Frictional wear test method and test device for sealing ring

A friction and wear, test method technology, applied in the direction of testing wear resistance, etc., to achieve the effect of improving service performance and life, and slowing excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of test method of sealing ring friction and wear, comprises the following steps:

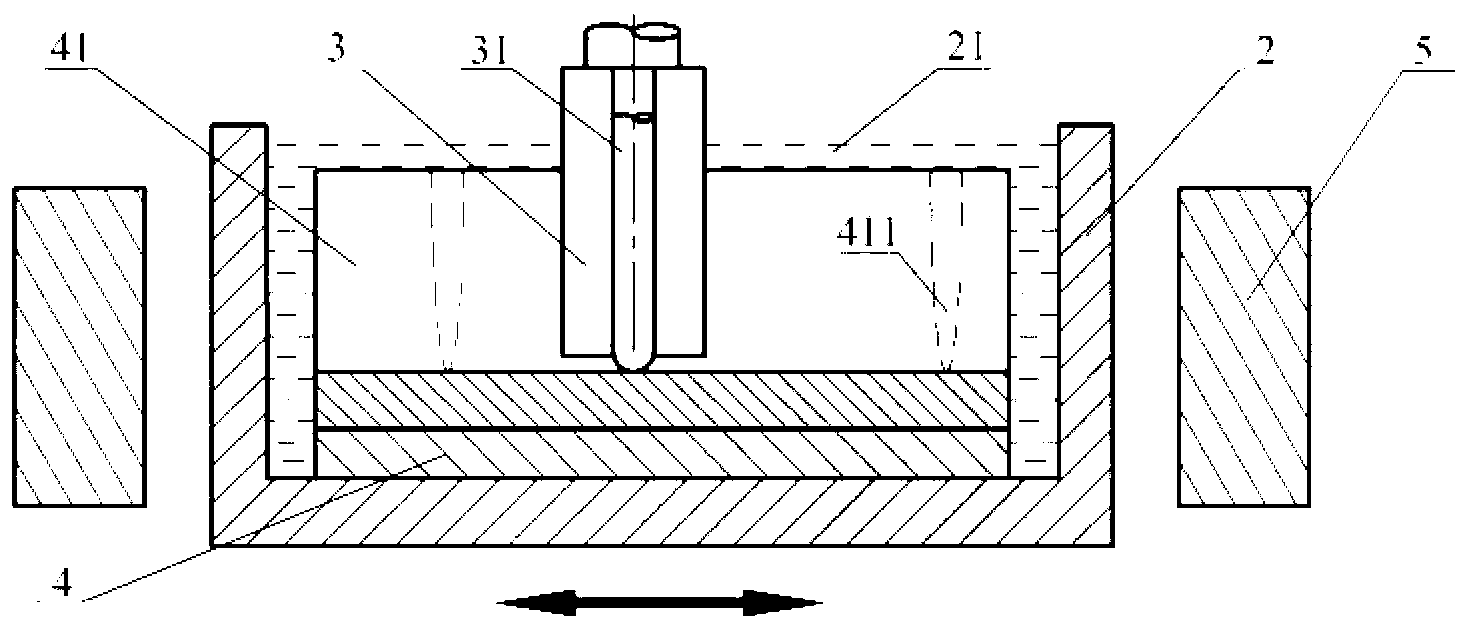

[0026] 1) Fix the lower test piece on the lower fixture, and keep the central axis of the semi-cylindrical groove of the lower test piece consistent with the movement direction of the horizontal reciprocating device;

[0027] 2) After inserting the upper test piece into the arc-shaped receiving groove between the upper fixture seat and the clamping cover, control the axial compression rate of the upper test piece by adjusting the adjusting bolt and fix it on the upper fixture; adjust the two-dimensional adjustable The position of the moving table is such that the central axis of the semi-cylindrical end face of the upper fixture and the central axis of the semi-cylindrical groove of the lower specimen are in the same vertical plane;

[0028] 3) Add the test medium into the medium tank and set the test temperature, normal load and friction frequency through the control ...

Embodiment 2

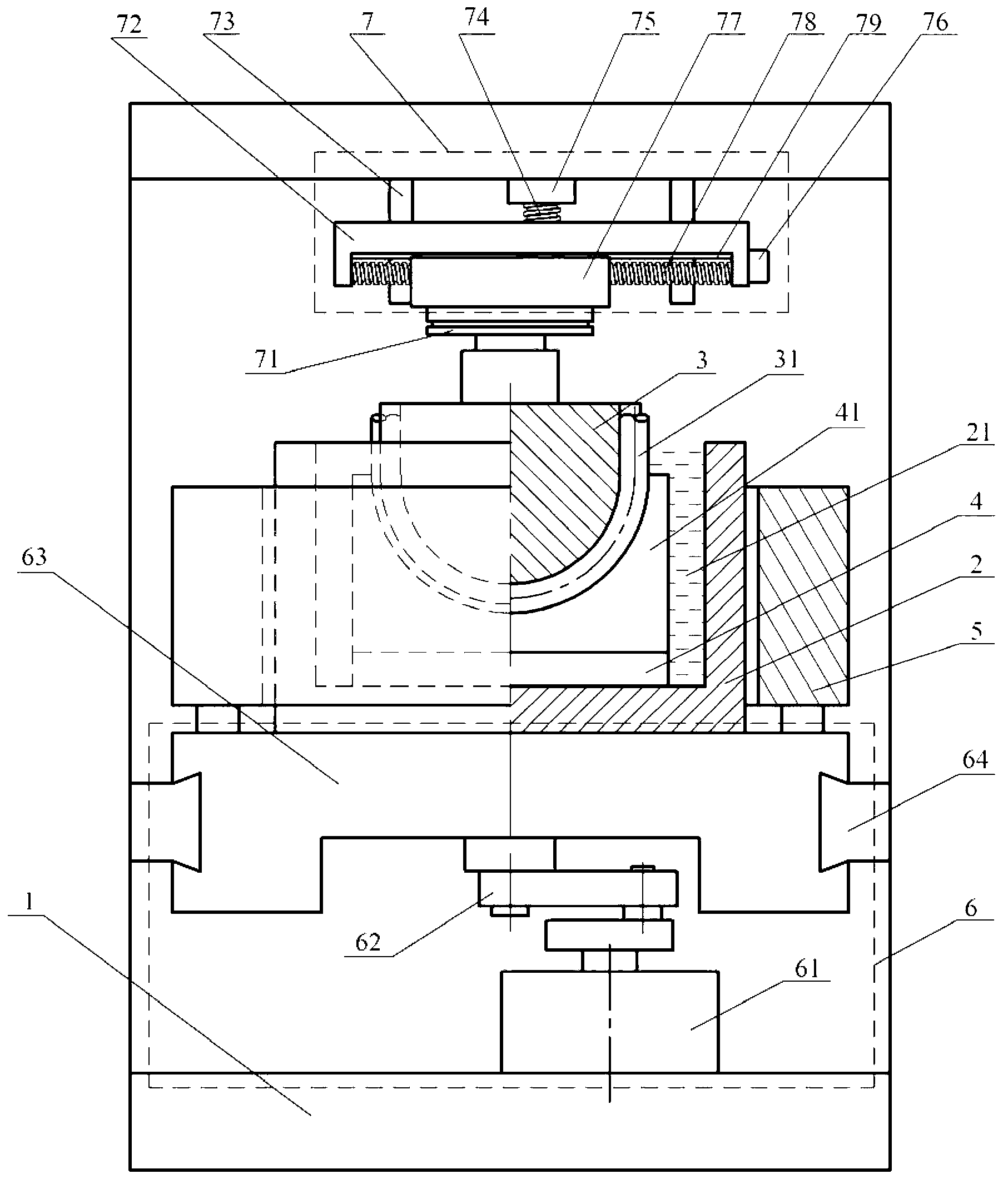

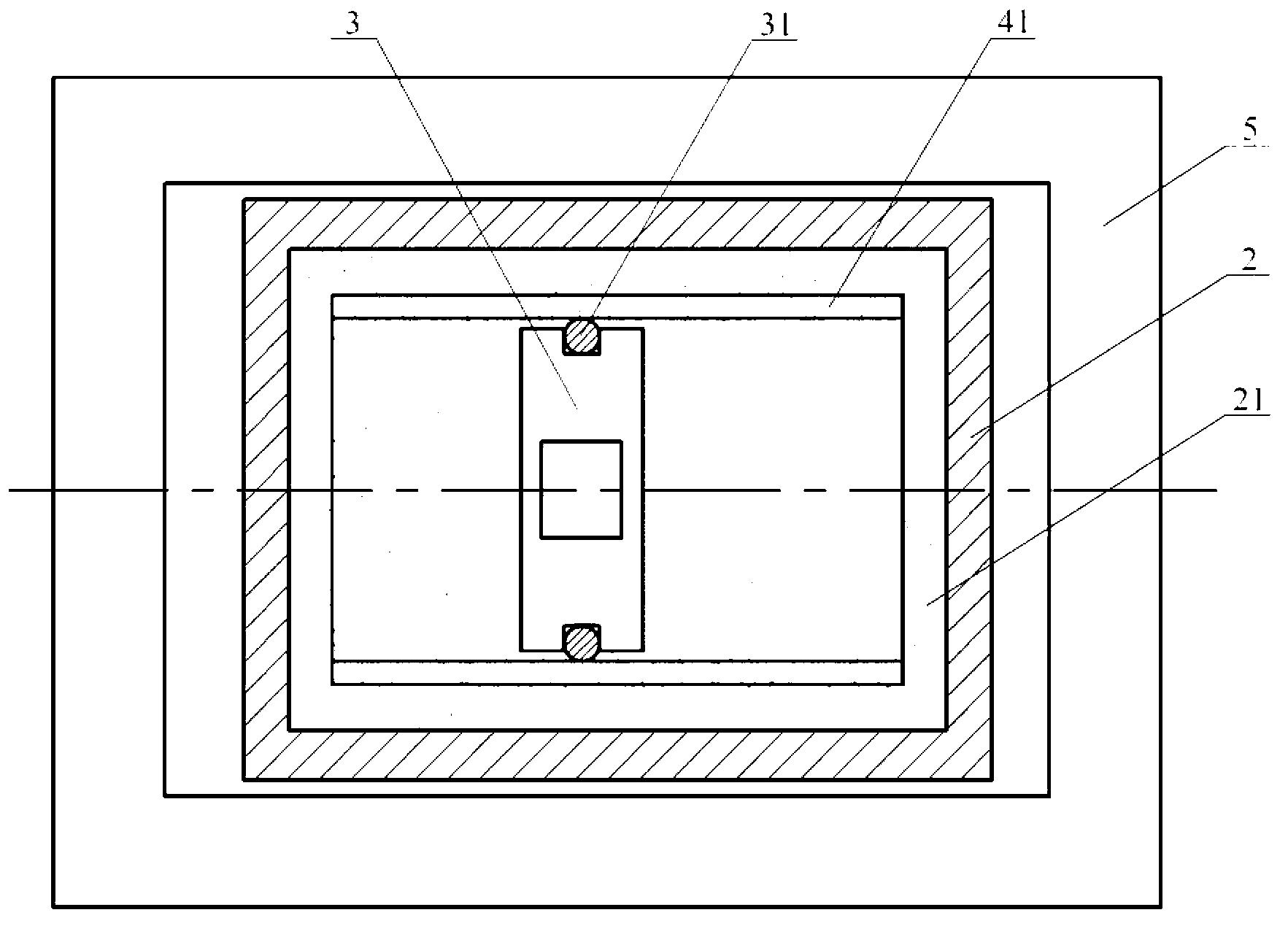

[0030] Example 2 A test device constructed according to the test method described in Example 1, including a machine base 1, a medium tank 2, an upper fixture 3, a lower fixture 4, a temperature console 5, a horizontal reciprocating device 6, and a two-dimensional adjustable moving Platform 7 and data acquisition control system, the two-dimensional adjustable mobile platform 7 is fixed on the upper part of the base 1, and the lower part of the two-dimensional adjustable mobile platform 7 is equipped with a two-dimensional force sensor 71; The two-dimensional mechanical sensor 71 fixedly clamps the upper fixture 3 of the upper test piece 31; the medium tank 2 is installed above the horizontal reciprocating device 6, and the medium tank 2 is fixed to clamp the lower test piece. The lower fixture 4 of the part 41, the test medium 21 is filled in the medium tank 2; the horizontal reciprocating device 6 is fixed on the base 1; the two-dimensional adjustable mobile table 7, the The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com