Low-temperature pack boronizing steel part surface-strengthening treatment device and method

A treatment device and surface strengthening technology, which is applied in the field of heat treatment devices, can solve the problems of reducing the effect of boronizing, etc., and achieve the effects of improving service life and capacity, simplifying the device, and improving surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

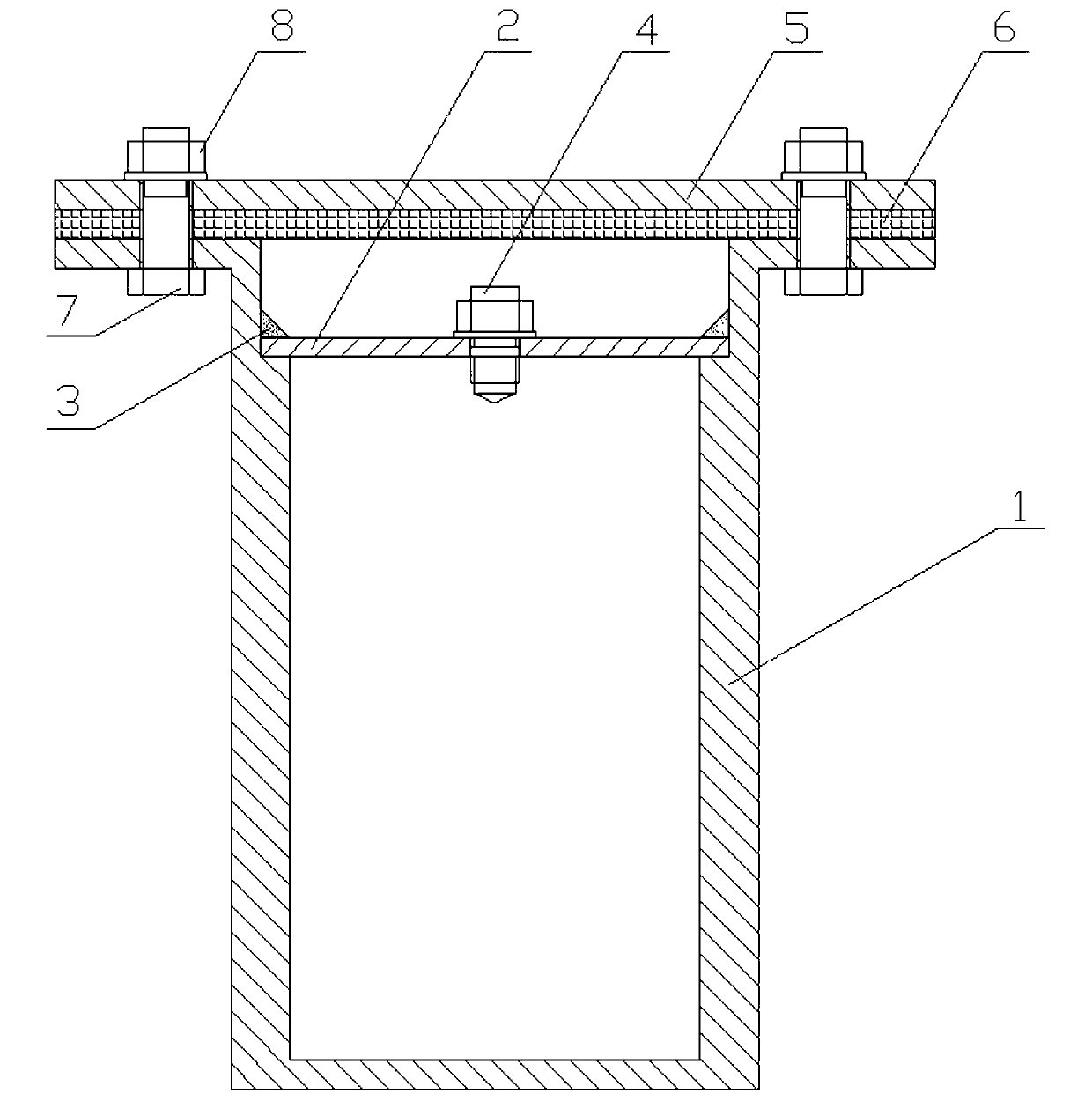

[0020] figure 1 It shows a low-temperature solid boronizing surface strengthening treatment device for steel parts, including seepage box 1, inner cover 2, water glass mud 3, short bolt 4, outer cover 5, asbestos board 6, clamping bolt 7, nut 8 . The seepage box 1 is made of stainless steel pipe and steel plate or common steel pipe and steel plate welded together, generally 10 mm steel plate is more suitable. The short bolt 4, the clamping bolt 7 and the nut 8 are made of stainless steel. The thickness of the asbestos board 6 is 5-15 mm.

[0021] The upper end of the seepage box 1 is open, and the upper mouth section of the seepage box 1 is provided with an inner cover fixing section with a slightly larger diameter, and the lower plane of the inner cover 2 is connected to the inner cover fixing section of the seepage box 1 to the inner chamber Match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com