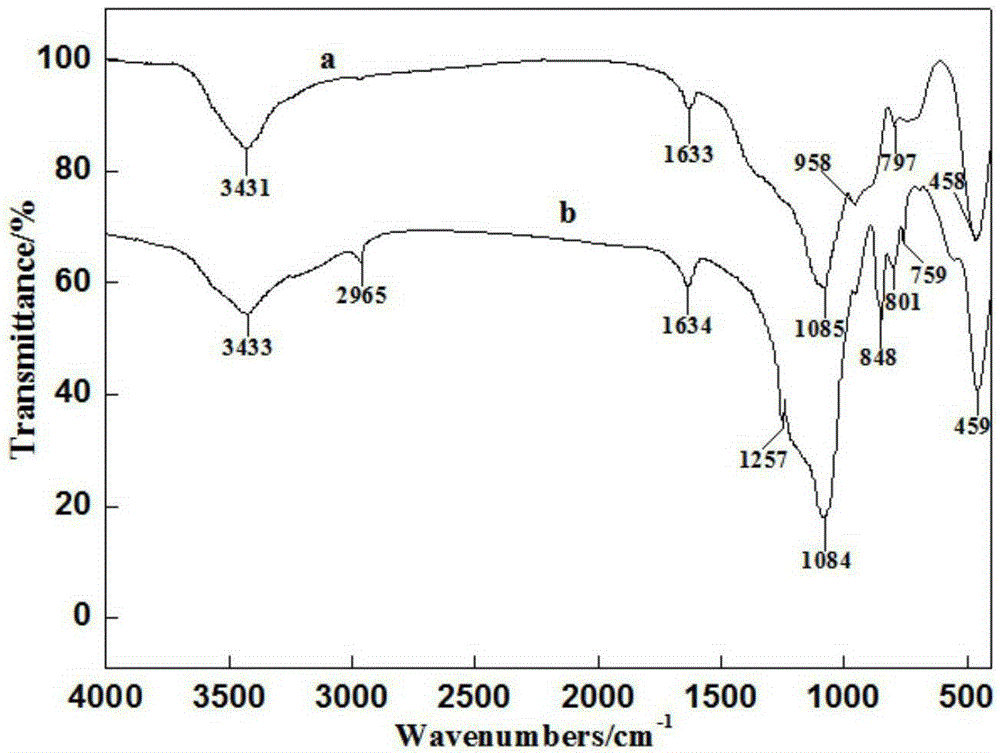

Composite fiber-reinforced hydrophobic SiO2 aerogel and preparation method thereof

A technology of composite fiber and aerogel, which is applied in the field of composite fiber reinforced hydrophobic SiO2 aerogel and its preparation, can solve the problems of poor flexibility, high brittleness and high rigidity of glass fiber, and achieves simple and fast method, small volume shrinkage, The effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A Composite Fiber Reinforced Hydrophobic SiO 2 The preparation method of airgel, comprises the steps:

[0026] (1) Preparation of silica sol: quickly mix 10.8g tetraethyl orthosilicate, 9.2g absolute ethanol, 3.6g deionized water and 1.4g formamide, after fully stirring, add a certain amount of hydrochloric acid to adjust the pH value to 3 Between -4, heat to 60°C and stir for 90 minutes, seal and store for one day to fully hydrolyze, add a certain amount of ammonia water after hydrolysis to adjust the pH between 6-8, and obtain silica sol;

[0027] (2) Composite and aging of silica sol and fiber: the silica sol prepared in step (1) is stirred and then slowly poured into composite fiber (the composite fiber is made of mullite fiber and polyester fiber by 1: ratio of 1) to stand still in a container, the volume ratio of the composite fiber to the silica sol is 1:1; after the silica sol forms a wet gel, cover the surface of the wet gel with 20ml of absolute ethanol, the ...

Embodiment 2

[0033] A Composite Fiber Reinforced Hydrophobic SiO 2 The preparation method of airgel, comprises the steps:

[0034] (1) Preparation of silica sol: quickly mix 10.8g tetraethyl orthosilicate, 13.2g absolute ethanol, 3.6g deionized water and 1.4 formamide, after fully stirring, add a certain amount of hydrochloric acid to adjust the pH value to 3- 4, heated to 50°C and fully stirred for 90 minutes, sealed and stored for one day to allow it to be fully hydrolyzed, after hydrolysis, add a certain amount of ammonia water to adjust the pH between 6-8, and obtain silica sol;

[0035] (2) Composite and aging of silica sol and fiber: the silica sol prepared in step (1) is stirred evenly and then slowly poured into the pre-treated composite fiber (the composite fiber is made of mullite fiber and polyester fiber) The fiber is compounded at a ratio of 1:1.5, and the composite fiber is soaked and pretreated with low concentration hydrochloric acid for 2h to 4h) and left standing in a co...

Embodiment 3

[0042] A Composite Fiber Reinforced Hydrophobic SiO 2 The preparation method of airgel, comprises the steps:

[0043] (1) Preparation of silica sol: quickly mix 10.8g tetraethyl orthosilicate, 13.2g absolute ethanol, 2.7g deionized water and 1.4g formamide, after fully stirring, add a certain amount of hydrochloric acid to adjust the pH value to 3 Between -4, heat to 60°C and stir for 90 minutes, seal and store for one day to fully hydrolyze, add a certain amount of ammonia water after hydrolysis to adjust the pH between 6-8, and obtain silica sol;

[0044] (2) Composite and aging of silica sol and fiber: the silica sol prepared in step (1) is stirred evenly and then slowly poured into the pre-treated composite fiber (the composite fiber is made of mullite fiber and polyester fiber) fibers are compounded at a ratio of 1:2) to stand still, and the volume ratio of the composite fibers to silica sol is 1:1; after the silica sol forms a wet gel, cover the surface of the wet gel w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com