Drill rod for directional branch drilling

A technology of directional branches and drill pipes, applied in the fields of drill pipes and directional drilling, which can solve the problems of easy locking of drilling tools, excessive wear of male and female joint threads, uneven drilling force of directional drilling, etc., and reduce the probability of fracture or deformation , Avoid excessive thread wear, avoid the effect of sundries on the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

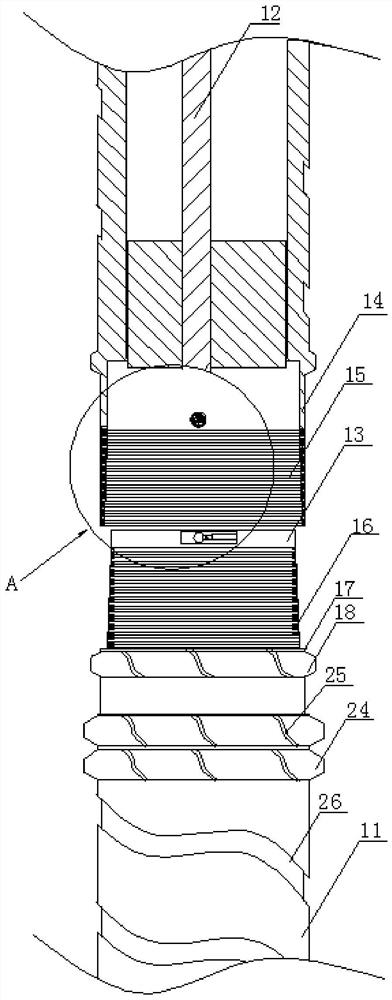

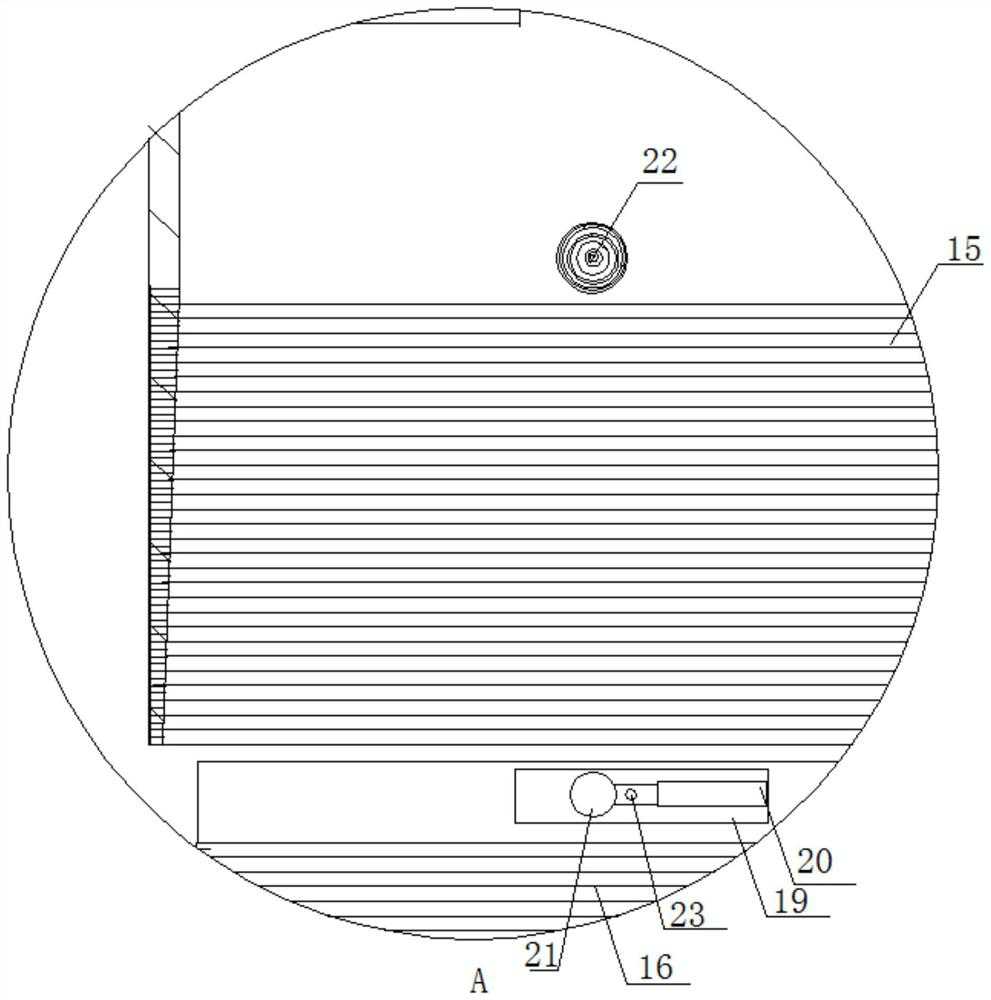

[0041] refer to figure 1 and figure 2 , the present embodiment provides a drill pipe for directional branch drilling, including interconnected drill pipe bodies, the drill pipe body includes a pipe body 11 and a cable 12 arranged in the pipe body 11, and one end of the pipe body 11 is provided with a male The joint 13, the other end of the pipe body 11 is provided with a female joint 14, the male joint 13 and the female joint 14 and the pipe body 11 are connected by friction welding, the inner peripheral wall of the female joint 14 is provided with an inner thread 15, and the outer peripheral wall of the male joint 13 is provided with a External thread 16, male connector 13 and the pipe body 11 are connected with a docking platform 17. The end of the female connector 14 is in contact with the docking platform 17. The outer circumference of the docking platform 17 is surrounded by a reinforcing protrusion 18 with a trapezoidal cross-section. An anti-loose clamping assembly is...

Embodiment 2

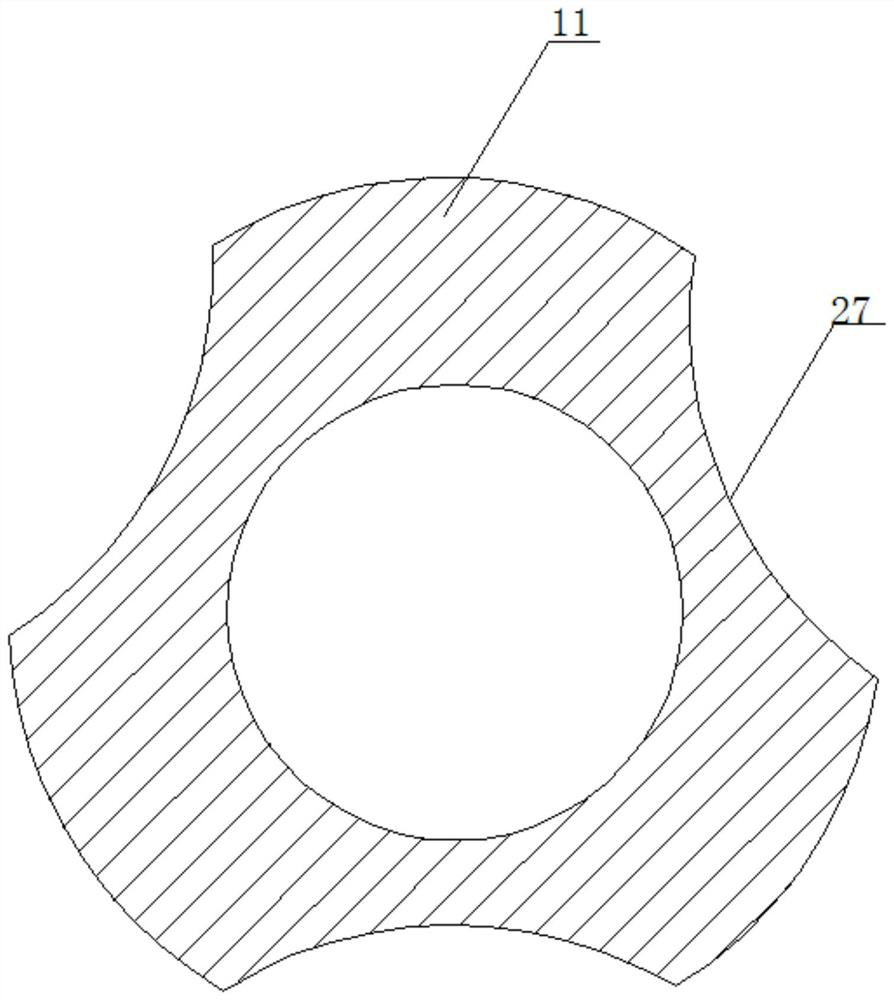

[0046] The structure of embodiment 2 is basically the same as that of embodiment 1, refer to image 3 , the difference is that the outer circumference of the pipe body 11 is provided with a discharge screw 26, the pitch of the discharge screw 26 is not less than 0.8cm, and the thread taper of the discharge screw 26 is 1:30.

[0047] Implementation principle: the outer circumference of the docking table 17 is surrounded by a reinforcing protrusion 18 with a trapezoidal cross-section, which can further strengthen the strength of the connection between the docking table 17 and the external thread 16 of the male joint 13 and the pipe body 11, and the reinforcing protrusion 18 can be worn first. , to avoid excessive wear of the docking station 17, and at the same time, the convex reinforcing protrusion 18 can clean the debris in the drilled hole and avoid debris from wearing the joint. It is provided with an anti-loose clamping component. During installation, the inner thread 15 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com