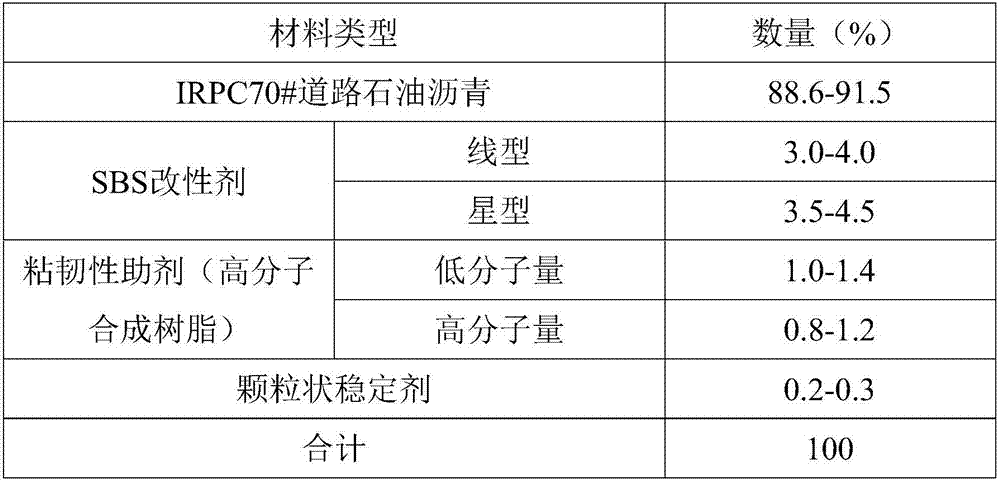

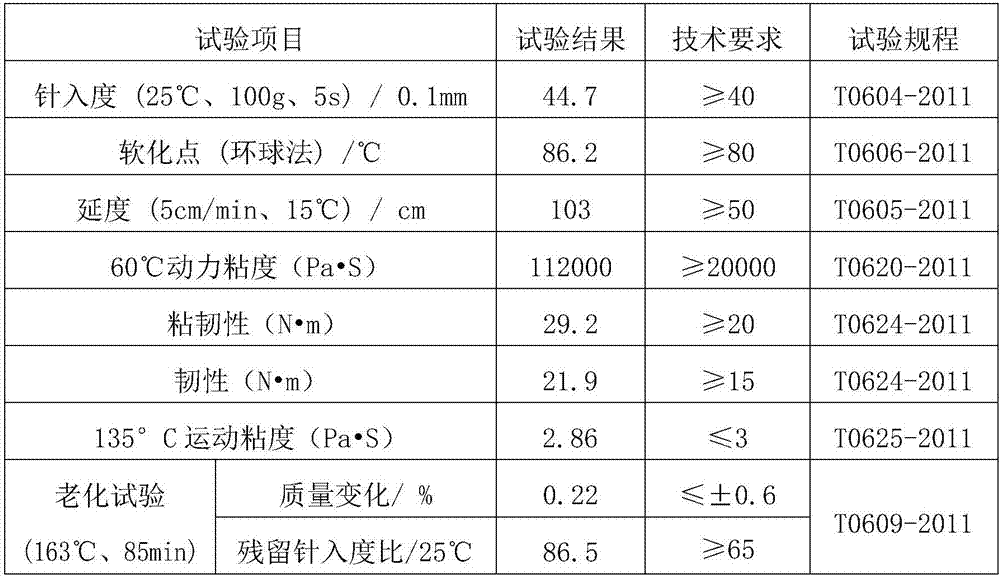

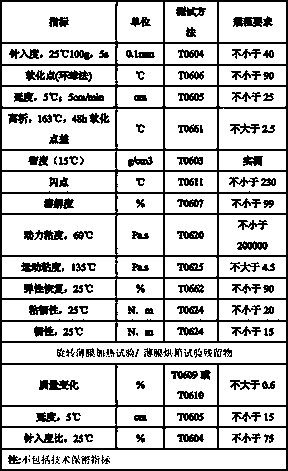

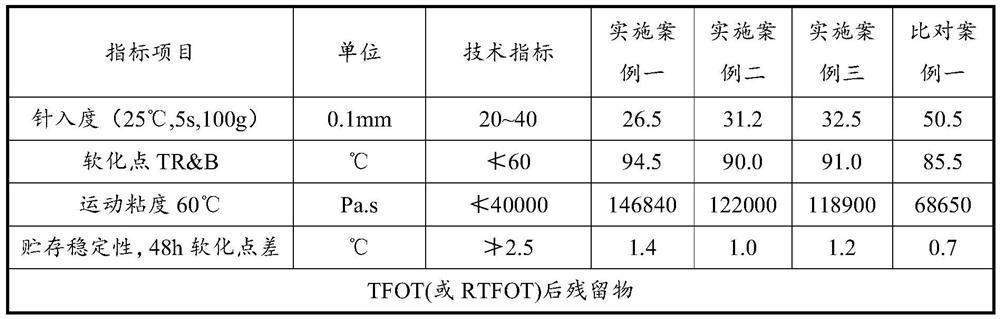

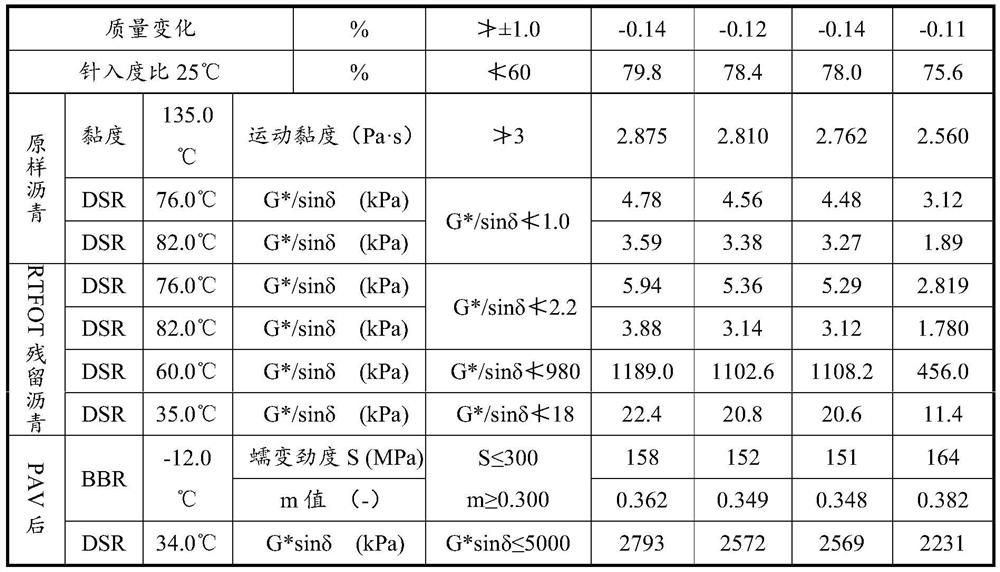

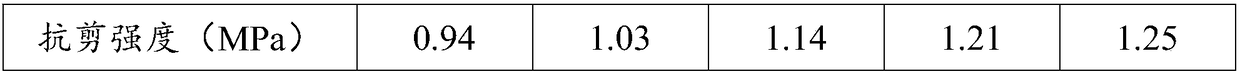

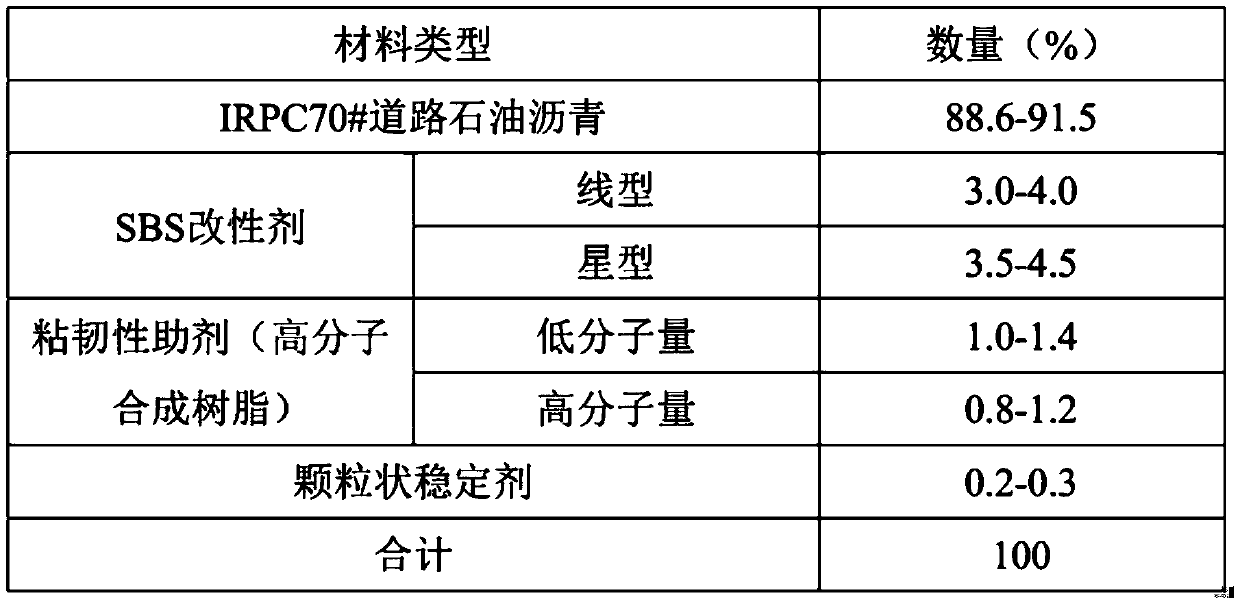

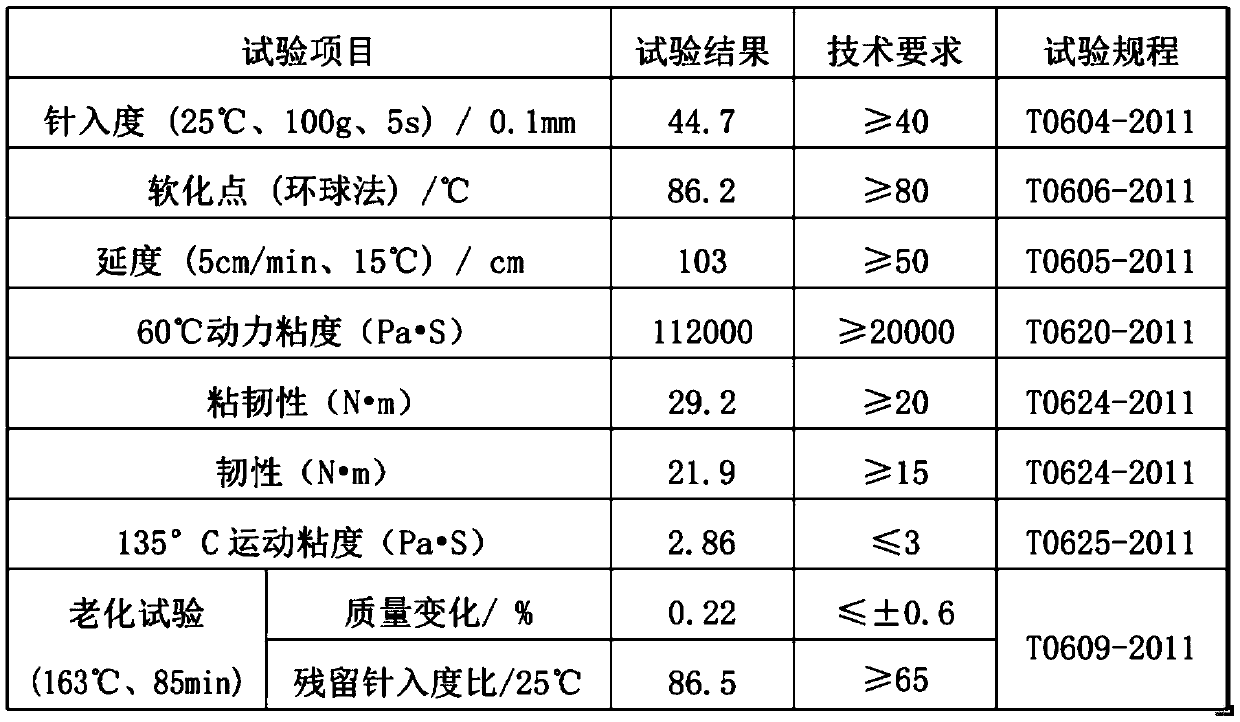

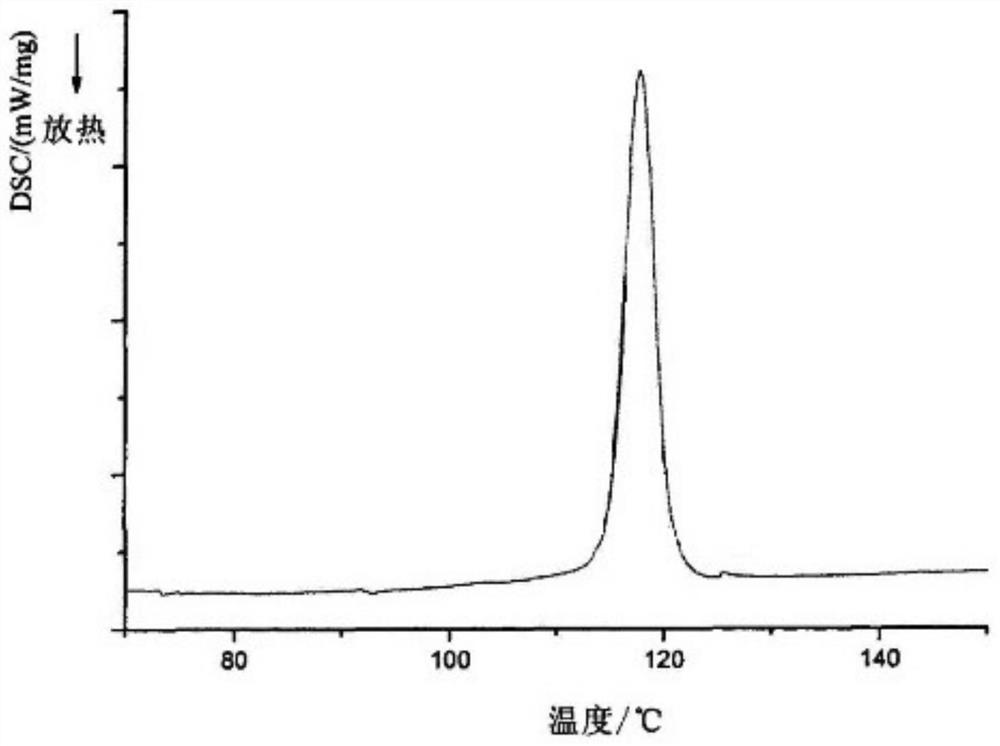

Modified high-viscosity asphalt and preparation method thereof

ActiveCN107189470AGood storage stabilityImprove toughnessBuilding insulationsPolymer sciencePolymer resin

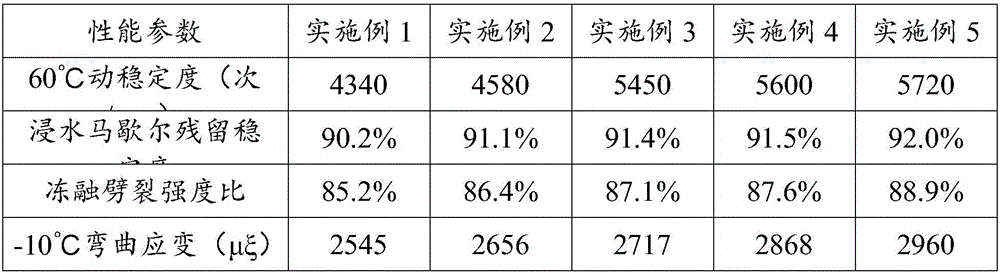

The invention provides modified high-viscosity asphalt and a preparation method thereof. The modified high-viscosity asphalt is prepared from, by mass, 88.6%-91.5% of pavement petroleum asphalt, 6.5%-8.5% of butadiene-styrene block copolymer, 1.0%-1.4% of low molecular weight polymer synthetic resin with the molecular weight of 1,480-2,200, 0.8%-1.2% of high molecular weight polymer synthetic resin with the molecular weight of 4,800-8,000 and 0.2%-0.3% of stabilizer. The modified high-viscosity asphalt has the advantage of being good in storage stability, the polymer resin which is slow in separation and is not degradable is used for compound modification, the toughness and visco-toughness of the modified pavement petroleum asphalt are good, the 60-DEG C dynamic viscosity is especially prominent, exceeds 110,000 Pa.S, and is far larger than that, being 60,000-80,000 Pa.S, of commercially available high-viscosity modified asphalt, and the anticorrosion performance is also good.

Owner:SHENZHEN MUNICIPAL ENG +2

SBR modified asphalt and preparation method thereof

ActiveCN110003672AWith low temperature performanceWith scalabilityBuilding insulationsAntioxidantPotassium

The invention discloses an SBR (styrene-butadiene rubber) modified asphalt and a preparation method thereof, and belong to the technical field of asphalt modification. Raw materials of the SBR modified asphalt comprise, by mass, 80-84.5% of matrix asphalt, 12-15% of aromatic oil and 3.5-5% of an SBR asphalt modifier, wherein raw materials of the SBR asphalt modifier comprise, by weight, 100 partsof a modified SBR emulsion (by dry rubber), 0.1-1 part of an antioxidant, 5-10 parts of an isolating agent, 3-6 parts of a dicyandiamide-formaldehyde condensate and 2-6 parts of potassium aluminum sulfate. The preparation method comprises the following steps: heating the matrix asphalt until melting, adding the aromatic oil and the SBR asphalt modifier, and shearing and swelling the obtained mixture to obtain the SBR modified asphalt. The SBR modified asphalt has good low temperature performances, ductility and bonding property, and has greatly improved viscosity, high temperature performancesand anti-aging property.

Owner:山东海方橡胶科技有限公司

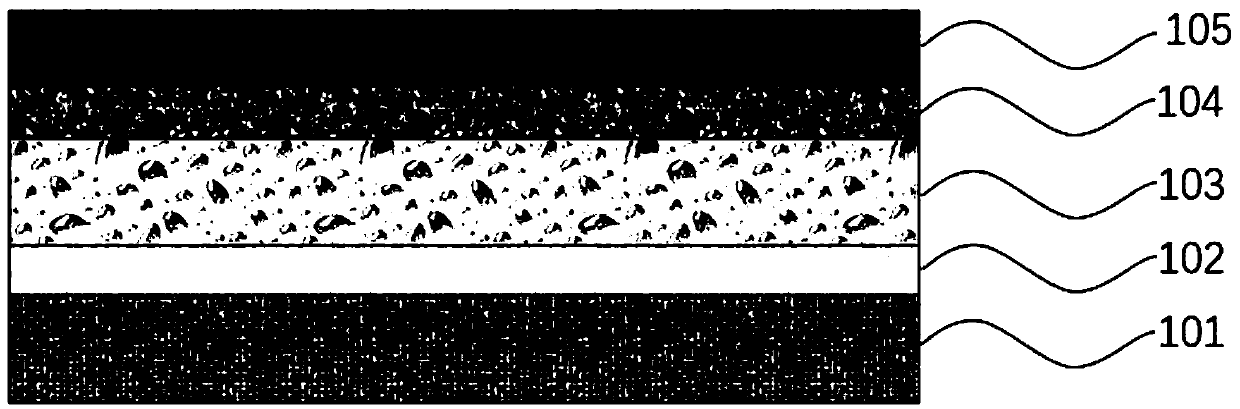

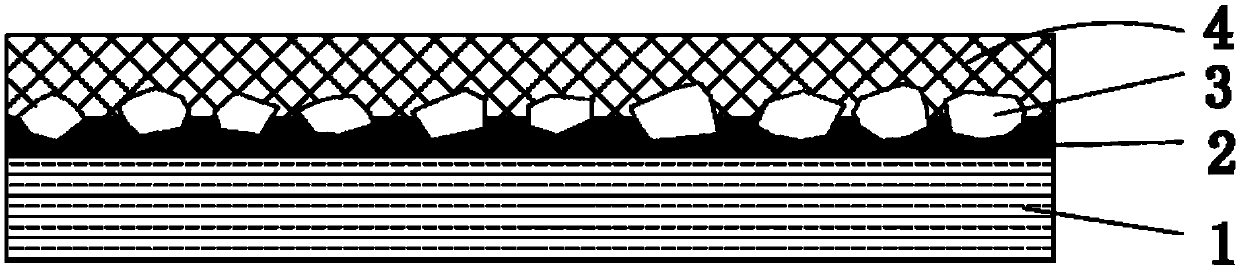

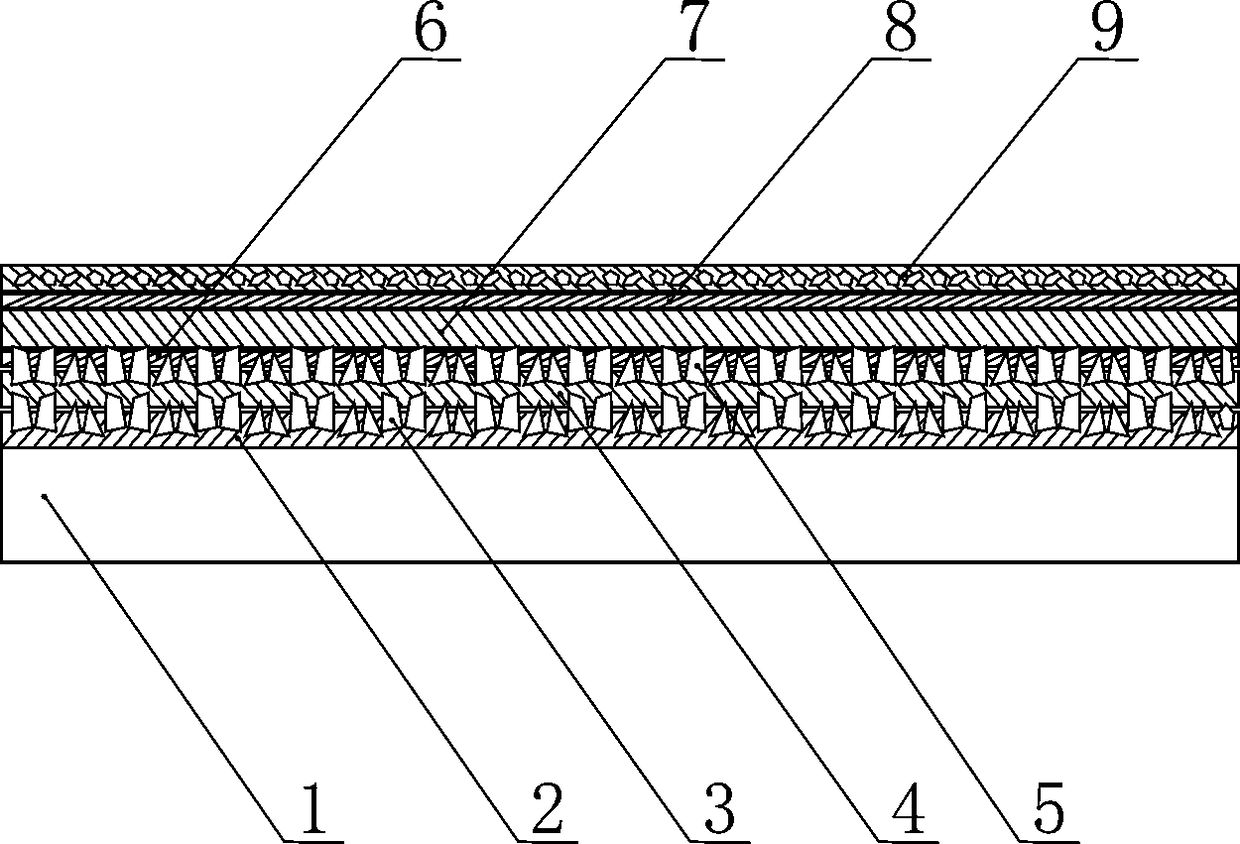

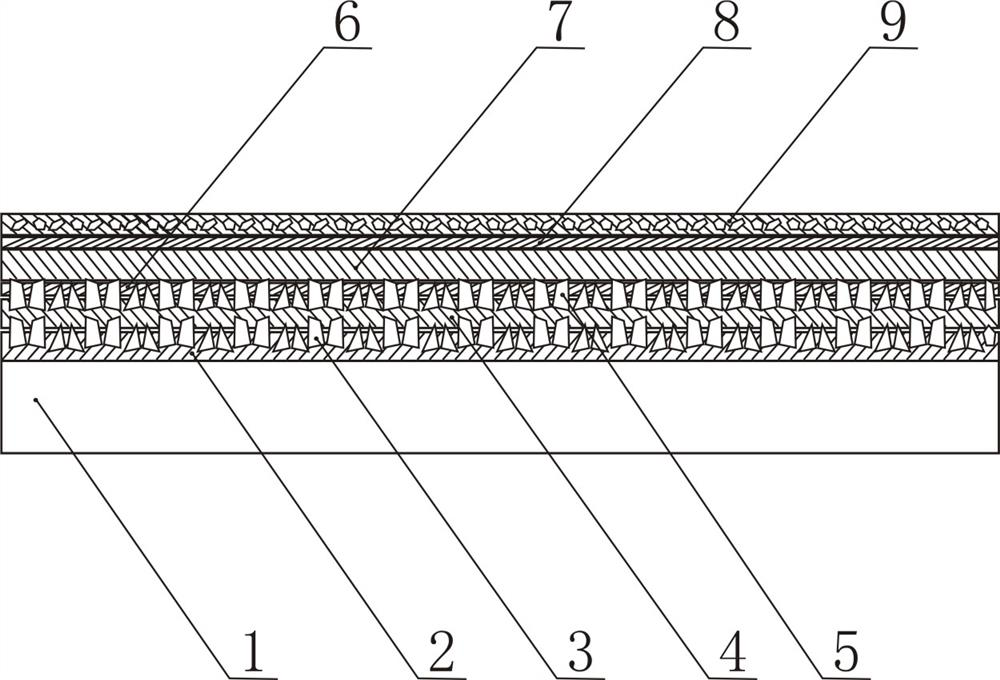

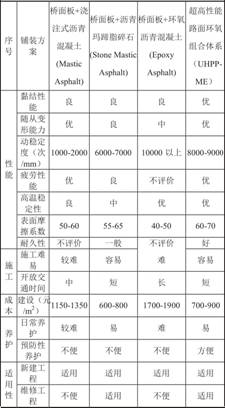

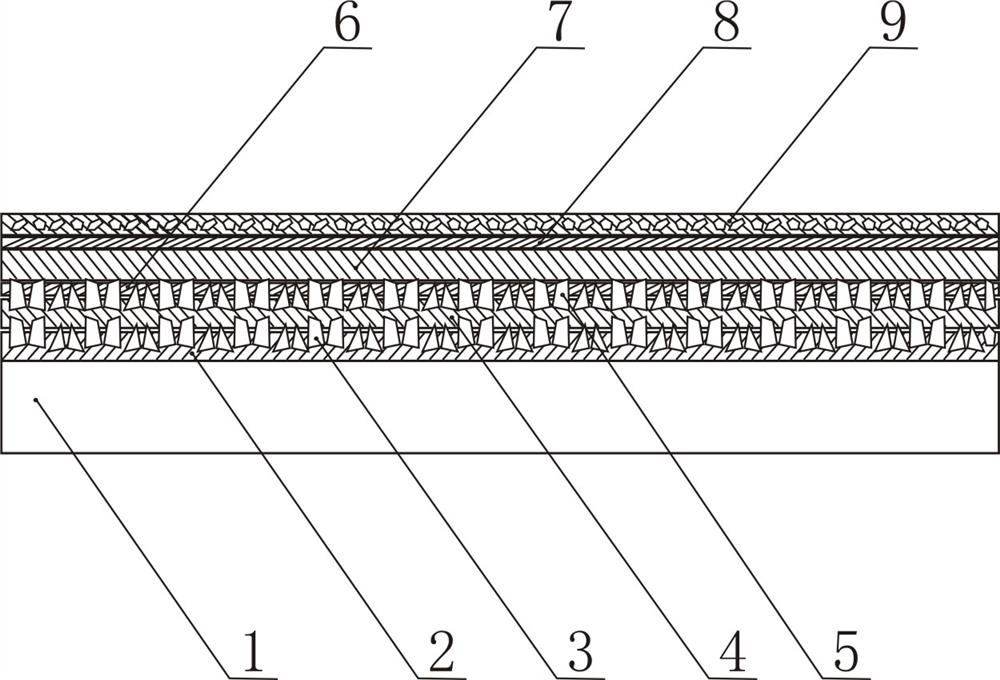

Pavement structure of steel bridge deck and construction method thereof

PendingCN109594471AClear functionalityClear securityBridge structural detailsBridge erection/assemblyEpoxyPolymer modified

The invention provides a pavement structure of a steel bridge deck and a construction method thereof. the pavement structure of the steel bridge deck comprises a first waterproof bonding layer, a modified epoxy asphalt macadam layer, a second waterproof bonding layer and an ultra-high performance structural layer which are sequentially paved on the surface of a steel plate of the steel bridge deck; the ultra-high performance structural layer is a pavement structural layer taking polymer modified asphalt as an adhesive, or comprises a pavement structural layer taking the polymer modified asphalt as the adhesive and a third waterproof bonding layer; the second waterproof bonding layer and the third waterproof bonding layer are the layers formed by at least one material of epoxy emulsified asphalt, polymer modified asphalt and polymer modified emulsified asphalt. The pavvement structure of the steel bridge deck provided by the invention has better resistance and stability.

Owner:广州珠江黄埔大桥建设有限公司 +2

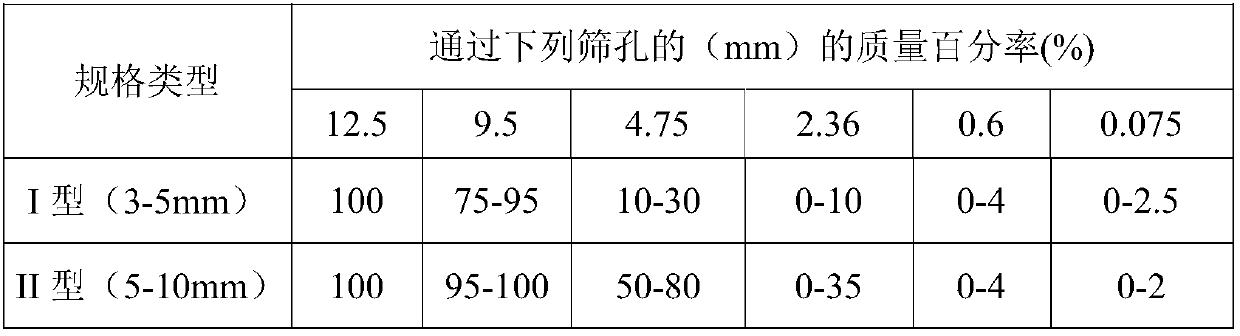

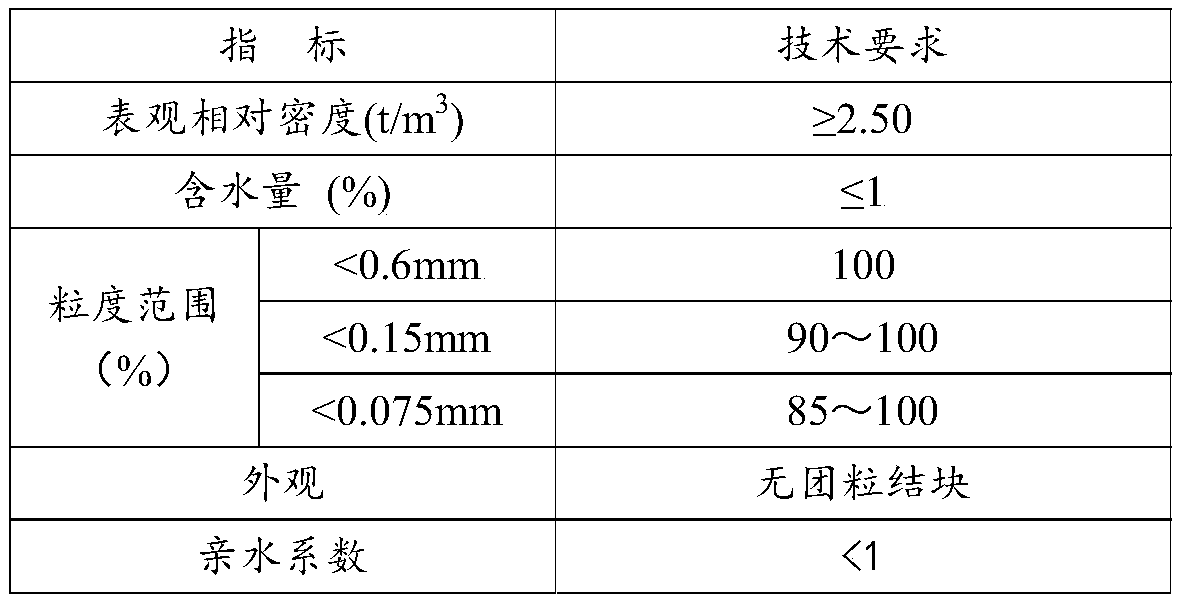

High-solid-content emulsified asphalt for stress absorbing layer, preparation method and construction method thereof

InactiveCN109535751AFix reflection cracksReduce construction proceduresIn situ pavingsRoads maintainenceChipsealColloid

The invention discloses a high-solid-content emulsified asphalt for a stress absorbing layer, a preparation method and a construction method thereof. The high-solid-content emulsified asphalt is prepared from ordinary asphalt, asphalt additive, emulgator, modifier, water and pH regulator; the solid content is 67-75%; the raw materials by weight percent are as follows: 50-70% of ordinary asphalt, 1-12% of asphalt additive, 0.2-3.0% of emulgator, 2.0-10.0% of modifier and the balance of water and pH regulator. The preparation method comprises the following steps: heating ordinary asphalt; addingasphalt additive into ordinary asphalt at a ratio and uniformly stirring, thereby acquiring a mixture of ordinary asphalt and asphalt additive; preparing emulgator into an aqueous solution, and thenadding modifier, thereby acquiring an emulgator liquid soup; using pH regulator for regulating pH value of the emulgator liquid soup, and then heating; successively putting the emulgator liquid soup and the mixture of ordinary asphalt and asphalt additive into a colloid mill, and then milling, thereby acquiring an end product of emulsified asphalt. According to the invention, a synchronous macadamseal coat vehicle is adopted for spraying / spreading emulsified asphalt and macadam; a 'prime coat and stress absorbing layer' effect can be achieved through once construction; construction process isreduced; construction cost is lowered.

Owner:山东高速建材集团有限公司

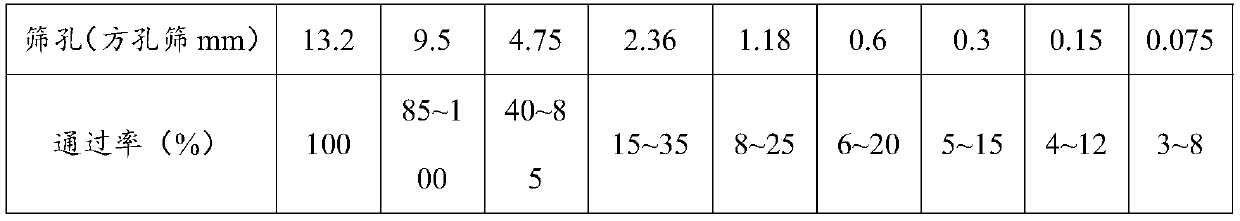

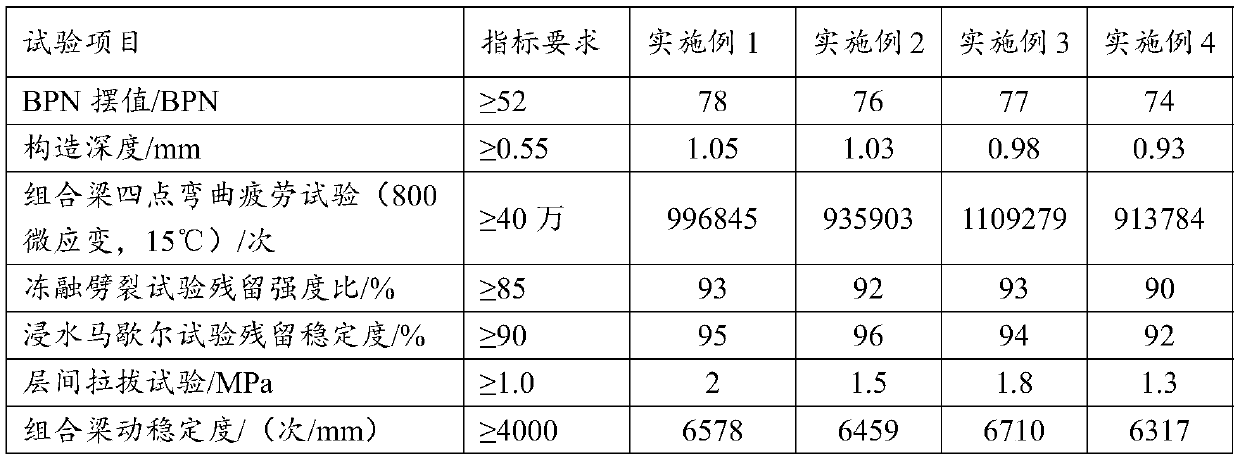

High-toughness, durable and anti-skid steel bridge deck pavement structure and construction method thereof

InactiveCN110952447AIncrease stiffnessImprove stabilityBridge structural detailsBridge erection/assemblyEpoxyBridge deck

The invention discloses a high-toughness, durable and antiskid steel bridge deck pavement structure and a construction method thereof. The steel bridge deck pavement structure comprises a steel bridgedeck steel plate; a bonding bottom layer, a buffer layer, an adhesion layer and a wearing layer are sequentially laid on the surface of the steel bridge deck steel plate from bottom to top; the buffer layer and the wearing layer are both made of high-toughness modified asphalt concrete composed of aggregate, filler and asphalt cement, the thickness of the buffer layer is 1-3 cm, and the thicknessof the wearing layer is 2-3 cm. The bridge deck pavement structure has good high-temperature rut resistance, fatigue durability, skid resistance, bonding strength and deformation compliance, comparedwith epoxy asphalt concrete, the engineering cost is greatly reduced, the construction process is simple, and later maintenance is convenient.

Owner:广州市市维新材料科技有限公司

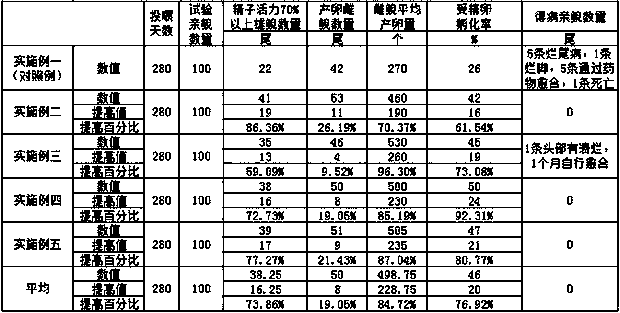

Mixed feed for parent salamander breeding

The invention relates to a mixed feed for parent salamander breeding. The mixed feed includes the following components in parts by weight: 65 parts of fish meat, 5 parts of A starch, 9 to 17 parts of astragalus membranaceus, 3 to 6 parts of bighead atractylodes rhizome, 3 to 5 parts of radices sileris, 5 to 9 parts of semen cuscutae, 4 to 6 parts of herba epimedii, 4 to 8 parts of prepared rehmannia roots, 0.3 to 0.6 part of calcium hydrophosphate, 2 to 4 parts of algae powder, 1 to 2 parts of unsaturated fatty acid, 1 to 2 parts of bacillus subtilis, 0.3 to 0.6 part of L-lysine monohydrochloride, 0.05 to 0.1 part of zinc citrate, 0.05 to 0.1 part of organic iron, 0.1 part of vitamins, and 0.2 part of trace elements; the fish meat is the meat of one or more kinds of the following fishes: black carps, grass carps, chubs, bighead carps, crucians and wild fishes; the vitamins include VA, VB1, VB2, VB6, VB12, VC, VD and VE; the trace elements include 1 to 3 kinds of the following elements: zinc, iron and calcium. The mixed feed for parent salamander breeding can meet the nutritional requirements of parent salamanders, improve the immunity of the parent salamanders as well as the gonad maturity of the parent salamanders in breeding seasons, and strengthen the sperm motility of male salamanders.

Owner:JIANGSU CHAOYANG ECOLOGICAL AGRI TECH

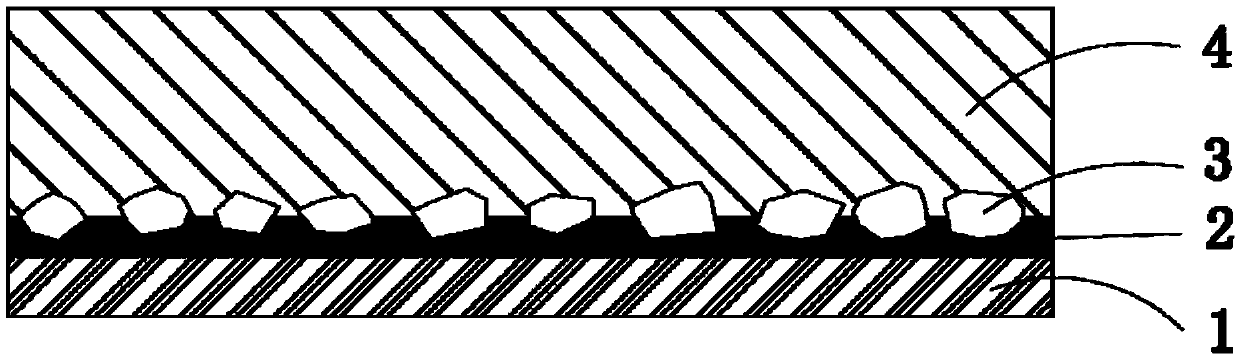

Combined-type steel bridge deck laying method

ActiveCN108797307AStrong adhesionStrong resistance to deformationBridge structural detailsSteel platesAsphalt

The invention discloses a combined-type steel bridge deck laying method. The combined-type steel bridge deck laying method comprises the following steps that A, a modified epoxy resin and gravel combined-type connection layer is laid, specifically, the surface of a steel plate of a steel bridge deck is subjected to sandblasting shot blasting, modified epoxy resin is laid and smeared on the surfaceof the steel plate to form a first modified epoxy resin layer, gravel is scattered on the surface of the first modified epoxy resin layer to form a first gravel layer, modified epoxy resin is evenlylaid and smeared on the surface of the first gravel layer according to the set dosage to form a second modified epoxy resin layer, and then gravel is scattered to form a second gravel layer; and B, ultra-high performance pavement is laid, specifically, active epoxy asphalt or high-viscosity modified emulsified asphalt is smeared on the surface of the connection layer to form a first waterproof bonding layer, then a stone mixture is laid and smeared to form a waterproof-type structure layer, and finally integrated spreading of a second waterproof bonding layer and a drainage-type abrasion layeris conducted through special equipment. According to the combined-type steel bridge deck laying method, sliding and delaminating between the structural layers are prevented, and the stability and durability of the structure are guaranteed.

Owner:广州珠江黄埔大桥建设有限公司 +2

Styrene-butadiene rubber (SBR) butadiene-styrene latex for modified emulsified asphalt and preparation method of SBR butadiene-styrene latex

ActiveCN110016234AImprove high temperature resistanceImprove anti-aging propertiesBuilding insulationsCross-linkEmulsion

The invention discloses styrene-butadiene rubber (SBR) butadiene-styrene latex for modified emulsified asphalt and a preparation method of the SBR butadiene-styrene latex, and belongs to the technicalfield of asphalt modification. The SBR butadiene-styrene latex is characterized by consisting of the following raw materials in parts by weight: 100 parts of a cross-linked grafted styrene-butadienerubber emulsion with a solid content of 40-60%, 2-6 parts of a nonionic emulsifier, 3-6 parts of a cationic emulsifier and 0.5-1.5 parts of a system pH regulator. The preparation steps are as the follows: concentrating the cross-linked grafted styrene-butadiene rubber emulsion until the latex concentration reaches 40-60%; adding the nonionic emulsifier, and carrying out stirring for 10-15 minutes;adding the cationic emulsifier according to the proportion of the raw materials, and carrying out stirring for 10-15 minutes; and adding the system pH regulator according to the proportion of the rawmaterials to adjust the pH value to be 2-5. The SBR butadiene styrene latex disclosed by the invention is convenient to use, has high stability after being mixed with emulsified asphalt, and can obviously improve high temperature resistance, viscosity toughness, toughness and anti-aging performance of the asphalt.

Owner:山东海方橡胶科技有限公司

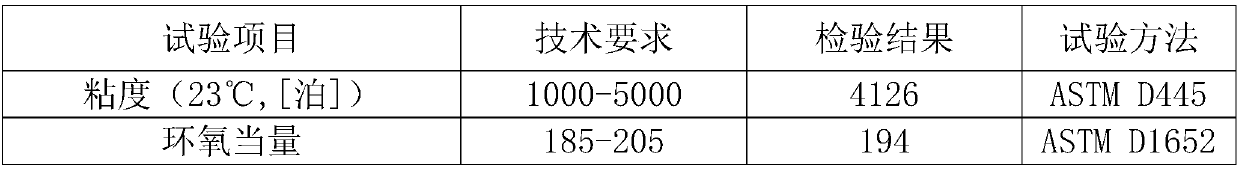

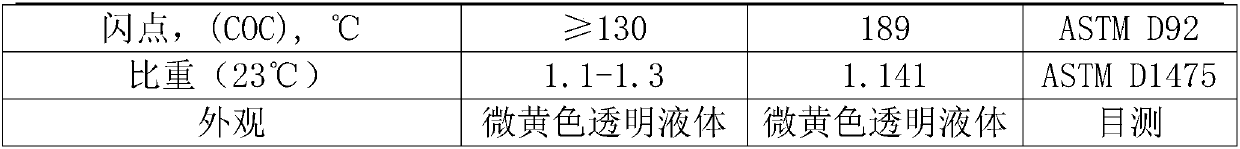

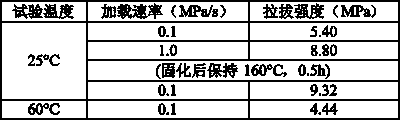

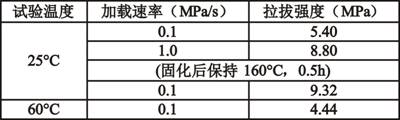

Aqueous emulsion-based resin modified crack-pouring material and preparation method thereof

ActiveCN106047283AImprove viscosity and toughnessImprove toughnessNon-macromolecular adhesive additivesOil/fat/wax adhesivesEpoxyRoad surface

The invention discloses an aqueous emulsion-based resin modified crack-pouring material composed of two groups, wherein the first-group material components comprise a substrate crack-pouring material, water, an emulsifier, a stabilizer B and a defoaming agent; the substrate crack-pouring material comprises aromatic hydrocarbon oil, rubber oil, a modifier, a tackifier, a toughening agent, a stabilizing agent and a curing agent, wherein the mass ratio of the aromatic hydrocarbon oil to the rubber oil to the modifier to the tackifier to the toughening agent to the stabilizing agent A to the curing agent is 100:(20-30):(2-8):(5-10):(1-5):(0.1-0.5):(10-20), and the mass ratio of the substrate crack-pouring material to the water to the emulsifier to the stabilizer B to the defoaming agent is 100:(60-80):(0.5-1.0):(0.5-1.0):(0.5-1.0). The second-group material components comprise epoxy resin, a plasticizer, a diluent and an interfacial modifier, wherein the mass ratio of the epoxy resin to the plasticizer to the diluent to the interfacial modifier is 100:(5-10):(10-15):(0.5-1.0). During crack pouring of asphalt pavements and treatment of cement concrete broken slabs, the aqueous emulsion-based resin modified crack-pouring material can be effectively poured into crack depths, also has the properties of flexibility, shrinkage resistance, high adhesion and the like, and can significantly treat the damage.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

High-modulus modified asphalt and production method thereof

InactiveCN112759939AImprove toughnessImproves rutting resistanceBuilding insulationsComponents of crude oilButadiene-styrene rubber

The invention discloses high-modulus modified asphalt and a production method thereof. The high-modulus modified asphalt comprises the following components in parts by weight: 70-80 parts of mixed road petroleum asphalt, 15-20 parts of anti-rutting master batch, 4-5 parts of SBS (Styrene Butadiene Styrene), 1-2 parts of polyethylene wax and 0.1-0.2 part of a stabilizer, wherein the mixed road petroleum asphalt is straight-run asphalt of which the needle penetration at 25 DEG C is 60-100 0.1 mm and the ductility at 10 DEG C is greater than 100cm; the asphalt mixture is formed by mixing two kinds of asphalt according to the mixing weight ratio of 2: (1-2). Two kinds of road petroleum asphalt are properly matched and mixed, then proper anti-rutting master batches, SBS and polyethylene wax are selected as auxiliary materials, and sulfur flakes are used as stabilizing agents, so that the prepared high-modulus modified asphalt has good high-temperature stability, viscosity and toughness, toughness and anti-rutting performance; the low-temperature performance index is also relatively good, and the characteristics of fatigue resistance, good aging resistance, high storage stability, low cost and simple preparation process are achieved.

Owner:亿虎控股有限公司

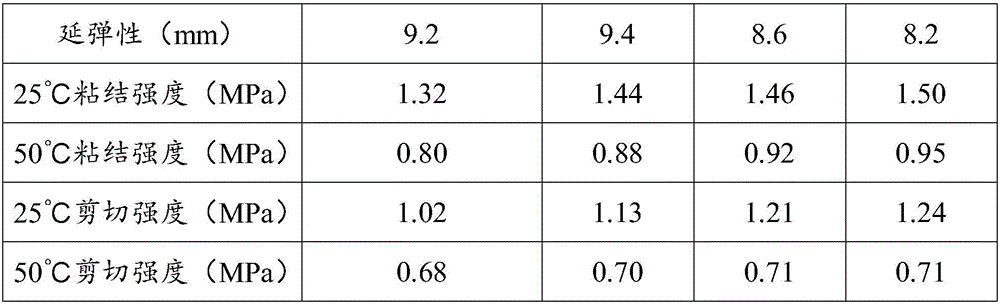

A kind of cold-mix colored asphalt mixture and preparation method thereof

The invention discloses a cold mixing color asphalt mixture and a preparation method. The preparation method comprises the following steps: selecting aromatic hydrocarbon oil, rubber oil, petroleum resin, epoxy resin, a modifier, a plasticizer, a diluent, diatomite, a pigment and stabilizers, and mixing the materials according to the mass proportion, thus obtaining color asphalt cement; selecting an emulsifier, the stabilizers and a defoamer, and mixing the three materials with the color asphalt cement in proportion, thus obtaining emulsified color asphalt cement; and selecting an aggregate, a filler, cement, a waterborne curing agent, an expansive agent and the emulsified color asphalt cement, and mixing the materials in proportion, thus obtaining the cold mixing color asphalt mixture.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

A kind of modified high-viscosity asphalt and preparation method thereof

ActiveCN107189470BGood storage stabilityImprove toughnessBuilding insulationsPolymer sciencePolymer resin

The invention provides modified high-viscosity asphalt and a preparation method thereof. The modified high-viscosity asphalt is prepared from, by mass, 88.6%-91.5% of pavement petroleum asphalt, 6.5%-8.5% of butadiene-styrene block copolymer, 1.0%-1.4% of low molecular weight polymer synthetic resin with the molecular weight of 1,480-2,200, 0.8%-1.2% of high molecular weight polymer synthetic resin with the molecular weight of 4,800-8,000 and 0.2%-0.3% of stabilizer. The modified high-viscosity asphalt has the advantage of being good in storage stability, the polymer resin which is slow in separation and is not degradable is used for compound modification, the toughness and visco-toughness of the modified pavement petroleum asphalt are good, the 60-DEG C dynamic viscosity is especially prominent, exceeds 110,000 Pa.S, and is far larger than that, being 60,000-80,000 Pa.S, of commercially available high-viscosity modified asphalt, and the anticorrosion performance is also good.

Owner:SHENZHEN MUNICIPAL ENG +2

High-performance rubber asphalt for asphalt pavement and preparation method thereof

The invention relates to the technical field of petrochemical engineering, in particular to high-performance rubber asphalt for an asphalt pavement and a preparation method thereof, and the high-performance rubber asphalt comprises the following raw material components: a low-wax asphalt matrix, SBS, a polyolefin modifier, waste rubber powder, diatomite and a sulfur modifier. Compared with the prior art, various modifiers are added into an asphalt matrix with low wax content, so that the comprehensive performance of the asphalt is greatly improved, the high-temperature storage stability, the high and low temperature performance, the aging performance, the viscoelasticity and the viscosity and toughness are obviously improved, and the use requirements of alpine regions or high-temperature regions are met.

Owner:河南金欧特实业集团股份有限公司

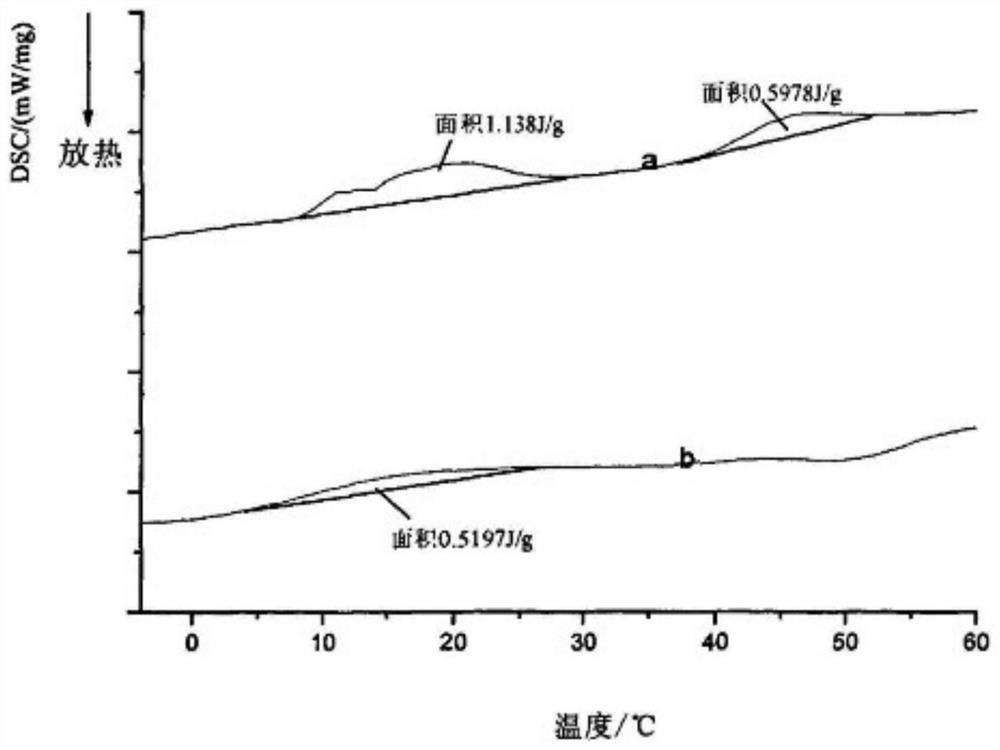

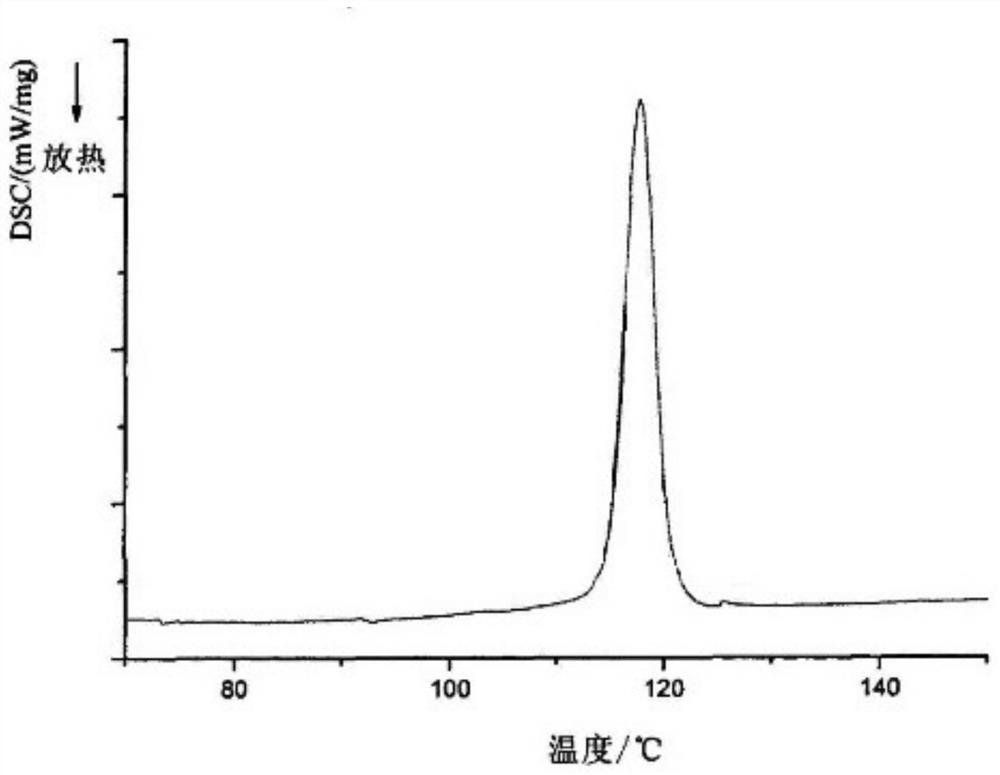

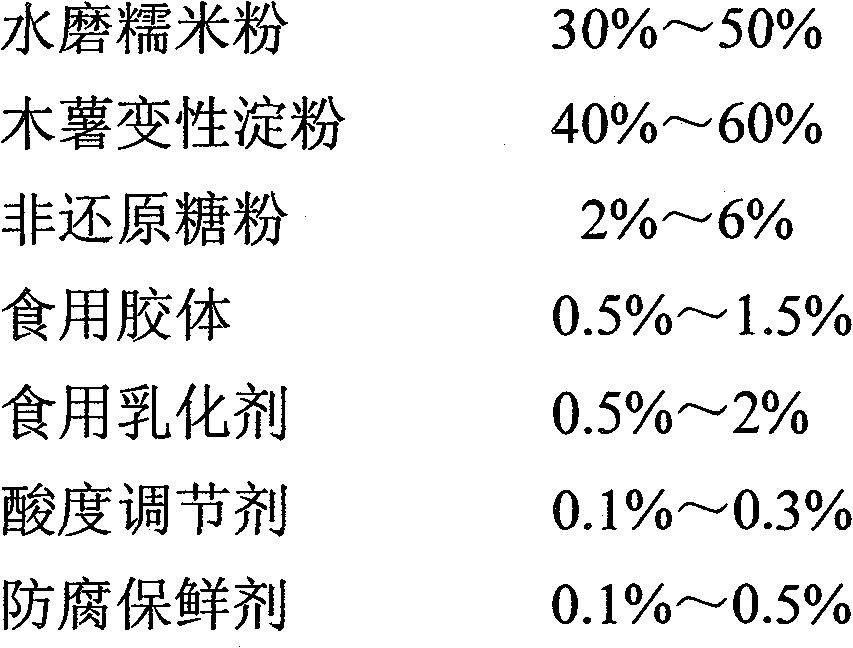

Mochi prepared mix with long guarantee period, mochi and preparation method of mochi prepared mix

ActiveCN101785543BImprove viscosity and toughnessChange the stickinessFood preparationPreservativeColloid

The invention discloses a mochi prepared mix with long guarantee period, a mochi and a preparation method of the mochi prepared mix. The mochi prepared mix is composed of the following ingredients by mass percent: 30%-50% of water-milled glutinous rice powder, 40%-60% of modified tapioca starch, 2%-6% of non-reduced sugar powder, 0.5%-1.5% of edible colloid, 0.5%-2% of edible emulsifier, 0.1%-0.3% of acidity regulator and 0.1%-0.5% of antiseptic preservative. The mochi has good taste. The mochi prepared mix according to the invention is not only good, smooth and elastic in taste, but also overcomes the defect of short guarantee period of traditional mochi; with strong starch aging-delaying performance and antiseptic fresh-keeping effect, the mochi prepared mix can be stored for 6 months at normal temperature (namely 25 DEG C) or for 12 months under refrigerating conditions, and can serve as a snack which is commercially available for a long time in order to meet the demands of market circulation.

Owner:广州合诚实业有限公司

Ceramic coating having high toughness

InactiveCN109280455AToughnessImprove viscosity and toughnessConjugated diene hydrocarbon coatingsChloropene polymer coatingsEpoxyCeramic coating

The invention provides a ceramic coating having high toughness and relates to the technical field of ceramic coating. The ceramic coating comprises, by weight, 13-28 parts of pure acrylic elastic emulsion, 20-28 parts of epoxy resin, 15-27 parts of polyethylene wax micropowder, 9-12 parts of high color carbon black, 17-23 parts of sodium silicate, 2-8 parts of an anti-aging agent, 5-12 parts of succinic anhydride, 14-23 parts of polyacrylic acid, 2-6 parts of phenolic resin, 18-26 parts of polytrifluorochloroethylene, 14-25 parts of powdery ethylene-propylene-diene monomer, 18-25 parts of polyphenylene sulfide, 10-16 parts of chloroprene rubber, 5-10 parts of butadiene rubber, 4-11 parts of polyether-ether-ketone, 2-7 parts of polyethersulfone resin and 3-8 parts of a flattening agent. Theceramic coating is improved in toughness and is not liable to cause separation and breaking between the components.

Owner:佛山市高明区生产力促进中心

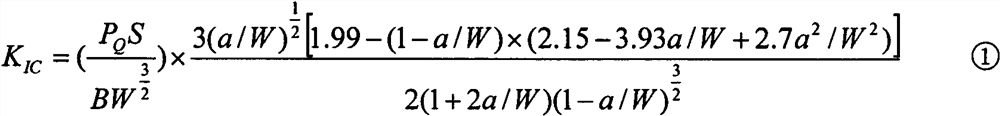

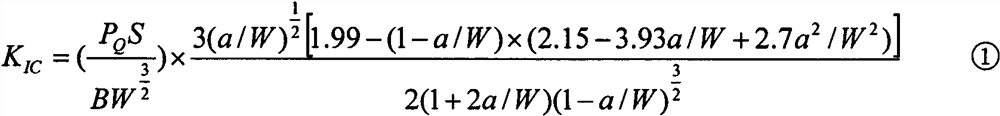

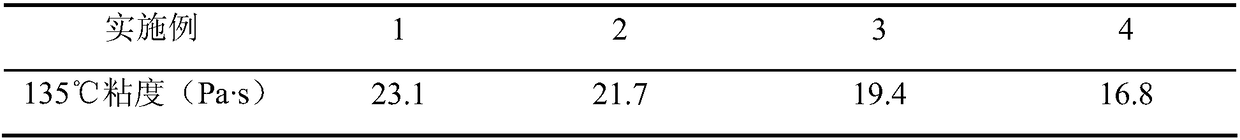

Method for researching viscosity and toughness improvement mechanism of asphalt by graphene

PendingCN113848130AReduced service lifeReduce ruttingMaterial analysis by optical meansMaterial strength using steady bending forcesScanning electron microscopeElectron microscope

The invention provides a method for researching a viscosity and toughness improvement mechanism of asphalt by graphene, which belongs to the technical field of asphalt performance enhancement, and researches a toughening mechanism of modified asphalt from the angles of binding energy of a two-phase interface and energy absorbed by fracture. The problem that evaluation is carried out only by qualitative judgment in a graphene modified asphalt toughening mechanism research method is solved. The method comprises the following steps of firstly, carrying out a viscosity and toughness test on an asphalt sample to obtain a viscosity and toughness curve and various mechanical property indexes, and analyzing through a calculation formula, then carrying out an impact resistance test and a fracture toughness test to obtain the impact absorbing energy, the borne maximum bending load and the fracture toughness of the asphalt sample under the room temperature condition, and observing the fracture notch morphology and the lattice image by using a scanning electron microscope and a transmission electron microscope, and finally, researching chemical bond change and interlayer spacing change before and after graphene is added by utilizing infrared spectroscopic analysis and X-ray diffraction test, thereby further revealing the improvement mechanism of the graphene on the viscosity and toughness of the asphalt.

Owner:NANJING FORESTRY UNIV

Combined Steel Bridge Deck Pavement Method

ActiveCN108797307BImprove high temperature performanceFull play of road usabilityBridge structural detailsEpoxyAbrasive blasting

The invention discloses a combined-type steel bridge deck laying method. The combined-type steel bridge deck laying method comprises the following steps that A, a modified epoxy resin and gravel combined-type connection layer is laid, specifically, the surface of a steel plate of a steel bridge deck is subjected to sandblasting shot blasting, modified epoxy resin is laid and smeared on the surfaceof the steel plate to form a first modified epoxy resin layer, gravel is scattered on the surface of the first modified epoxy resin layer to form a first gravel layer, modified epoxy resin is evenlylaid and smeared on the surface of the first gravel layer according to the set dosage to form a second modified epoxy resin layer, and then gravel is scattered to form a second gravel layer; and B, ultra-high performance pavement is laid, specifically, active epoxy asphalt or high-viscosity modified emulsified asphalt is smeared on the surface of the connection layer to form a first waterproof bonding layer, then a stone mixture is laid and smeared to form a waterproof-type structure layer, and finally integrated spreading of a second waterproof bonding layer and a drainage-type abrasion layeris conducted through special equipment. According to the combined-type steel bridge deck laying method, sliding and delaminating between the structural layers are prevented, and the stability and durability of the structure are guaranteed.

Owner:广州珠江黄埔大桥建设有限公司 +2

A kind of SBR styrene-butadiene rubber modified asphalt and preparation method thereof

ActiveCN110003672BImprove high temperature resistanceImprove anti-agingBuilding insulationsPolymer scienceAntioxidant

Owner:山东海方橡胶科技有限公司

A kind of high permeability anti-aging modifier and preparation method thereof

The invention is applied to the field of road engineering materials, and discloses a high-permeability anti-aging modifier which is prepared from the following raw materials in parts by mass: 35-45 parts of a light component, 4-6 parts of a permeation promoting component, 20-25 parts of a plastification component, 4-5 parts of a tolerance component, 5-10 parts of an anti-aging component, 4-8 parts of water and 18-25 parts of an SBS component. The permeation effect of the high-permeability anti-aging modifier on aged asphalt is improved by virtue of polarization treatment of the light component, the regeneration effect is improved, meanwhile secondary aging of regenerated alphabet in the mixing and service process, and moreover the adhesion and toughness property of alphabet is improved. The Marshall stability of an anti-aging regenerated alphabet mixed material is up to 12KN, the flexural-tensile strain of the anti-aging regenerated alphabet mixed material is up to 2568mu epsilon, the anti-aging property of the anti-aging regenerated alphabet mixed material is remarkably improved, and application of a high-volume regenerated alphabet mixed material in a road surface layer structure is possible.

Owner:WUHAN UNIV OF TECH +1

A kind of SBR styrene-butadiene latex for modified emulsified asphalt and preparation method thereof

ActiveCN110016234BImprove high temperature resistanceImprove anti-aging propertiesBuilding insulationsPolymer scienceBitumen emulsion

The invention discloses SBR styrene-butadiene latex for modifying emulsified asphalt and a preparation method thereof, belonging to the technical field of asphalt modification. It is characterized in that the composition of raw materials by weight is: 100 parts of cross-linked grafted styrene-butadiene rubber emulsion with a solid content of 40%~60%, 2~6 parts of nonionic emulsifier, 3~6 parts of cationic emulsifier, system pH regulator 0.5~1.5 parts; The preparation steps are: Concentrate cross-linked grafted styrene-butadiene latex and stop when the latex concentration reaches 40%~60%; add nonionic emulsifier, stir for 10 min~15min; add cationic emulsifier according to the ratio of raw materials , stir for 10 min~15min; add system pH regulator according to the ratio of raw materials, and adjust the pH to 2~5. The SBR styrene-butadiene latex of the invention is easy to use, has high stability after being mixed with emulsified asphalt, and can significantly improve the high-temperature resistance performance, viscosity toughness, toughness and anti-aging performance of the asphalt.

Owner:山东海方橡胶科技有限公司

Combined Steel Bridge Deck Pavement Structure

ActiveCN108797333BImprove high temperature performanceFull play of road usabilityBridge structural detailsEpoxyBridge deck

The invention discloses a combined type steel deck pavement structure. The combined type steel deck pavement structure comprises a steel deck steel plate and is characterized in that a first modifiedepoxy resin layer, a first crushed-rock layer, a second modified epoxy resin layer, a second crushed-rock layer, a first waterproof adhesive layer, a waterproof structural layer, a second waterproof adhesive layer and a water drainage type wearing layer. According to the combined type steel deck pavement structure, the first modified epoxy resin layer, the first crushed-rock layer, the second modified epoxy resin layer and the second crushed-rock layer form a modified epoxy resin and crushed-rock combined connecting layer. The first waterproof adhesive layer, the waterproof structural layer, the second waterproof adhesive layer and the water drainage type wearing layer form an ultra high performance pavement (called UHPP for short ). According to the combined type steel deck pavement structure, through UHPP-ME, the slipping and delaminating between the structural layers are prevented; and the stability and durability of the structure are guaranteed.

Owner:广州珠江黄埔大桥建设有限公司 +1

Preparation method of normal-temperature regenerated anti-crack waste asphalt mixture

The invention discloses a preparation method of a normal-temperature regenerated anti-crack waste asphalt mixture. The preparation method comprises the following steps: stirring a plasticizer epoxidized soybean oil, petroleum resin and a modifier maleic anhydride at 95-105 DEG C to uniformly mix to obtain polymerized oil; quickly mixing and dissolving 80-100 parts by weight of polymeric oil and 1-20 parts by weight of an active toughening agent on a shearing machine under the condition of 80-100 DEG C to obtain high-toughness filling polymeric oil; cooling the high-toughness filling polymeric oil to 30-40 DEG C, adding a surfactant vinyltriethoxysilane aqueous solution, uniformly stirring and mixing, and curing to obtain a normal-temperature anti-crack regenerant. The normal-temperature anti-crack regenerant not only can fully activate aged asphalt, but also can improve the cracking resistance and water damage resistance of a cold recycled asphalt mixture together with interface enhanced emulsified asphalt and pre-hydrated cement. According to the invention, the crack resistance and water damage resistance of the regenerated waste asphalt mixture are superior to those of the conventional regenerated asphalt pavement.

Owner:GAOYUAN HIGHWAY MAINTENANCE TECH HENAN PROV +1

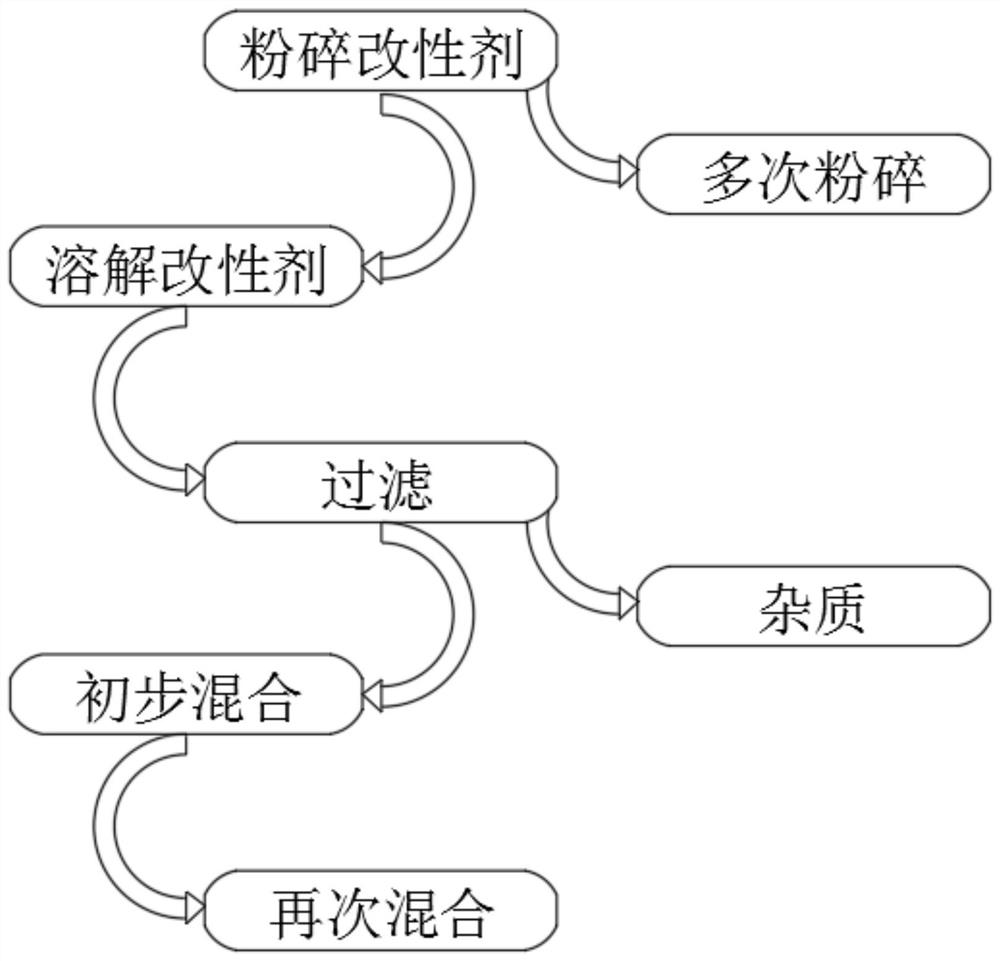

High-performance modified asphalt and manufacturing method thereof

PendingCN113717536AImprove viscosity and toughnessImprove performance and lifeBuilding insulationsProcess engineeringAsphalt

The invention relates to the technical field of asphalt preparation, and discloses high-performance modified asphalt. The high-performance modified asphalt is prepared from the following components in parts by weight: 15-30 parts of auxiliary materials, 10-18 parts of a modifier, 50-100 parts of raw asphalt and 2-25 parts of a solvent. The invention also discloses a manufacturing method of the high-performance modified asphalt. The manufacturing method comprises the following steps: S1, crushing of the modifier: putting the modifier into a crusher for crushing for 10-30 minutes, and then conducting screening with a 200-to-400-mesh sieve to obtain the crushed modifier; and S2, dissolving of the modifier: adding the crushed modifier and a solvent into a mixing tank, and carrying out stirring and mixing to obtain a mixed solution A. By adding the modifier, the viscosity and toughness, the softening point, the low-temperature cracking resistance and the elasticity of the modified asphalt can be effectively improved; and by doping an anti-stripping agent and an anti-aging agent, the use performance of a pavement material can be improved, and the service life of the pavement material can be prolonged.

Owner:镇江越辉新材料有限公司

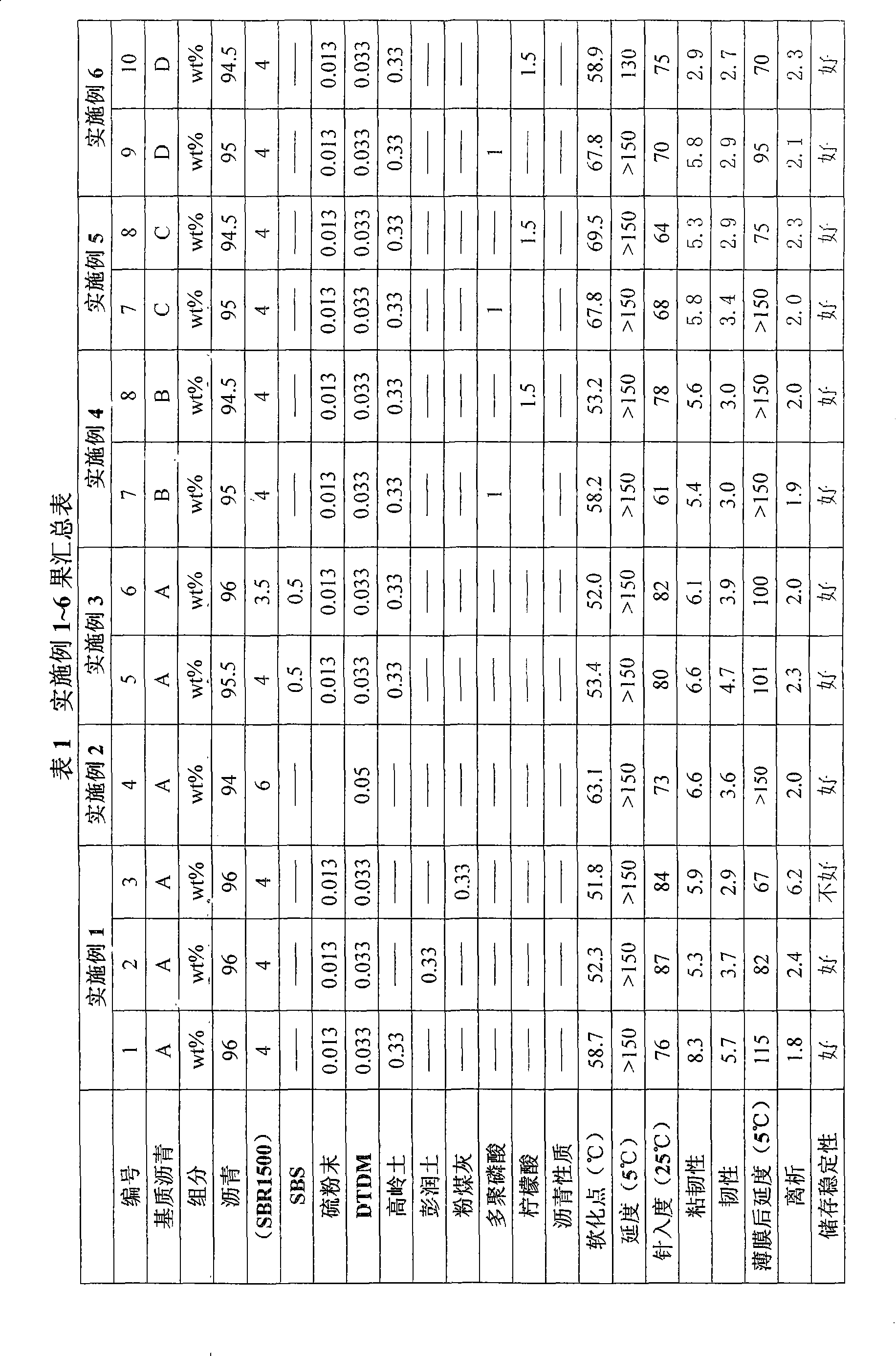

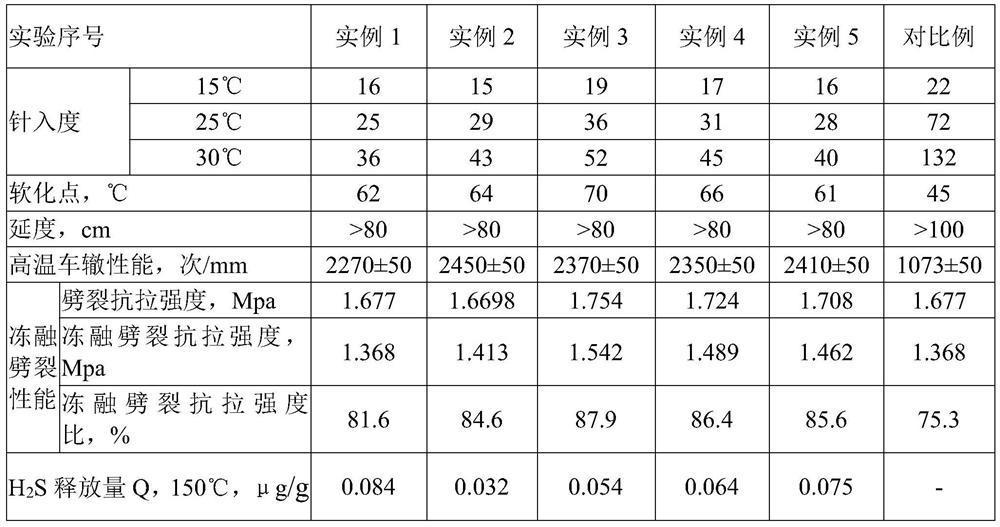

High-toughness composite SBR modified asphalt for warm-mixed asphalt technology, and preparation method thereof

InactiveCN102276993BImprove viscosity and toughnessImprove toughnessIn situ pavingsClimate change adaptationPolymer scienceToughness

The invention relates to high-toughness composite SBR modified asphalt for a warm-mixed asphalt technology, and a preparation method thereof, and belongs to the technical field of composite modified asphalt. The high-toughness composite SBR modified asphalt is prepared through mixing matrix asphalt, an alkyl condensation substance, an asphalt modifier and a stabilizer. The raw materials comprise,by mass, 85-95% of the matrix asphalt, 1-5% of the alkyl condensation substance, 2-10% of the asphalt modifier and 0.2-2% of the stabilizer. The preparation method comprises the following steps: (1) weighing the matrix asphalt according to the mass percentage of 85-95%, then placing the matrix asphalt in a heating and mixing container, carrying out heating to a temperature of 120-160 DEG C to enable the matrix asphalt to be molten completely, carrying out heat insulation while carrying out stirring; (2) weighing the asphalt modifier according to the mass percentage of 2-10%, weighing the alkyl condensation substance according to the mass percentage of 1-5%, then adding the asphalt modifier and the alkyl condensation substance to the molten matrix asphalt, and carrying out stirring and mixing; (3) heating to the temperature of 160-180 DEG C, weighing the stabilizer according to the mass percentage of 0.2-2%, then adding the stabilizer to the resulting mixture from the step (2), uniformly stirring and mixing, removing the material from the heating and mixing container to prepare the high-toughness composite SBR modified asphalt.

Owner:南京中公材料科技发展有限公司

High-quality cold asphalt pavement and construction method thereof

InactiveCN113215906AImprove structural strengthImprove performanceIn situ pavingsRoads maintainenceStructural engineeringRoad surface

The invention relates to the technical field of road construction and particularly relates to a high-quality cold-state asphalt pavement and a construction method thereof. The high-quality cold-state asphalt pavement comprises an asphalt surface layer, a base layer, a subbase layer and a cushion layer which are sequentially laid on a roadbed from top to bottom. Compared with the prior art, the construction method is advantaged in that the stress condition of the pavement structure is improved, the number of reflection cracks is reduced, and use performance of the highway pavement is improved, so the service life of the pavement is prolonged, the structural strength of the pavement is effectively improved by reasonably limiting the elasticity modulus and laying thickness of the asphalt surface layer, the base layer and the subbase layer, reflection cracks formed by asphalt pavement are reduced, and the road service life is increased. According to the modified rubber asphalt, various modifiers are added into an asphalt matrix with low wax content, so comprehensive performance of the asphalt is greatly improved, high-temperature storage stability, the high and low temperature performance, the aging performance, the viscoelasticity and viscosity and toughness are obviously improved, and the use requirements in alpine regions or high-temperature regions are met.

Owner:河南金欧特实业集团股份有限公司

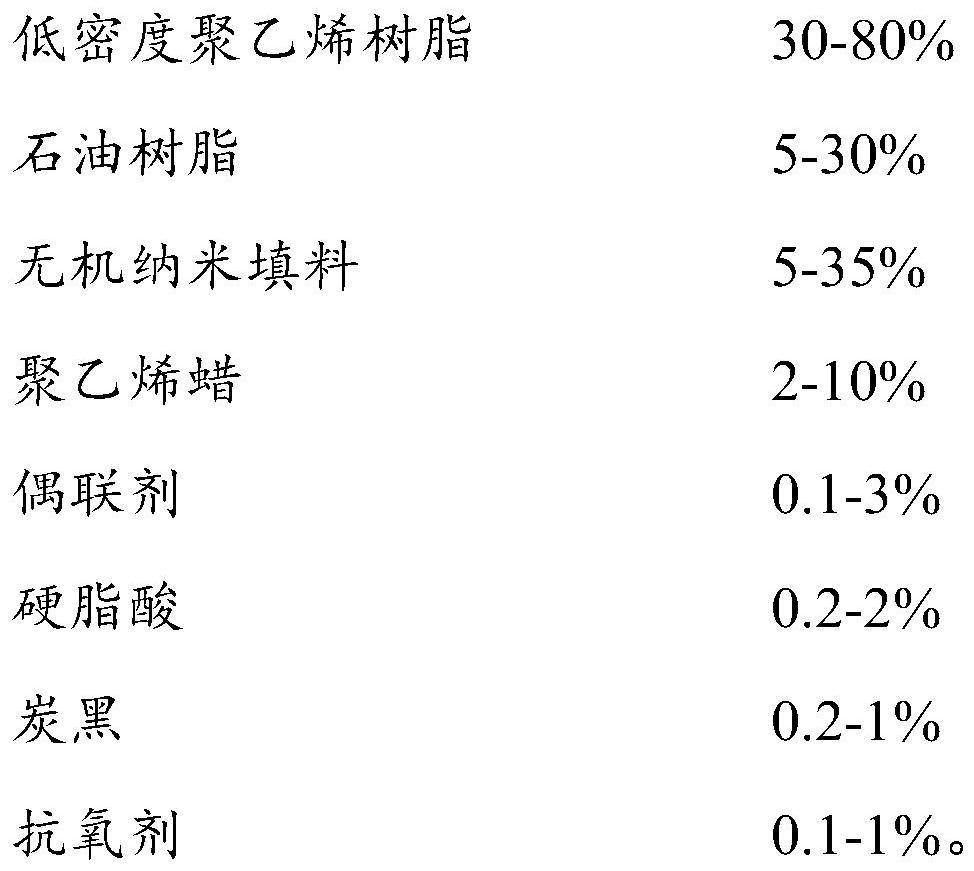

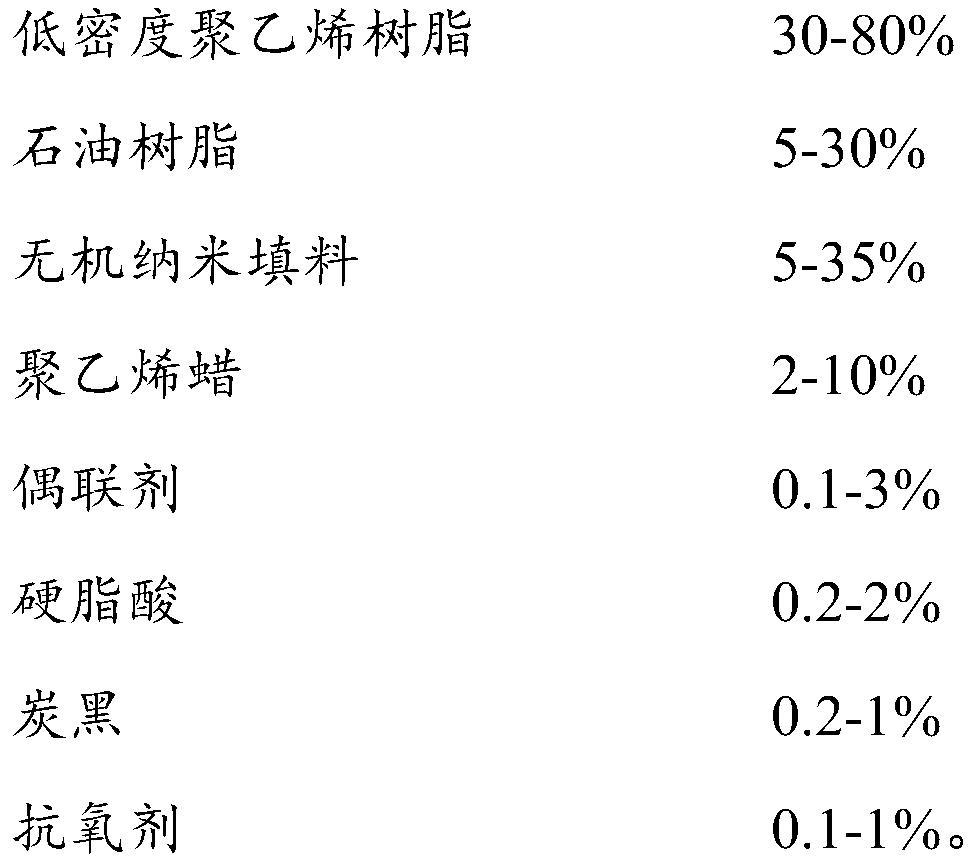

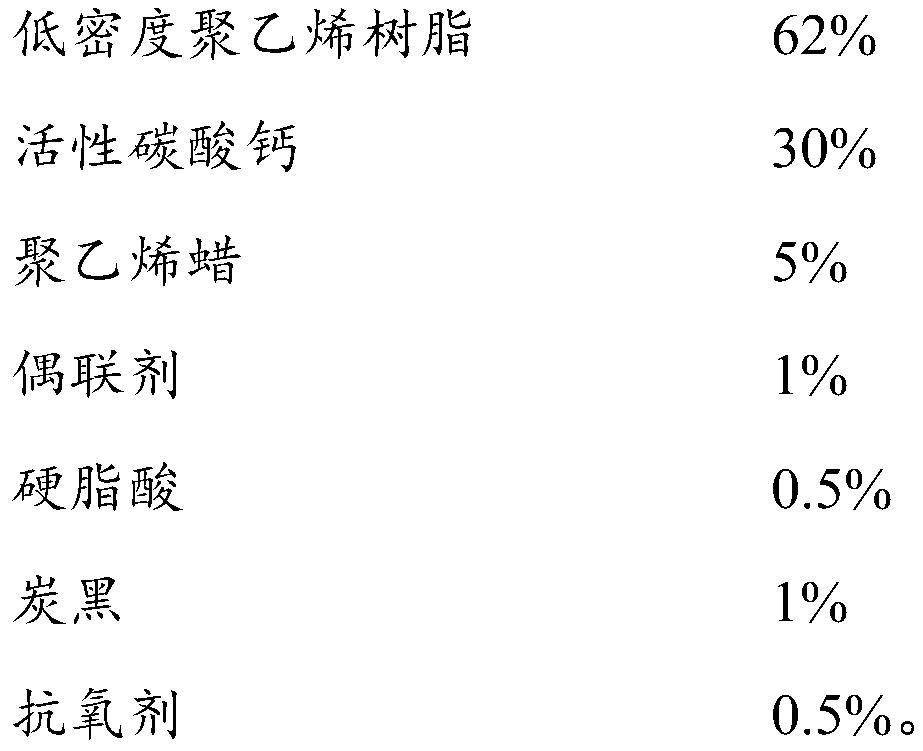

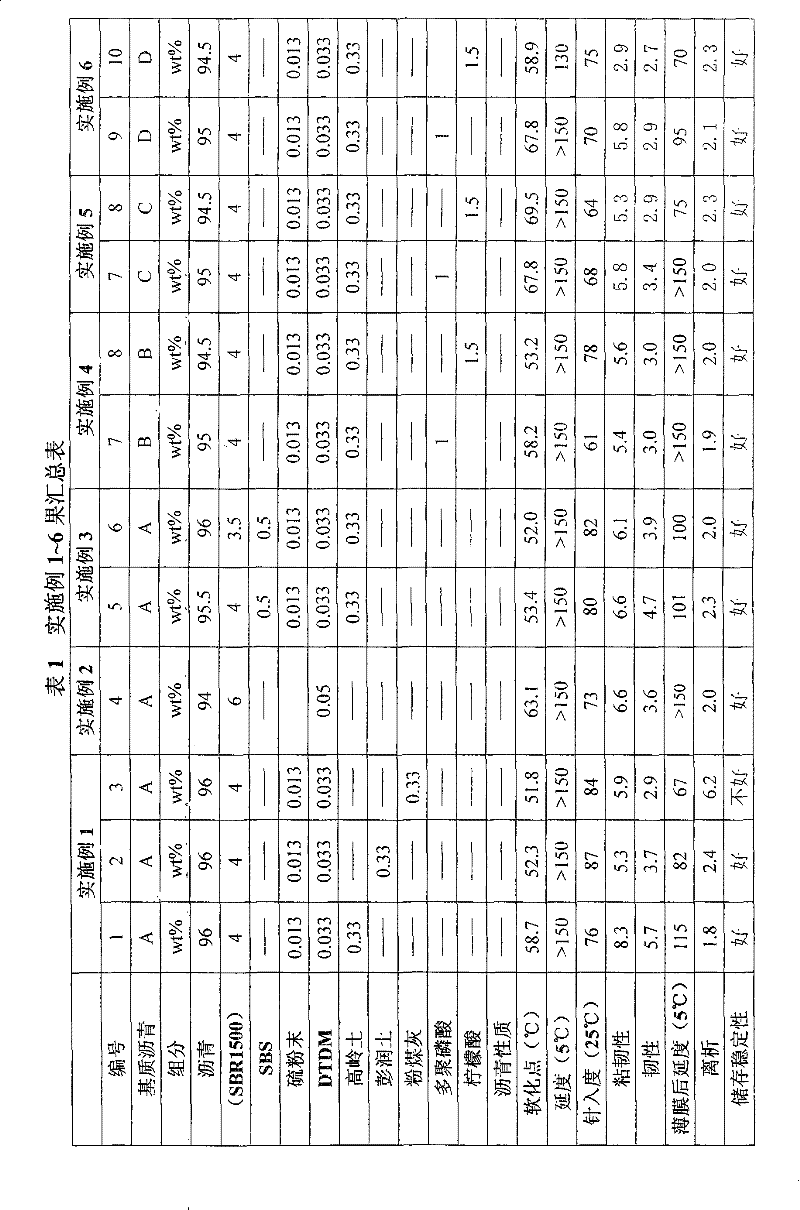

High-temperature-resistant high-viscosity asphalt modified material, modified asphalt and preparation method

PendingCN114805987AImprove ductilityImprove toughnessBuilding insulationsLow-density polyethylenePetroleum resin

The invention relates to the technical field of asphalt, in particular to a high-temperature-resistant and high-viscosity asphalt modified material, modified asphalt and a preparation method.The high-temperature-resistant and high-viscosity asphalt modified material is prepared from 30%-80% of low-density polyethylene resin, 5%-30% of petroleum resin, 5%-35% of inorganic nanofiller, 2%-10% of polyethylene wax, 0.1%-3% of coupling agent, 0.2%-2% of stearic acid, 0.2%-1% of carbon black and 0.1%-1% of antioxidant. Asphalt modified by the high-temperature-resistant and high-viscosity asphalt modified material has the characteristics of high ductility, high temperature resistance and high viscosity and toughness.

Owner:DONGGUAN JISHUO IND CO LTD

Polymer chemically-modified asphalt composition capable of being stably stored at high temperature and preparation method thereof

InactiveCN101613533BGood storage stability at high temperatureMeet usable requirementsBuilding insulationsElastomerViscous liquid

The invention relates to a high polymer chemically-modified asphalt composition and a preparation method thereof. The preparation method comprises the following steps: chemically modifying rubber, elastomer and base asphalt, and additionally matching stuffing and processing aids; premixing the materials by high polymer processing equipment to prepare the master batch of the modified asphalt; and fully dispersing the master batch into the asphalt by a high-speed shear mixer or by mechanical stirring. Or the modified asphalt material can be prepared by firstly pre-preparing a viscous liquid mixture of modified asphalt and then stirring and mixing the viscous liquid mixture of modified asphalt with the base asphalt. The modified asphalt material prepared by the invention has stable storage performance at high temperature, good performance at high temperature and low temperature, stable processing and preparation and simple and convenient method, and not only can be directly used in factory production but also can be used for road laying sites and in the construction of waterproofing materials.

Owner:NORTHWEST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com