Treatment process method for improving performance of 5052 aluminum alloy friction stir welding joint

A friction stir and treatment technology technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problem that friction stir welded joints tend to soften, there is no report on the cryogenic treatment technology of friction stir welded joints, and the mechanical properties of the joints decline. and other problems, to achieve the effect of improving mechanical properties, strength and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] After the 5052 aluminum alloy is welded by friction stir welding, it is treated at -160~-190°C for 20~24 hours.

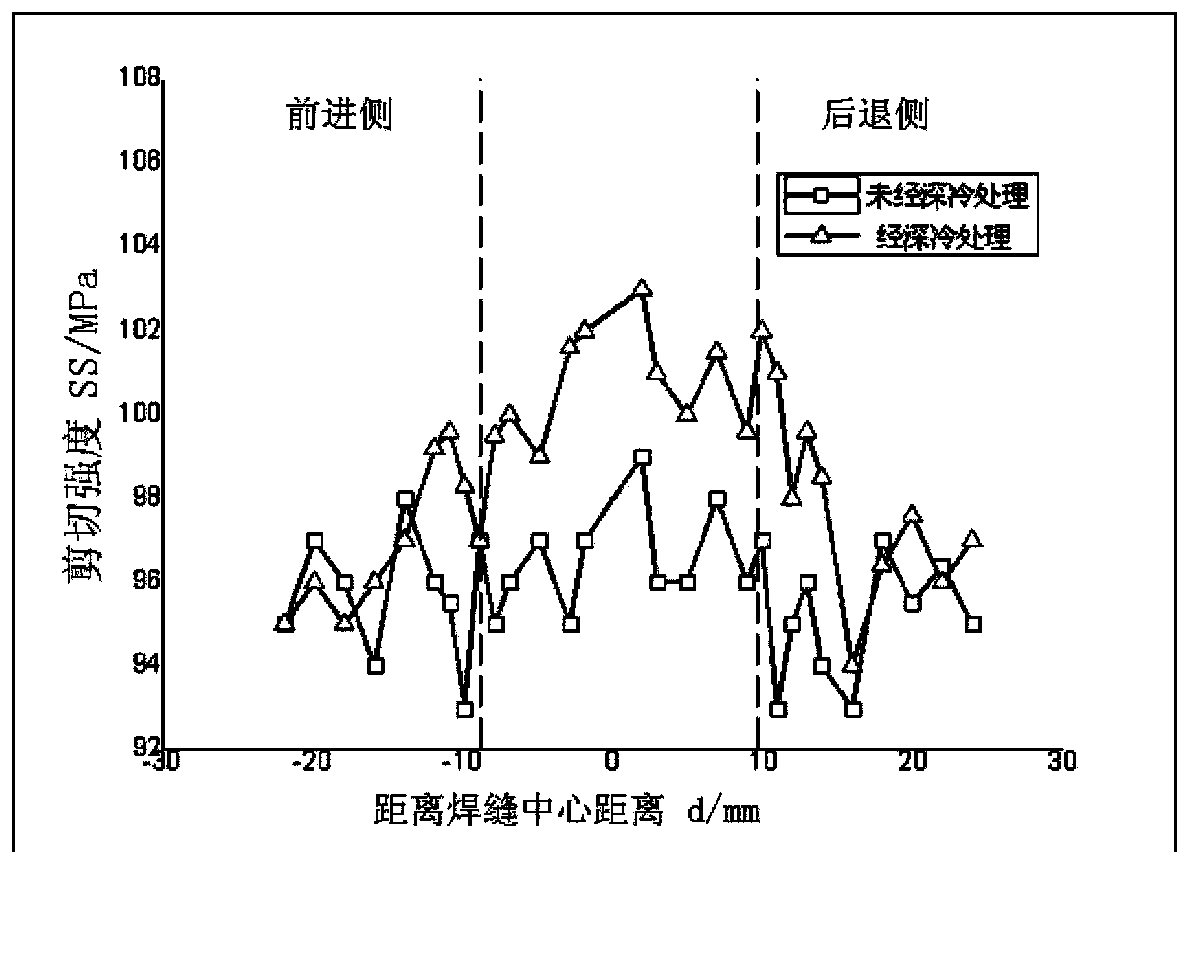

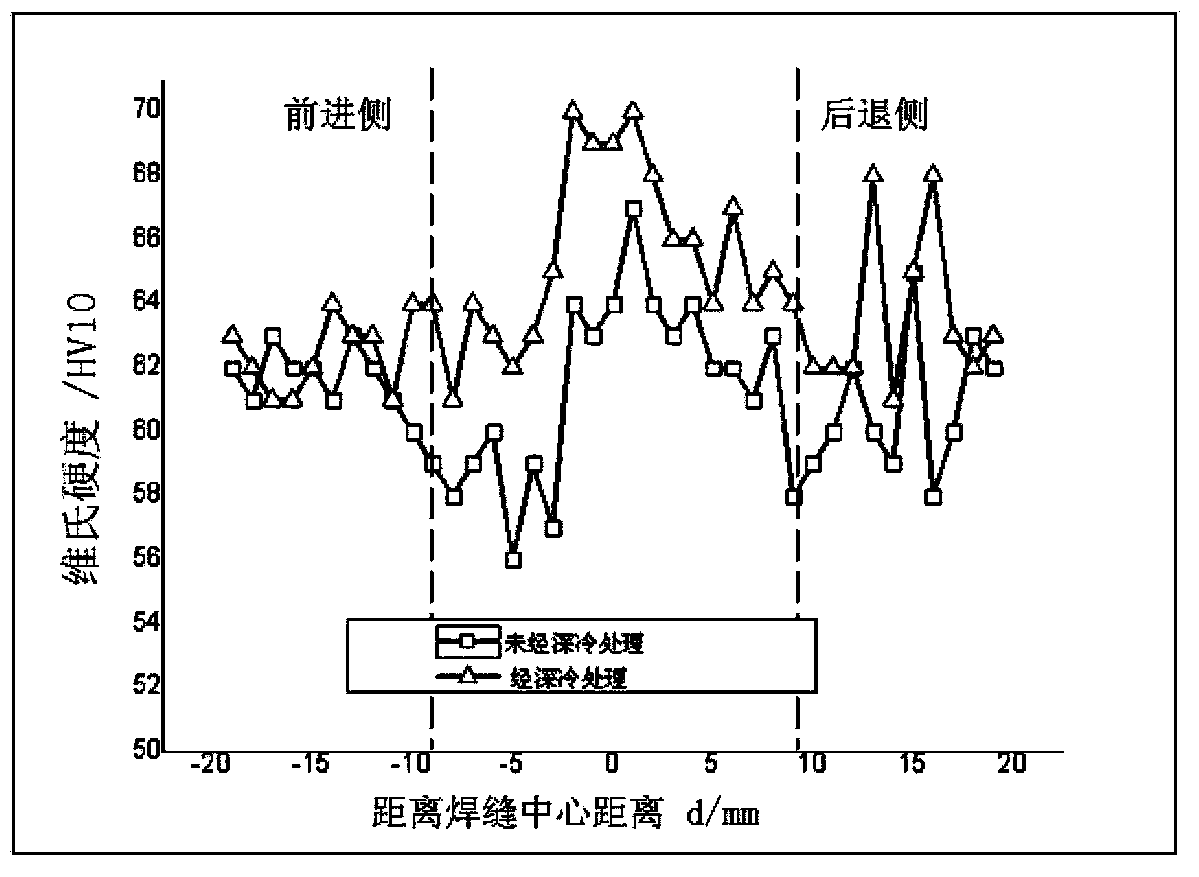

[0018] Wherein the micro-shear strength value and hardness value distribution parameters of each zone of the welded joint obtained in embodiment 1 are as follows: figure 1 and figure 2 shown. The distribution of micro-shear strength and hardness value of the welded joint obtained by the method is obviously higher than that of the friction stir welded joint without cryogenic treatment.

Embodiment 2

[0020] After the 5052 aluminum alloy is welded by friction stir welding, it is treated at -160 to -190°C for 4 to 6 hours.

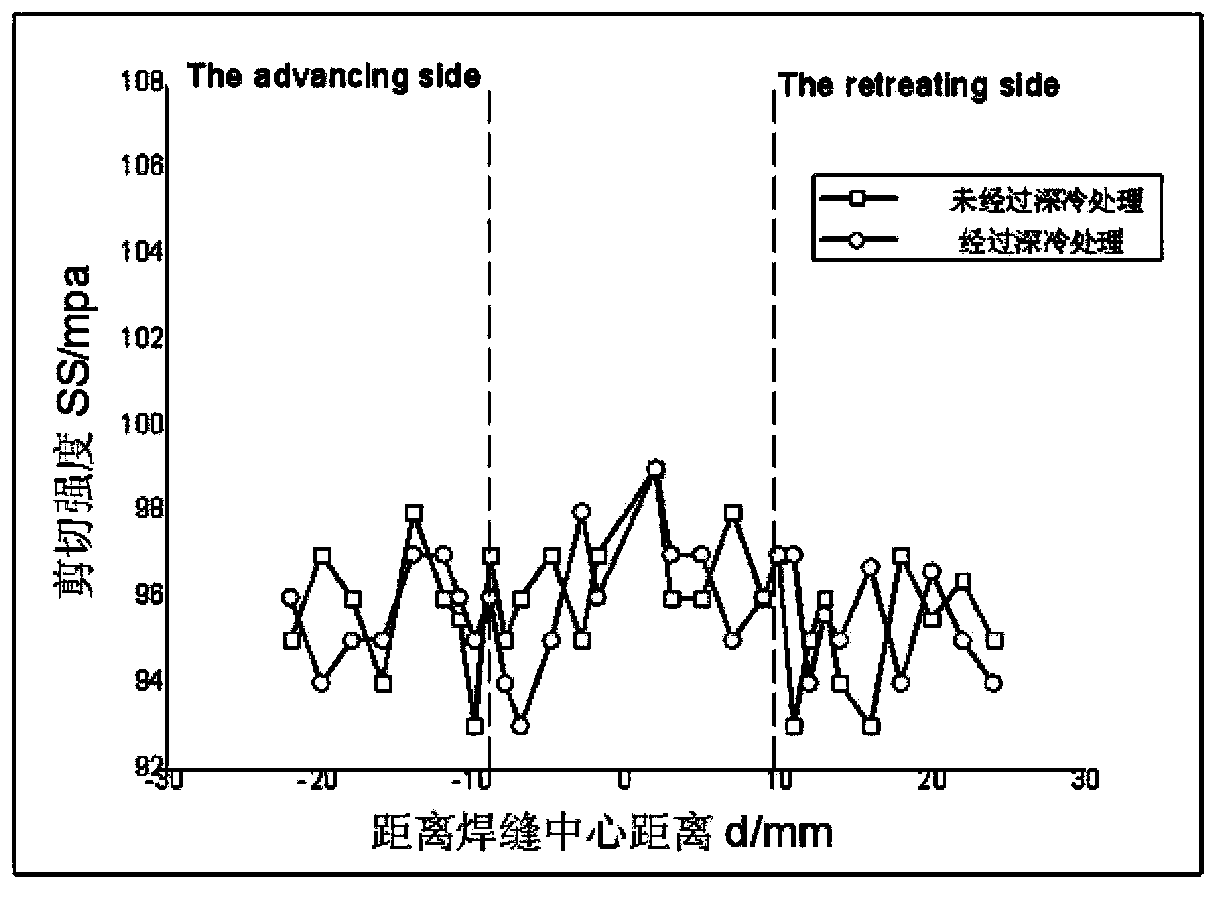

[0021] Wherein the micro-shear strength value and hardness value distribution parameters of each zone of the welded joint obtained in embodiment 1 are as follows: figure 2 and image 3 shown. The distribution of micro-shear strength and hardness value in some regions of the welded joint obtained by the method is higher than that of the friction stir welded joint without cryogenic treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com