Water-based protective paint for protective fence of residential quarter and preparation method of water-based protective paint

A protective paint and guardrail technology, which is applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of high VOC content in paint, serious pollution and fires, poor coating film of water-based paint, etc., and achieve low VOC value , Reduce sagging and settlement, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

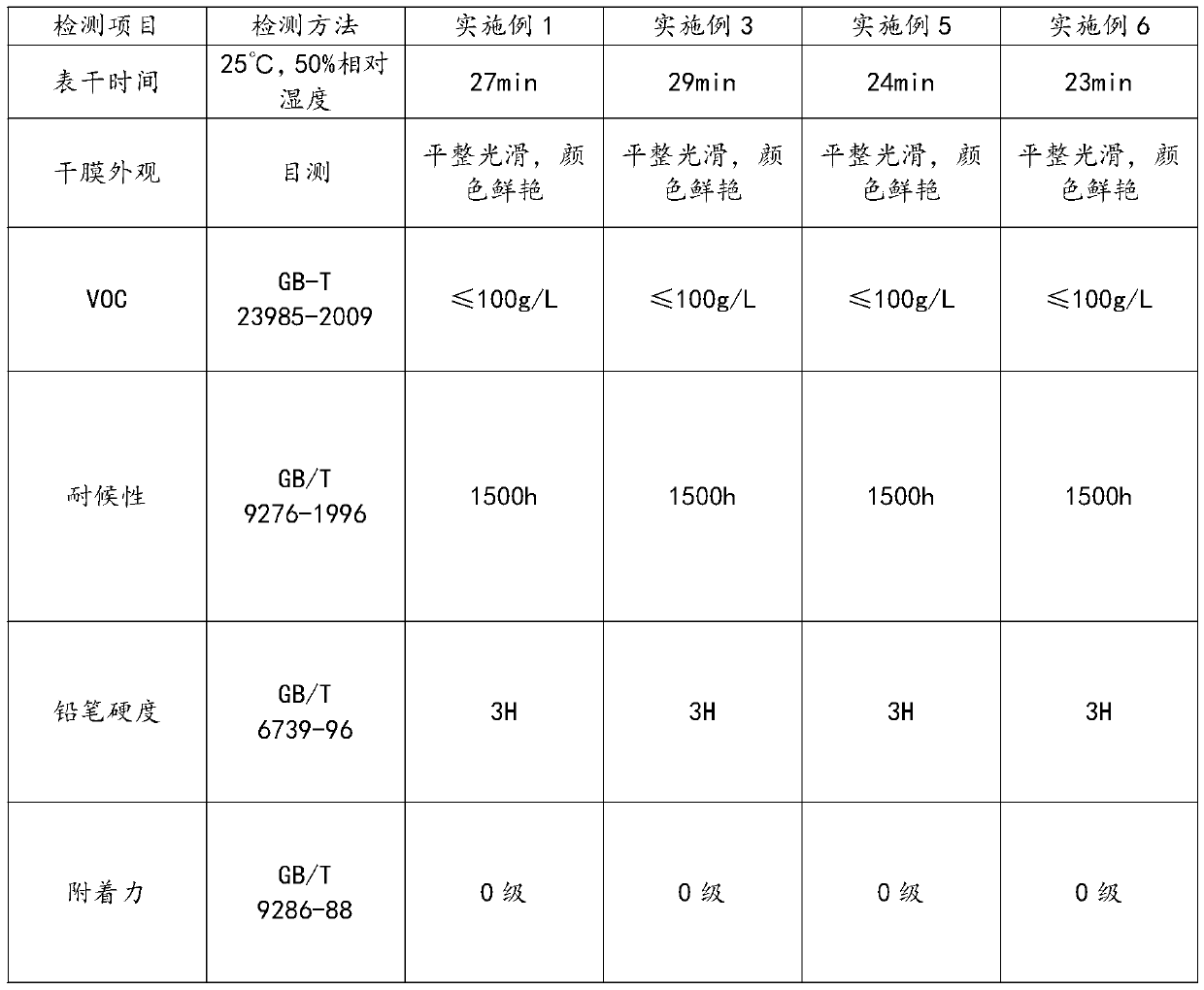

Examples

Embodiment 1

[0047] A water-based protective paint for residential fences, comprising the following raw materials in parts by weight: 10 parts of water-based alkyd resin, 65 parts of water-based acrylic emulsion, 6.5 parts of environmentally friendly solvent, 1.2 parts of neutralizer, 1.5 parts of dispersant, disinfectant 0.7 parts of foaming agent, 0.4 parts of substrate wetting agent, 0.48 parts of anti-settling agent, 0.5 parts of thickener, 1.5 parts of anti-flash rust agent, 0.5 parts of rheological agent, 1.2 parts of coupling agent, 0.2 parts of leveling agent, 6 parts of phthalocyanine blue, 2 parts of rutile titanium dioxide, 2.7 parts of talcum powder, 6 parts of aluminum tripolyphosphate, 8 parts of composite zinc phosphate, and 15 parts of deionized water.

[0048] The preparation method of described waterborne protective paint is to comprise the following steps:

[0049]A. According to the raw material ratio, stir the water-based alkyd resin evenly at a speed of 600r / min, then...

Embodiment 2

[0052] A water-based protective paint for residential fences, comprising the following raw materials in parts by weight: 18 parts of water-based alkyd resin, 50 parts of water-based acrylic emulsion, 7.5 parts of environmentally friendly solvent, 1.5 parts of neutralizer, 1.3 parts of dispersant, disinfectant 0.5 parts of foaming agent, 0.3 parts of substrate wetting agent, 0.4 parts of anti-settling agent, 0.8 parts of thickener, 1 part of anti-flash rust agent, 1.2 parts of rheological agent, 0.8 parts of coupling agent, 0.3 parts of leveling agent, 3 parts of phthalocyanine blue, 4 parts of rutile titanium dioxide, 2.5 parts of talcum powder, 8 parts of aluminum tripolyphosphate, 5 parts of composite zinc phosphate, and 20 parts of deionized water.

[0053] The preparation method of described waterborne protective paint is to comprise the following steps:

[0054] A. According to the raw material ratio, stir the water-based alkyd resin evenly at a speed of 400r / min, then ad...

Embodiment 3

[0057] A water-based protective paint for residential fences, comprising the following raw materials in parts by weight: 14 parts of water-based alkyd resin, 57 parts of water-based acrylic emulsion, 7 parts of environmentally friendly solvents, 1.3 parts of neutralizer, 1.4 parts of dispersant, disinfectant 0.6 parts of foaming agent, 0.35 parts of substrate wetting agent, 0.44 parts of anti-settling agent, 0.65 parts of thickener, 1.25 parts of anti-flash rust agent, 0.8 parts of rheological agent, 1 part of coupling agent, 0.25 parts of leveling agent, 4.5 parts of phthalocyanine blue, 3 parts of rutile titanium dioxide, 2.6 parts of talcum powder, 7 parts of aluminum tripolyphosphate, 6.5 parts of composite zinc phosphate, and 17.5 parts of deionized water.

[0058] The preparation method of described waterborne protective paint is to comprise the following steps:

[0059] A. According to the raw material ratio, stir the water-based alkyd resin evenly at a speed of 500r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com