Pavement structure of steel bridge deck and construction method thereof

A technology of steel bridge deck and pavement structure, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of lack of pathological characteristics, poor tolerance, poor stability, etc., and achieve the effect of convenient construction and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

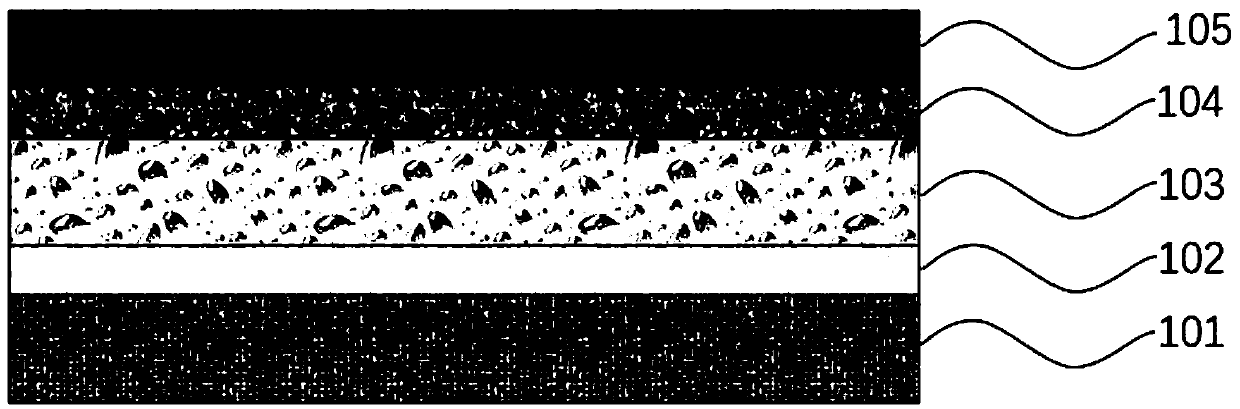

[0042] This example focuses on the main causes of steel bridge deck pavement damage, such as incomplete design considerations, improper construction management and control, and poor operating environment, through the analysis of pathological characteristics of steel bridge deck pavement damage and problems in pavement structure design, construction, and maintenance. According to research, a steel bridge deck pavement structure is provided. The pavement structure is to sequentially lay the first waterproof adhesive layer 102, the modified epoxy asphalt macadam layer 103, and the second waterproof layer on the steel plate surface of the steel bridge deck 101. Adhesive layer 104, ultra-high performance structural layer 105. The combined pavement structure has the characteristics of clear structural function, stable and durable material performance, excellent performance, convenient construction and maintenance conditions, and obvious advantages in economic and technical indicators...

Embodiment 2

[0099] The present embodiment provides a construction method of a pavement structure of a steel bridge deck, the construction method comprising the following steps:

[0100] 1. Construction of the first waterproof bonding layer and modified epoxy asphalt macadam layer

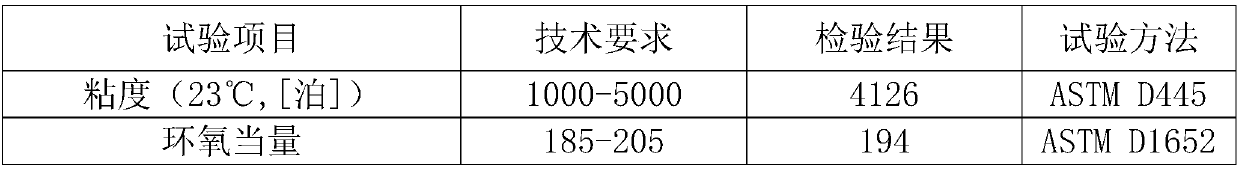

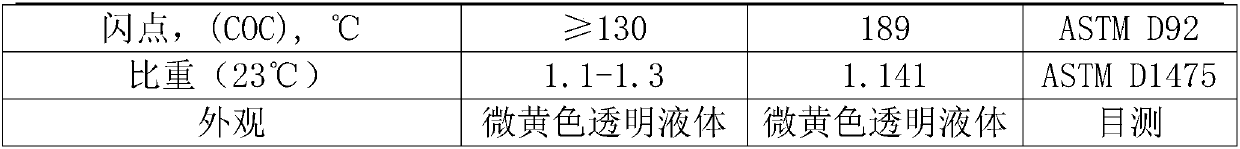

[0101] (1) The surface of the steel plate on the steel bridge deck is sandblasted and shot blasted to Sa2.5, dust removed, dry, and pollution-free. The first waterproof bonding layer (modified epoxy resin 1, curing agent quality) shall be constructed within 4 hours after the above steel plate is treated. The ratio is 45-55:55-45) to ensure air isolation.

[0102] The construction methods of the first waterproof adhesive layer include mechanical spraying or brushing with a roller brush at 1.5kg / m 2 .

[0103] (2) After the modified epoxy resin 1 (modified epoxy resin main agent component and the curing agent component used in conjunction with the mass ratio is 45-55:55-45) is sprayed, the obtained first waterp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com