A reprocessing device for construction waste steel bars

A technology for reprocessing and rebar, which is used in grinding drive devices, devices for coating liquid on surfaces, and manufacturing tools, etc., to ensure the needs of stirring, ensure the quality of rust removal, and reduce excessive wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

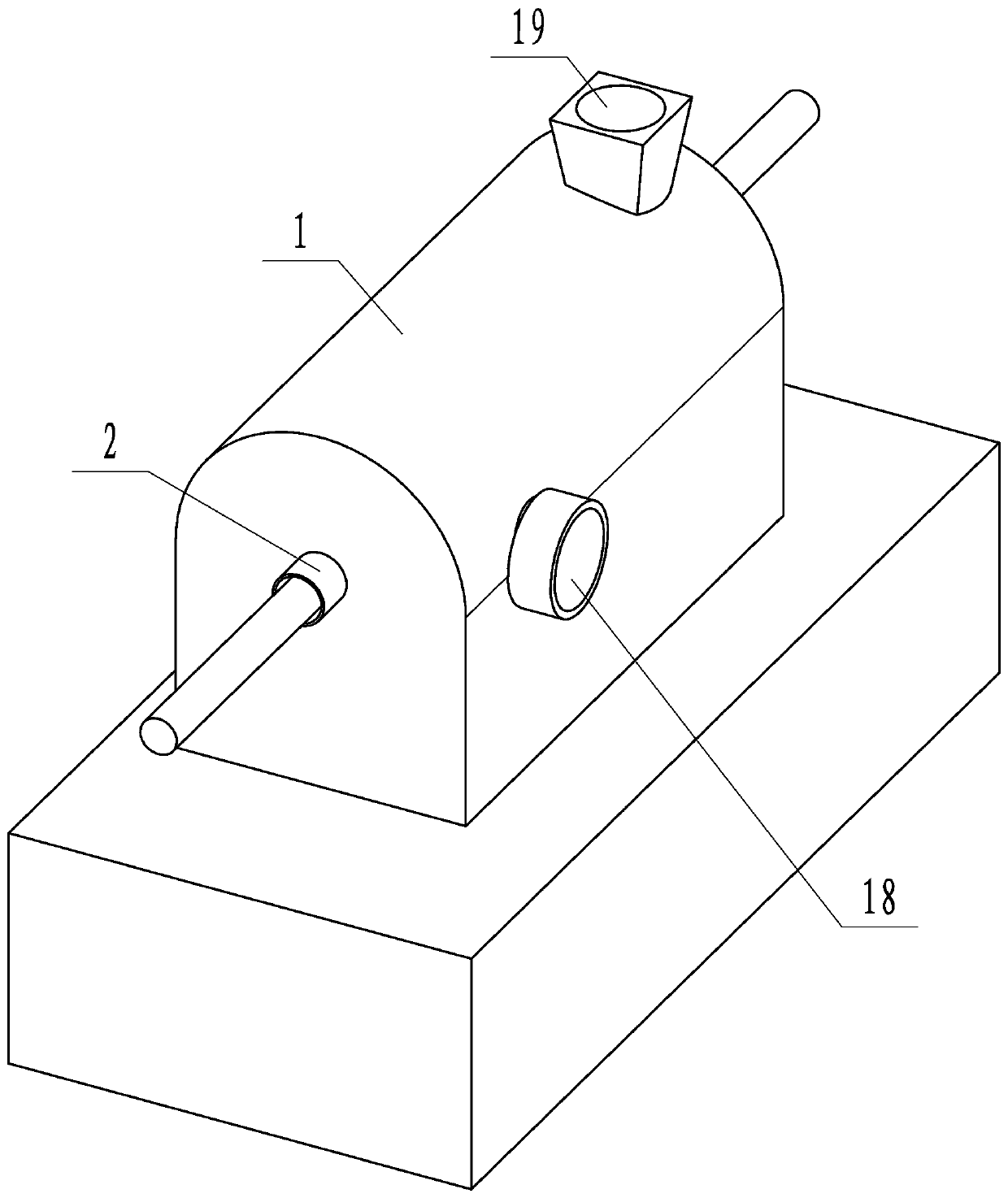

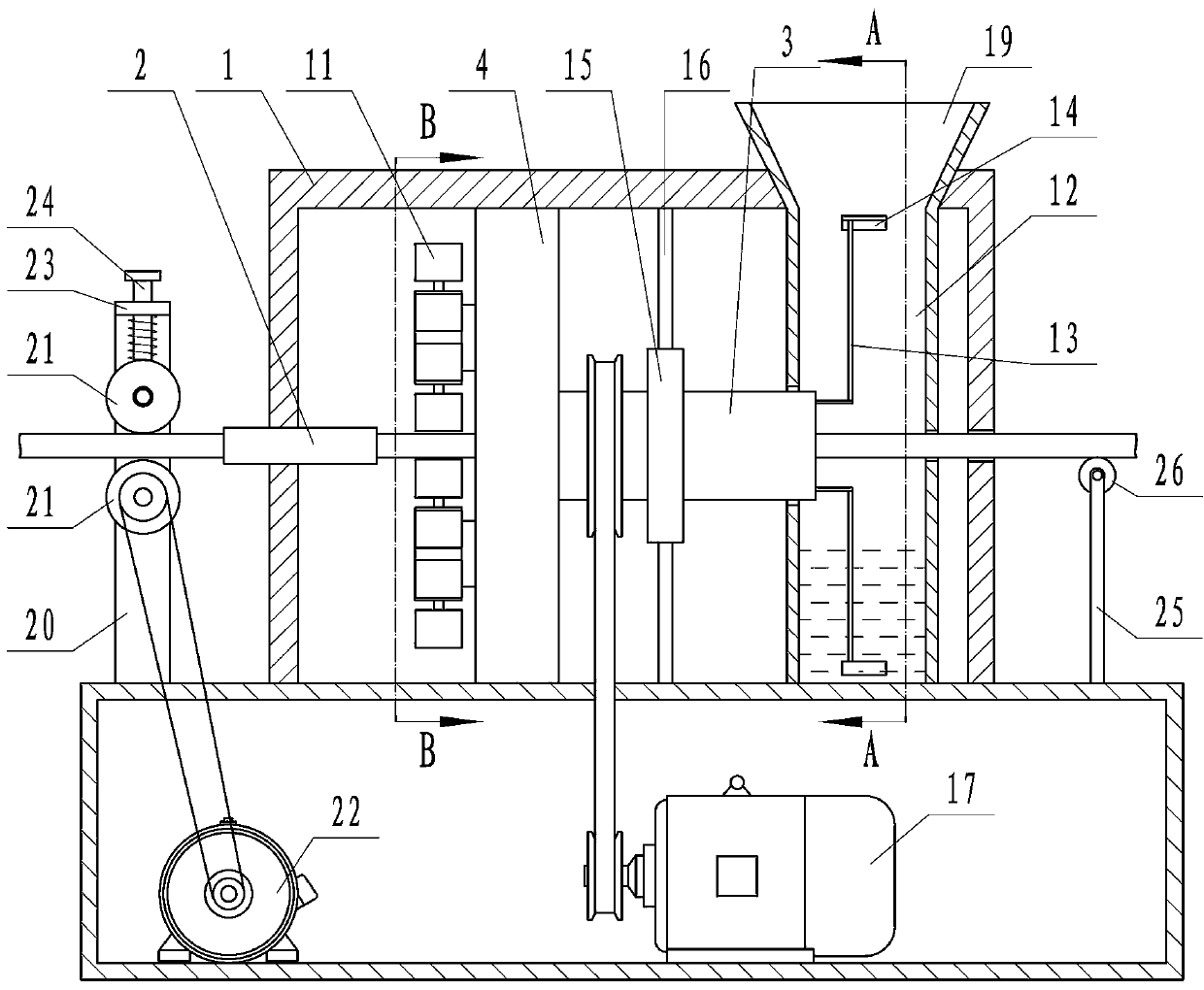

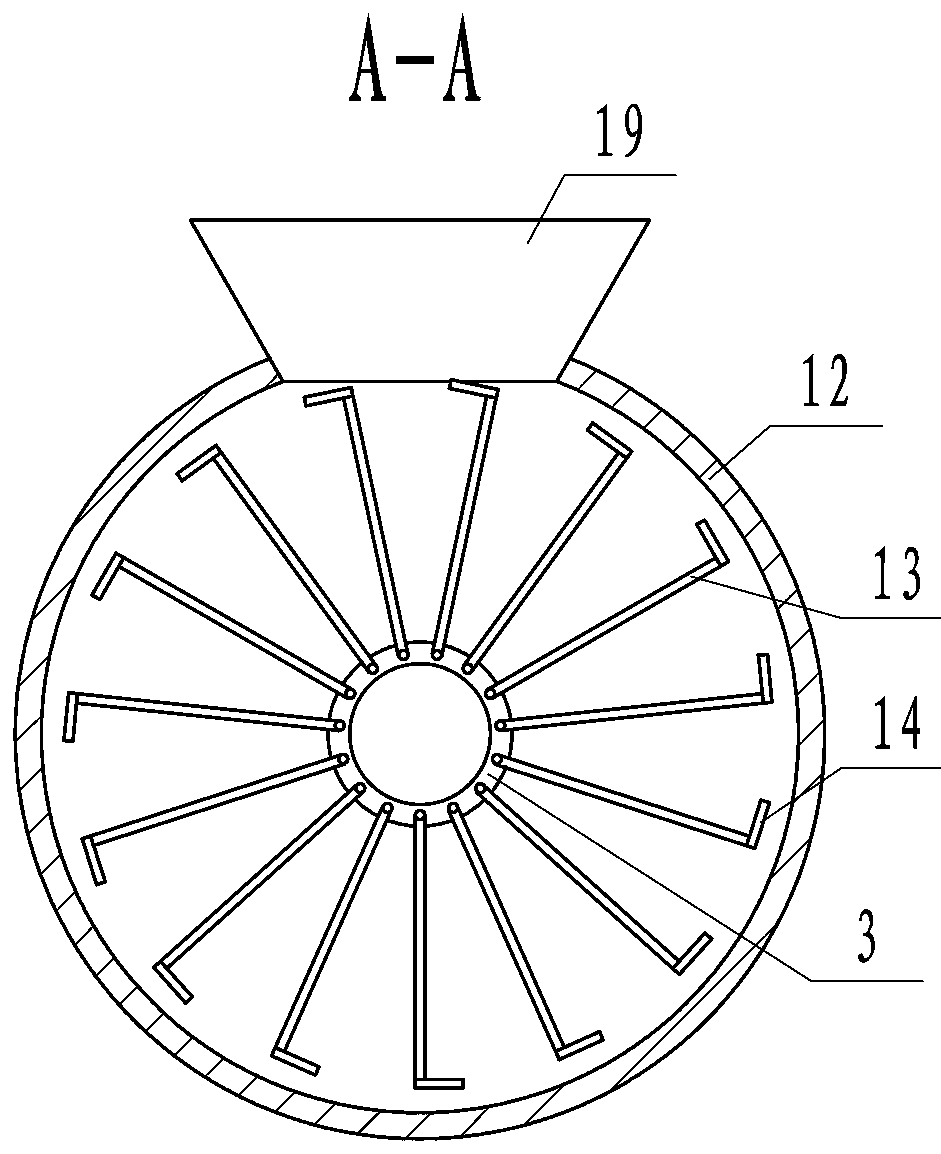

[0016] Depend on Figure 1 to Figure 6 Given, the present invention comprises housing 1, and the left side of housing 1 is equipped with steel bar propulsion device and guide cylinder 2, and the sleeve 3 that is coaxial with guide cylinder 2 and can rotate is installed in housing 1; The left end is set with a planetary gear set, the outer ring gear 4 of the planetary gear set is fixedly connected with the housing 1, the sun gear 5 of the planetary gear set is set on the sleeve 3, and the sleeve 3 can drive the sun gear 5 to rotate; the planetary gear set A disk 7 is coaxially fixed on the left side of each planetary wheel 6; a plurality of radial blind holes 8 are evenly distributed on the circumference of each disk 7; 8. A movable push rod 9; a compression spring 10 is connected between the inner end of the push rod 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com