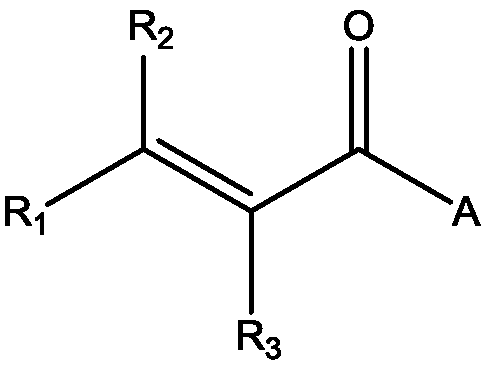

A kind of comb type macromonomer and preparation method thereof, a kind of polymer polyol and polyurethane foam

A macromonomer and polymer technology, applied to comb macromonomers and their preparation, can solve the problems of high product viscosity, device shutdown, easy polymerization, etc., and achieve excellent stability, low usage, and high conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

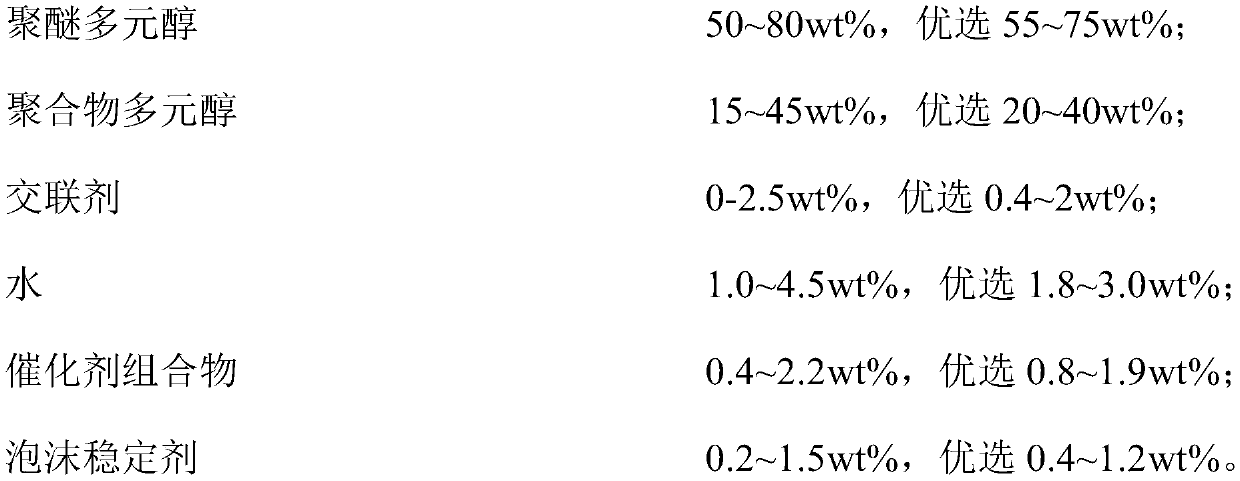

Examples

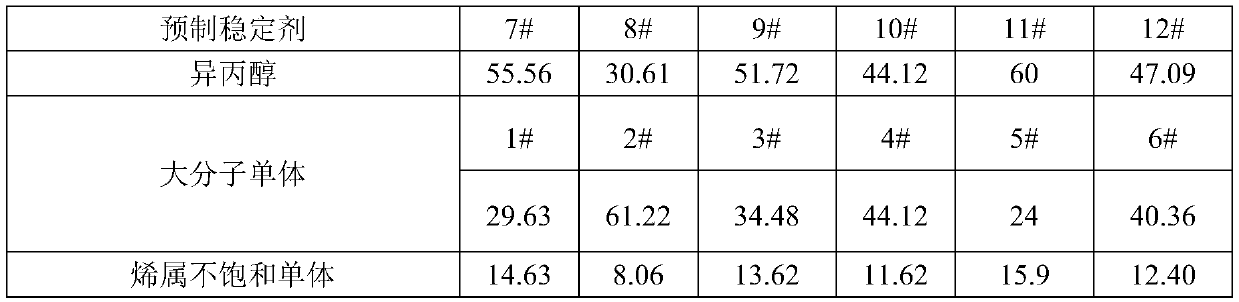

Embodiment 1

[0084] step 1)

[0085] Add: 79.80 g of acrylic acid, polyethylene glycol with a weight average molecular weight of about 370 in a 1 liter reactor equipped with a stirrer, a heater, a thermocouple, a condensing device with a water separator, an inlet and an outlet device, and under nitrogen protection 450.71g, toluene 200g, hydroquinone 3g, p-toluenesulfonic acid 0.6g, mix well, maintain 110°C for 4h, then cool to room temperature.

[0086] Step 2)

[0087] Add 66.50 g of butadiene and 3 g of benzoyl peroxide (BPO) initiator into the reaction solution in step 1), raise the temperature to 80° C. under stirring, react for 2 hours, and obtain 1# comb-shaped macromer solution after cooling down.

Embodiment 2

[0089] step 1)

[0090] In a 1 liter reactor equipped with a stirrer, a heater, a thermocouple, a condensing device with a water separator, an inlet and an outlet device, under nitrogen protection, add: 22.07 g of acrylic acid, 119.41 g of polypropylene glycol with a weight average molecular weight of 370, 640 g of toluene, 0.8 g of hydroquinone, and 0.2 g of tert-butyl titanate were mixed uniformly, maintained at 120° C. for 4 h, and then cooled to room temperature.

[0091] Step 2)

[0092] Add 17.56 g of isoprene and 0.96 g of benzoyl peroxide (BPO) initiator into the reaction solution in step 1), raise the temperature to 90° C. under stirring, and react for 2 h. Obtain 2# comb type macromonomer solution after cooling.

Embodiment 3

[0094] step 1)

[0095] In a 1-liter reactor equipped with a stirrer, a heater, a thermocouple, a condensing device with a water separator, an inlet and an outlet device, and under nitrogen protection, add: 89.43 g of methacrylic acid, polyethylene glycol with a weight average molecular weight of 290 235g of alcohol, 97.11g of polypropylene glycol with a weight-average molecular weight of 350, 320g of toluene, 2.4g of hydroquinone, and 0.5g of t-butyl titanate were mixed uniformly, and kept at 110°C for 4 hours, and then cooled to room temperature.

[0096] Step 2)

[0097] Add 54.93 g of butadiene and 3.36 g of benzoyl peroxide (BPO) initiator into the reaction liquid in step 1), raise the temperature to 80° C. under stirring, and react for 2 h. Obtain 3# comb type macromonomer solution after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com