Grinding equipment for aluminum profile fracture

An aluminum profile and fracture technology, which is used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of easy excessive wear of the section, easy to scratch the side wall of the section, scratched workers, etc., to avoid excessive fracture wear. , to avoid excessive starting current and reduce excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

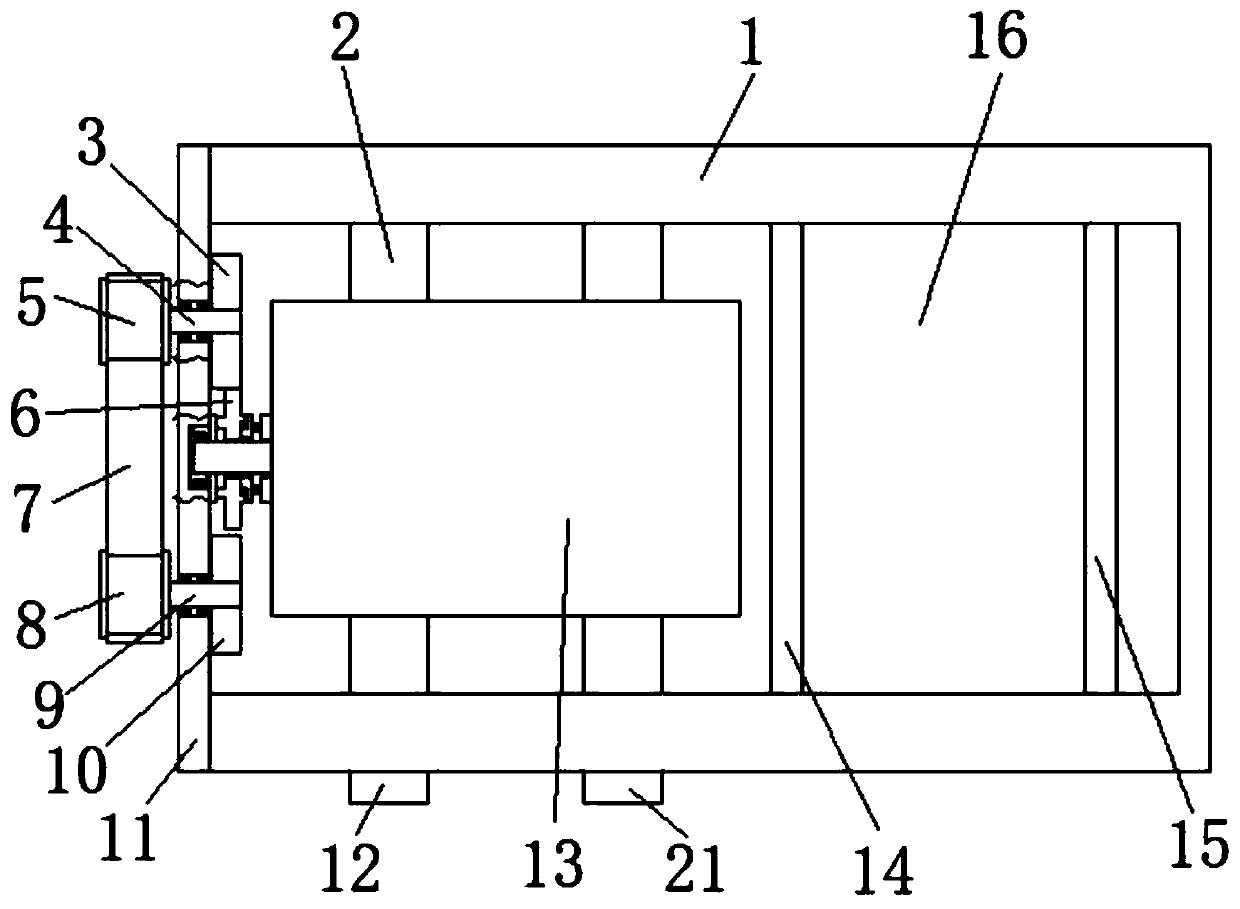

[0026] When in use, the main motor 13 is controlled by the main control switch 21 to provide electric energy for the first switch 12 and the push rod motor 61. When grinding is required, the push rod motor 61 is controlled by the first switch 12 to work, and the chainring 63 is pushed to the left At this time, the main motor 13 continues to work and drives the power wheel 65 to rotate. When the friction edge 66 contacts the friction power wheel 65, it drives the toothed plate 63 to rotate, and then the power generated by the main motor 13 passes through the toothed plate 63 and the transmission gear. The meshing relationship of 3 is transmitted, and then the driving pulley 5 is rotated, and then the abrasive belt 7 is driven by the driving pulley 5 to move, touch the fracture of the aluminum profile, and perform grinding. When there is no need for grinding, release the first switch 12, push the The motor 61 is powered off, and the return spring 67 pulls the connection wheel 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com