Brushless magnetic drive submersible pump with built-in water cooling system

A technology of magnetic drive and water cooling system, which is applied to components, pumps, and pump devices of elastic fluid pumping devices, and can solve problems such as submersible pump burnout, short service life, and rotor damage, and extend service life , Guarantee normal operation and reduce temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

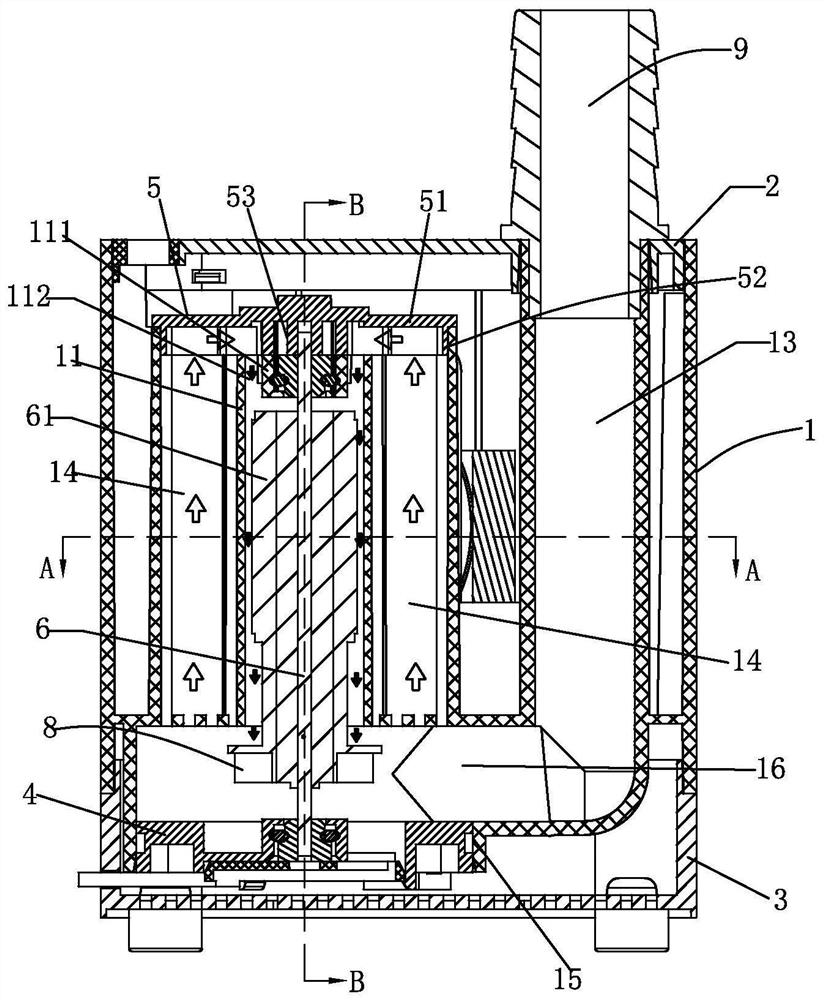

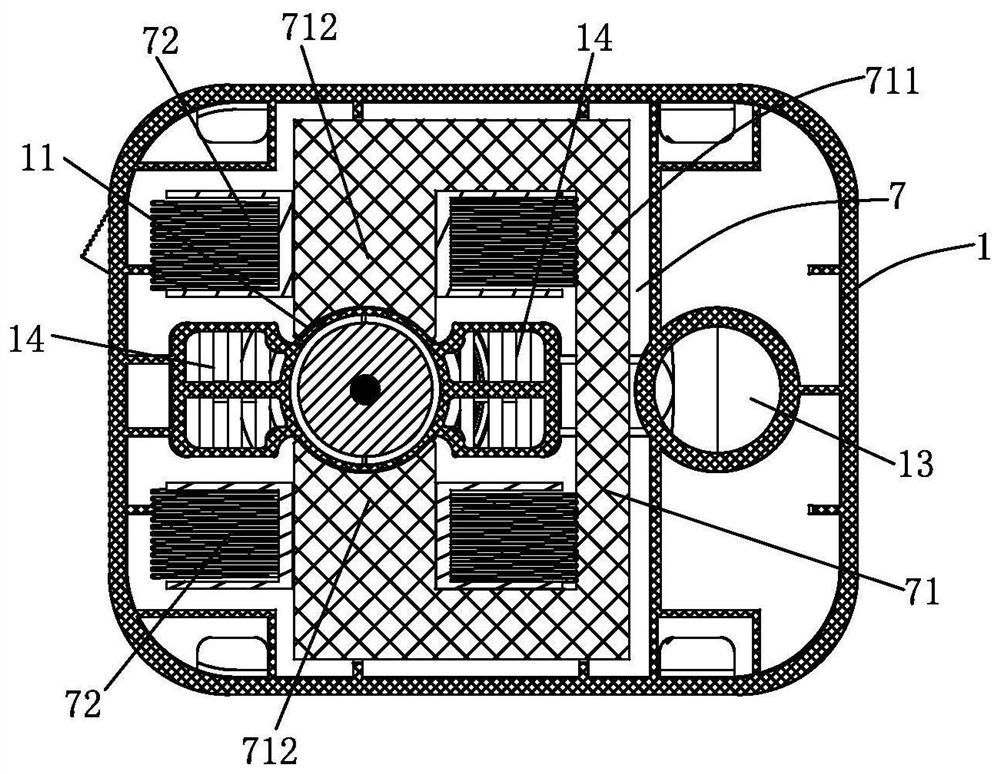

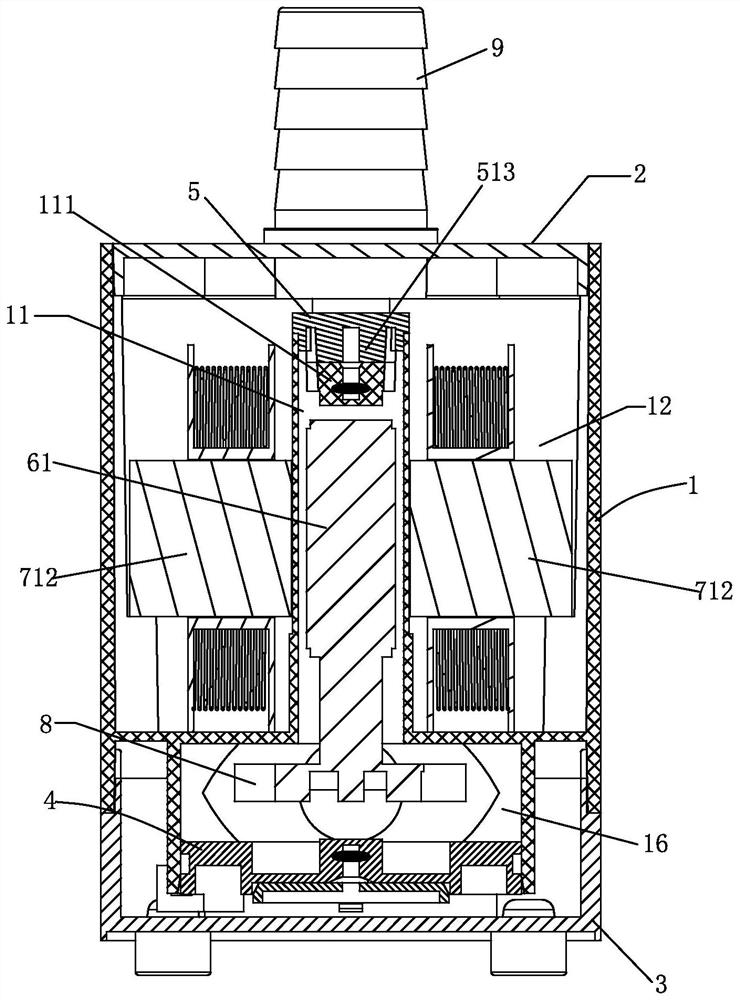

[0027] Such as figure 1 , figure 2 As shown, a brushless magnetic drive submersible pump with a built-in water cooling system is a brushless submersible pump with a built-in water cooling system, including a pump body 1, a pump cover 2, a water inlet casing 3, a lower end cover 4, an upper end cover 5, and a motor Shaft 6, rotor 61, stator 7, impeller 8 and water outlet pipe 9 arranged on the motor shaft, and the pump body 1 is provided with a rotor chamber 11, a stator chamber 12, a pump pressure chamber 16, a pump water inlet 15 and an outlet pipe 13 , the stator 7 includes an iron core 71 and a winding coil 72, and the motor shaft 6 rotates with the lower end cover 4 and the upper end cover 5;

[0028] The housing 1 also includes two longitudinal water passages 14 arranged in the stator cavity 12, such as figure 1 , as shown in Figure 5, the upper part of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com