Integrated engine oil filter

A technology of oil filter and oil filtration, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., which can solve the problems of not being able to adapt to the engine, the impact of environmental protection, and a large volume, so as to facilitate replacement and reduce pollution , The effect of improving the life of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose of the present invention can be achieved through the following technical solutions:

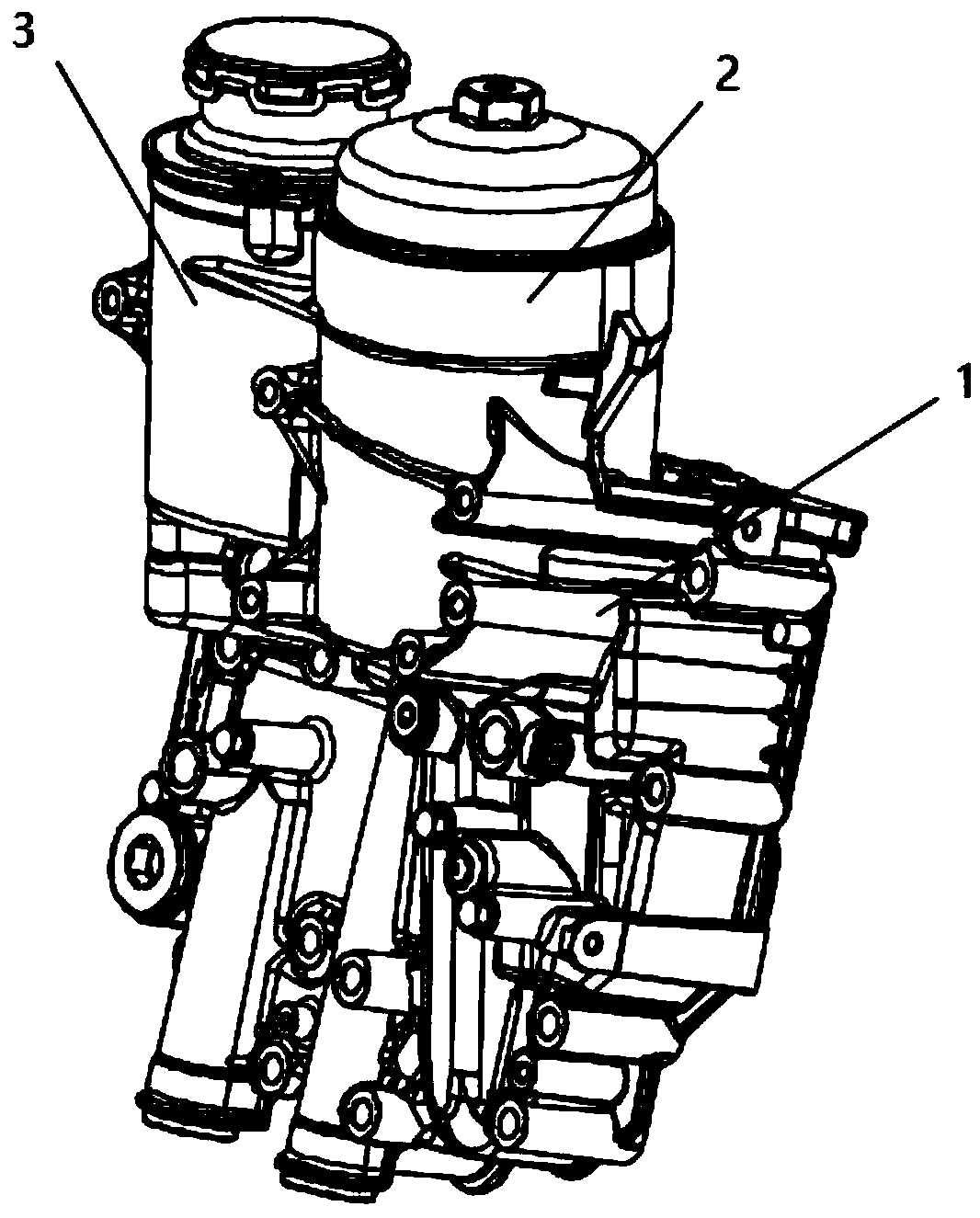

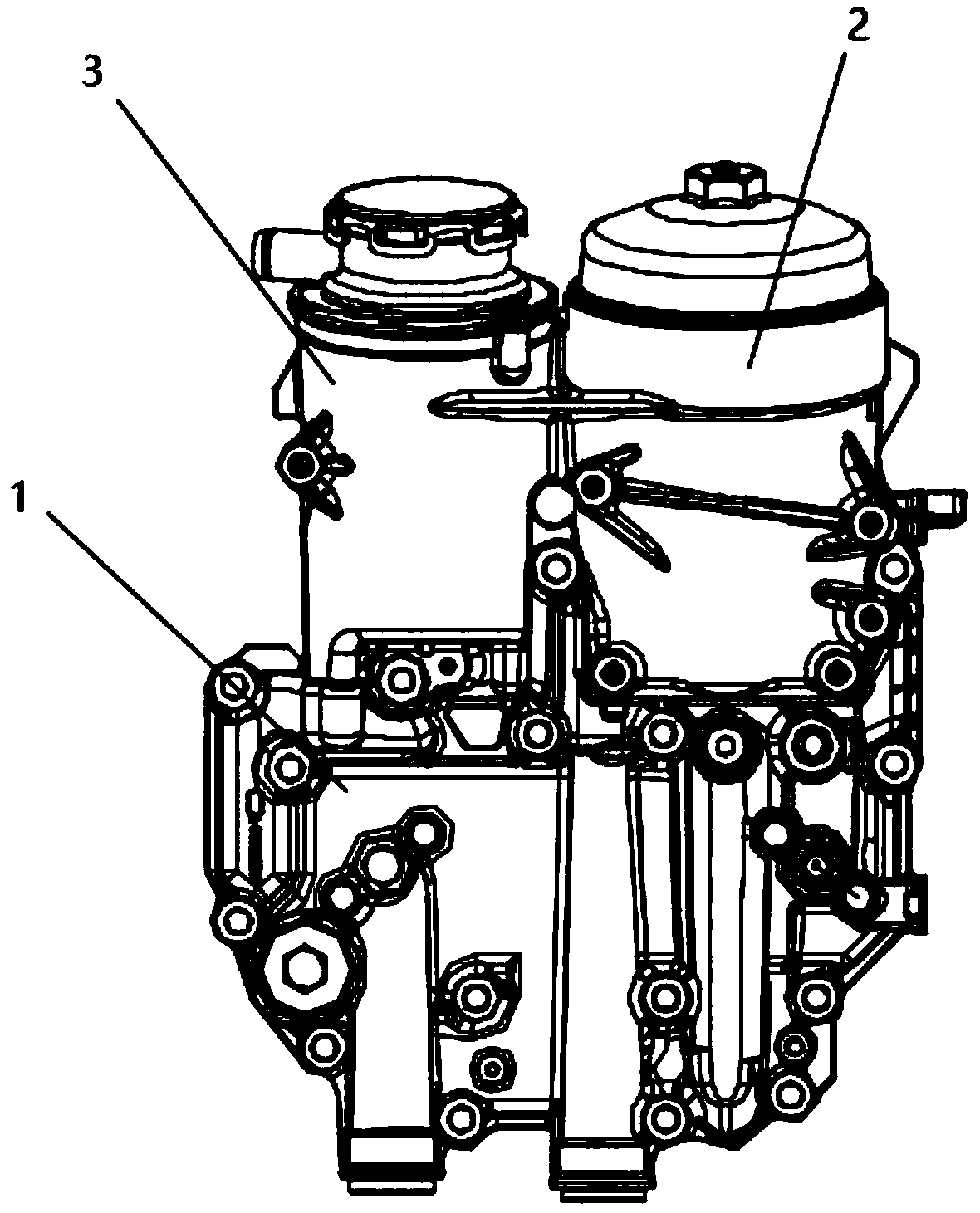

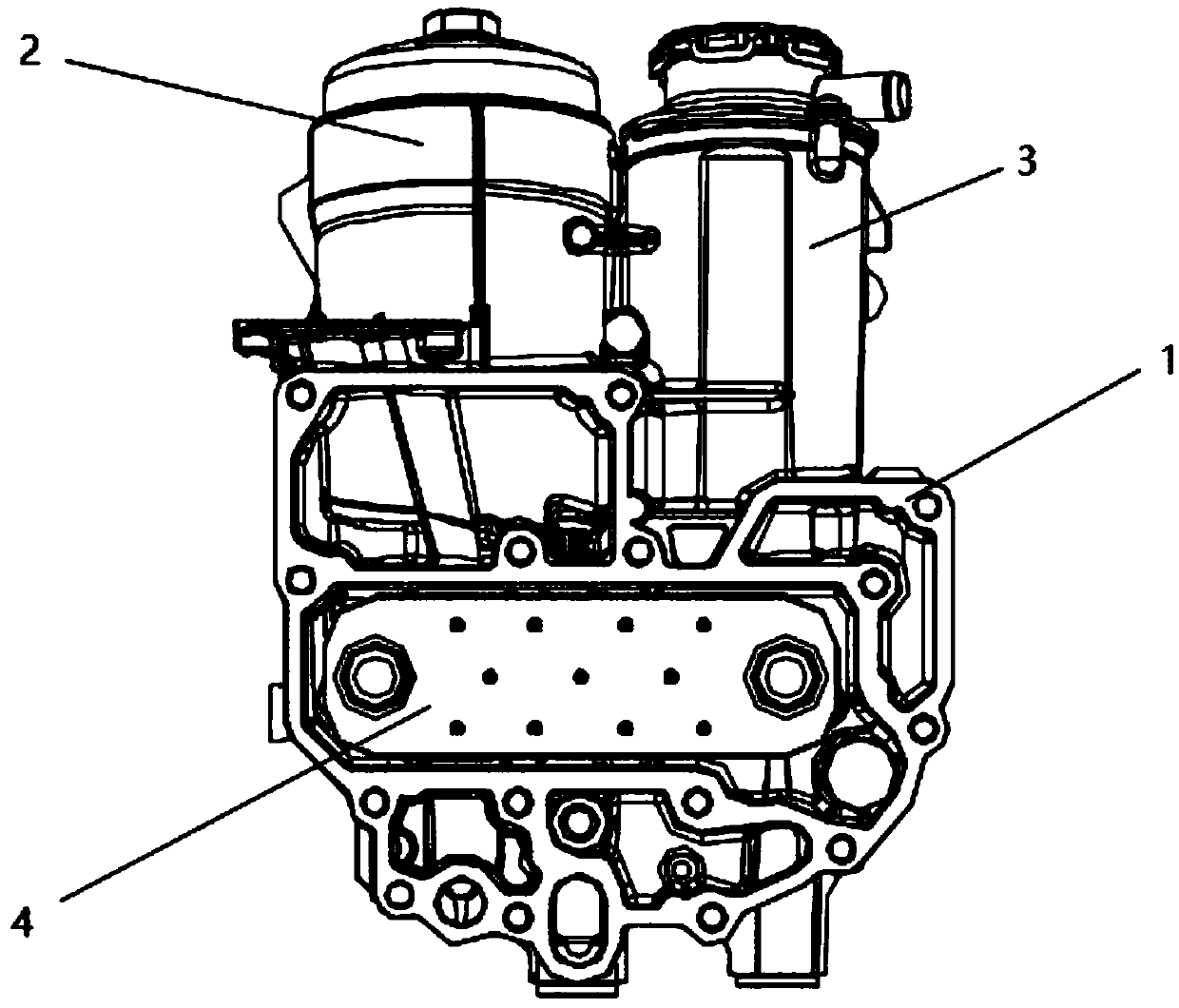

[0029] An integrated oil filter, see Figure 1-8 , including housing 1, oil filter module 2, oil-gas separation module 3, oil cooler 4, paper filter element 5, bypass valve 6, service valve 7, safety valve 8;

[0030] The top of the housing 1 is provided with an oil filter module 2 and an oil-gas separation module 3, and an oil cooler 4 is installed on the housing 1 below the oil filter module 2 and the oil-gas separation module 3; the oil filter module 2 is separated from the oil-gas Module 3 is independent in function. The engine oil filter module 2 filters the engine oil in the engine lubrication system to reduce the excessive wear of the engine caused by particles and improve the service life of the engine; the oil-gas separation module 3 purifies the engine to prevent air leakage from the piston cylinder; The oil particles in the piston cylinder are separated, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com