Battery thermal management system based on oil-electricity hybrid electric vehicle

An oil-electric hybrid power and battery thermal management technology, applied in electric vehicles, secondary batteries, electric traction, etc., can solve the problems of high cost and consumption of internal combustion engine power, achieve low manufacturing cost, improve performance and life, overall simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

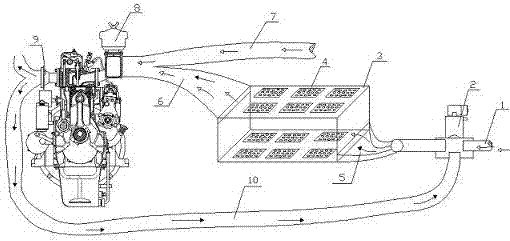

[0010] A battery thermal management system based on a gasoline-electric hybrid vehicle, characterized in that it includes an air-cooled intake pipe 1 connected in sequence, a two-position three-way solenoid valve 2, a power battery box intake pipe 5, a power battery box 3, Power battery box air outlet 6, air filter element 8, exhaust gas recirculation device 9, exhaust gas recirculation manifold 10, a gasoline-electric hybrid vehicle consists of two power source systems, an internal combustion engine and a power battery, when the actual temperature of the power battery 4 is higher than At the upper limit of the ideal working temperature, by adjusting the position of the two-position three-way solenoid valve 2, the air-cooled intake pipe 1 and the power battery box intake pipe 5 are connected, and the negative pressure formed by the internal combustion engine during the intake stroke is used to introduce the power of atmospheric flow The battery box 3 air-cools the power battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com