Modified high-viscosity asphalt and preparation method thereof

A sticky asphalt and modification technology, applied in the field of modified high-viscosity asphalt and its preparation, can solve the problems of storage stability, toughness, insufficient stickiness and toughness, etc., and achieve good stickiness and toughness, good corrosion resistance, and good storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

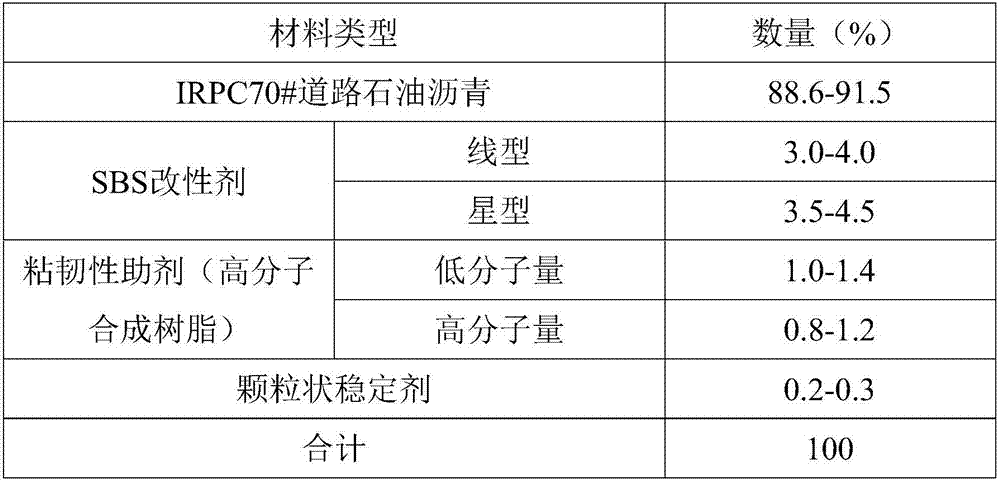

[0026] The formula of embodiment 1 modified high-viscosity asphalt

[0027] The compound modified high-viscosity asphalt formula of this embodiment is shown in Table 1:

[0028] Table 1: Compound Modified High Viscosity Asphalt Formula

[0029]

[0030] This embodiment takes Thai Petrochemical IRPC70# road petroleum asphalt as the base road petroleum asphalt, adopts star-shaped and linear butadiene-styrene block copolymer (SBS) as modifier; selects two kinds of polymers with different molecular weights to synthesize Resin is used as a viscous and toughness additive. Its molecular structure contains active groups such as hydroxyl groups and ether bonds, and its solid content is 100%. During the reaction process, new —OH and —O— are further generated to make the modified high-viscosity modified Asphalt has high cohesion and adhesion; use domestic granular stabilizer, the role of the stabilizer can reduce the interfacial energy between the base asphalt and SBS, viscosity and ...

Embodiment 2

[0034] Embodiment 2: the preparation method of composite modified high-viscosity road petroleum asphalt

[0035] The specific preparation process of the composite modified high-viscosity road petroleum asphalt in this embodiment is as follows:

[0036] (1) First weigh the SBS modifier, resin viscosity and toughness additive, and granular stabilizer;

[0037] (2) Heat the base asphalt to about 180°C, heat while stirring, so that the asphalt is heated evenly, then pour the high-temperature molten base asphalt into the modified asphalt sample container, put the sample container into the electric heating mantle, and use electric heating Continue heating the jacket to keep the temperature at 180°C;

[0038] (3) Put down the shearing mixing head so that it is 1 / 3 from the bottom of the liquid surface, turn on the shearing machine, and control the speed at 2500-3000r / min, so that the high-temperature asphalt liquid moves in a vortex without splashing. For the pre-weighed SBS modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com