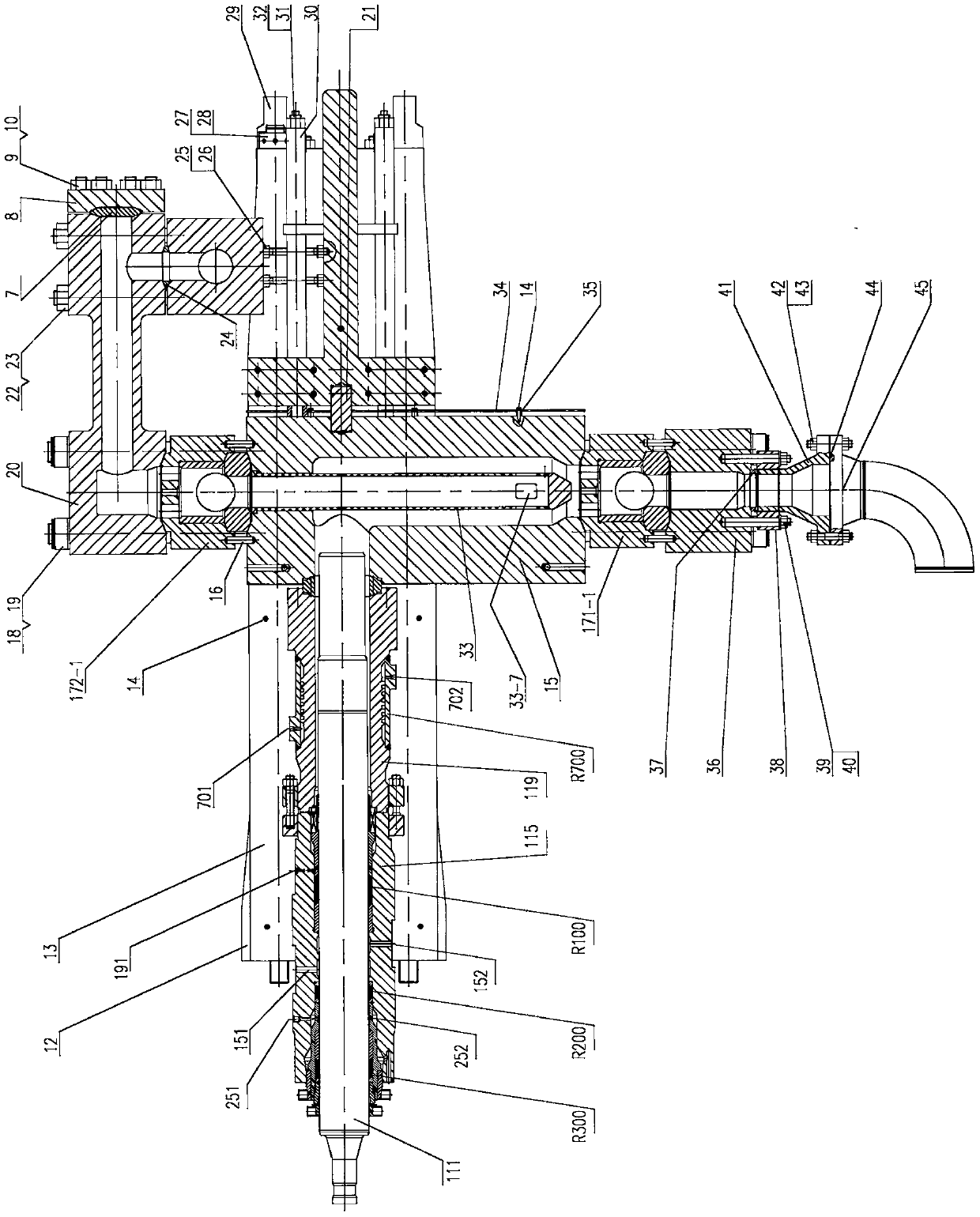

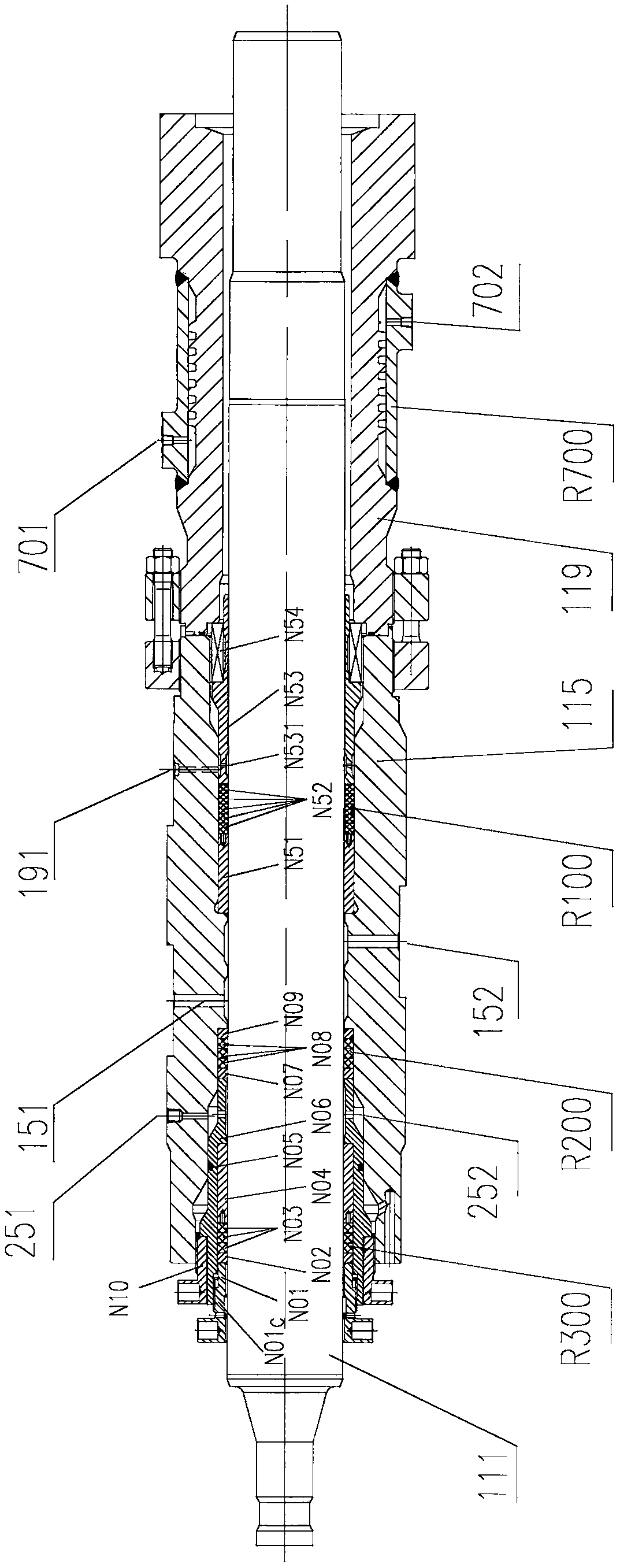

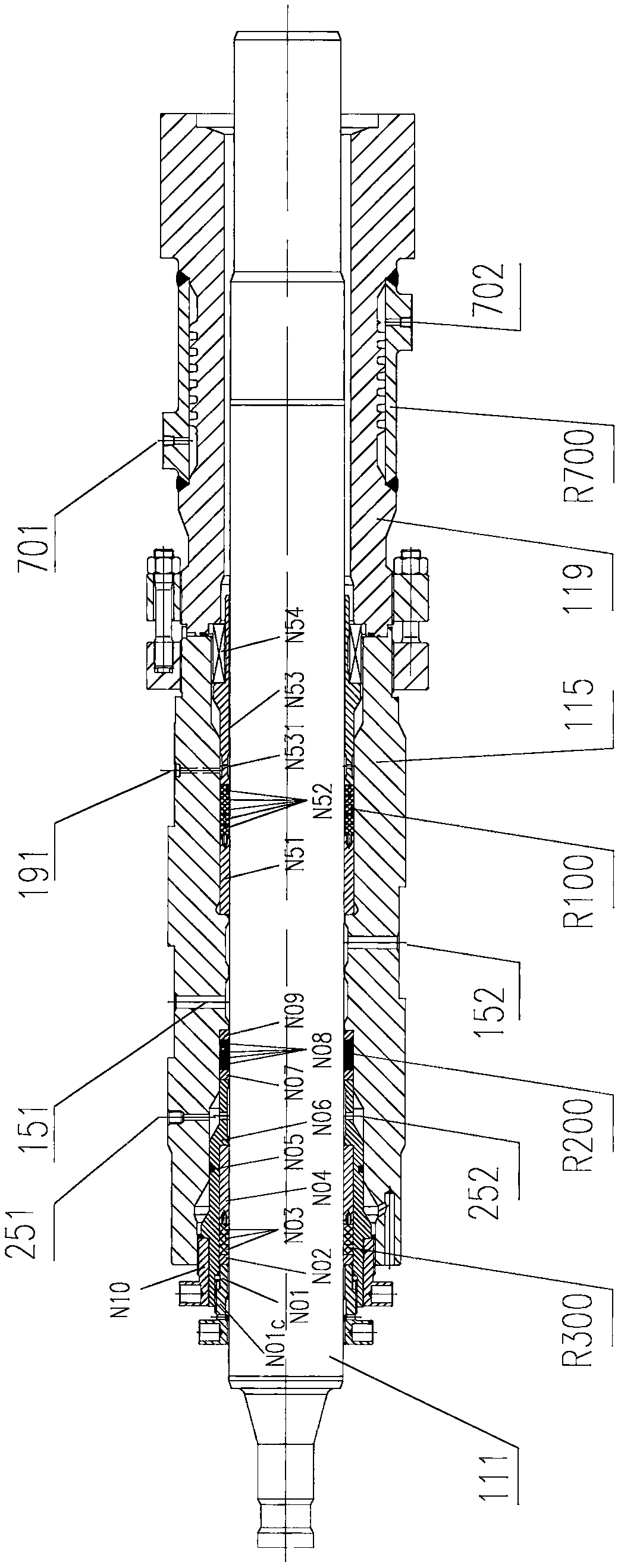

Three-filler type reciprocating seal using pressurizing middle flushing cavity and reciprocating pump thereof

A packing type, reciprocating pump technology, which is applied to parts of pumping devices for elastic fluids, variable displacement pump parts, pump components, etc., and can solve problems such as no clear operation method of flushing oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0462] As described in Table 1, the coal slurry feed pump SHFB of Shenhua Erdos Coal-to-oil Branch Company adopts image 3 As shown in the technical scheme of the plunger stuffing box assembly of the present invention, the flushing chamber system between the first packing seal and the intermediate packing seal adopts a pressurized flushing scheme, which can make the main liquid of the pump cylinder harmful ( The probability of high temperature liquid, high solid concentration slurry, corrosive or explosive or toxic or radioactive components) passing through the first packing seal and leaking into the intermediate flushing cavity is almost reduced to zero, which is also conducive to the intermediate flushing liquid entering the first flushing chamber. 1 The gap between the packing seal and the plunger lubricates and cools them, which is beneficial to reduce the oil consumption of high-pressure injection, and can significantly improve the operation safety of the plunger end.

[...

Embodiment 4

[0500] The three-plunger oil-coal slurry feed pump pump set described in Embodiment 4 is a set of electromechanical instrument integration product, and the start, stop, control and monitoring of the pump set can be controlled by a supporting PLC (programmable logic controller) system Execute, and monitor and protect through protocol Ethernet and touch screen, the required hardware and software will be implemented through supporting PLC and SIS (Instrument Safety System).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com