Reinforcing treatment method for non-uniform settlement of foundation of heavy equipment workshop foundation

A technology of heavy equipment and treatment methods, which is applied in the repair of infrastructure, infrastructure engineering, construction, etc., can solve the problems of uneven foundation of heavy equipment workshops, and achieve the effects of avoiding foundation settlement, good support, and strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

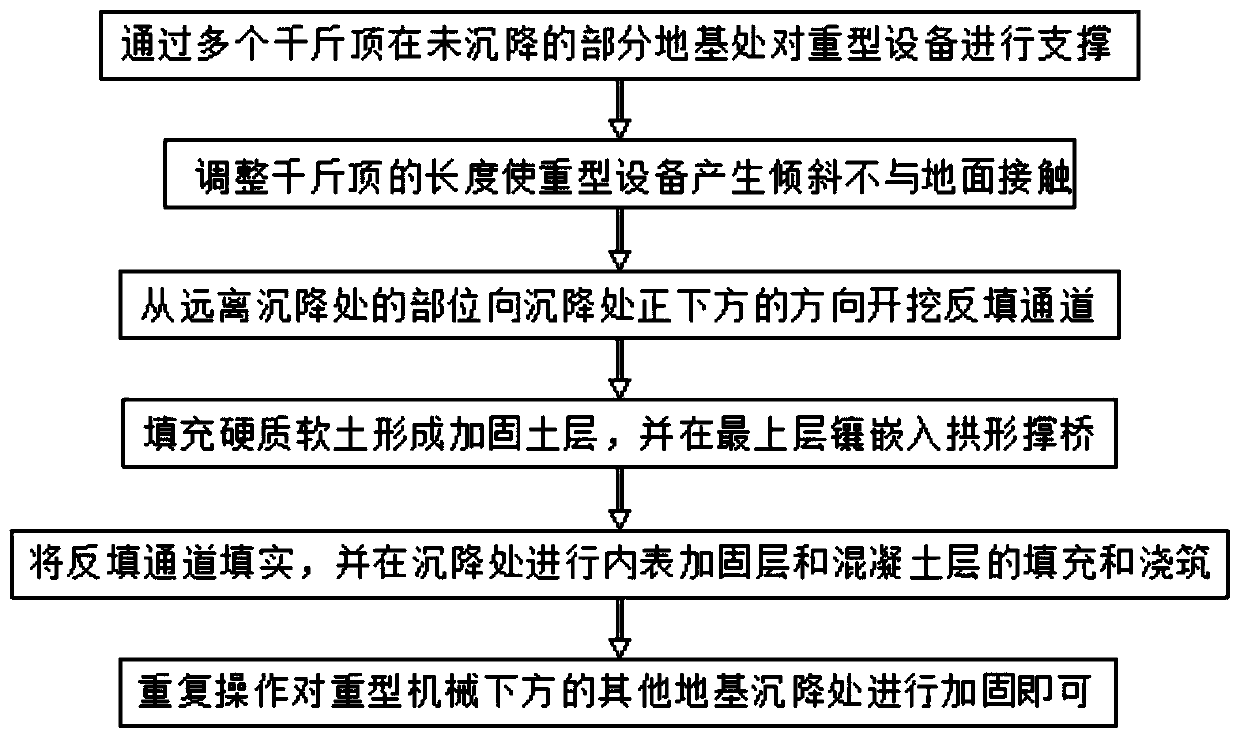

[0053] see figure 1 , a method for reinforcing uneven settlement of foundations of heavy equipment workshops, comprising the following steps:

[0054] S1. First, at the bottom of the heavy equipment, support the heavy equipment at the part of the foundation that has not settled through multiple jacks;

[0055] S2. Adjust the length of the jack, and increase the length of the jack near the subsidence side to make the heavy equipment tilt to a certain extent so that the heavy equipment on this side does not contact the ground;

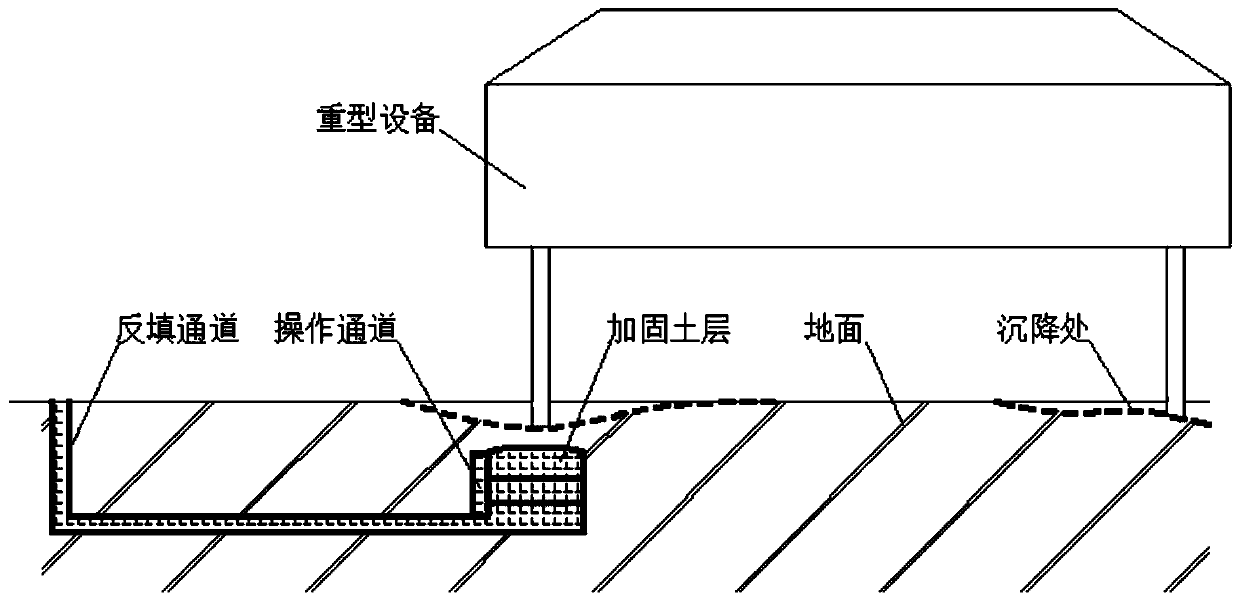

[0056] S3, see figure 2 , and then excavate the backfill channel from the part far away from the settlement to the direction directly below the settlement;

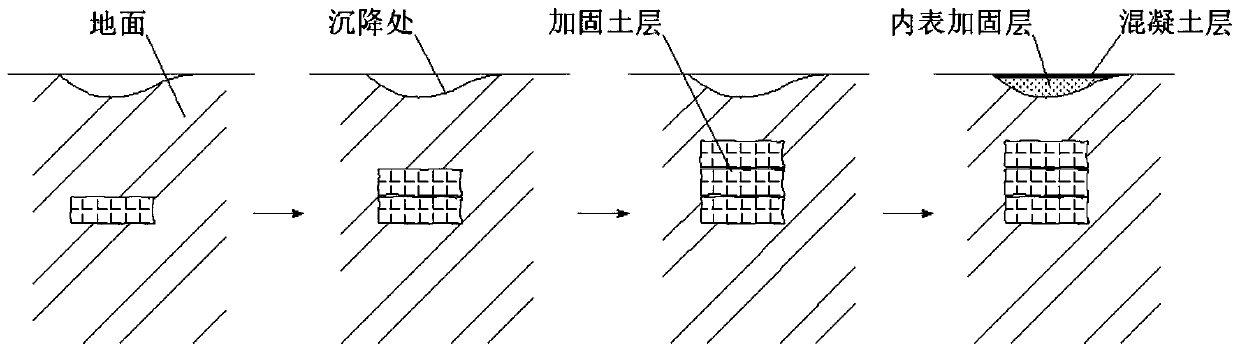

[0057] S4. When the backfill channel is dug below the settlement, excavate layer by layer from bottom to top and fill with hard and soft soil to form a reinforced soil layer, and insert an arched bridge in the uppermost layer;

[0058] S5. Please refer to image 3 , and then reversely fill the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com