Special-shaped grabbable storage and release device based on advanced composite material performance

An advanced composite material and composite material technology, applied in the field of special-shaped graspable storage and release devices, can solve the problems of weak load capacity, affecting the application of soft manipulators, lack of dynamic models, etc., and achieve strong opening ability, multi-function and practicality , the effect of excellent radial and axial tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

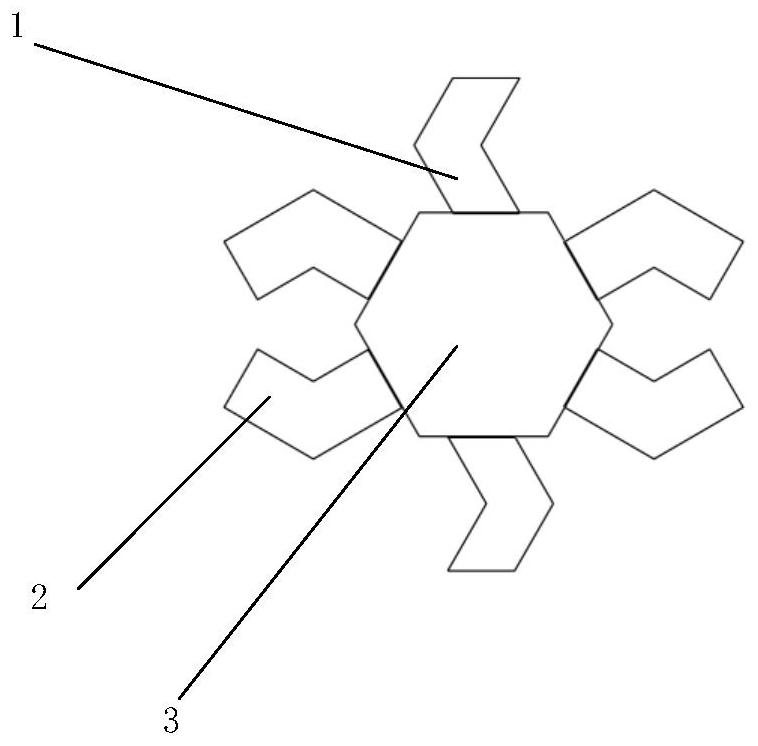

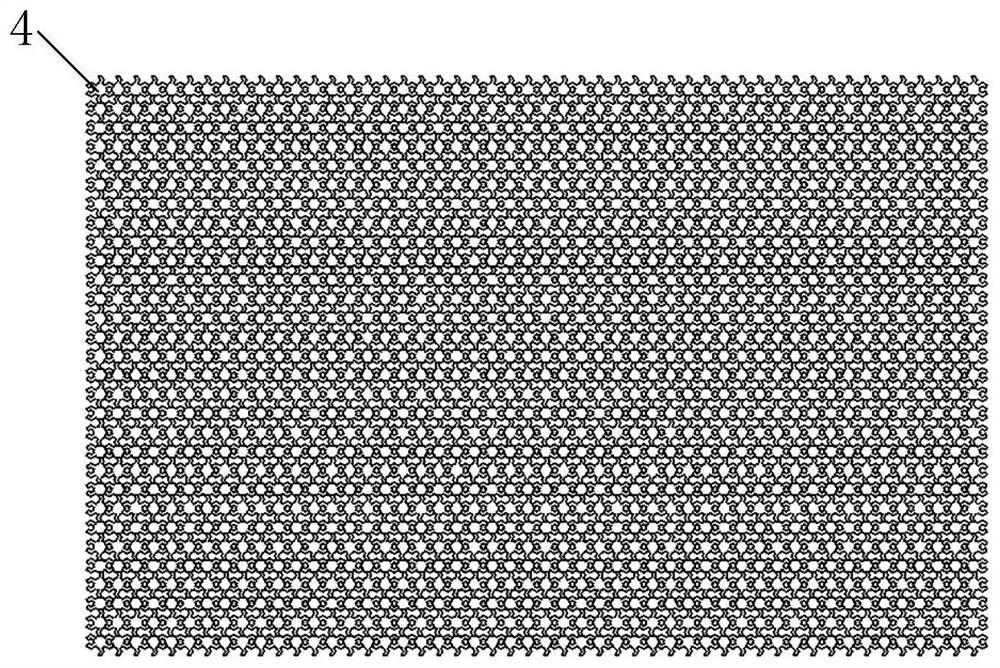

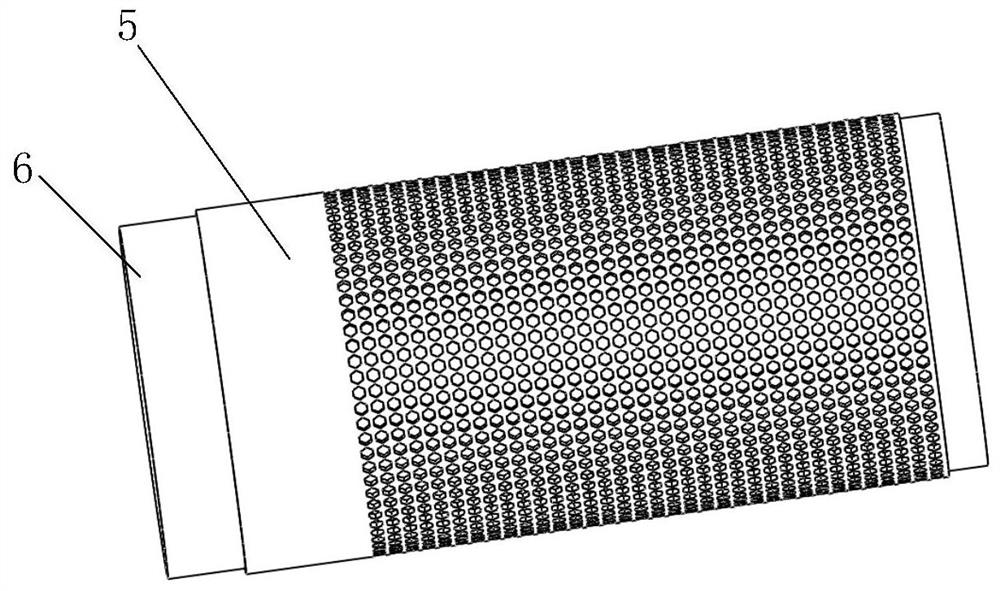

[0048] Such as figure 1 and figure 2 As shown, the SMP composite grippers 5, 13, 16, and 33 are structures surrounded by the SMP composite material itself with a snake scale imitation structure. The SMP composite material is mainly composed of 4 periodic arrays of SMP composite material units to form a square planar structure. Each SMP composite material unit 4 includes a rubber sheet 3 and a plurality of strip-shaped SMP connecting sections 1 and 2 connected around the rubber sheet 3. Two adjacent SMP composite material units 4 are connected by respective SMP connecting sections 1 and 2, so that the SMP connecting sections 1 and 2 between adjacent two SMP composite material units 4 are connected to form a V shape.

[0049] The rubber sheet 3 is a regular hexagon, and each side of each rubber sheet 3 is connected to one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com