Aqueous emulsion-based resin modified crack-pouring material and preparation method thereof

A technology for joint filling material and base resin, which is applied in the field of water-emulsion-based resin modified joint filling material and preparation, and can solve the problems of general effect, short construction time, low filling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

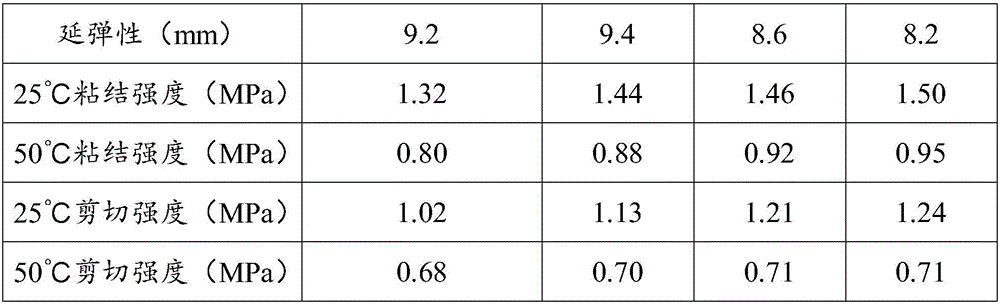

Embodiment 1

[0022] Preparation of the first component of water emulsion resin modified joint filling material:

[0023] Aromatic hydrocarbon oil by mass ratio: rubber oil: modifier: tackifier: toughening agent: stabilizer A: curing agent A=100:20:2:5:1:0.1:10, select aromatic hydrocarbon oil, rubber oil , Modifier, tackifier, toughening agent, stabilizer A and curing agent, spare.

[0024] Mix the curing agent and the toughening agent uniformly to obtain mixture A. Heat the rubber oil to 150°C, and add the modifier while stirring. After the modifier is added, keep stirring for about 12 minutes to form a uniform mixture B. Heat the reaction vessel to about 160°C, add aromatic oil and tackifier in turn, after the two are melted and mixed, add mixture B, turn on the shearing equipment, shear at low speed (3000r / min) for 15min, then high speed (8000r / min) ) cut for 8min. Keep the low shear rate (3000r / min) and the heating temperature at 160°C, add mixture A and stabilizer A, keep stirring ...

Embodiment 2

[0051] Preparation of the first component of water-emulsion-based resin modified joint filling material:

[0052] Aromatic hydrocarbon oil by mass ratio: rubber oil: modifier: tackifier: toughening agent: stabilizer A: curing agent A=100:22:3:5:2:0.2:12, select aromatic hydrocarbon oil, rubber oil , Modifier, tackifier, toughening agent, stabilizer A and curing agent, spare.

[0053] Mix the curing agent and the toughening agent uniformly to obtain mixture A. Heat the rubber oil to 150°C, and add the modifier while stirring. After the modifier is added, keep stirring for about 12 minutes to form a uniform mixture B. Heat the reaction vessel to about 160°C, add aromatic oil and tackifier in turn, after the two are melted and mixed, add mixture B, turn on the shearing equipment, shear at low speed (3000r / min) for 15min, then high speed (8000r / min) ) cut for 8min. Keep the low shear rate (3000r / min) and the heating temperature at 160°C, add mixture A and stabilizer A, keep sti...

Embodiment 3

[0080] Preparation of the first component of water-emulsion-based resin modified joint filling material

[0081] Aromatic hydrocarbon oil by mass ratio: rubber oil: modifier: tackifier: toughening agent: stabilizer A: curing agent A=100:25:4:8:3:0.3:15, select aromatic hydrocarbon oil, rubber oil , Modifier, tackifier, toughening agent, stabilizer A and curing agent, spare.

[0082] Mix the curing agent and the toughening agent uniformly to obtain mixture A. Heat the rubber oil to 150°C, and add the modifier while stirring. After the modifier is added, keep stirring for about 12 minutes to form a uniform mixture B. Heat the reaction vessel to about 160°C, add aromatic oil and tackifier in turn, after the two are melted and mixed, add mixture B, turn on the shearing equipment, shear at low speed (3000r / min) for 15min, then high speed (8000r / min) ) cut for 8min. Keep the low shear rate (3000r / min) and the heating temperature at 160°C, add mixture A and stabilizer A, keep stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com