High-performance rubber asphalt for asphalt pavement and preparation method thereof

A technology of asphalt pavement and rubber asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve problems such as unmeasured sales, inconvenient storage and transportation, large manpower consumption, material and financial safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] S1. Preparation of sulfur modifier: After mixing 80g of methyldiethanolamine and 11g of stearic acid, stir and add 8g of liquid sodium hydroxide with a mass fraction of 30%, heat up to 50°C for 2-3 hours, and wait for the pH value of the reaction solution to neutrality, then add hydroxypropyl methylcellulose into the reaction liquid, keep warm for 1-2 hours, and finally add 5g of pour point depressant JN-50 and 25g of modified coconut oil alcohol ZR-08, continue to keep warm for 1 hour , cooling to obtain hydrogen sulfide inhibitor; fully mix sulfur, waste rubber powder, fly ash, hydrogen sulfide inhibitor and isoamyl acetate with a mass ratio of 100:5:8:1.5:0.5, and heat to sulfur molten state Finally, after stirring for 0.5h, pour the mixture into cooling water at a constant speed to obtain a granular finished product;

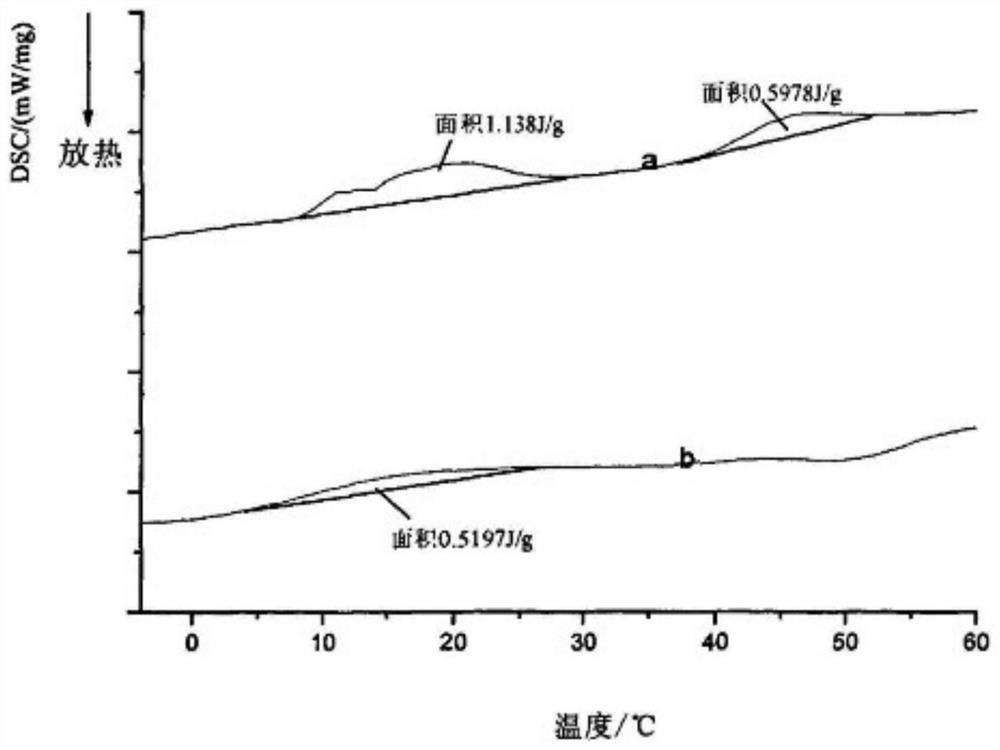

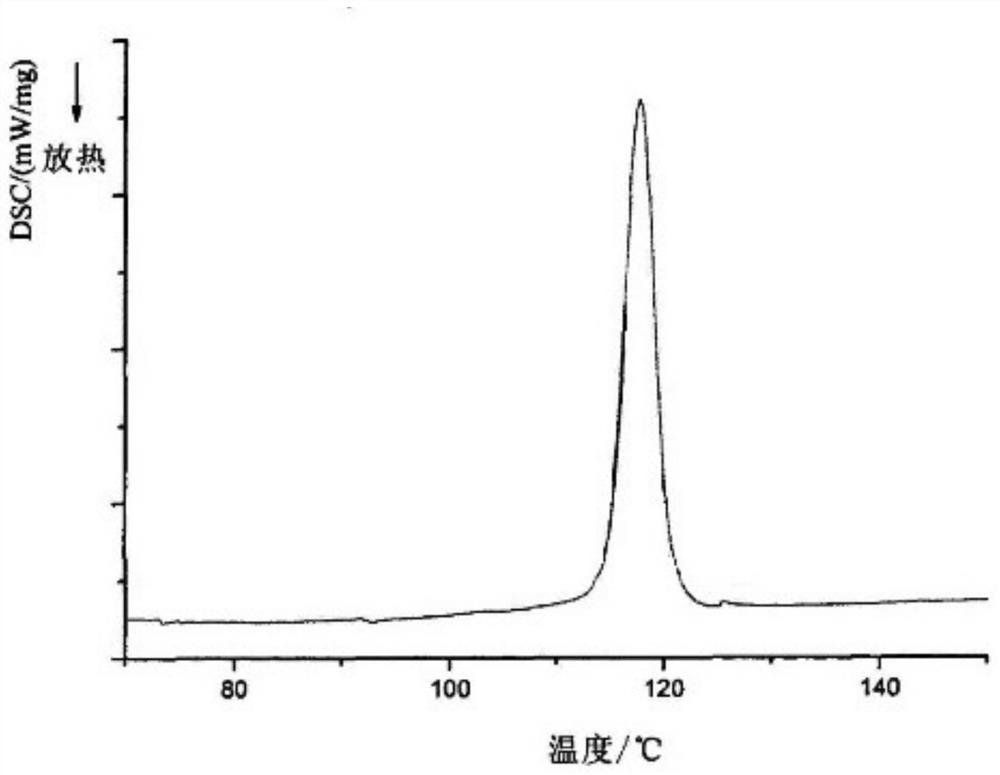

[0024] S2. After heating 55 parts of low-wax asphalt matrix with a wax content of 2% to 120°C, add 9 parts of linear SBS, 5 parts of waste rubber pow...

Embodiment 2

[0028] S1. Preparation of sulfur modifier: After mixing 120 g of methyldiethanolamine and 18 g of stearic acid, stir and add 10 g of liquid sodium hydroxide with a mass fraction of 30%, heat up to 90° C. and react for 3 to 5 hours. to neutrality, then add hydroxypropyl methylcellulose into the reaction solution, keep warm for 1-2 hours, and finally add 12g of pour point depressant JN-50 and 38g of modified coconut oil alcohol ZR-08, and continue to keep warm for 2 hours , cooling to obtain hydrogen sulfide inhibitor; fully mix sulfur, waste rubber powder, fly ash, hydrogen sulfide inhibitor and isoamyl acetate with a mass ratio of 100:15:12:3:2, and heat to sulfur molten state Finally, after stirring for 2 hours, pour the mixture into cooling water at a constant speed to obtain a granular finished product;

[0029] S2. After heating 75 parts of low-wax asphalt matrix with a wax content of 5% to 140°C, add 16 parts of star-shaped SBS, 12 parts of waste rubber powder and 8 parts...

Embodiment 3

[0033] S1. Preparation of sulfur modifier: After mixing 100 g of methyldiethanolamine and 15 g of stearic acid, stir and add 15 g of liquid sodium hydroxide with a mass fraction of 30%, heat up to 60° C. and react for 3 to 5 hours. to neutrality, then add hydroxypropyl methylcellulose into the reaction solution, keep warm for 1-2 hours, and finally add 20g of pour point depressant JN-50 and 65g of modified coconut oil alcohol ZR-08, and continue to keep warm for 2 hours , cooling to obtain hydrogen sulfide inhibitor; fully mix sulfur, waste rubber powder, fly ash, hydrogen sulfide inhibitor and isoamyl acetate with a mass ratio of 100:12:10:2:1, and heat to sulfur molten state Finally, after stirring for 2 hours, pour the mixture into cooling water at a constant speed to obtain a granular finished product;

[0034] S2. After heating 65 parts of low-wax asphalt matrix with a wax content of 4% to 130°C, add 12 parts of linear SBS, 8 parts of waste rubber powder and 10 parts of L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com