Automobile ceiling and manufacturing method thereof

A technology for automobile roofs and manufacturing methods, applied in chemical instruments and methods, vehicle parts, lamination, etc., can solve problems such as difficult control of foaming uniformity, uneven density of roof substrates, high total VOC content, etc. To achieve the effect of keeping the air fresh, preventing the detachment between layers, and reducing the VOC value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

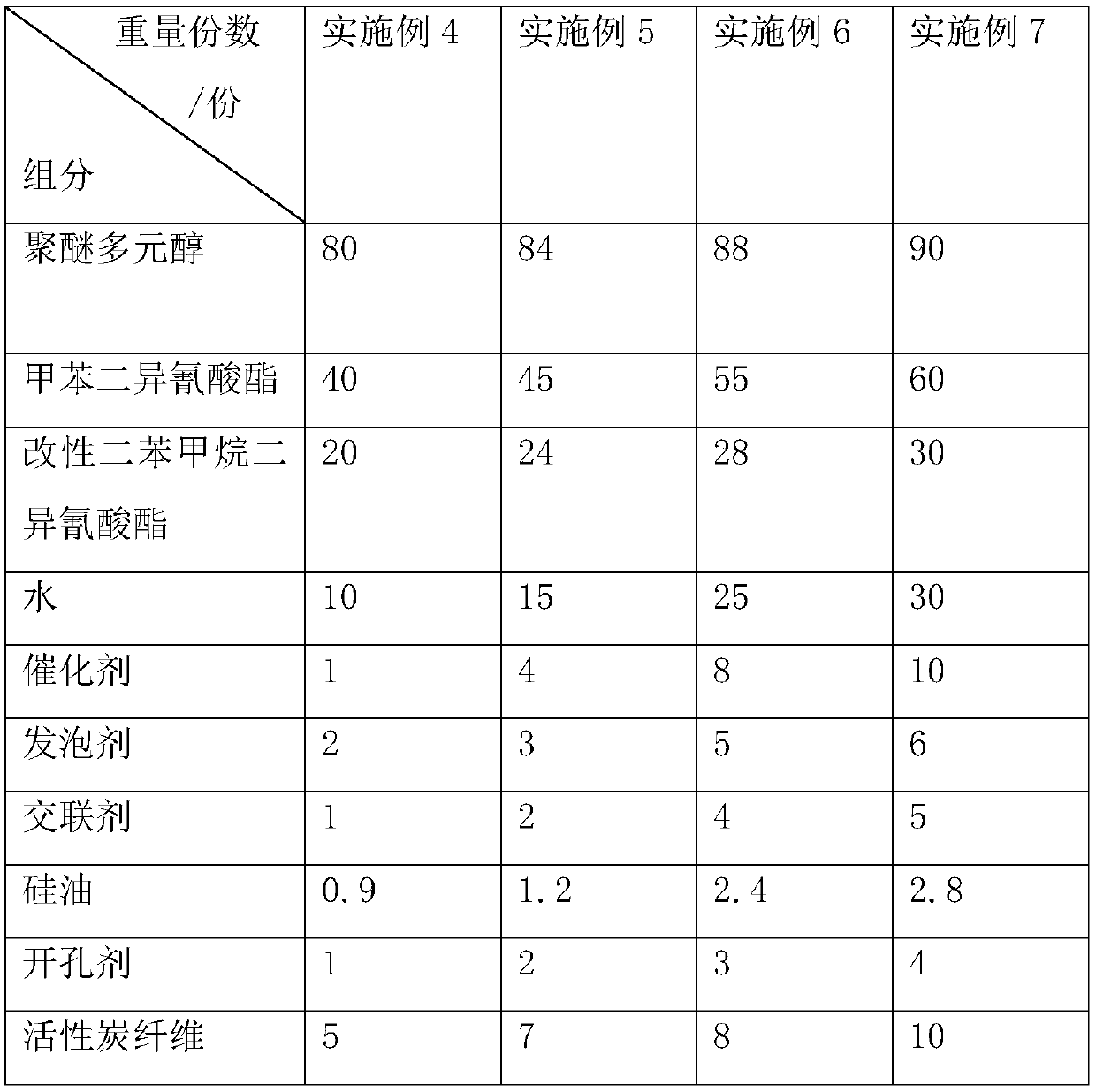

[0043] Preparation Example 1: Put 20 kg of activated carbon, 10 kg of diatomaceous earth, 5 kg of alumina and 15 kg of silica gel into the reactor, mix and stir evenly, then add 20 kg of manganese dioxide, pour 10 kg of urea solution, 20 kg Ethylenediamine solution, after mixing and stirring evenly, pour 5 kg of low-VOC adhesive and 50 kg of deionized water, and then mix and stir evenly; wherein the mass fraction of urea solution is 35%, and the mass fraction of ethylenediamine solution is 18% The low-VOC adhesive is 3M94CA transparent high-strength post-molding low-VOC adhesive.

preparation example 2

[0044] Preparation Example 2: Put 25 kg of activated carbon, 13 kg of diatomaceous earth, 8 kg of alumina and 17 kg of silica gel into the reactor, mix and stir evenly, then add 35 kg of manganese dioxide, pour 15 kg of urea solution, 25 kg Ethylenediamine solution, after mixing and stirring evenly, pour 8 kg of low-VOC adhesive and 55 kg of deionized water, and then mix and stir evenly; wherein the mass fraction of urea solution is 38%, and the mass fraction of ethylenediamine solution is 20% , The low-VOC adhesive is 3M94CA transparent high-strength post-molding low-VOC adhesive.

preparation example 3

[0045] Preparation Example 3: Put 30 kg of activated carbon, 15 kg of diatomaceous earth, 10 kg of alumina and 20 kg of silica gel into the reactor, mix and stir evenly, then add 50 kg of manganese dioxide, pour 20 kg of urea solution, 30 kg of Ethylenediamine solution, after mixing and stirring evenly, pour 10 kg of low-VOC adhesive and 60 kg of deionized water, and then mix and stir evenly; wherein the mass fraction of urea solution is 40%, and the mass fraction of ethylenediamine solution is 22% , The low-VOC adhesive is 3M94CA transparent high-strength post-molding low-VOC adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com