Cold mixing color asphalt mixture and preparation method

A technology of colored asphalt and mixture, applied in the field of pavement materials, can solve the problems of single color, insufficient compaction, poor adhesion between organic modifier and inorganic pigment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

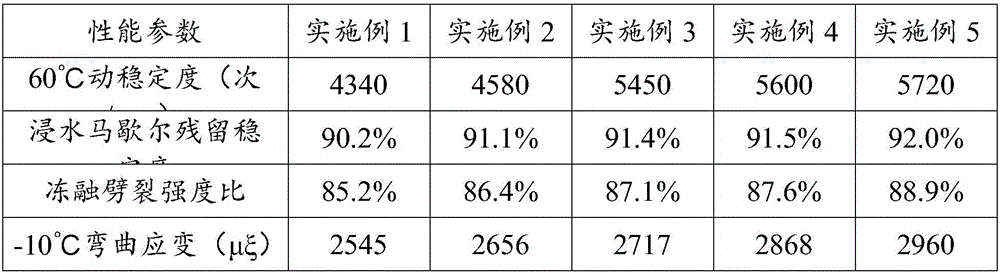

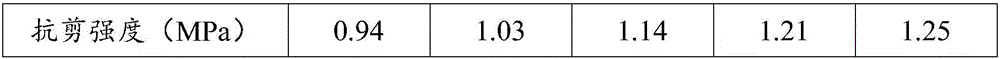

Examples

Embodiment 1

[0017] Preparation of colored asphalt binder:

[0018] Aromatic hydrocarbon oil by mass ratio: rubber oil: petroleum resin: epoxy resin: modifier: plasticizer: diluent: diatomaceous earth: pigment: stabilizer A=100:10:20:10:5:5: 2:10:15:0.5, select aromatic oil, rubber oil, petroleum resin, epoxy resin, modifier, plasticizer, diluent, diatomaceous earth, pigment and stabilizer A, and set aside.

[0019] First, heat the rubber oil to 140°C, and add the modifier while stirring. After the modifier is added, keep stirring for 15 minutes to form a uniform mixture A. Mix epoxy resin and diluent uniformly to obtain mixture B. Mix the pigment and diatomaceous earth evenly to obtain mixture C. Heat the reaction vessel to about 160°C, add aromatic oil and petroleum resin in turn, after the two are melted and mixed, add mixture A, turn on the shearing equipment, shear at low speed (2500r / min) for 10min, then high speed (7000r / min) Cut for 6min. Keep low shear rate (2500r / min) and hea...

Embodiment 2

[0045] Preparation of colored asphalt binder:

[0046] Aromatic hydrocarbon oil by mass ratio: rubber oil: petroleum resin: epoxy resin: modifier: plasticizer: diluent: diatomaceous earth: pigment: stabilizer A=100:11:25:12:6:6: 3:11:16:0.6, select aromatic oil, rubber oil, petroleum resin, epoxy resin, modifier, plasticizer, diluent, diatomaceous earth, pigment and stabilizer A, and reserve.

[0047] First, heat the rubber oil to 140°C, and add the modifier while stirring. After the modifier is added, keep stirring for 15 minutes to form a uniform mixture A. Mix epoxy resin and diluent uniformly to obtain mixture B. Mix the pigment and diatomaceous earth evenly to obtain mixture C. Heat the reaction vessel to about 160°C, add aromatic oil and petroleum resin in turn, after the two are melted and mixed, add mixture A, turn on the shearing equipment, shear at low speed (2500r / min) for 10min, then high speed (7000r / min) Cut for 6min. Keep low shear rate (2500r / min) and heati...

Embodiment 3

[0073] Preparation of colored asphalt binder:

[0074] Aromatic hydrocarbon oil by mass ratio: rubber oil: petroleum resin: epoxy resin: modifier: plasticizer: thinner: diatomaceous earth: pigment: stabilizer A=100:12:30:15:7:7: 4:12:17:0.7, select aromatic oil, rubber oil, petroleum resin, epoxy resin, modifier, plasticizer, diluent, diatomaceous earth, pigment and stabilizer A, and set aside.

[0075] First, heat the rubber oil to 140°C, and add the modifier while stirring. After the modifier is added, keep stirring for 15 minutes to form a uniform mixture A. Mix epoxy resin and diluent uniformly to obtain mixture B. Mix the pigment and diatomaceous earth evenly to obtain mixture C. Heat the reaction vessel to about 160°C, add aromatic oil and petroleum resin in turn, after the two are melted and mixed, add mixture A, turn on the shearing equipment, shear at low speed (2500r / min) for 10min, then high speed (7000r / min) Cut for 6min. Keep low shear rate (2500r / min) and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com