Combined Steel Bridge Deck Pavement Structure

A steel bridge deck, combined technology, used in bridges, bridge construction, bridge parts, etc., can solve problems such as large deformation, hidden dangers, and testing of the steel bridge deck system, and achieve strong deformation resistance, shear resistance, and security. The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application The features in the embodiments and the embodiments can be combined with each other.

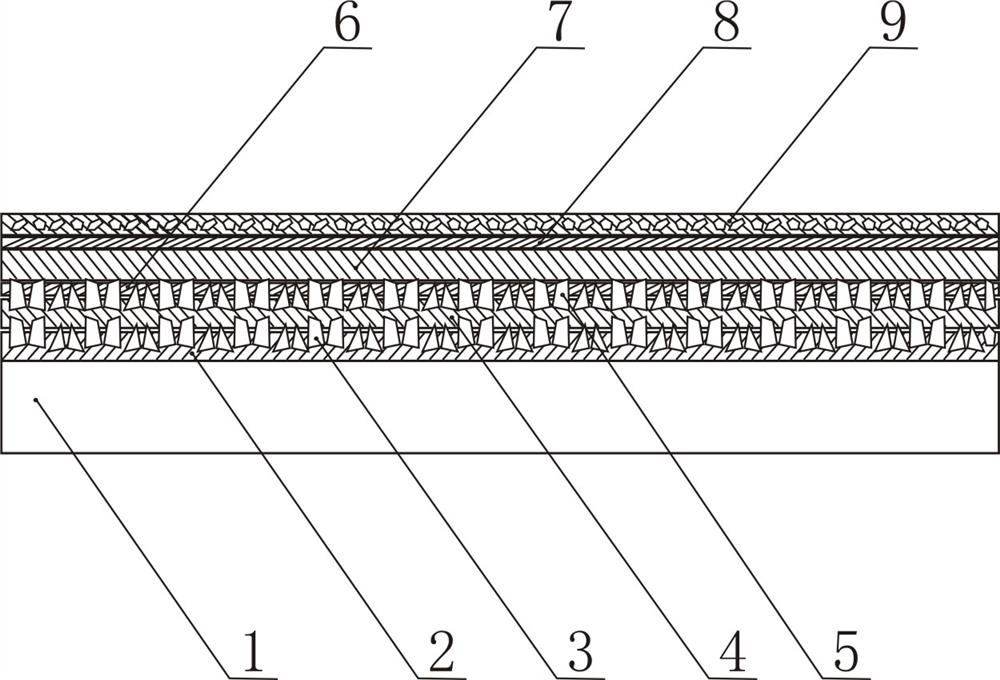

[0026] Such as figure 1 As shown, the combined steel bridge deck paving structure includes a steel bridge deck steel plate 1. The surface of the steel bridge deck steel plate 1 is sequentially laid with a first modified epoxy resin layer 2 and a first gravel layer from bottom to top. 3. The second modified epoxy resin layer 4, the second crushed stone layer 5, the first waterproof adhesive layer 6, the waterproof structural layer 7, the waterproof adhesive layer 8 and the drainage type abrasion layer 9, wherein the drainage type abrasion The layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com