High-modulus modified asphalt and production method thereof

A technology of modified asphalt and production method, applied in building components, building insulation materials, construction and other directions, can solve the problems affecting the normal, safe driving, and rutting of vehicles, and achieve the effects of low cost, good toughness, and good anti-rutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

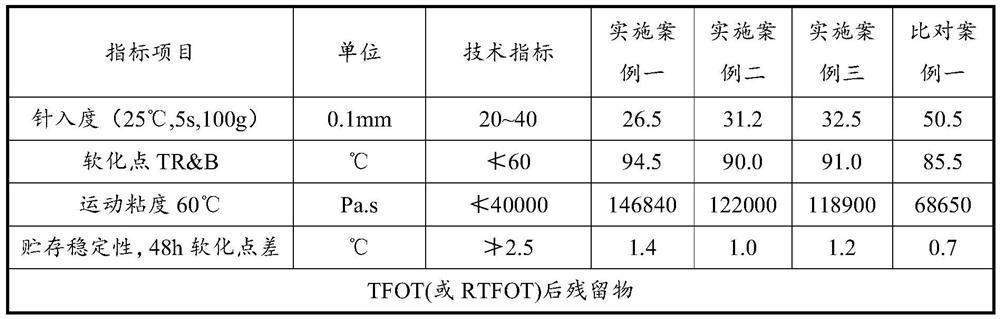

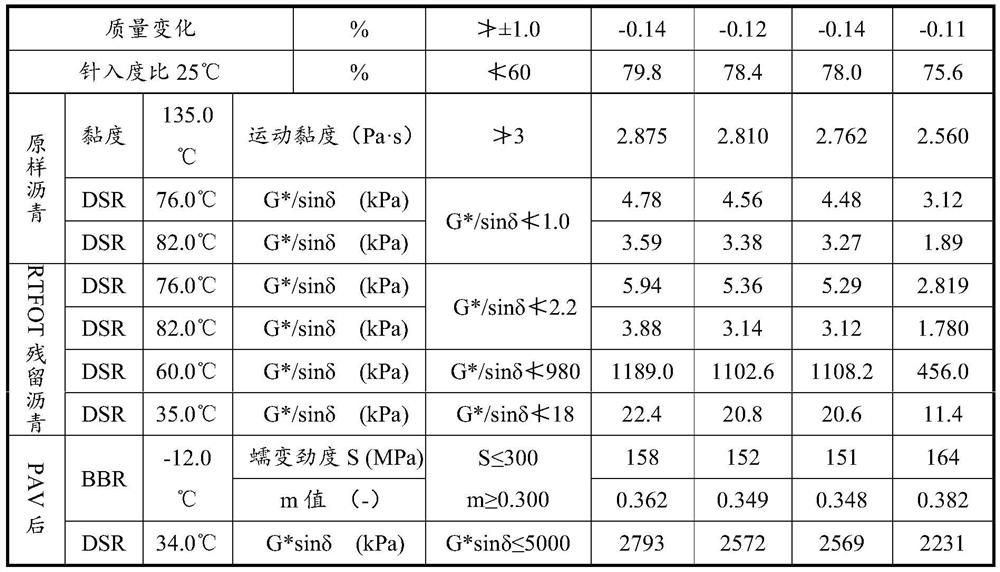

Embodiment 1

[0023] This embodiment is to prepare a kind of high modulus modified asphalt, the specific operation is as follows:

[0024] 50 tons of Korean Ssangyong 70# asphalt and 25 tons of Dalian Xitai 70# asphalt were rapidly raised from the raw material tank to 140°C through a heat exchanger, and pumped into a 150-ton high-temperature tank. After stirring for 1 hour, the heat exchanger quickly raised the temperature to 180 ℃, pumped into the workshop reaction kettle, at the same time, 4.8 tons of Sinopec YH791H SBS was lifted into the reaction kettle through the frequency conversion transmission pipe, and passed through two German SIEFER colloid mills in series (the gap between the colloid mills was adjusted to 0.3 and 0.25 units respectively) once Enter the finished product tank, open the finished product tank and stir for 2 hours, slowly and evenly add 160kg of sulfur flakes, the feeding time is controlled at 10 minutes, and after continuing to stir for 4 hours, 16 tons of I-type ru...

Embodiment 2

[0026] This embodiment also prepares a kind of high modulus modified asphalt, and the specific operation is consistent with embodiment 1:

[0027] 50 tons of Korean SK70# asphalt and 26 tons of Zhenhai 70# asphalt were rapidly raised to 150°C from the raw material tank through a heat exchanger, and pumped into a 150-ton high-temperature tank. After stirring for 1 hour, the heat exchanger rapidly raised the temperature to 185°C. Pumped into the reaction kettle of the workshop, at the same time, 4.5 tons of SBS of Xinjiang Dushanzi T6302H is lifted into the reaction kettle through the frequency conversion transmission pipe, and enters through two German SIEFER colloid mills in series (the gap between the colloid mills is adjusted to 0.3 and 0.25 units respectively). In the finished product tank, after opening the finished product tank and stirring for 2 hours, slowly and evenly add 150kg of sulfur flakes, the feeding time is controlled at 15 minutes, and after continuing to stir ...

Embodiment 3

[0029] This embodiment is also to prepare a kind of high modulus modified asphalt, and the specific operation is also consistent with embodiment 1:

[0030] 50 tons of Korean GS70# bitumen and 26 tons of Keyuan 70# bitumen were rapidly raised to 150°C from the raw material tank through the heat exchanger, and pumped into a 150-ton high-temperature tank. After stirring for 1 hour, the heat exchanger quickly raised the temperature to 185°C , pumped into the workshop reactor, and at the same time, 4.5 tons of Jinhai Chenguang T7302H SBS was lifted into the reactor through the frequency conversion transmission tube, and entered through two series-connected German SIEFER colloid mills (the gap between the colloid mills was adjusted to 0.3 and 0.25 units respectively). In the finished product tank, after opening the finished product tank and stirring for 2 hours, slowly and evenly add 180kg of sulfur flakes, the feeding time is controlled at 20 minutes, and after continuing to stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com