Device for controlling temperatures of pole sole of magnetic track brake and track as well as control method thereof

A technology of temperature control device and magnetic rail brake, which is applied in the direction of brake, brake safety system, railway brake system, etc. where the braking element interacts with the track, can solve the problems of increased wear and easy rise, and achieve improved adhesion. , prolong the service life, reduce excessive wear and the effect of stick welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

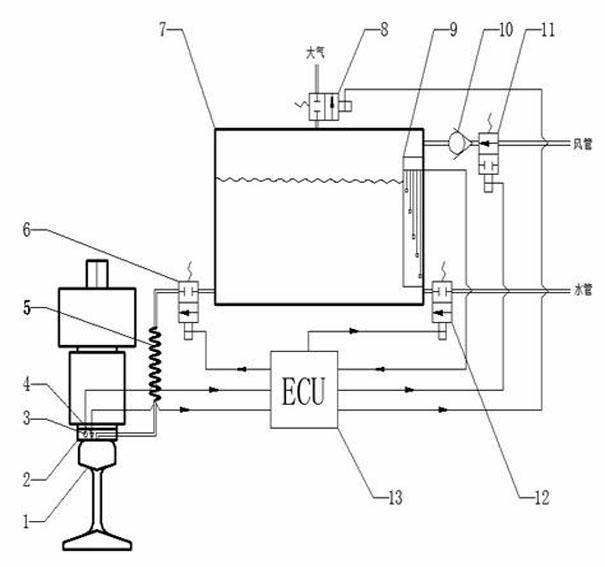

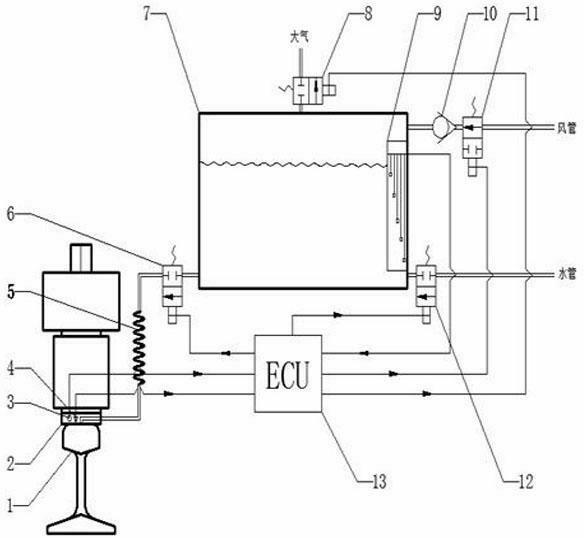

[0015] Such as figure 1 As shown, a control device for magnetic rail brake pole shoes and track temperature of the present invention includes an electronic control unit 13 and first and second non-contact temperature sensors 3 and 4 connected to the electronic control unit 13 through signal lines, wherein, The first non-contact temperature sensor 3 detects the temperature of the brake pole shoe 2 , and the second non-contact temperature sensor 4 detects the temperature of the rail 1 .

[0016] There is a water hole on the side of the brake pole shoe 2, and a small water spray hole is opened on the bottom of the brake pole shoe 2. The water hole and the water spray hole are connected inside the brake pole shoe 2. The elastic hose 5 and the first solenoid valve 6 that is normally closed and powered on are connected to the lower part of the airtight water tank 7 . The cooling water in the water tank 7 enters by the side water holes of the brake pole shoe 2, and can spray water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com