Mochi prepared mix with long guarantee period, mochi and preparation method of mochi prepared mix

A technology for ready-mixed powder and shelf life, applied in the field of cakes, can solve the problems of high content of mochi reducing sugar, affecting the edible quality of mochi, affecting the sensory characteristics of the product, etc., and achieves the effect of reducing the content of reducing sugar, avoiding spoilage, and having a remarkable fresh-keeping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

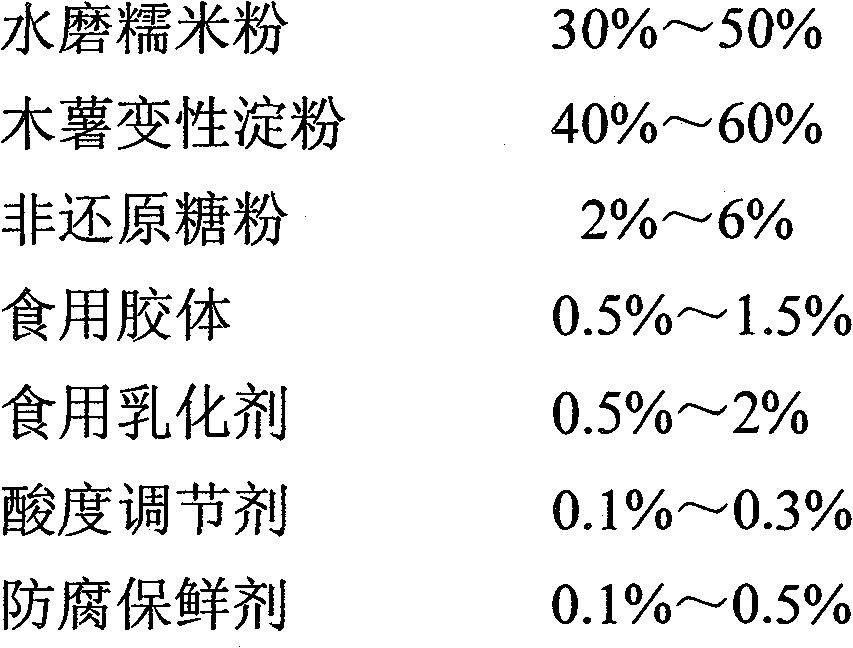

Method used

Image

Examples

Embodiment 1

[0039] (1) Grind 3kg of glutinous rice flour with water, 6kg of hydroxypropyl distarch phosphate starch, 0.6kg of non-reducing powdered sugar (containing 0.3kg of sucrose and 0.3kg of trehalose), 0.15kg of edible colloid (containing 0.10kg of carrageenan and konjac manna) polysaccharide 0.05kg), molecularly distilled monoglyceride 0.20kg, acidity regulator citric acid 0.01kg and potassium sorbate 0.04kg mix, stir in mixing mixer, obtain mochi premix powder 10kg;

[0040] (2) Put the mochi premix powder obtained in step (1) into the steamer, add 7kg of clear water, and stir into a uniform dough; control the internal pressure of the steamer at 0.035Mpa and steam for 25min; feed steam to reduce the steam pressure Control at 0.04Mpa, add 50kg of high maltose syrup, stir evenly and add 1kg of emulsified oil to obtain mochi skin slurry;

[0041] (3) Fry the mochi skin slurry obtained in step (2) for 25 minutes, control the solid content at 77%, and cool to 40°C to obtain the mochi s...

Embodiment 2

[0045] (1) Mill glutinous rice flour 5kg, oxidized hydroxypropyl starch 4kg, galactomannan 0.2kg, sodium alginate 0.15kg, edible emulsifier 0.20kg (containing calcium stearoyl lactylate 0.10kg and sodium stearoyl lactylate 0.10kg) kg), acidity regulator sodium citrate 0.03kg and sodium dehydroacetate 0.01kg mix, stir in mixing mixer, obtain mochi premixed powder 9.59kg;

[0046] (2) Put the mochi premix powder obtained in step (1) into the steamer, add 4.795kg of clear water, and stir into a uniform dough; control the internal pressure of the steamer at 0.025Mpa and steam for 20min; The pressure is controlled at 0.05Mpa, 33.57kg of high maltose syrup is added, after stirring evenly, 1.918kg of emulsified oil is added to obtain mochi skin slurry;

[0047](3) fry the mochi skin slurry obtained in step (2) for 30 minutes, control the solid content at 76%, and cool to 25° C. to obtain the mochi skin material;

[0048] (4) Wrapping the mochi skin material obtained in step (3) with...

Embodiment 3

[0051] (1) Water-milled glutinous rice flour 4kg, acetylated distarch phosphate starch 5kg, trehalose 0.5kg, edible colloid 0.05kg (containing sodium alginate 0.03kg and gelatin 0.02kg), modified soybean lecithin 0.05kg, acidity regulator Potassium citrate 0.02kg is mixed with natamycin 0.05kg, and is stirred uniformly in a blender to obtain mochi premix powder 9.67kg;

[0052] (2) Put the mochi premix powder obtained in step (1) into a steamer, add 5.80kg of clear water, and stir into a uniform dough; control the internal pressure of the steamer at 0.045Mpa and steam for 30min; The pressure is controlled at 0.06Mpa, 38.68kg of high maltose syrup is added, after stirring evenly, 1.45kg of emulsified oil is added to obtain mochi skin slurry;

[0053] (3) Fry the mochi skin slurry obtained in step (2) for 15 minutes, control the solid content at 75%, and cool to 30° C. to obtain the mochi skin material;

[0054] (4) Wrapping the mochi skin material obtained in step (3) with stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com