Modification method of continuous PBO fiber for strengthening interface of bimaleimide resin base composite material

A technology of maleimide resin and composite materials, which is applied in fiber types, fiber treatment, textiles and papermaking, etc. It can solve the problems of poor adhesion of active group resin matrix, limited application, and PBO fiber can not play the best performance, etc. problems, to achieve the effect of improving interface performance, excellent comprehensive performance, and improving mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

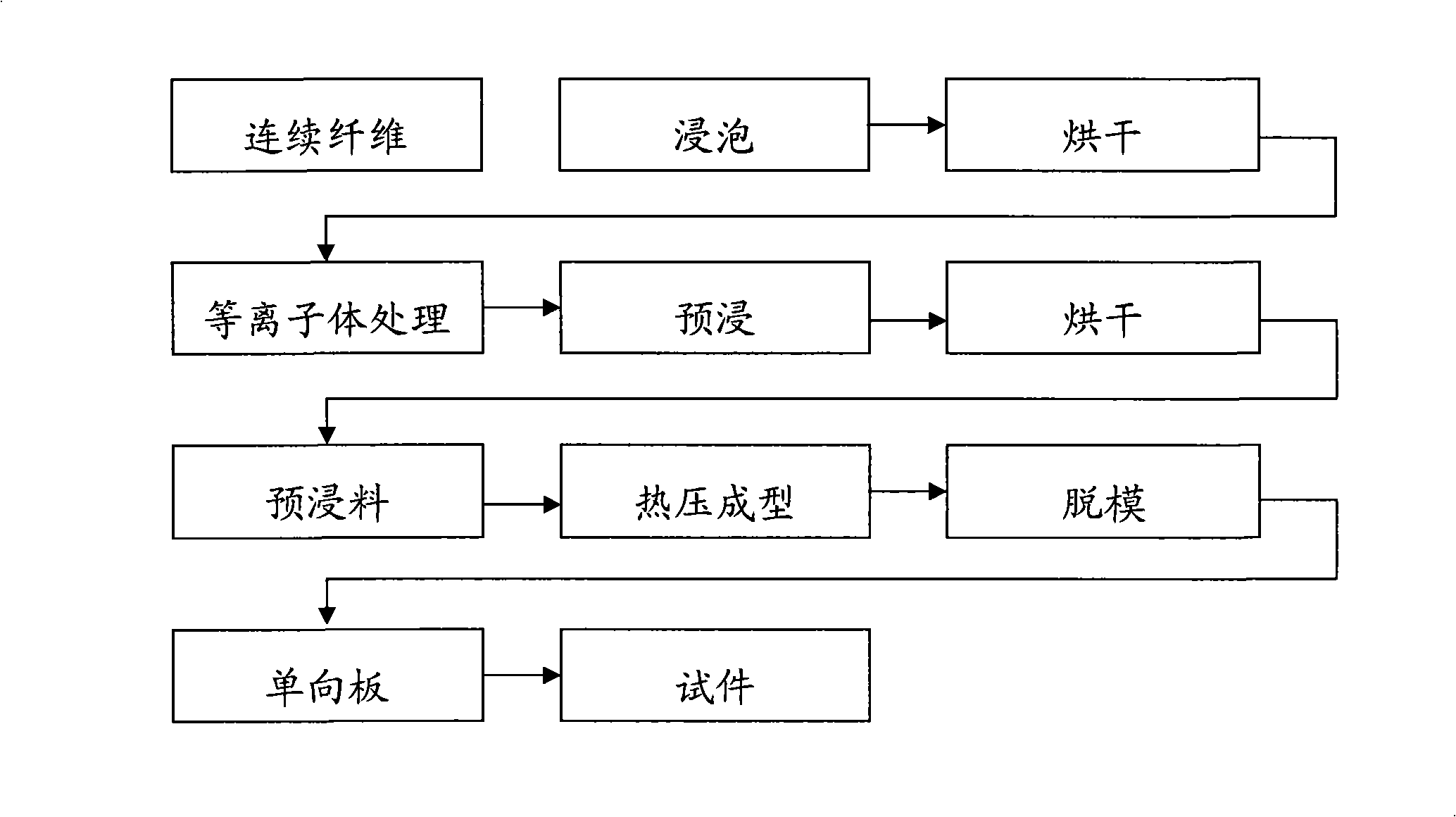

[0044] see figure 1 , the implementation steps of the interface modification method of continuous PBO fiber reinforced bismaleimide resin-based composite material:

[0045] Fiber Surface Modification Treatment The continuous PBO fiber was successively placed in acetone and deionized water for 24 hours respectively, and after taking it out, it was dried in an oven at 110°C for 3 hours. Wrap the treated continuous PBO fiber evenly on the glass frame, place it in the central area of the cavity of the RF Inductively Coupled Microwave Plasma (ICP) device, turn on the vacuum pump to draw the vacuum of the plasma cavity below 1Pa, and adjust the gas inlet The mass flow controller is used to make the oxygen flow rate of 10-150sccm into the plasma processing device, the air pressure is kept at 10-100Pa, and the plasma output power is 20-400W for 1-30 minutes;

[0046] Make fiber prepregs and quickly take out the fibers by continuous winding method and bismaleimide (BMI) resin (one o...

Embodiment 2

[0054] see figure 1 , the implementation steps of the interface modification method of continuous PBO fiber reinforced bismaleimide resin-based composite material:

[0055] The difference from Example 1 is that after placing the treated continuous PBO fiber in the central area of the cavity of a radio frequency inductively coupled microwave plasma (ICP) device, nitrogen gas is passed into the plasma processing device. Other content is identical with embodiment 1.

Embodiment 3

[0057] see figure 1 , the implementation steps of the interface modification method of continuous PBO fiber reinforced bismaleimide resin-based composite material:

[0058] The difference from Example 1 is that after placing the treated continuous PBO fiber in the central area of the cavity of a radio frequency inductively coupled microwave plasma (ICP) device, ammonia gas is passed into the plasma processing device. Other content is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com