Patents

Literature

128results about How to "Comprehensive functions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

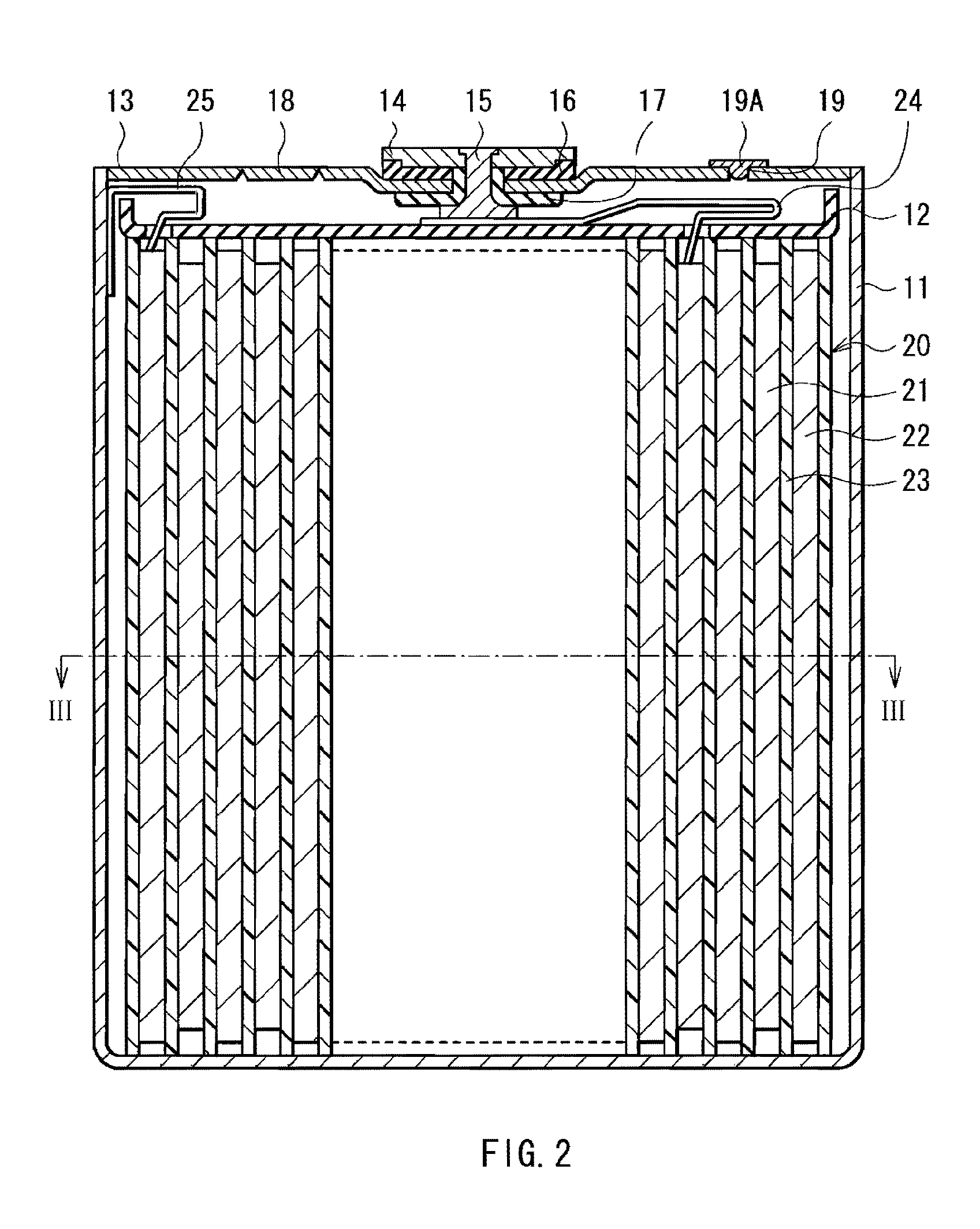

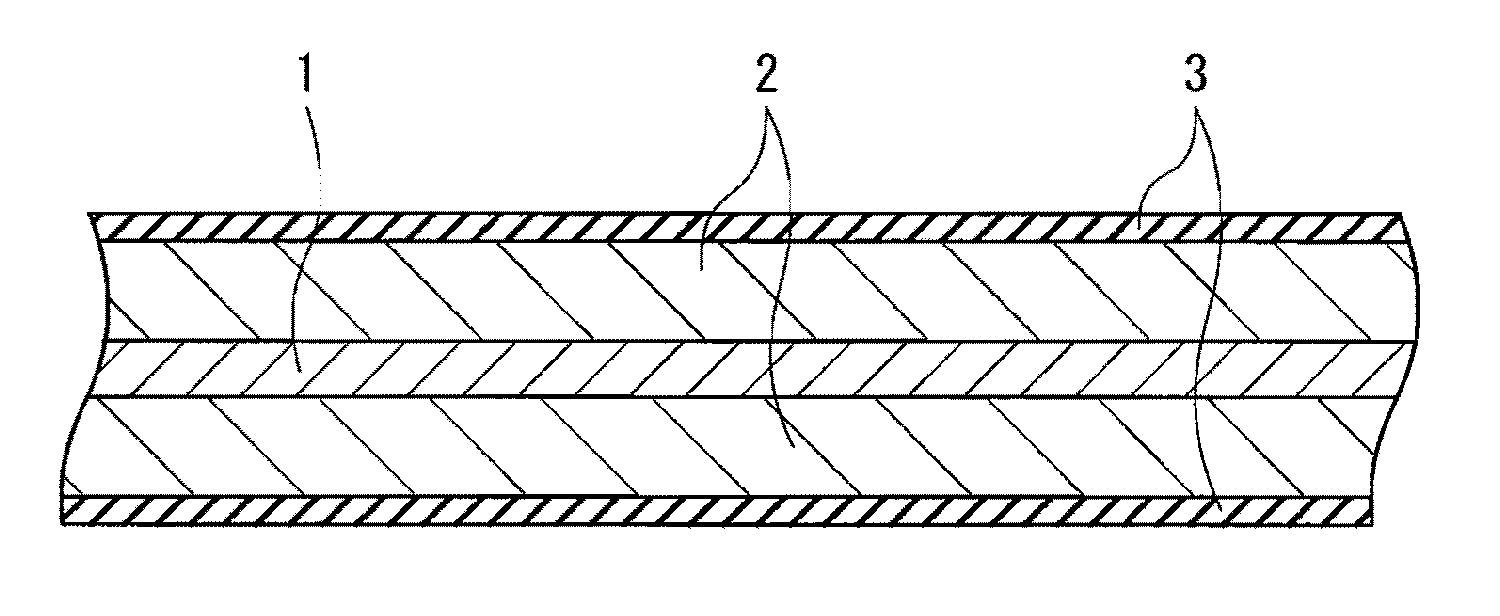

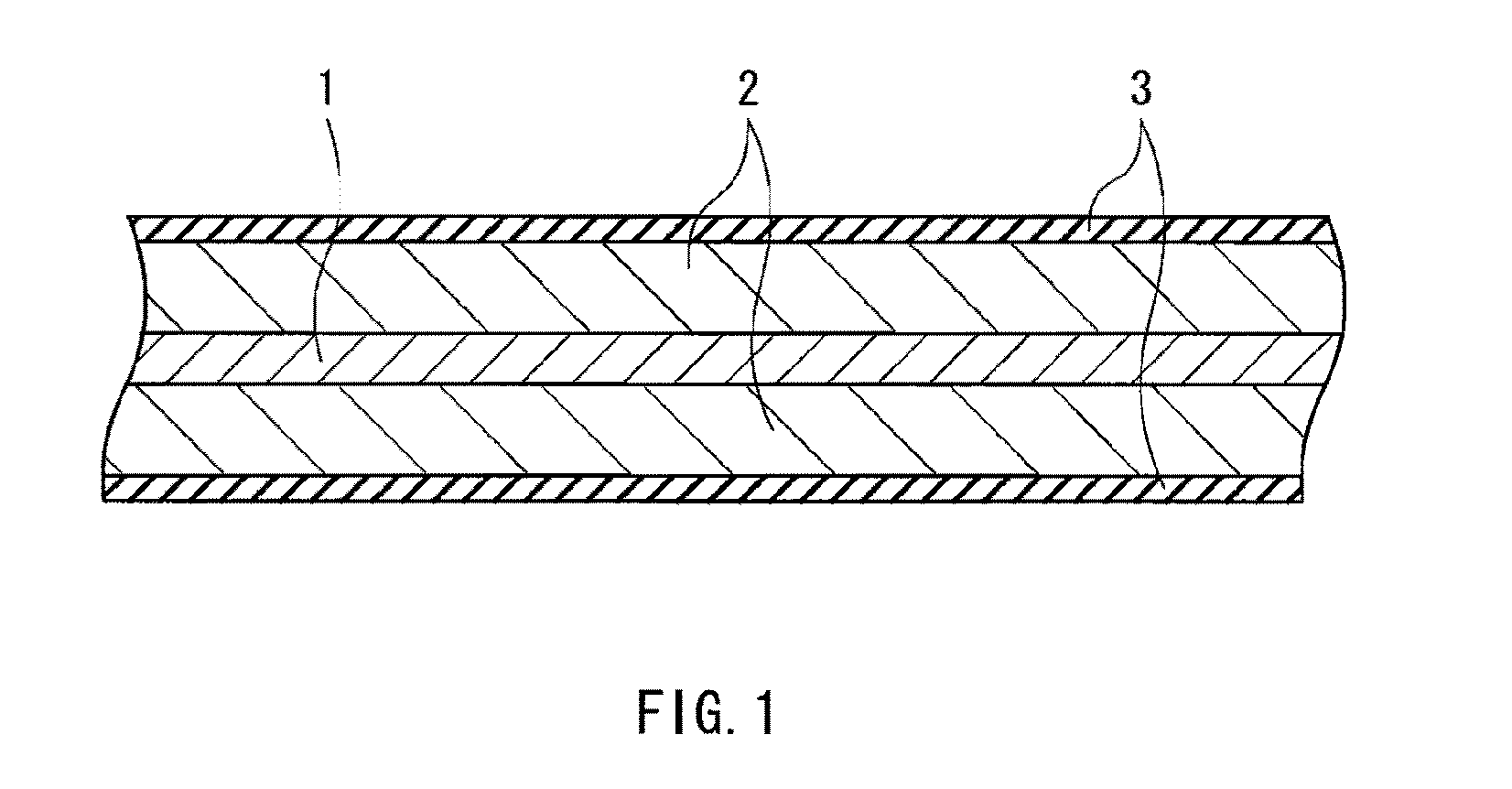

Anode and secondary battery

ActiveUS20090253033A1Improve performanceExcellent cycle characteristicsAlkaline accumulatorsFinal product manufacturePore diameterMaterials science

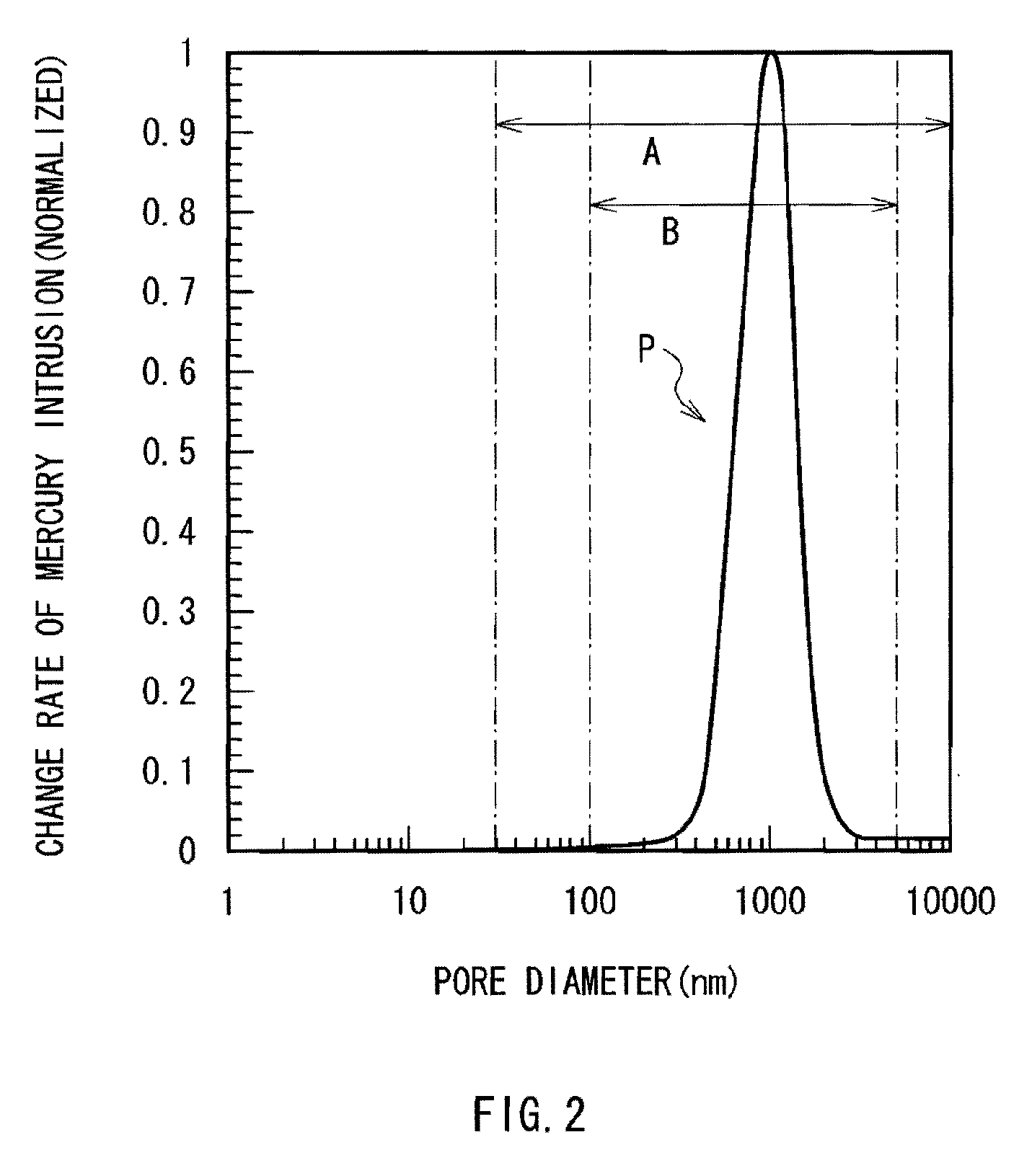

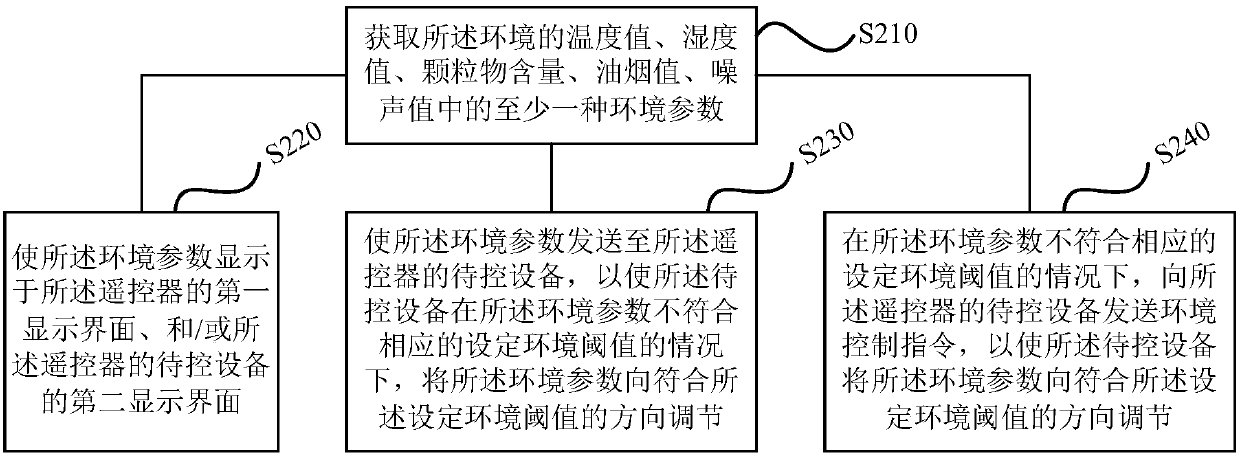

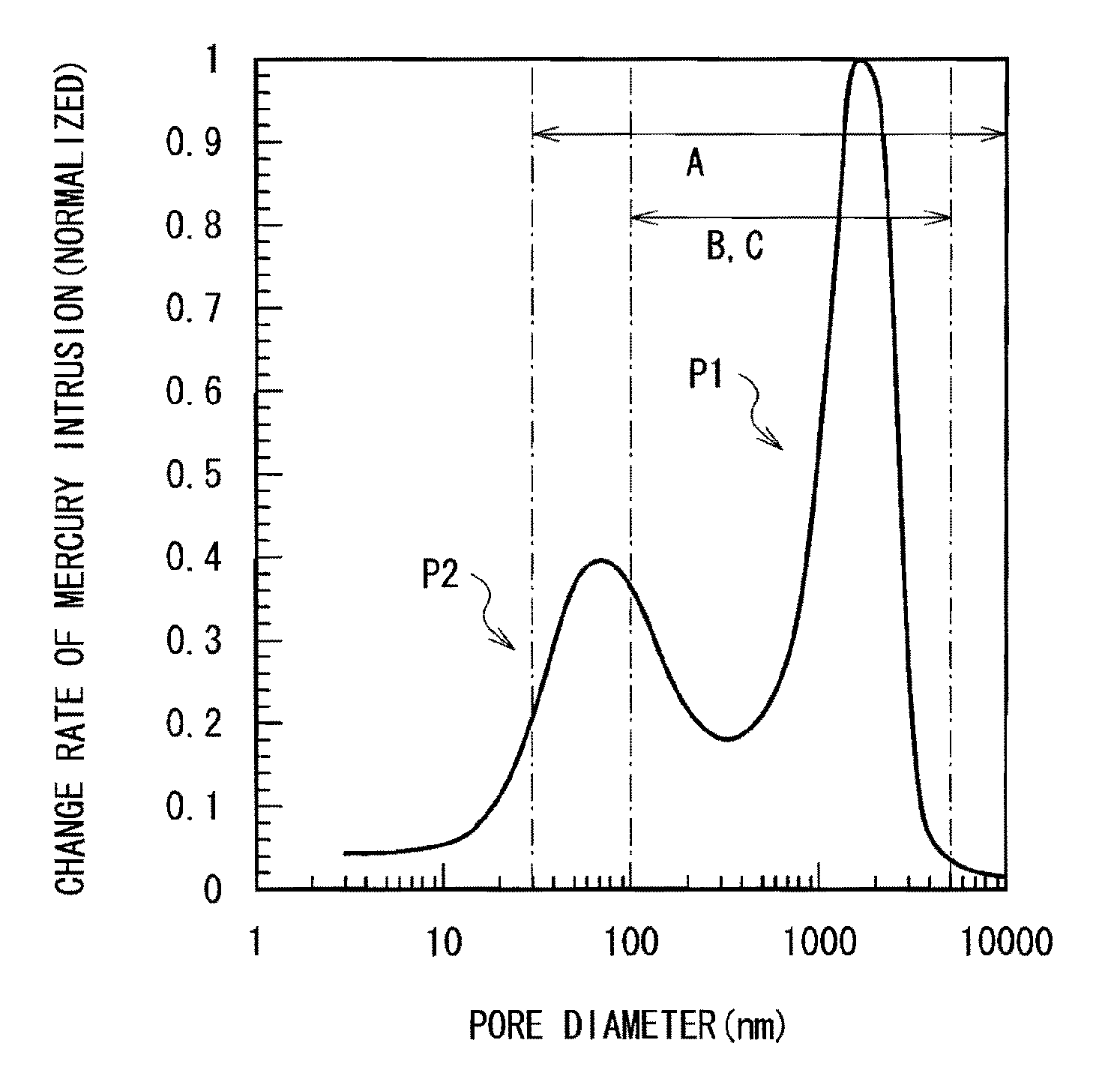

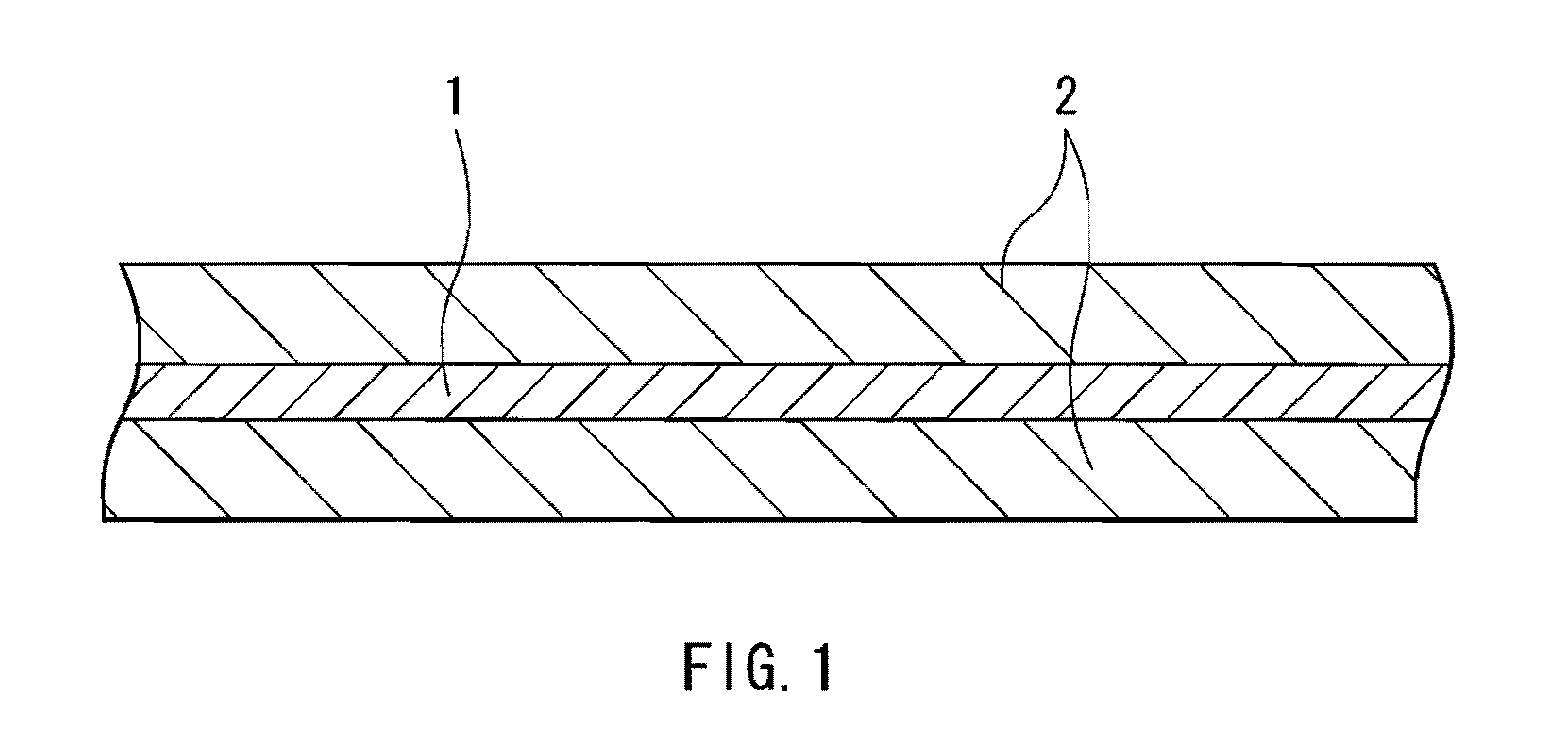

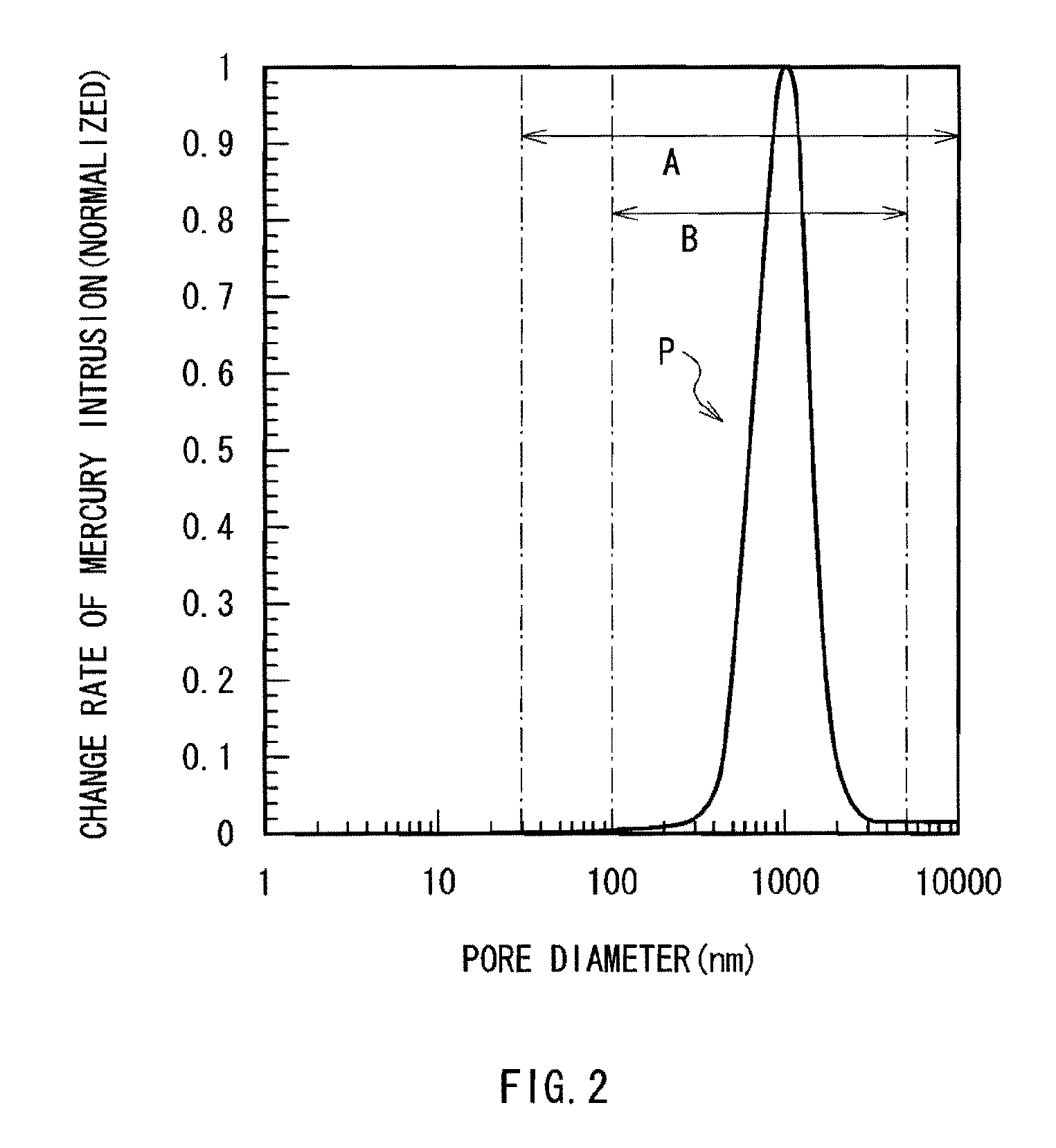

A secondary battery capable of improving the cycle characteristics and the swollenness characteristics is provided. The secondary battery includes a cathode, an anode, and an electrolytic solution. The anode includes an anode active material layer having a plurality of fine pores on an anode current collector. The anode active material layer contains an anode active material and an anode binder. A change rate of a mercury intrusion into the plurality of fine pores measured by mercury penetration technique is distributed to show a peak in the pore diameter range from 30 nm to 10000 nm, both inclusive.

Owner:MURATA MFG CO LTD

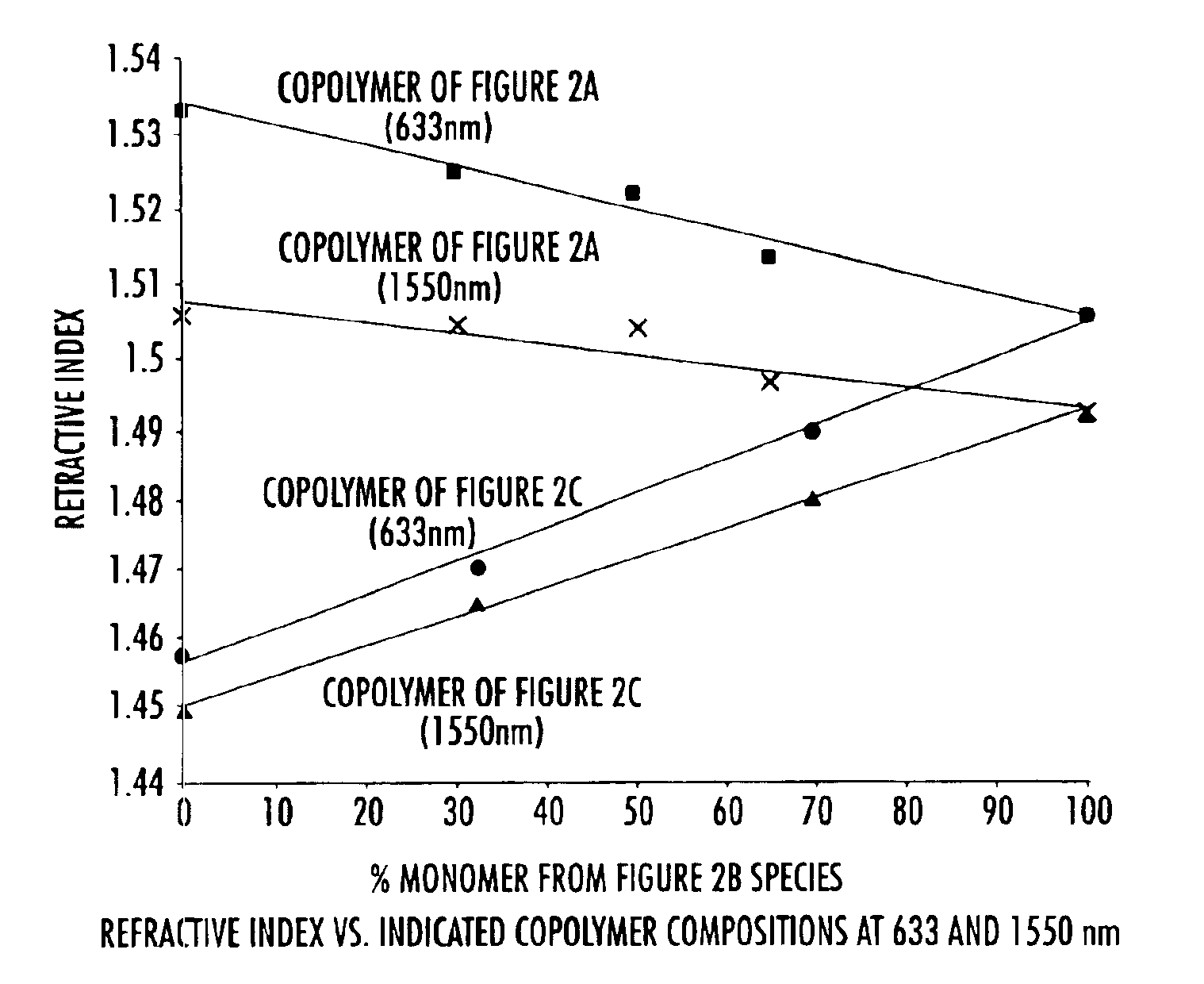

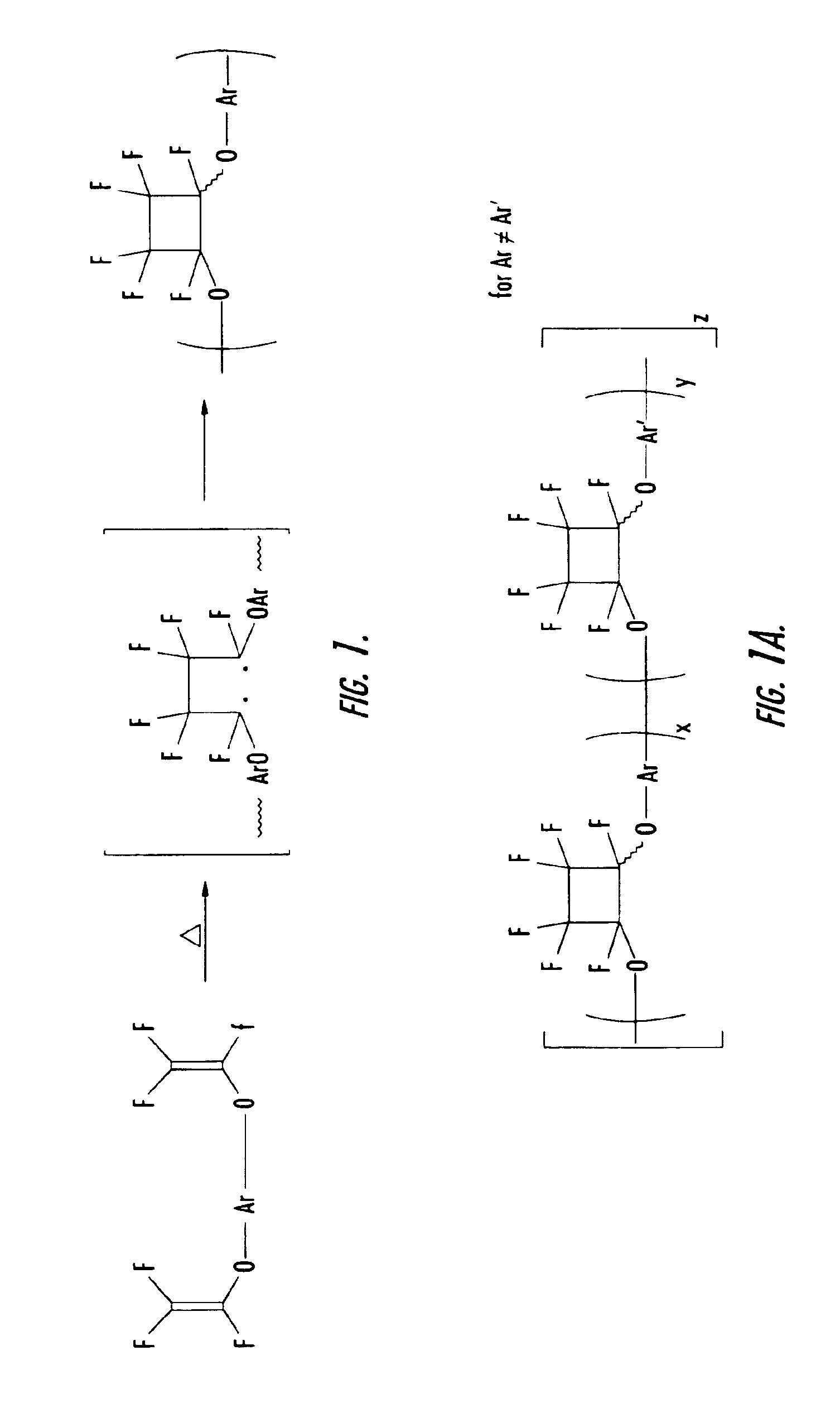

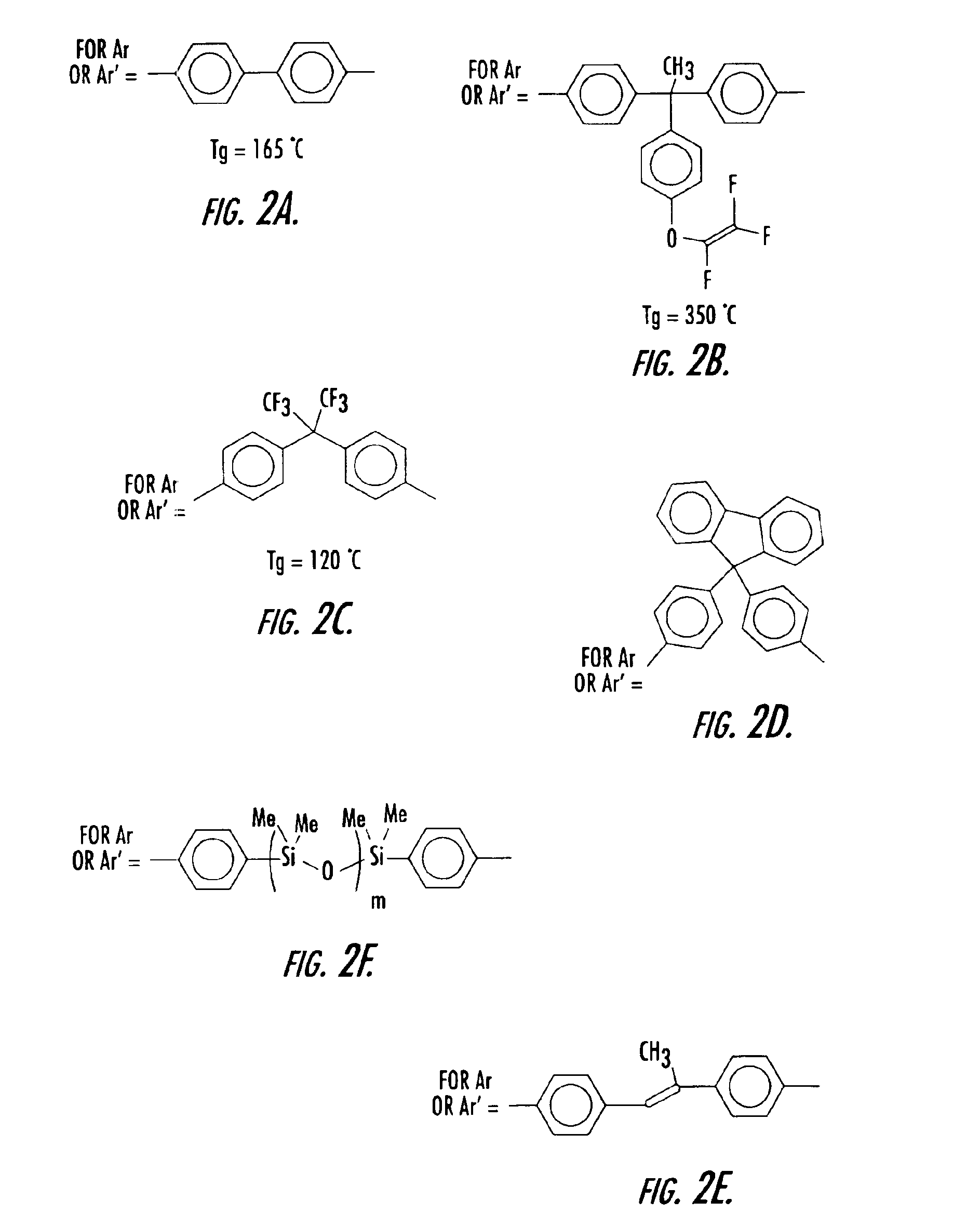

Fluoropolymer compositions, optical devices, and methods for fabricating optical devices

InactiveUS6953653B2Tunable optical propertyTunable thermal propertyDiffusion transfer processesPhotomechanical apparatusInformation processingTelecommunications link

Optical waveguides interconnect optical information processing devices, or connect such devices with other optical communication links such as glass optical fibers. Fluoropolymers consisting of alternating perfluorocyclobutane and aryl ether linkages possess suitable properties for optical waveguides and other devices due to tunability in optical properties of the copolymers. Perfluorocyclobutane (PFCB) copolymer may be employed in solutions that exhibit a high solids content. Such solutions show useful physical properties for optical waveguide devices since the solutions are capable of achieving single step film thicknesses, when applied to a substrate, of greater than about 0.6 microns, and sometimes may achieve a thickness of 10 microns or more.

Owner:CLEMSON UNIVERSITY

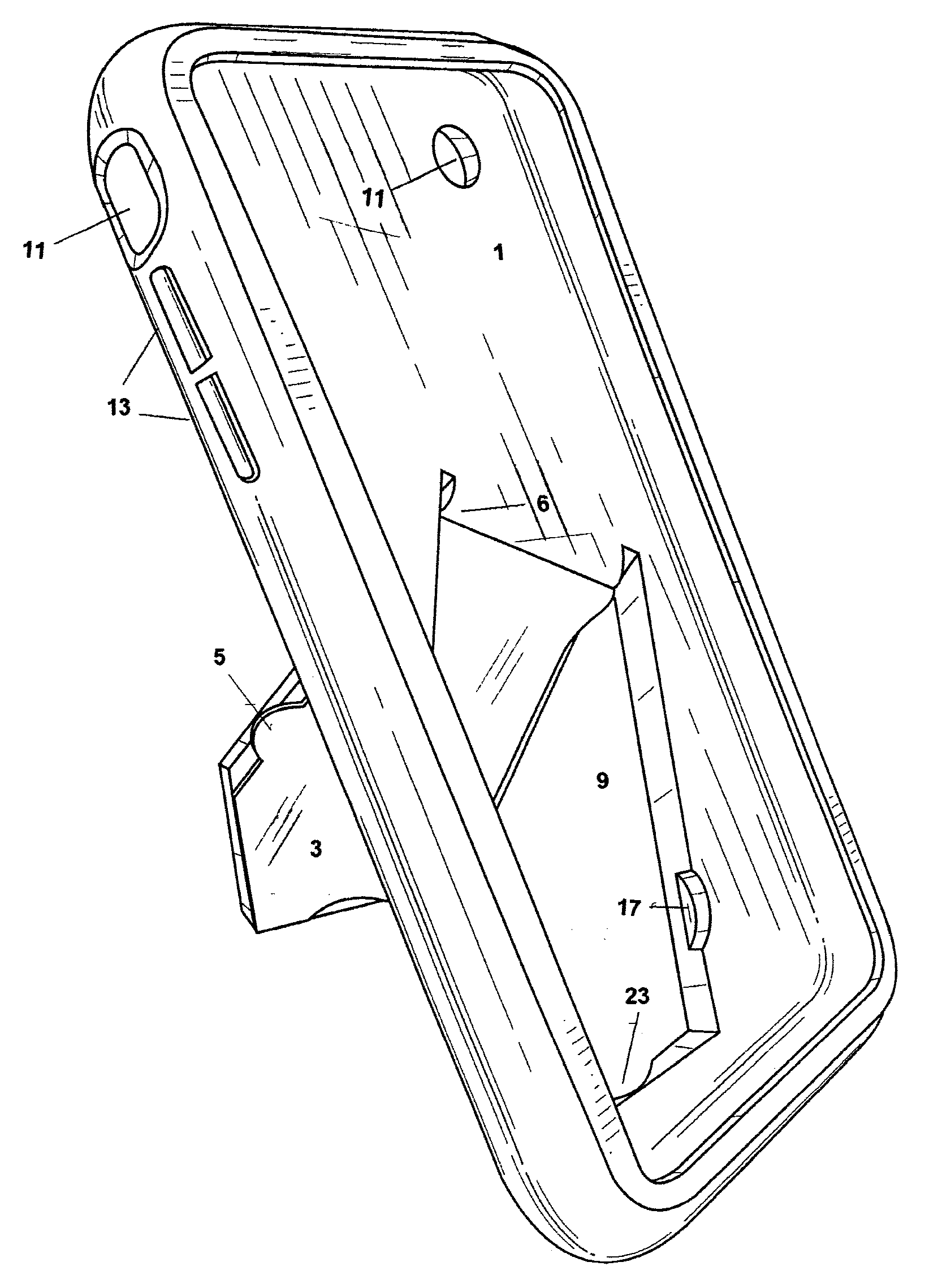

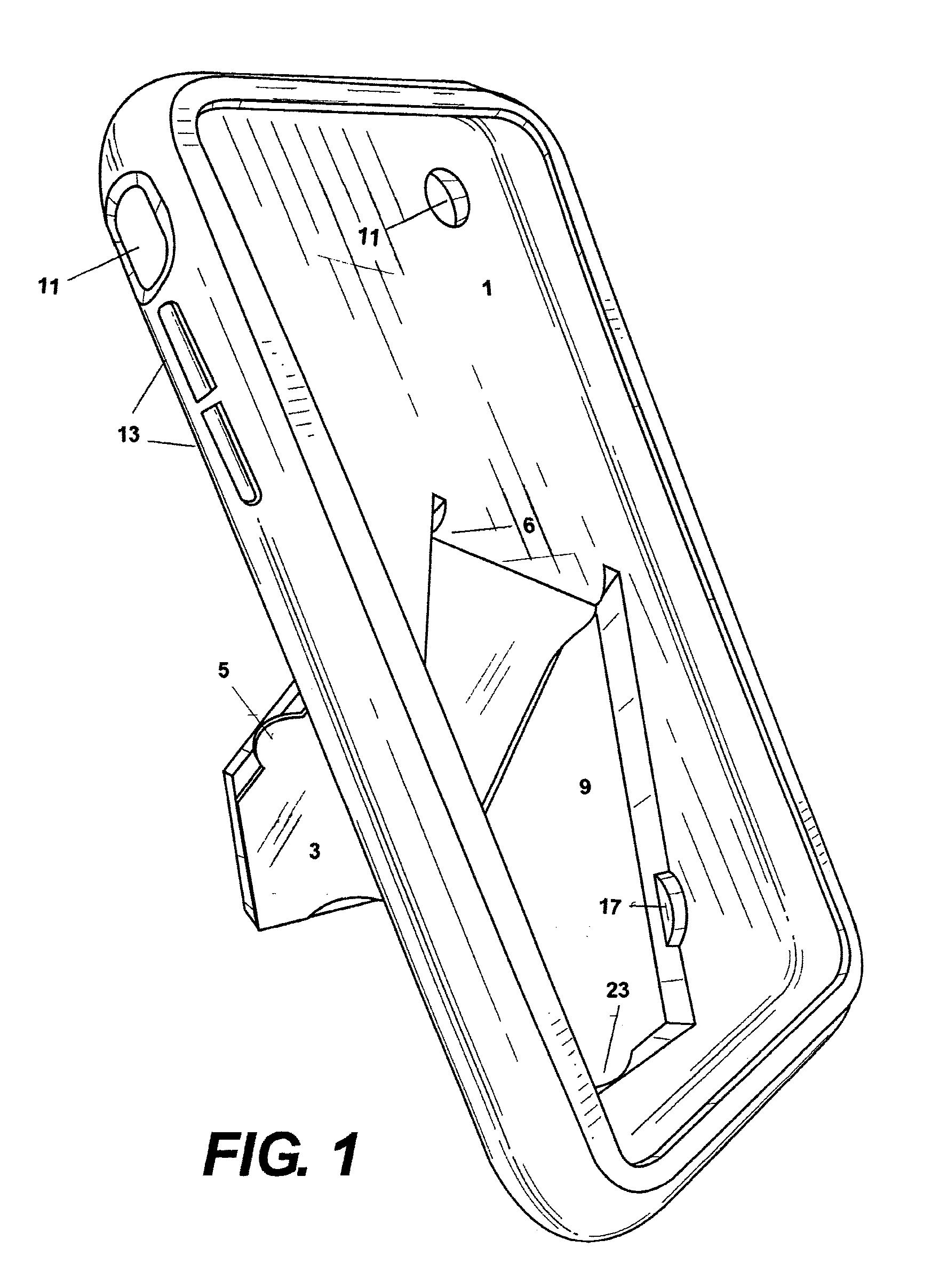

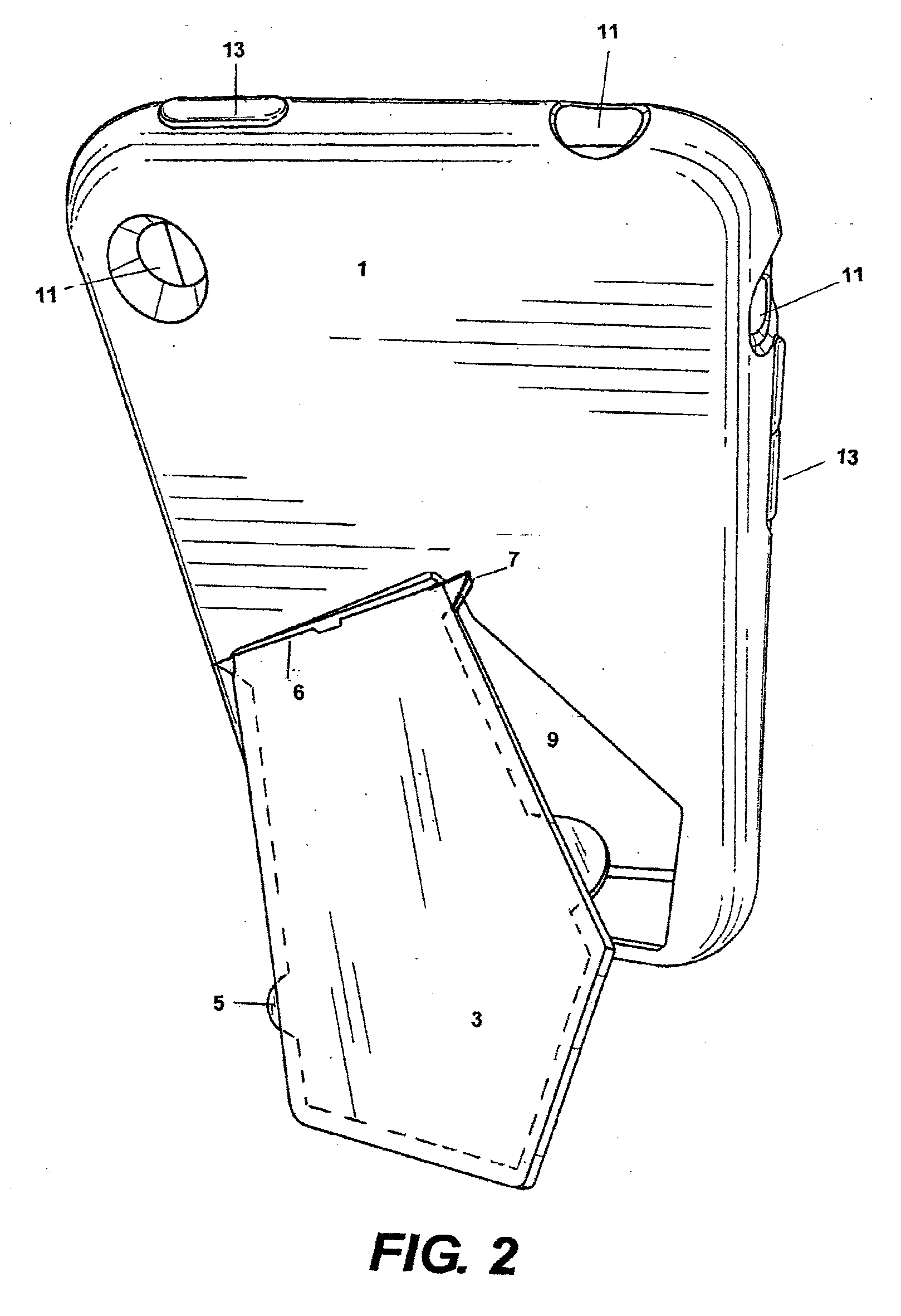

Integrated Frame/Stand for Portable Electronic Devices

InactiveUS20100059649A1Improve featuresLess bulkyStands/trestlesKitchen equipmentEngineeringTouchscreen

The present invention relates to protective frames for portable electronic devices that can also be used to support the device in an upright display position. In particular, embodiments of the present invention include protective frames for electronic devices that have a support arm attached to, integrated with, and recessed into the frame by a hinge or other secure mechanism that is movably attached, allowing it to be supported in horizontal and vertical positions. Embodiments of the present invention may be used with any type of portable electronic device including portable media players and portable cellular telephones. It may be particularly useful with portable electronic devices that use a touchscreen input.

Owner:BUXTON PIERCE ALFRED

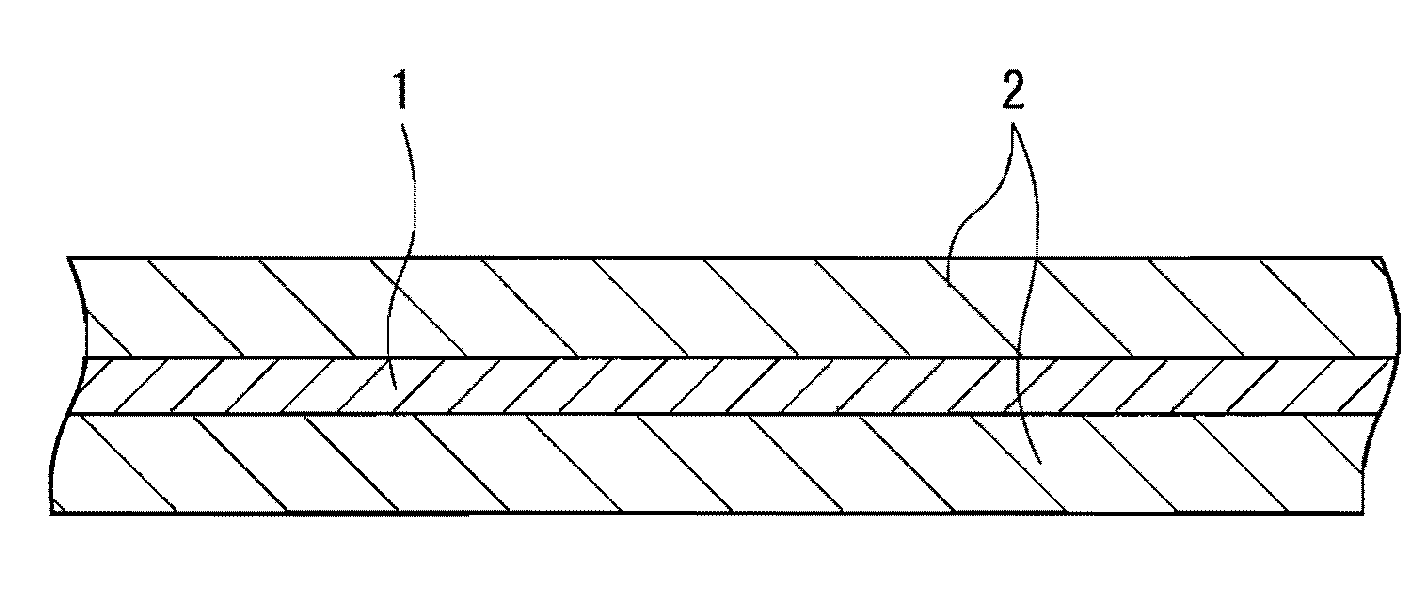

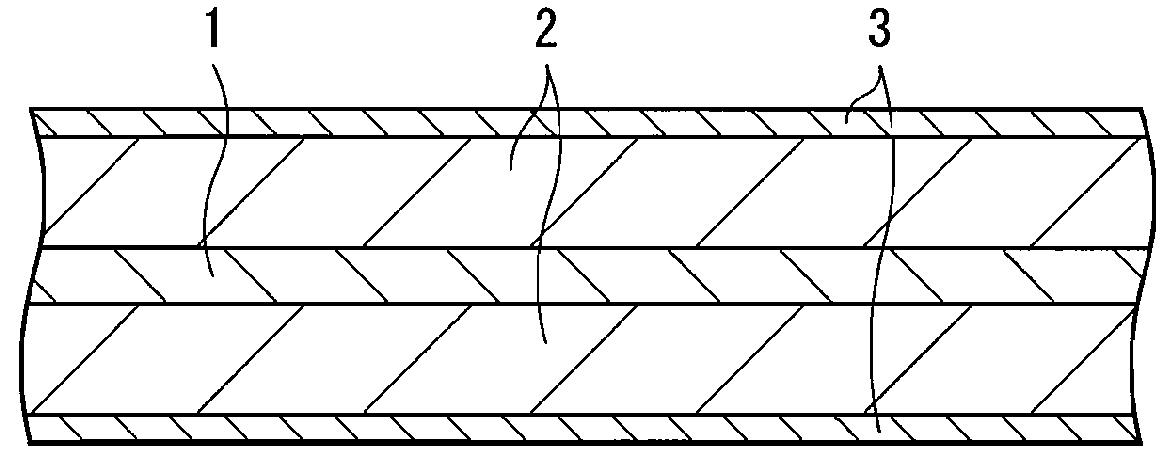

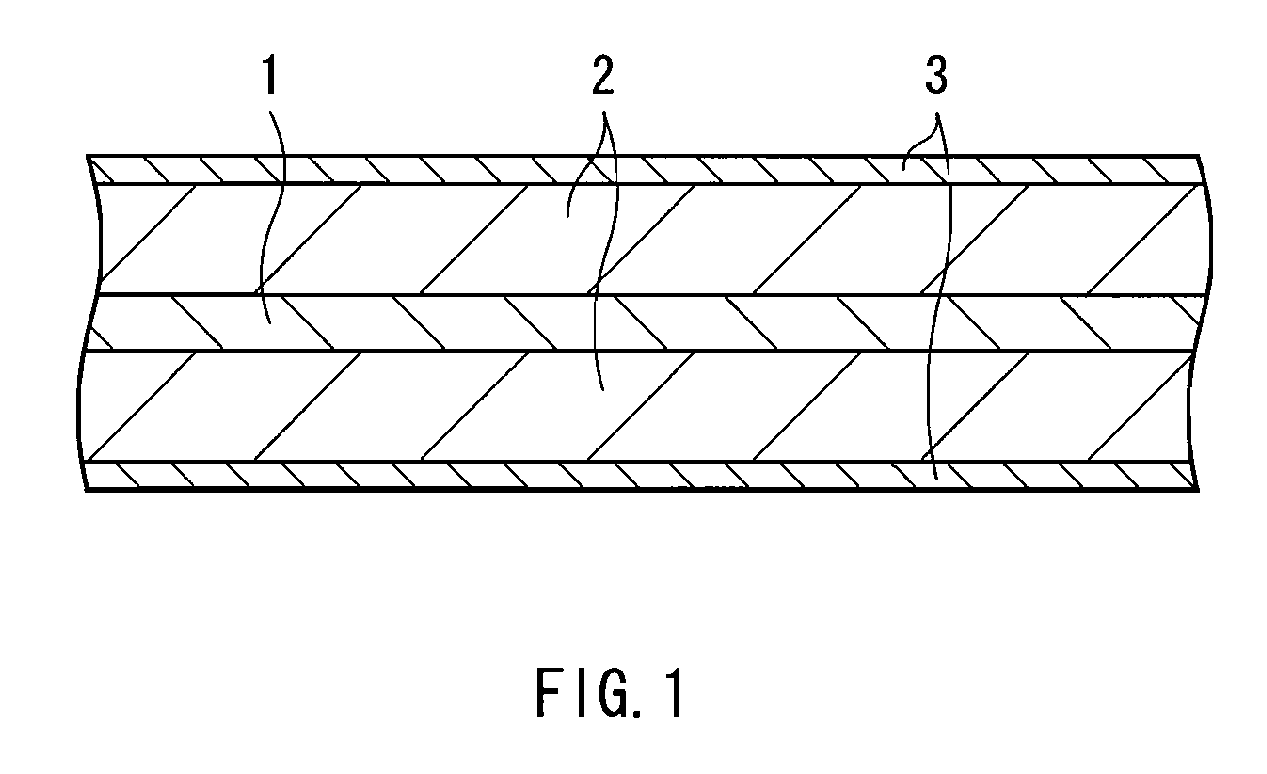

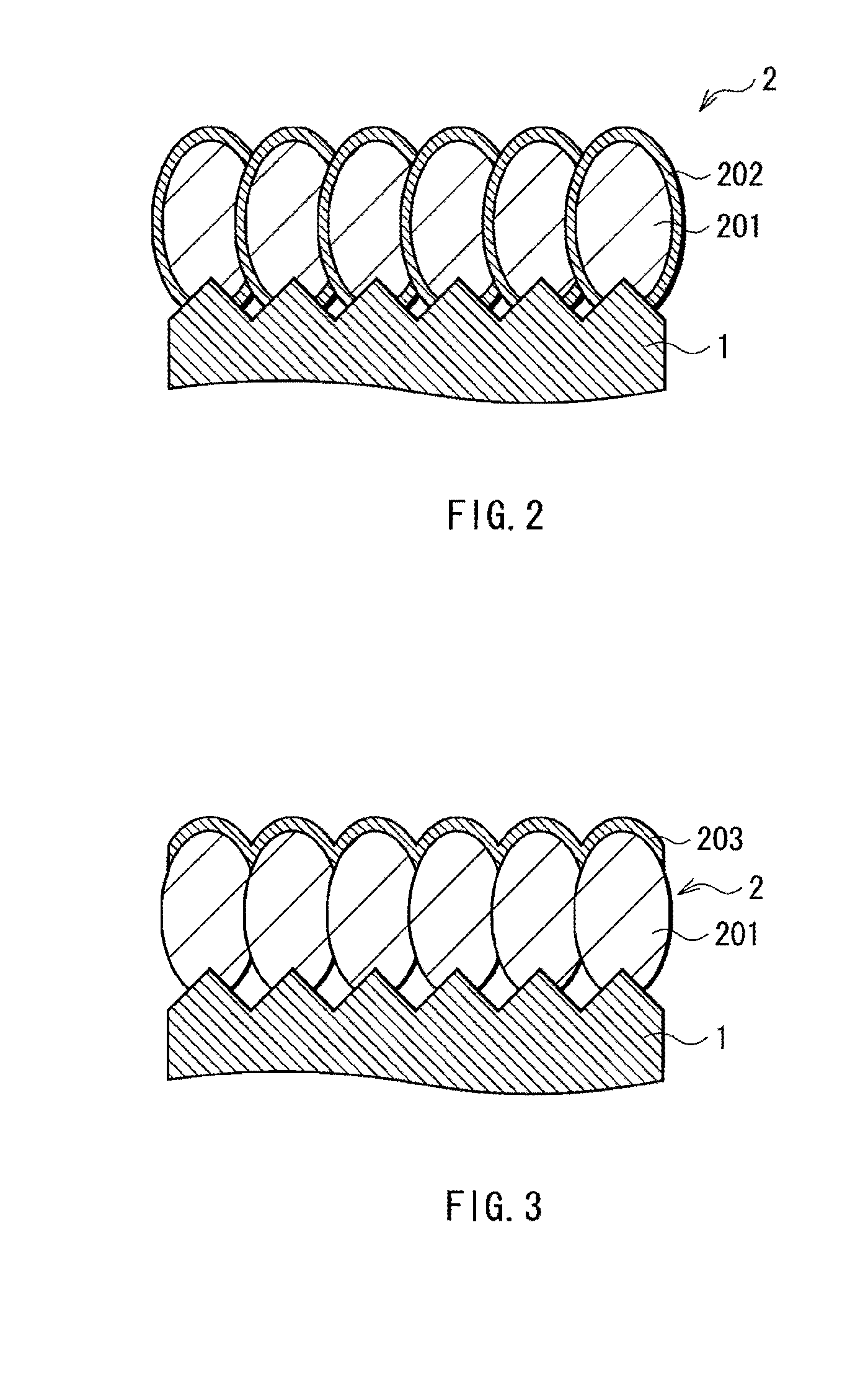

Anode active material, anode, and battery

ActiveUS20090111031A1Improve performanceExcellent cycle characteristicsFinal product manufactureElectrode carriers/collectorsX-rayPeak intensity

A battery capable of improving the cycle characteristics is provided. The battery includes a cathode, an anode, and an electrolytic solution. The anode has an anode active material layer that contains an anode active material containing silicon on an anode current collector, and intensity ratio I1 / I2 between peak intensity I1 originated in (220) crystalline plane of silicon obtained by X-ray diffraction and peak intensity I2 originated in (111) crystalline plane of silicon obtained by X-ray diffraction is 0.05 or more.

Owner:MURATA MFG CO LTD

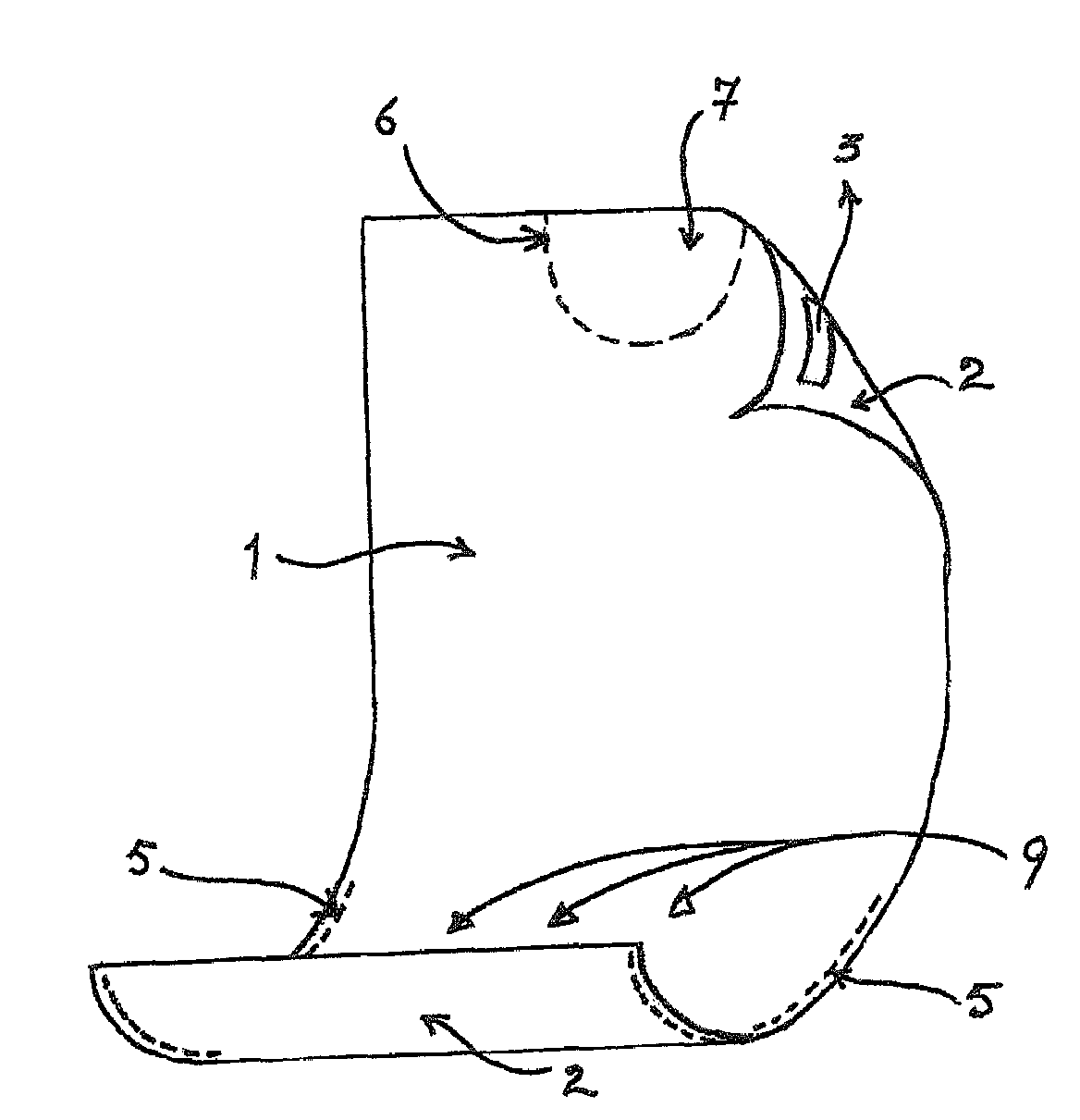

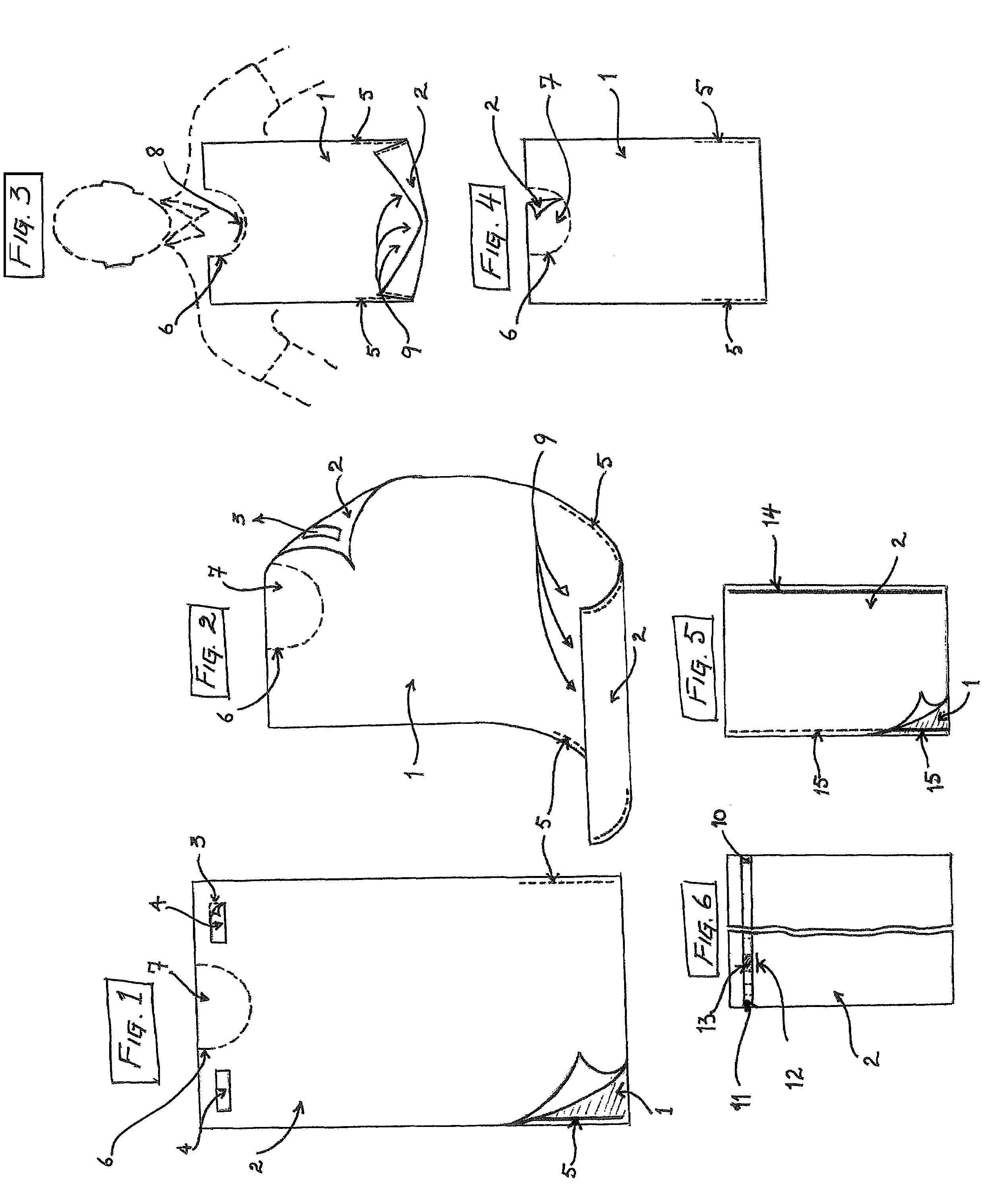

Deformable bib and method for using same

InactiveUS7380284B1Low manufacturing costSimple to useHandkerchiefsBaby linensPressure sensitiveMechanical engineering

A disposable protective covering, namely, a bib or napkin of generally rectangular shape is disclosed consisting of two layers, a first layer of soft absorbent paper and a second layer made of water impermeable material, embossed or bonded together, having two pressure sensitive adhesive strips with protective liners on the corners of the upper portion of the second layer, a rapture (perforated) line for a neck line cut-out in the center of the upper portion and edge portions including wires (embedded between the first & second layer) attached parallel to the length of the bib at the lower portion to retain a manipulated shape of the bib.

Owner:DODANI KANEYO L

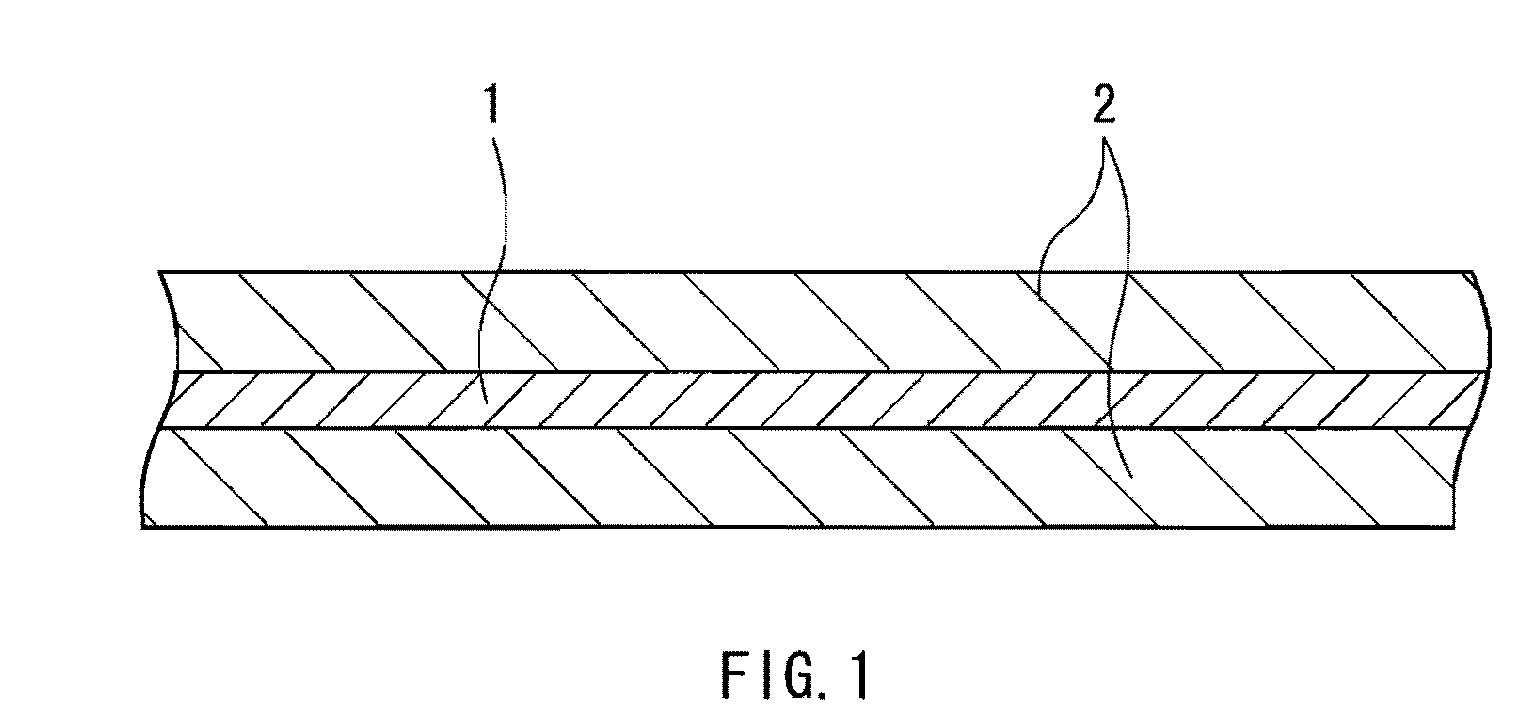

Anode and secondary battery

InactiveUS20090311608A1Improve performanceReduced characteristicsSilver accumulatorsElectrode carriers/collectorsSiliconVoltage

A secondary battery capable of improving the cycle characteristics and the voltage retention characteristics is provided. The secondary battery includes a cathode, an anode, and an electrolyte. The anode includes an anode current collector, an anode active material layer formed on the anode current collector and including an anode active material containing silicon as an element, and a coat formed on the anode active material layer and having an integral structure of three-dimensional network.

Owner:SONY CORP

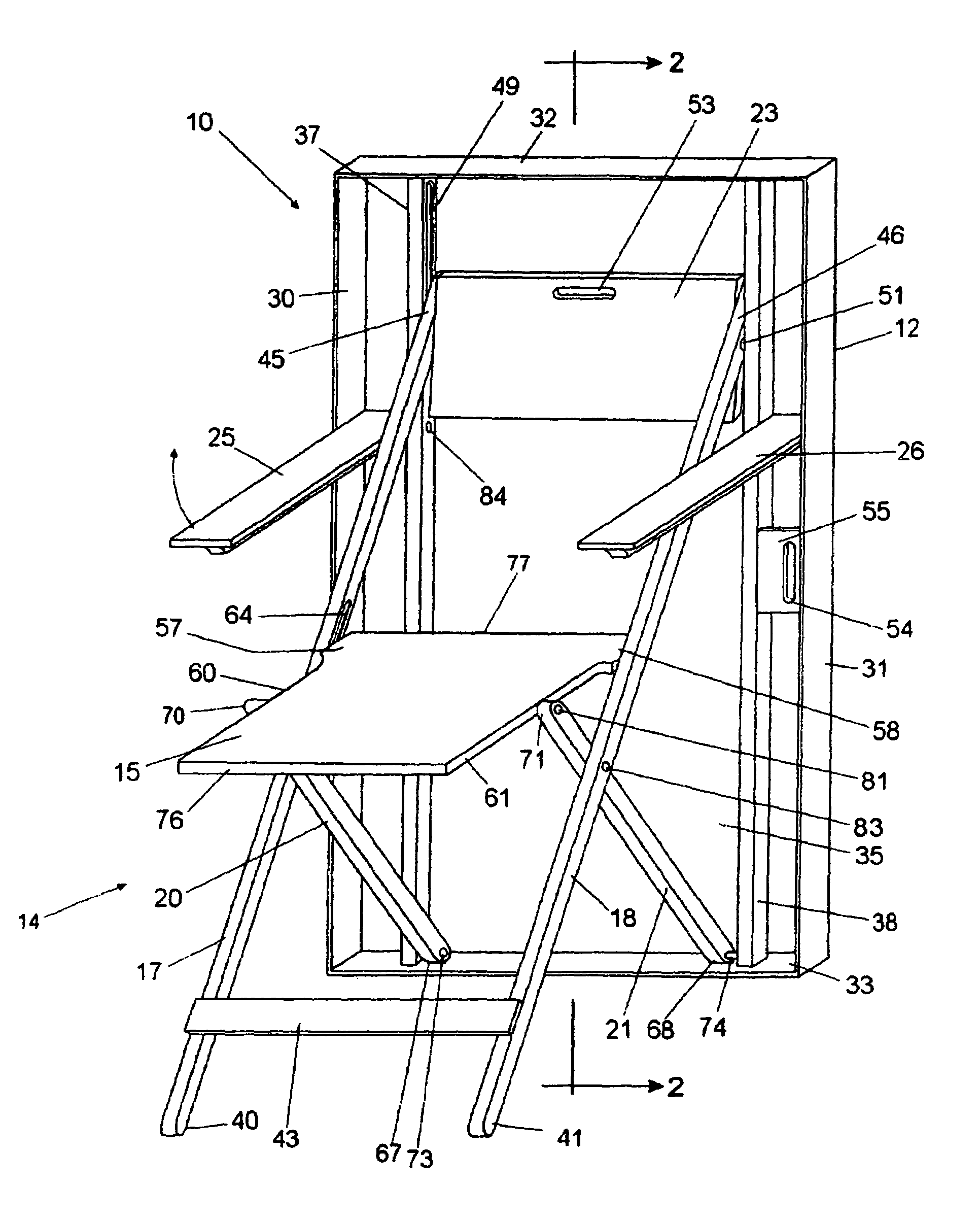

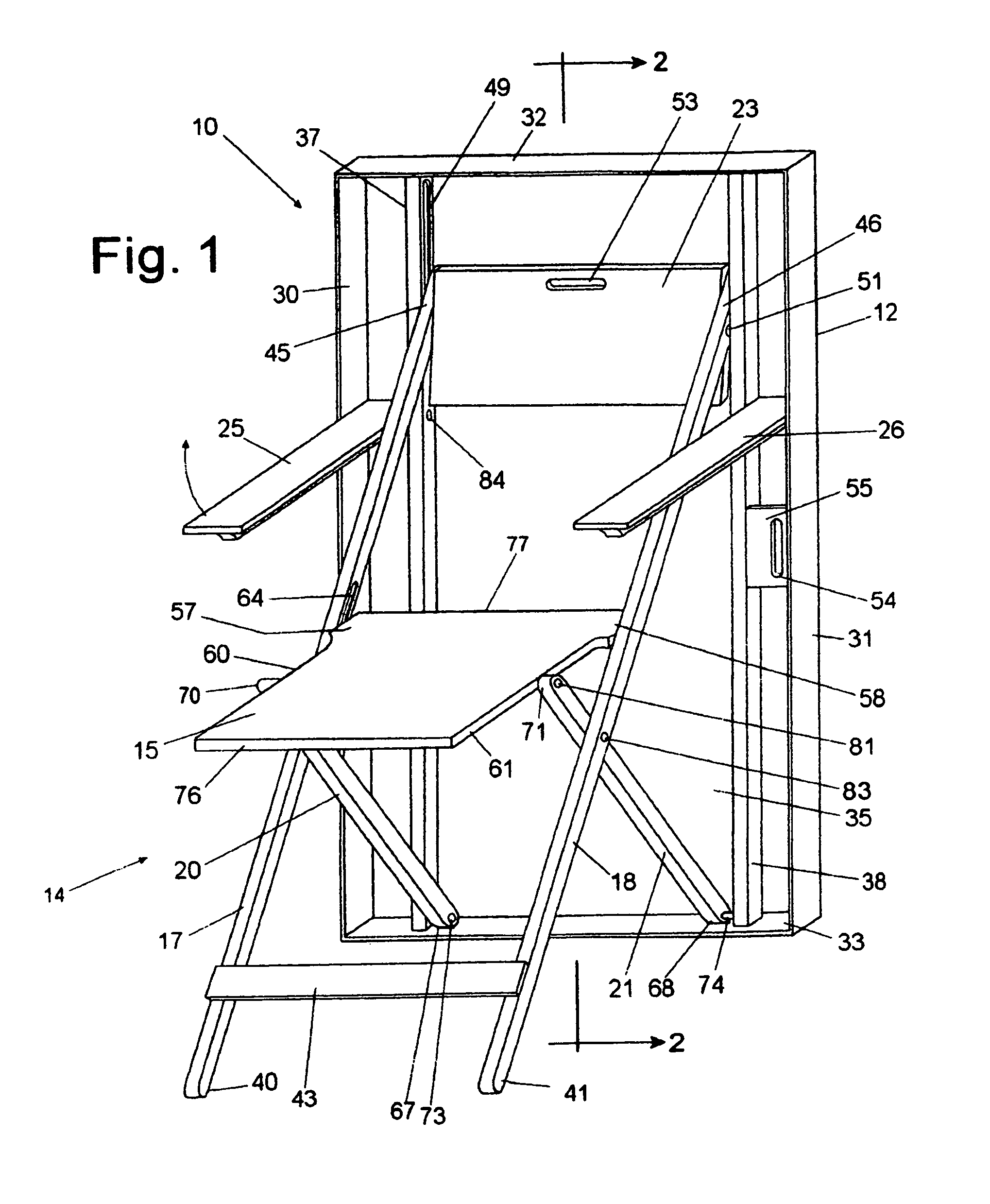

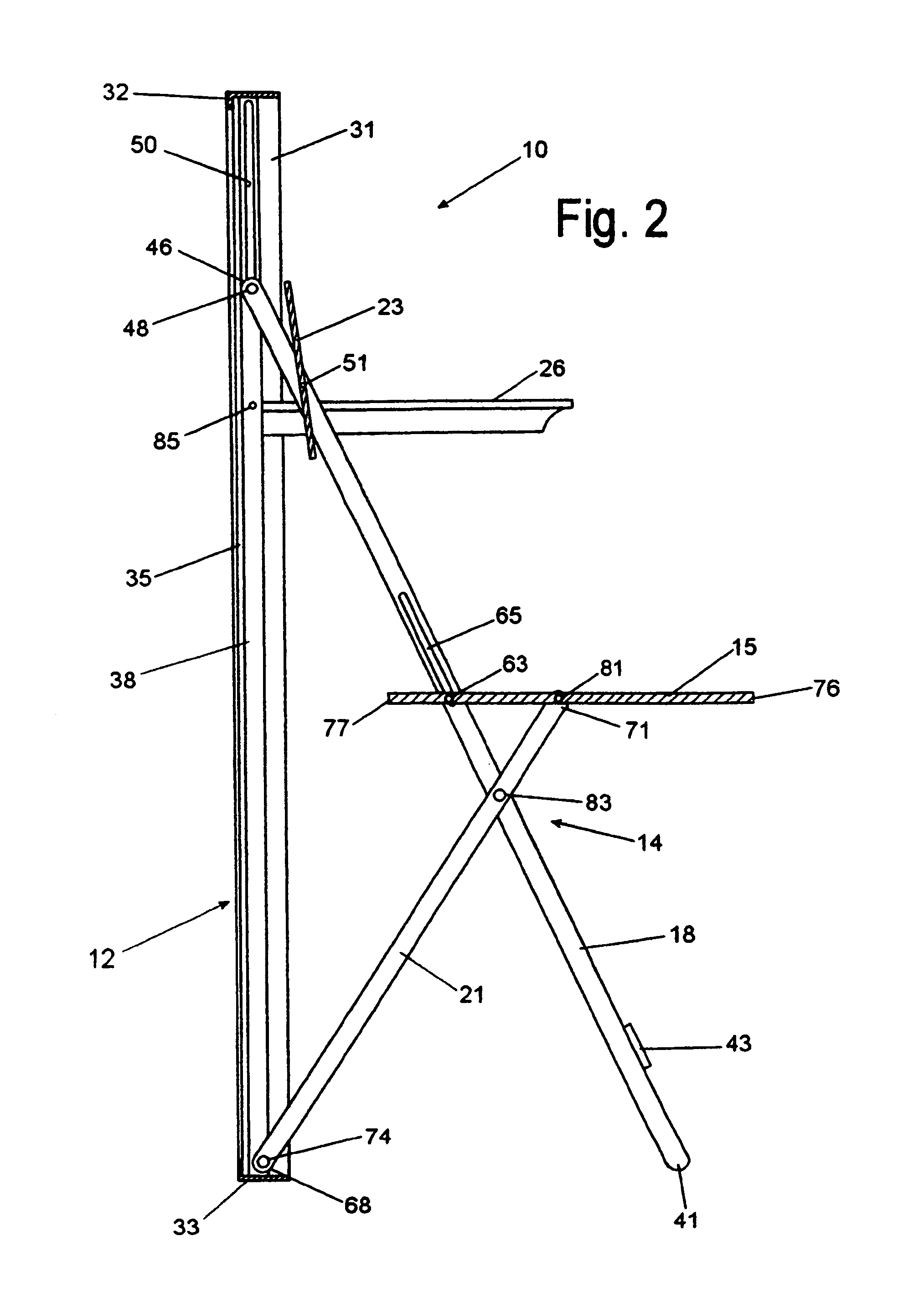

Folding chair

A folding chair assembly includes a frame having side, top and bottom walls, first and second pairs of legs, a seat between the legs, a first pair of leg pivots connecting respective legs together, a second pair of leg pivots engaging a first pair of cooperating slots for connecting first leg upper ends to the frame, a third pair of leg pivots for connecting second leg lower ends to the frame, a first pair of seat pivots for connecting the seat to second leg upper ends, and a second pair of seat pivots rearward on the seat of the first seat pivots engaging a pair of cooperating slots for connecting the seat to the first leg pair, whereby the chair is foldable from an open position with seat and legs extended to a closed position with seat and legs aligned within the frame. Pivoting arm rests can be provided.

Owner:FOY MICHAEL B

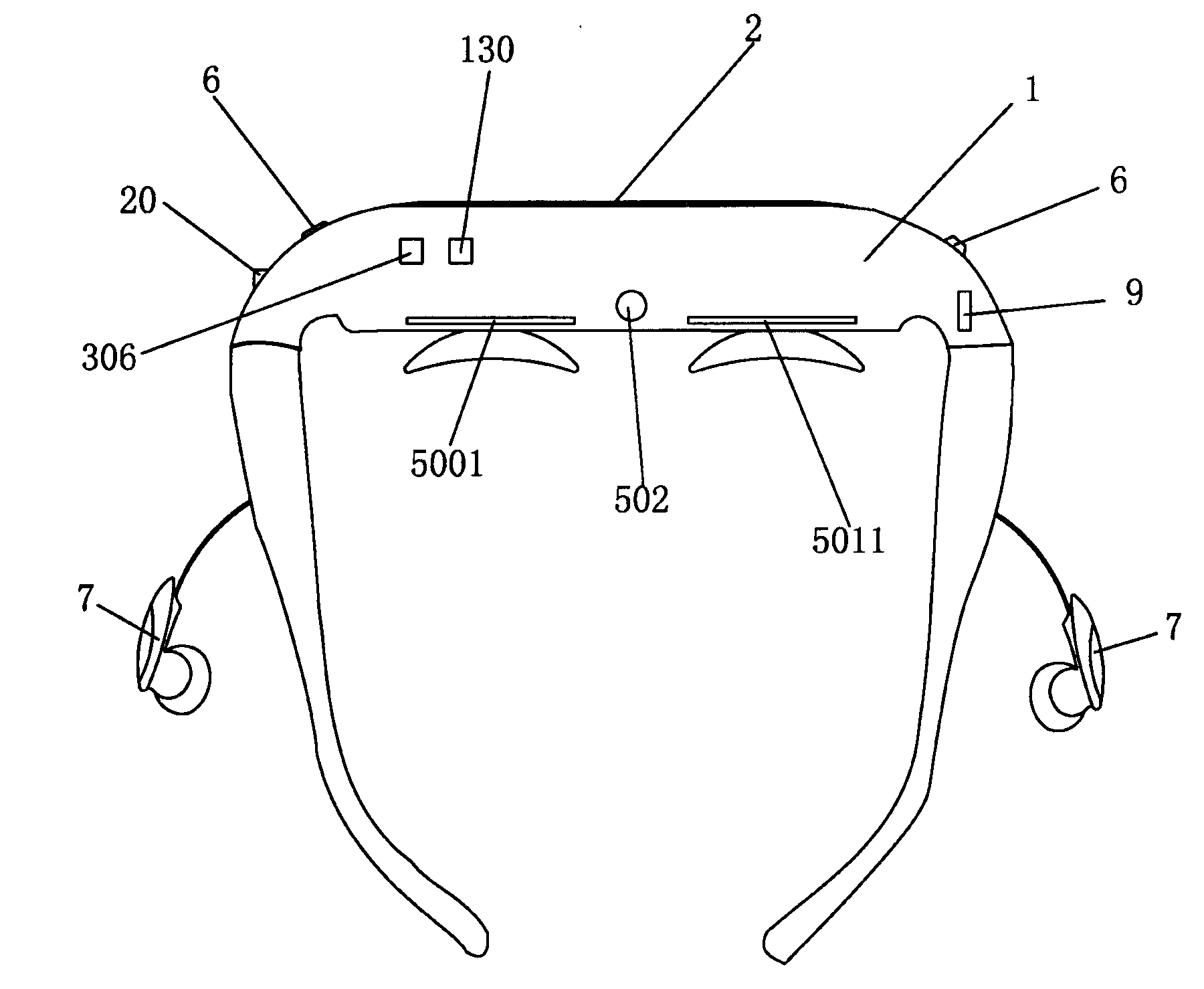

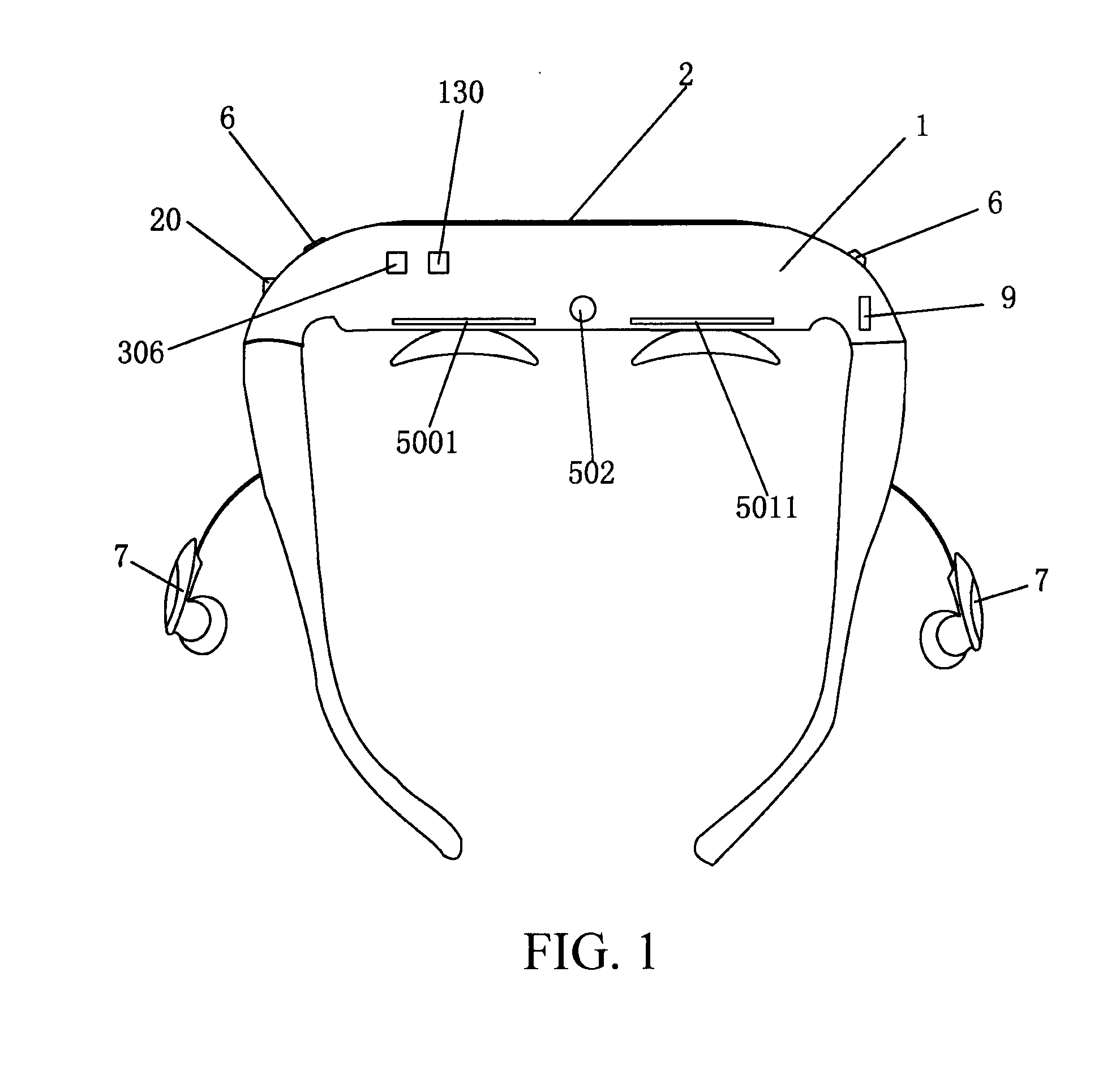

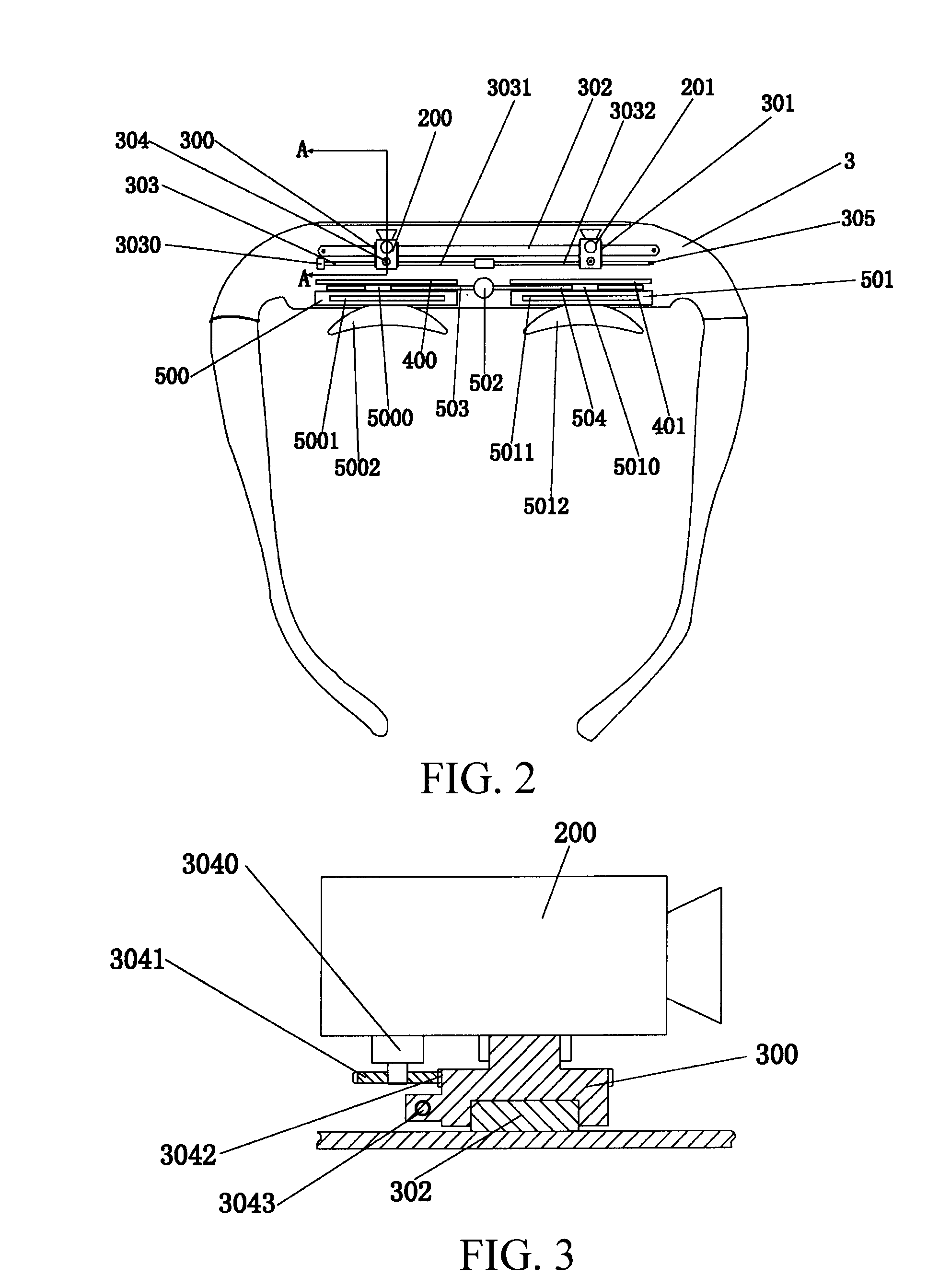

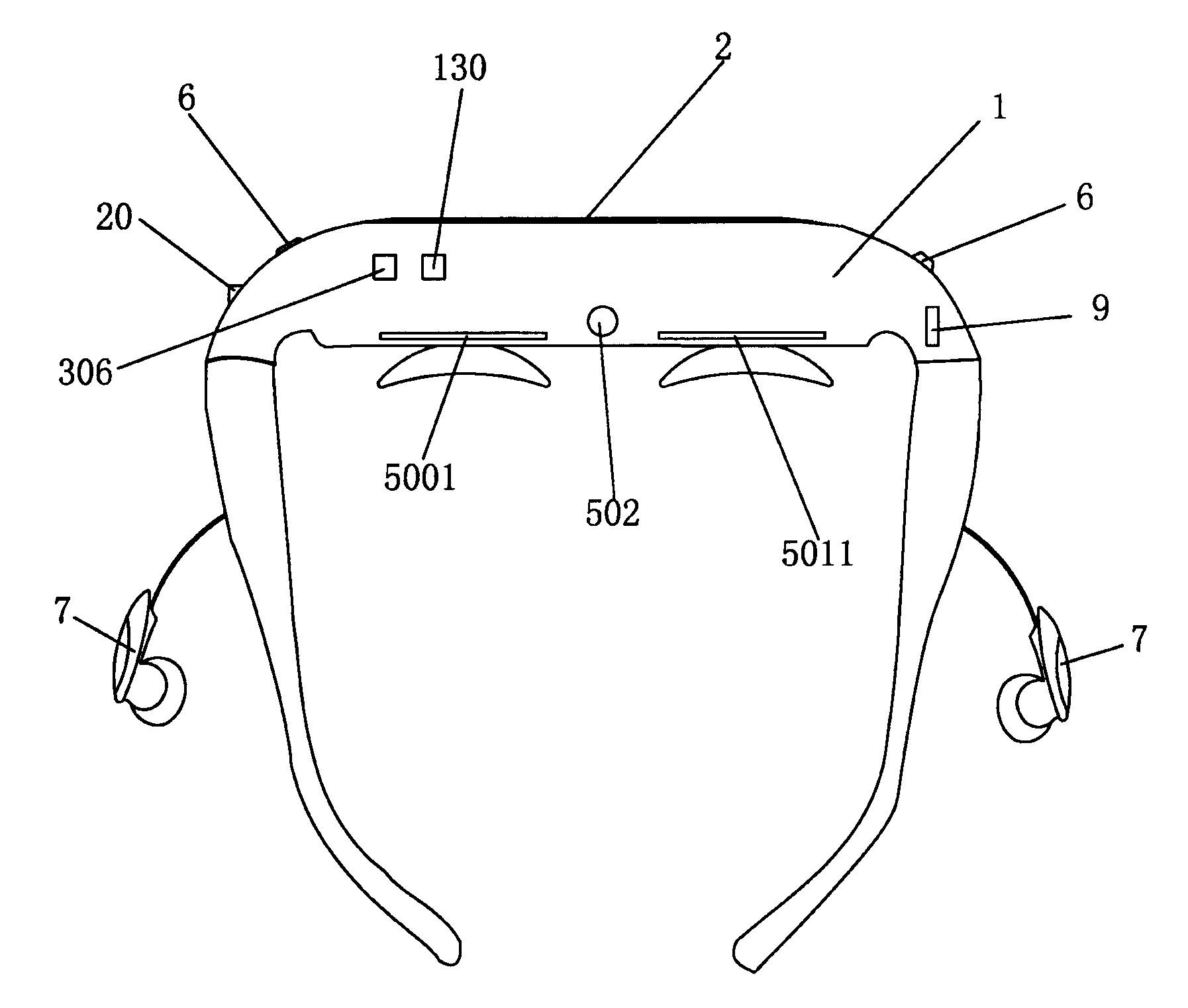

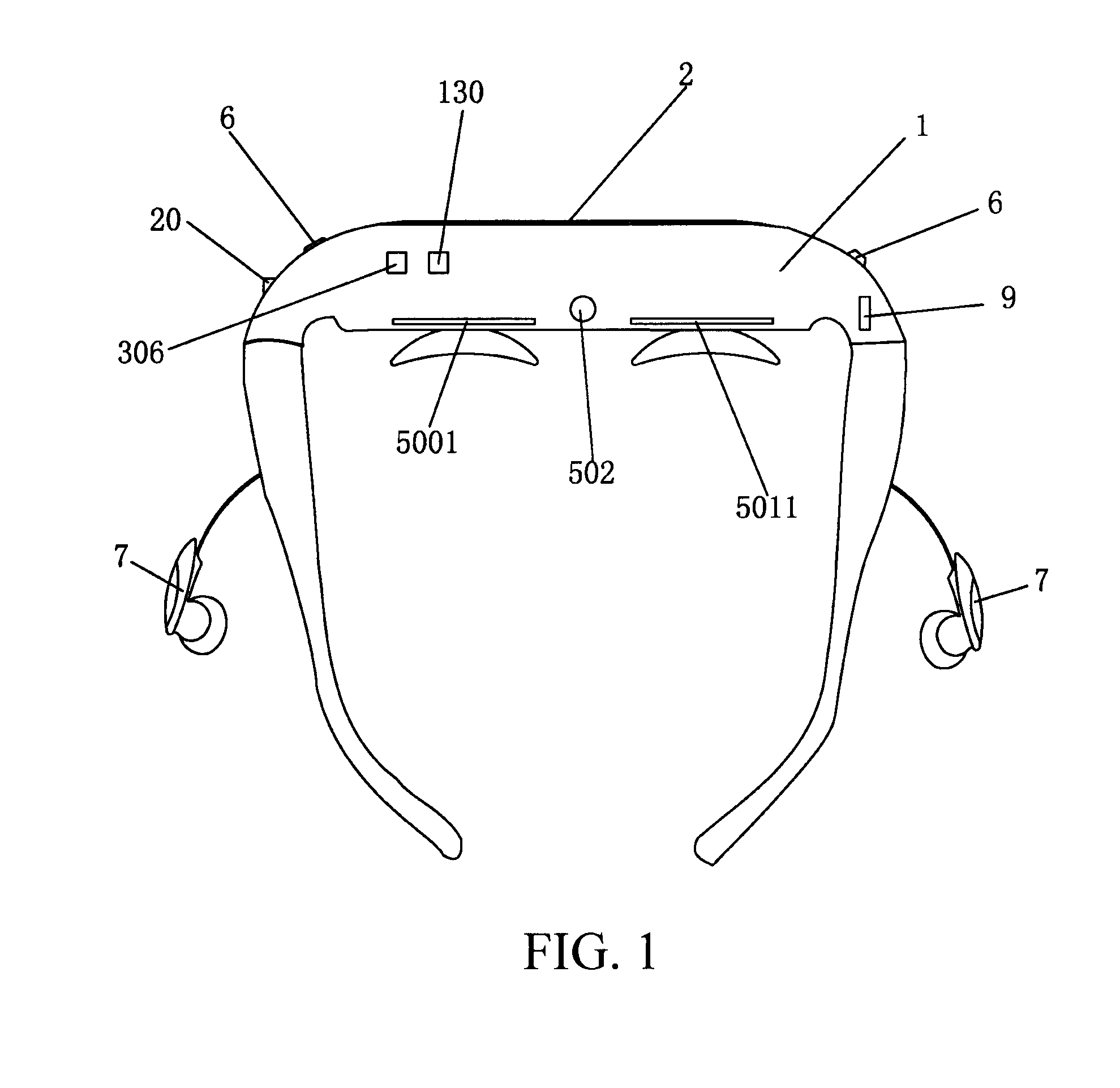

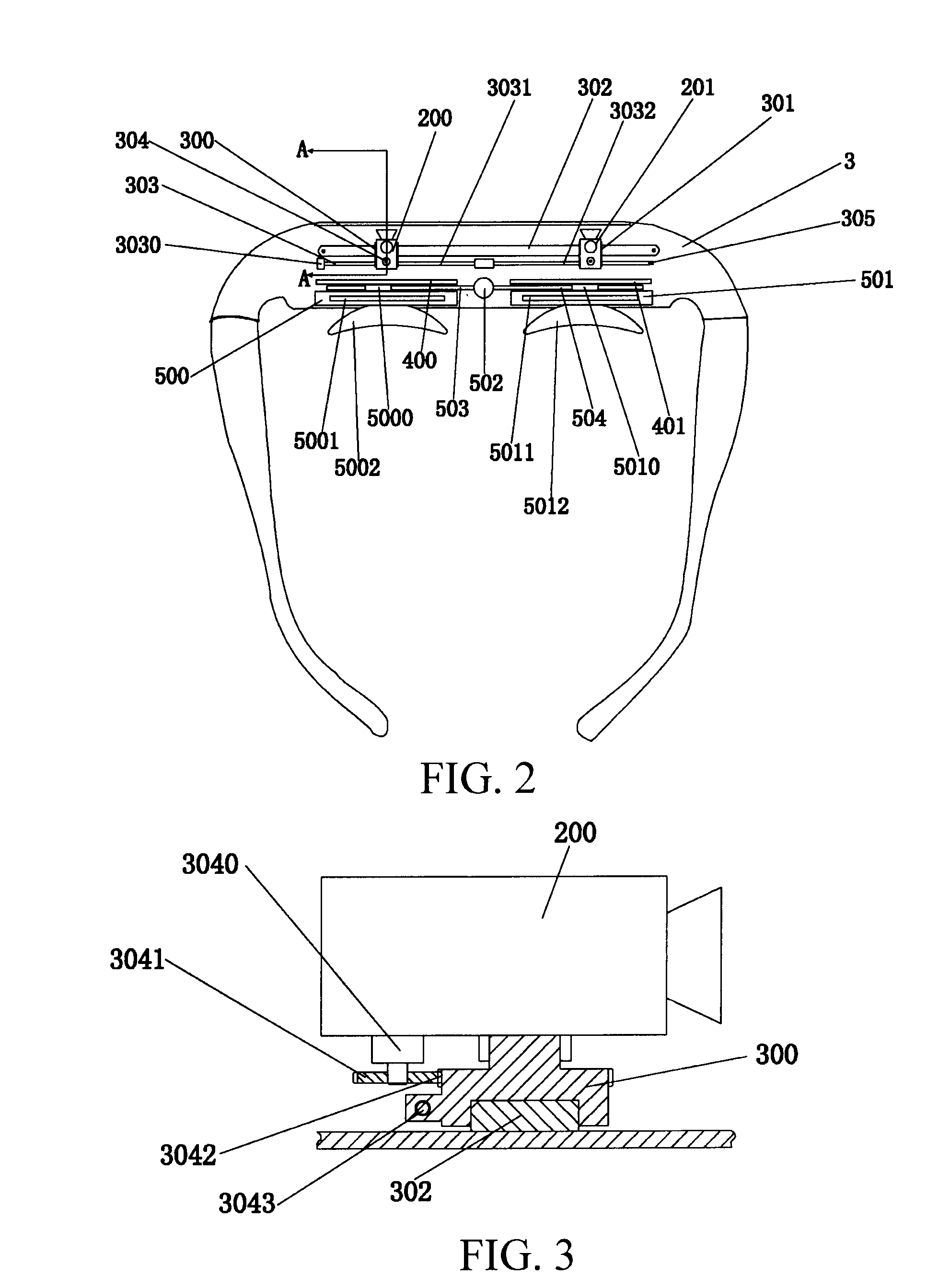

Integrative spectacle-shaped stereoscopic video multimedia device

ActiveUS20100177168A1Simple structureLow costTelevision system detailsColor television detailsLoudspeakerDigital camera

An integrative spectacle-shaped stereoscopic video multimedia device includes a blinder and a video device disposed in the blinder. The video device includes two digital camera modules, an adjusting device for adjusting an axle distance and included angle between the digital camera modules, a binocular stereoscopic viewing module, a viewing module hole distance adjusting mechanism, sound pickups, loudspeakers, a memory, a plurality of analog / digital converters, a processor, a power source, and process control software coordinating the above members. The invention has advantages of a simple structure, a low cost, and a vivid stereoscopic effect, and is suitable for personal use.

Owner:INLIFE HANDNET CO LTD

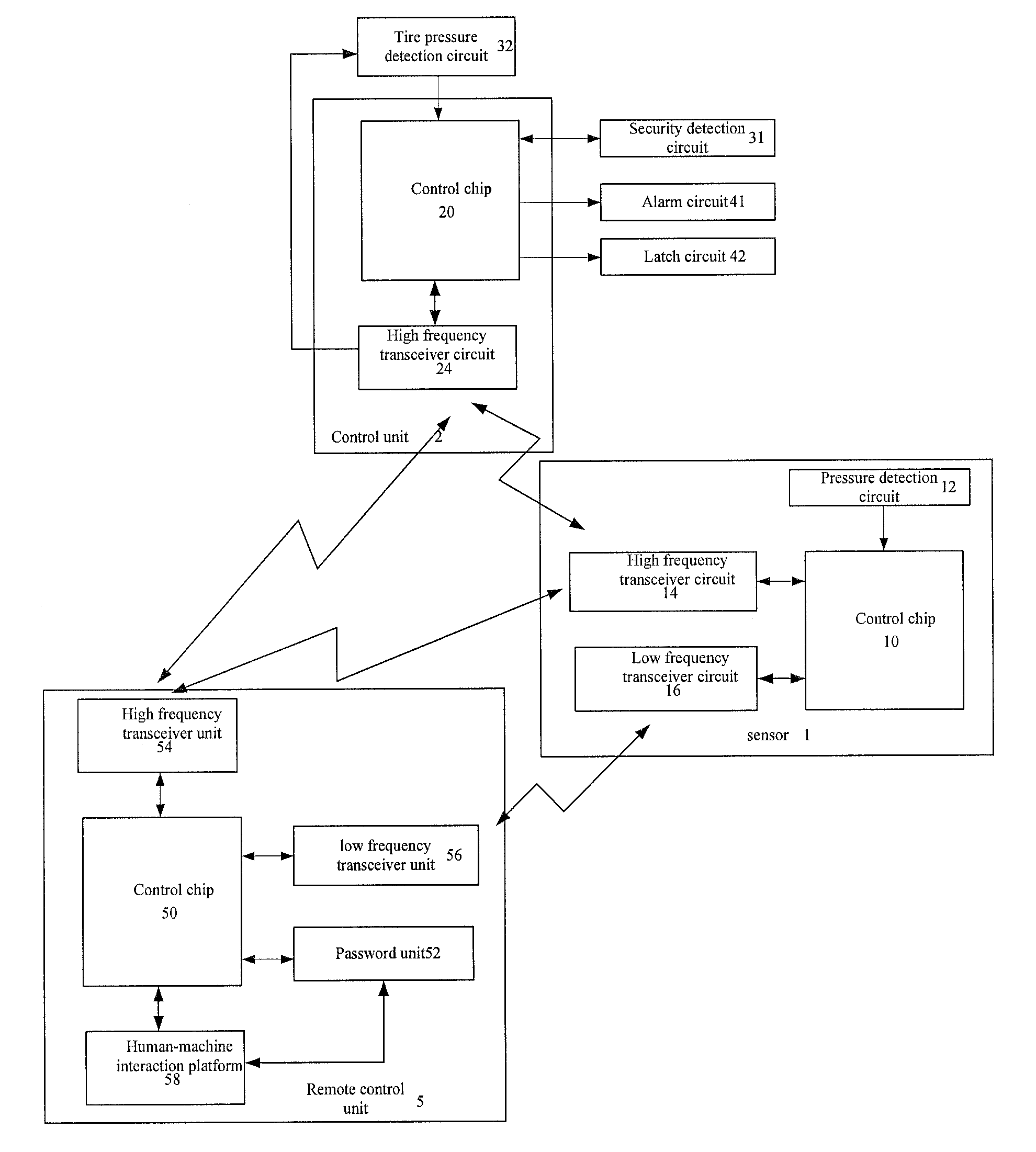

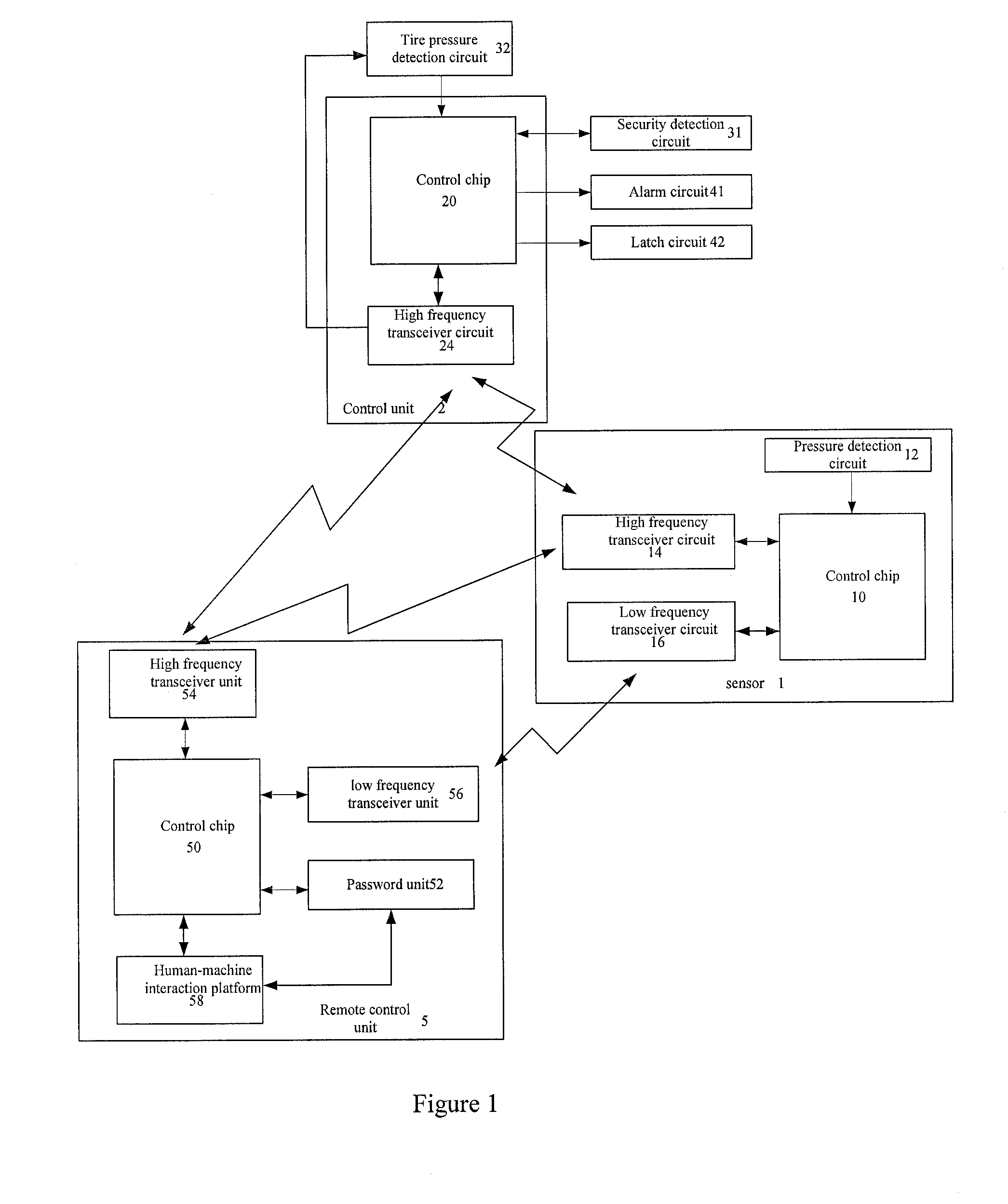

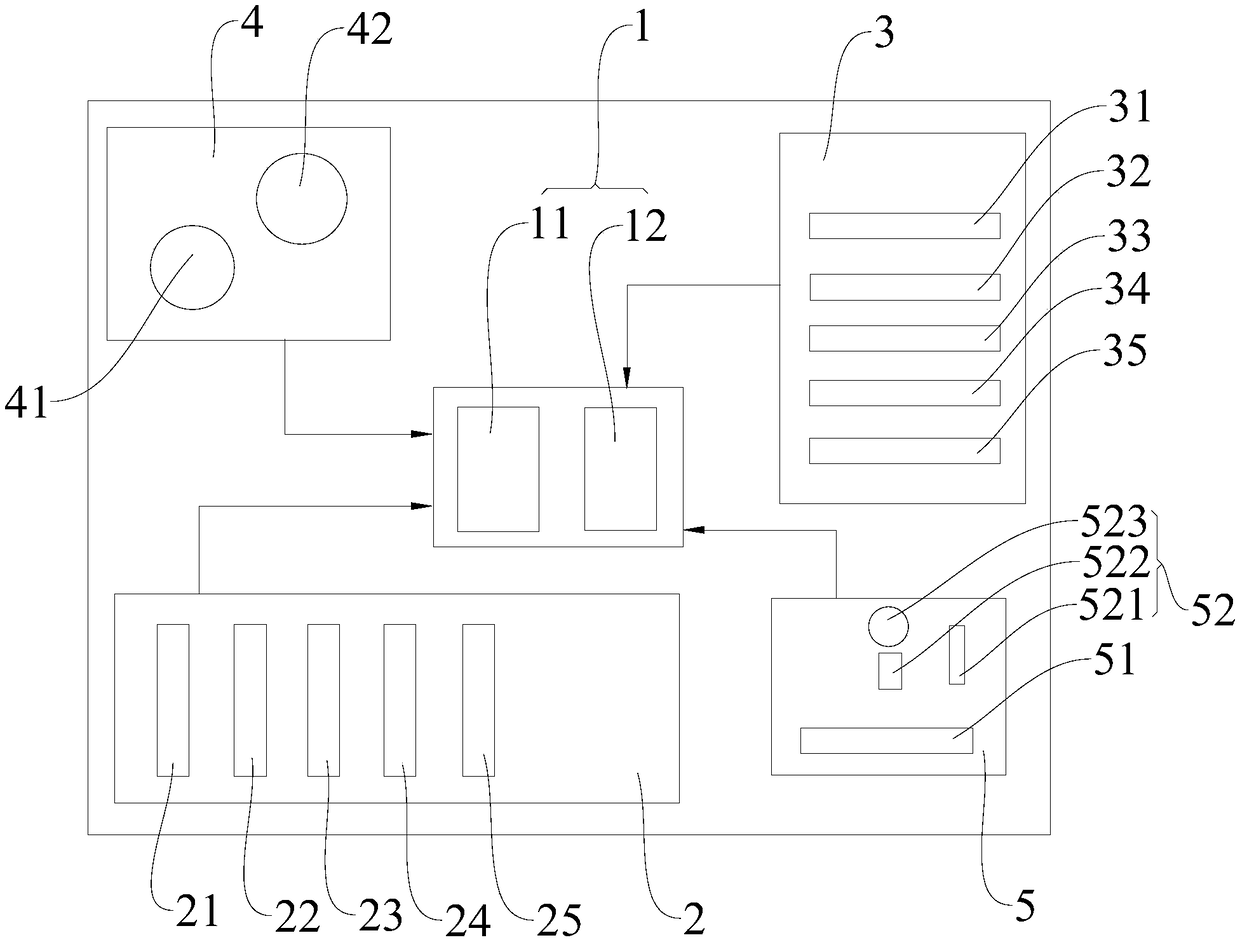

Tire pressure monitoring-car security integrated system and tire pressure monitoring method

The invention provides a tire pressure monitoring-car security integrated system for realizing car security and tire pressure monitoring and method thereof In the system, a conventional tire pressure monitoring system and car security system are integrated with each other. The learning machine or signal match device of the &Inner is also combined with the remote control portion of the latter. The central monitor portion of the former is combined with the car security host machine of the latter. Control logic and electrical construction thereof is also optimized. Therefore, the invention is reasonable in its design and low cost. In addition, use convenience is also improved and great commercial success may be realized.

Owner:STEELMATE CO LTD

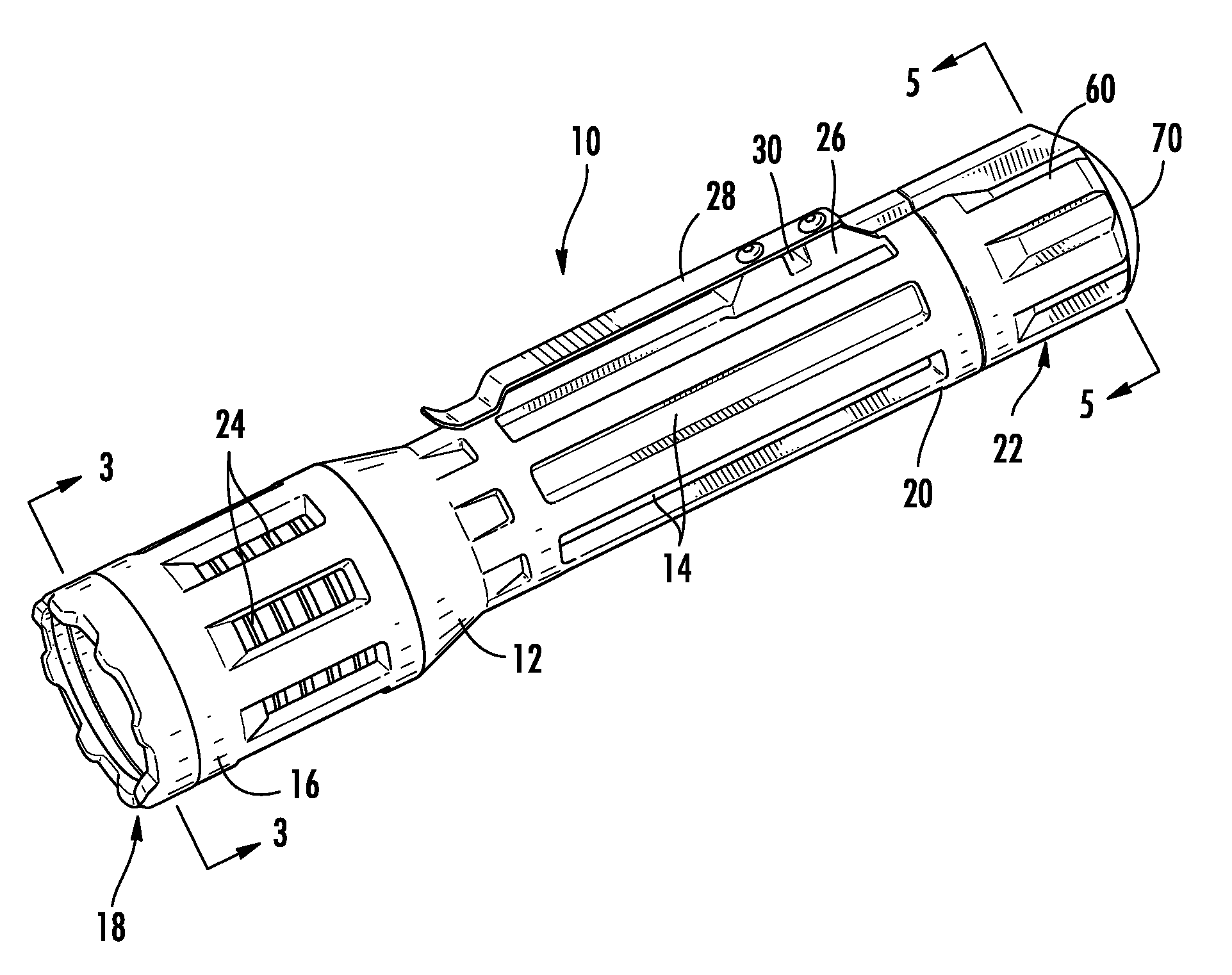

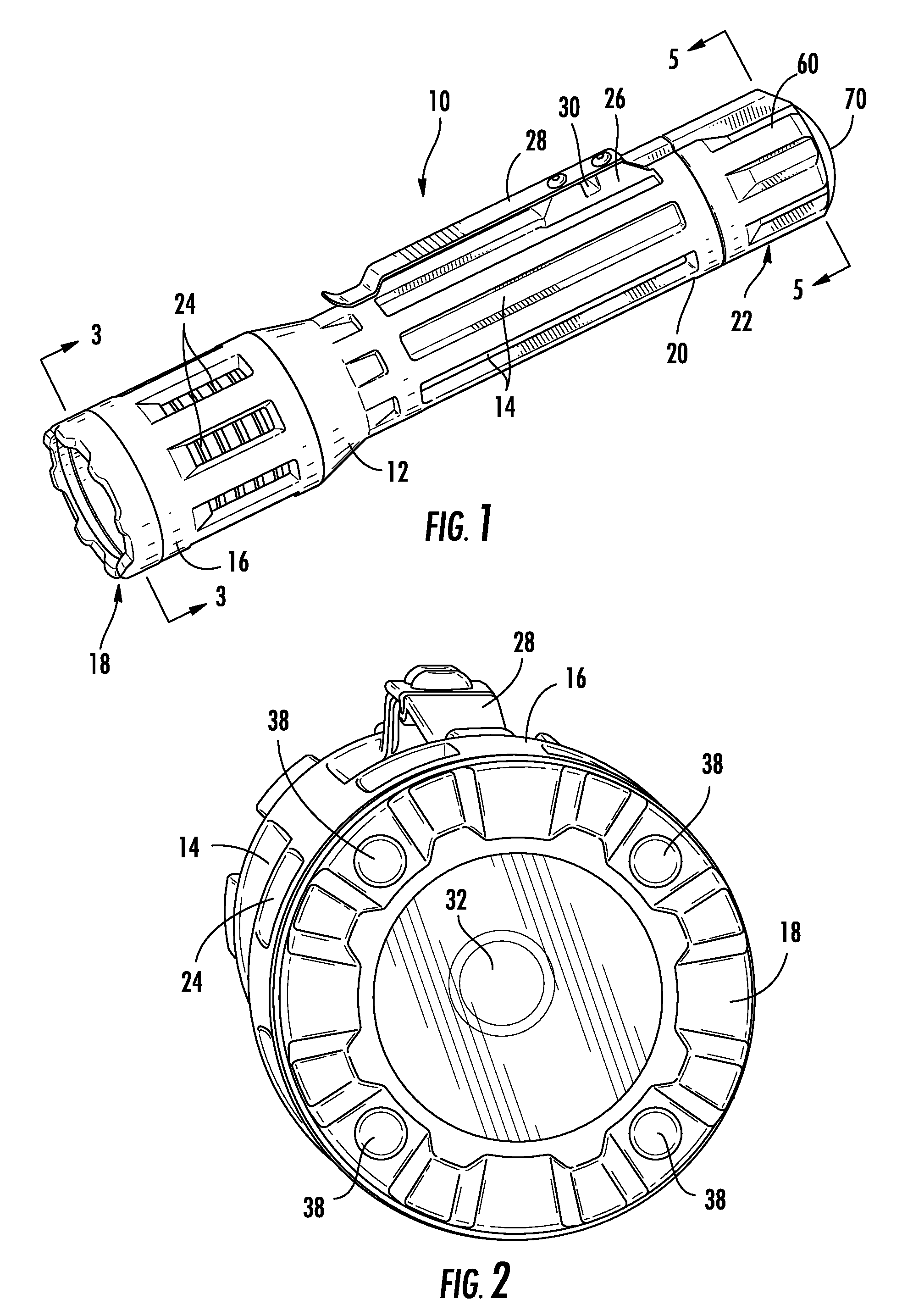

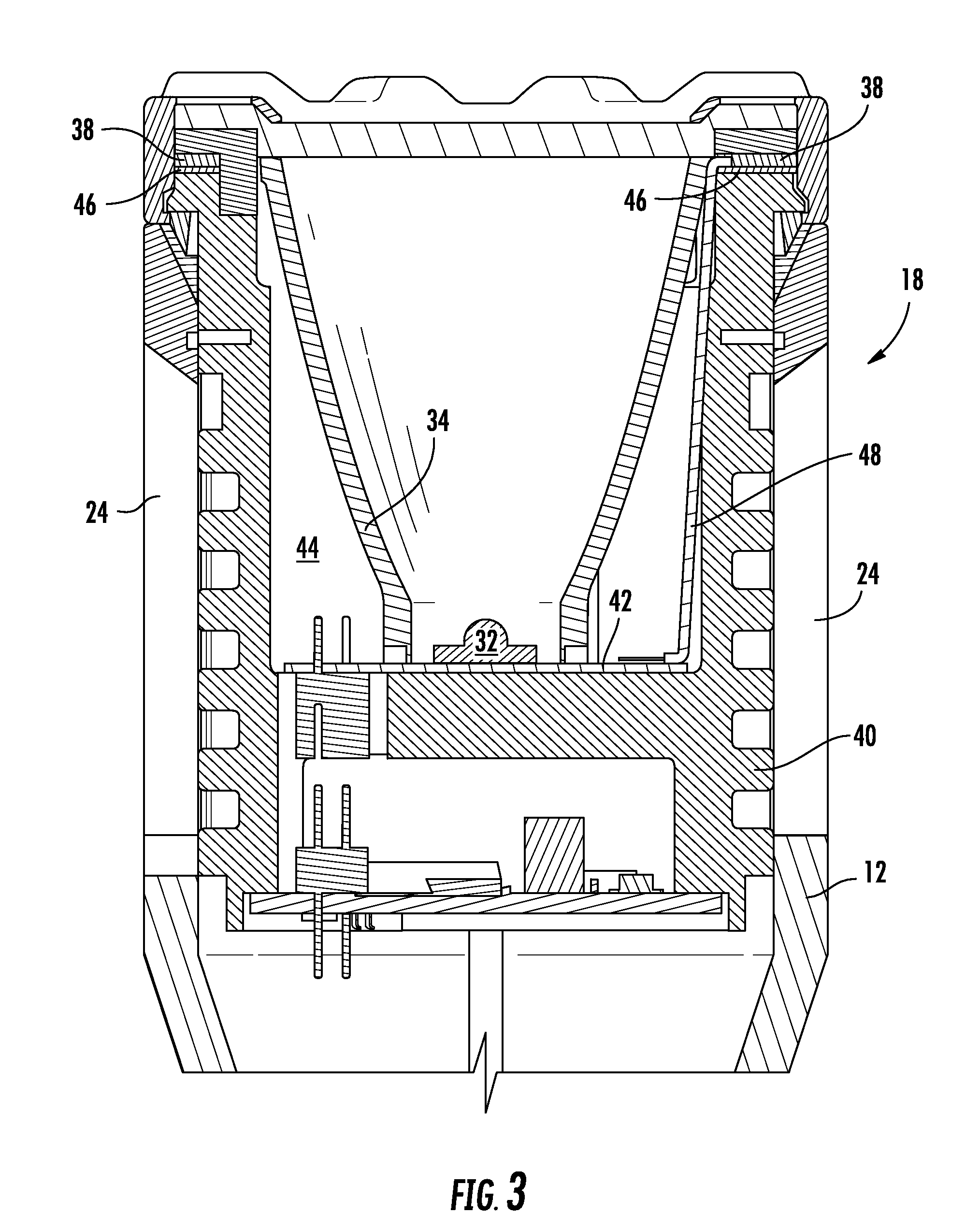

Multi-function flashlight

InactiveUS20090190339A1Easy to operateEasy to integratePoint-like light sourceElectric circuit arrangementsEngineeringFlashlight

A multi-function flashlight device is provided in either an all white light emitting diode (LED) or a colored LED version that allows versatile functionality. The flashlight is fashioned to have an outer housing that includes both an integrated means for interfacing the flashlight with a firearm and a surface thereon that serves as a handgrip. The outer housing of the flashlight is configured to be engaged by a clamping assembly that facilitates integration of the flashlight with standard firearm accessory rail assemblies. The flashlight head includes a high-output white LED positioned centrally within an optical element such as a reflector. Should the flashlight be a colored light, four other positions are provided around the periphery of the lens that contain colored LEDs. The flashlight provides the user the ability to selectively and individually control the mode of operation for all of the LEDs contained therein.

Owner:EMISSIVE ENERGY A DELAWARE

Integrative spectacle-shaped stereoscopic video multimedia device

ActiveUS8259159B2Simple structureLow costSteroscopic systemsStereoscopic videoComputer graphics (images)

Owner:INLIFE HANDNET CO LTD

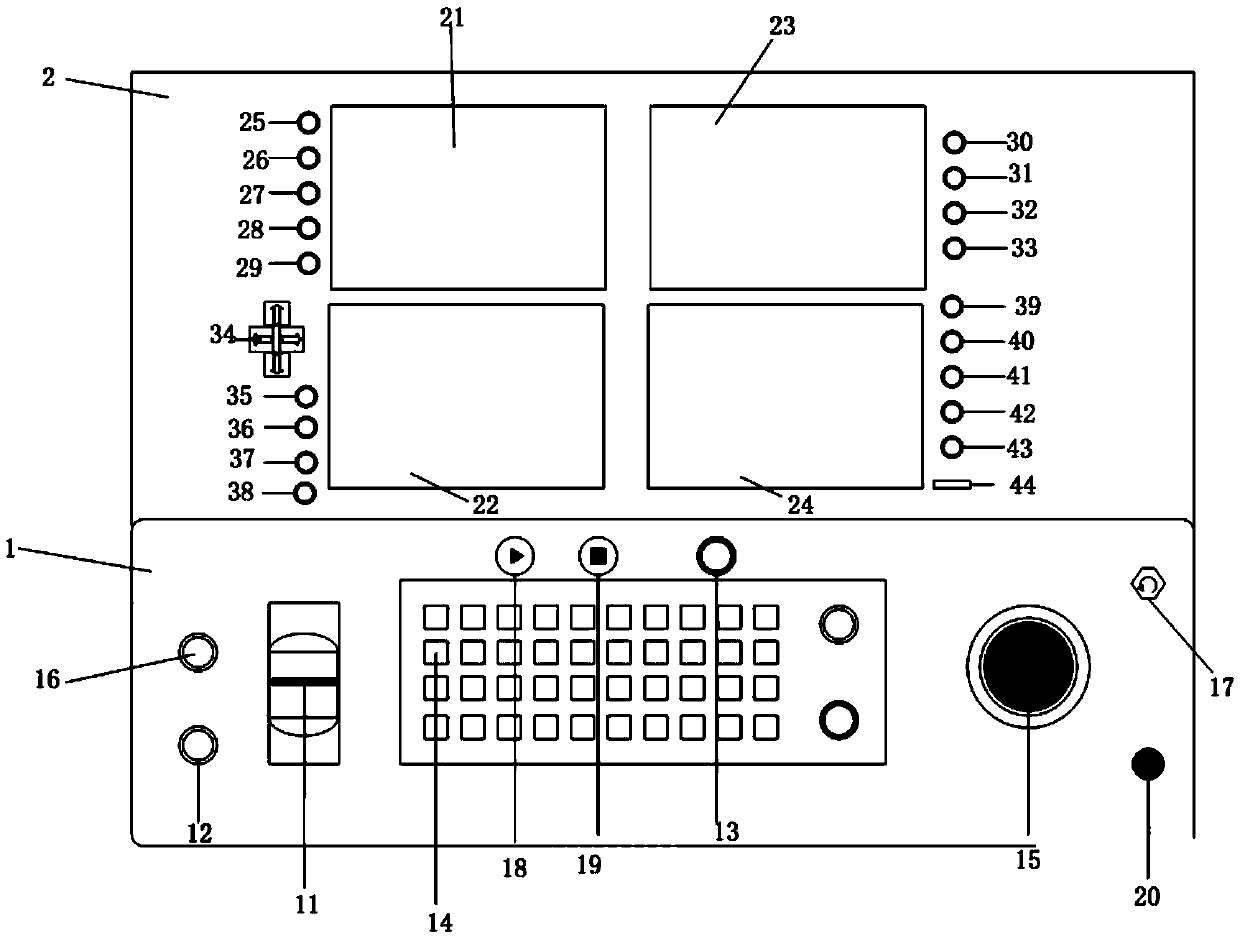

Ground control station based on airborne system of unmanned aerial vehicle

InactiveCN105513433AEasy to operateEasy to understandMultiple aircraft traffic managementFar distanceRemote control

The invention provides a ground control station based on an airborne system of an unmanned aerial vehicle. The ground control station comprises a remote control operation panel and a display screen panel, wherein the display screen panel comprises a flight state display screen, a flight path display screen, an online consultation display screen and a task system display screen; the display screen panel is further provided with function buttons of all the display screens; the remote control operation panel comprises an accelerator rocking bar, a cloud deck knob, a dialing knob, a computer system control region, a flight control rocking bar, a flight mode selection button and a remote control takeover button. The ground control station provided by the invention is provided with the four screens in total so that various states of the unmanned aerial vehicle can be independently displayed and an operator can conveniently know about a plurality of types of needed information; the remote control operation panel is reasonably arranged so that the operator can conveniently manipulate the unmanned aerial vehicle; the ground control station is used as supplementation and upgrading of a handheld portable ground station and provides a more comfortable operation mode and more flight functions and task functions; by using airborne advantages of the ground control station, measurement and control operation in a relatively far distance can be carried out.

Owner:HEFEI INST FOR PUBLIC SAFETY RES TSINGHUA UNIV +1

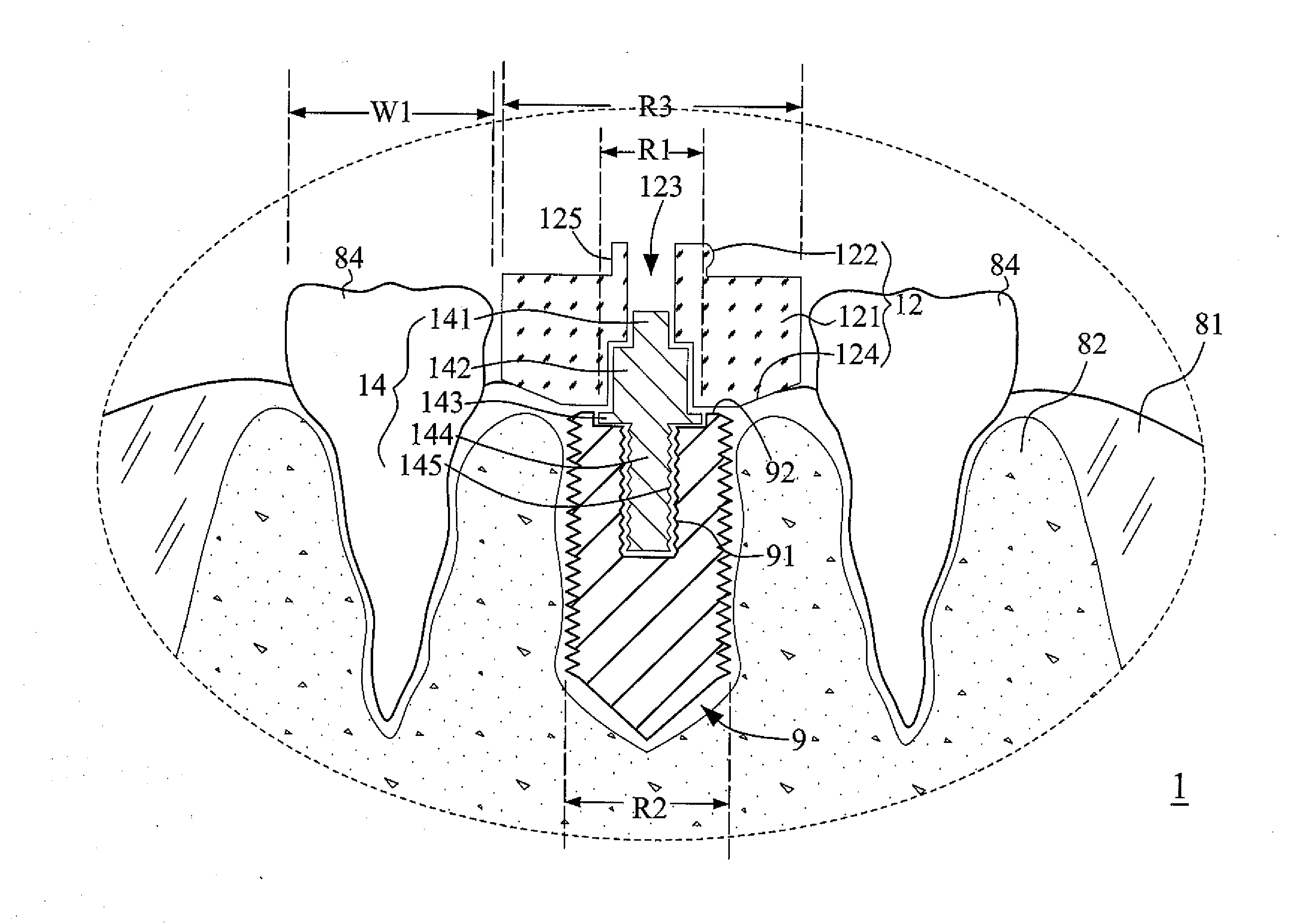

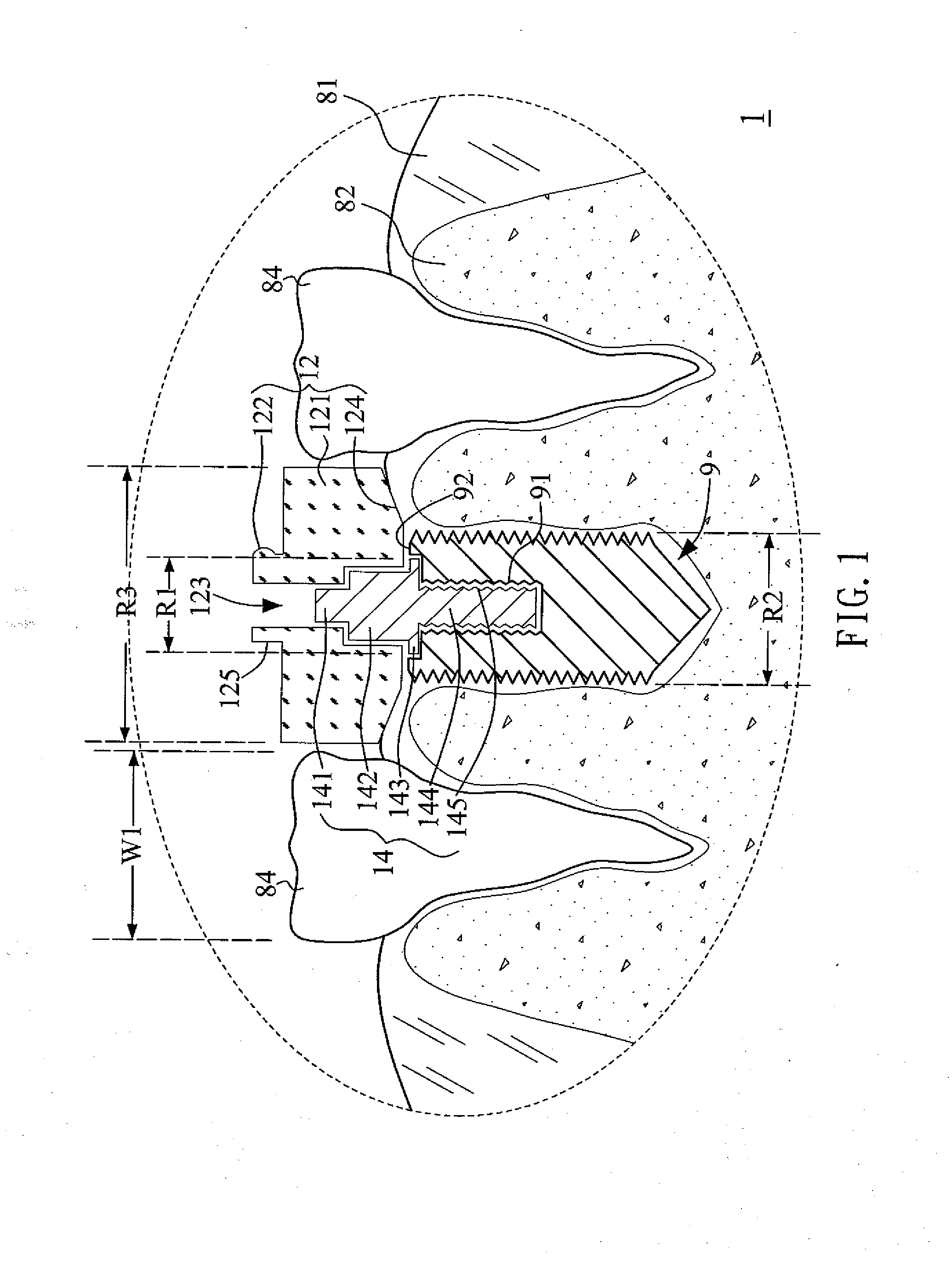

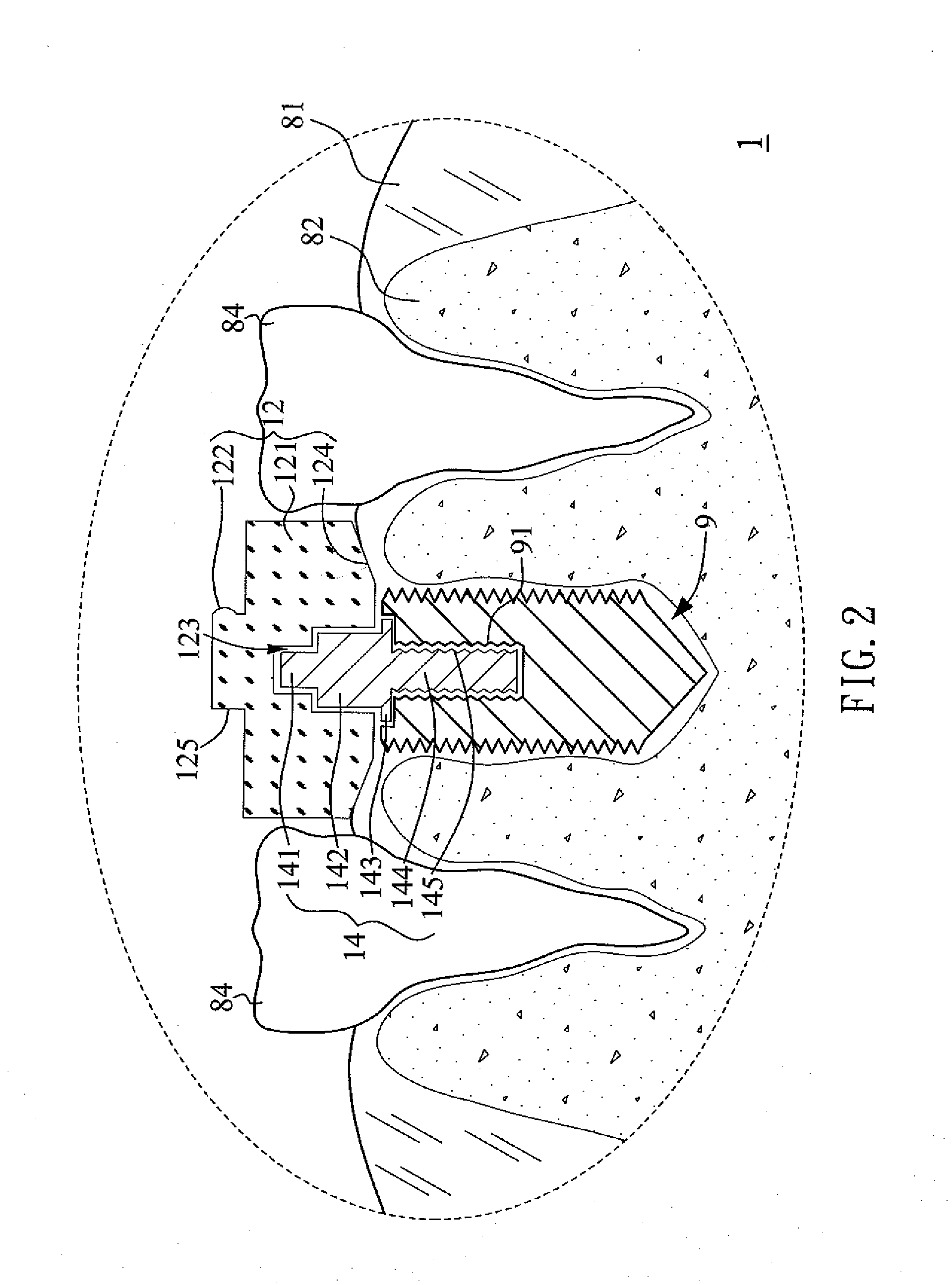

Multi Functional Implanting Suite and Implanting Method Thereof

InactiveUS20140178835A1Comprehensive functionsSimple and convenient designDental implantsImpression capsAbutmentDental clinic

A multi functional implanting suite for an implant utilized in tooth reconstruction, artificial tooth implanting or dental restoration is disclosed. The implanting suite comprises a cap and a fastening member, in which it may be equipped with multi functions including healing abutment, scan jig, mold taking suite, temporary crown or UCLA abutment, so that the dental clinics may merely purchase one dental tool and then solve may tooth reconstruction, artificial tooth implanting or dental restoration situations.

Owner:LIN CHEN YI

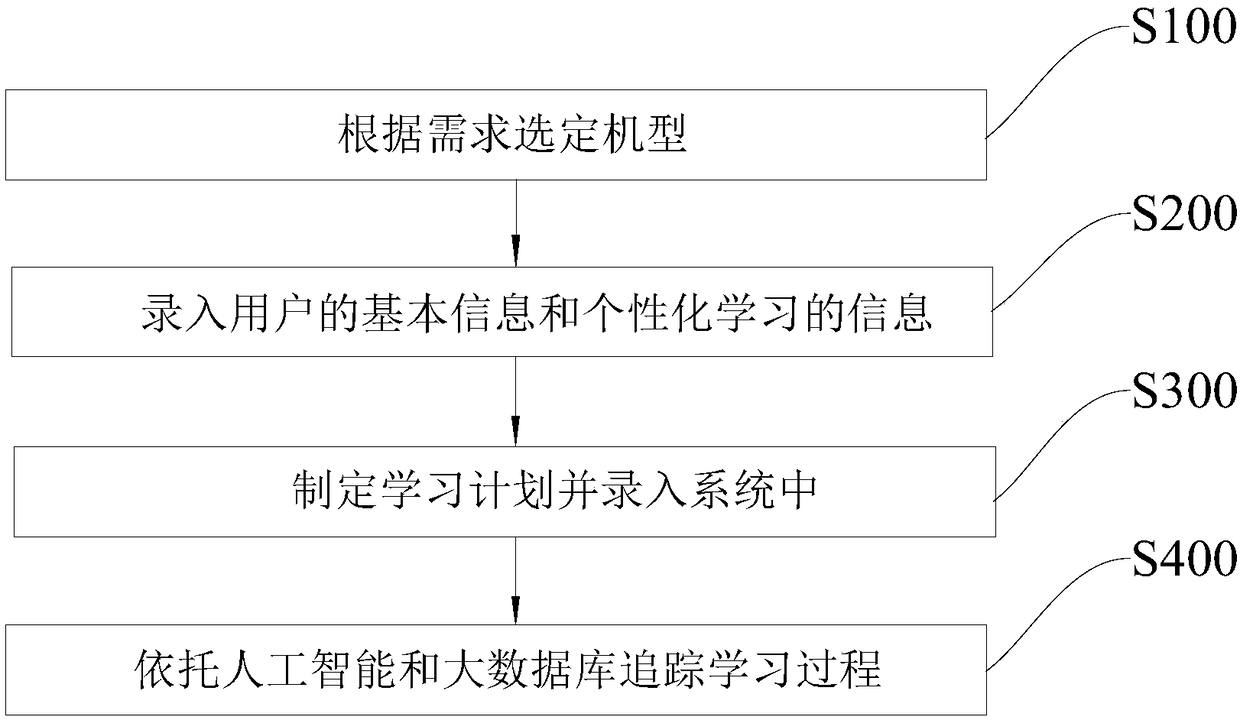

English training system and method based on artificial intelligence

InactiveCN109118860ABuilding Capabilities for Personalized LearningImprove experienceElectrical appliancesPersonalizationPersonalized learning

The invention discloses an English training system based on artificial intelligence. The English training system comprises a central processing unit and a platform database and a background service module, a personalized learning module, an operation module and an output module which are connected with the central processing unit and the platform database. The invention also discloses an English training method based on artificial intelligence. The English training method comprises the following steps: selecting the model; inputting the user and personalized learning information; making the learning plan; and intelligently memorizing and tracking the learning process. The English training system and method based on artificial intelligence can effectively improve the learning efficiency, realize sustainable and healthy learning and cultivate users' personalized learning ability and has high interactivity and can increase more user experience and functions and more interaction with learners through the cloud service operation mode so as to achieve the purpose of safe and convenient learning and pleasure teaching.

Owner:江苏金惠甫山软件科技有限公司

Anode, battery, and methods of manufacturing them

ActiveUS20090136855A1High performanceCharacteristic degradationElectrode manufacturing processesConductive materialDecompositionCurrent collector

A battery capable of improving the cycle characteristics and the swollenness characteristics is provided. The battery includes a cathode, an anode, and an electrolytic solution. The electrolytic solution is impregnated in a separator provided between the cathode and the anode. The anode has a coat on an anode active material layer provided on an anode current collector. The coat contains a metal salt. The metal salt has a hydroxyl group and at least one of a sulfonic acid group and a carboxylic acid group. Thereby, lithium ions are easily inserted in the anode and extracted from the anode, and decomposition of the electrolytic solution is prevented.

Owner:MURATA MFG CO LTD

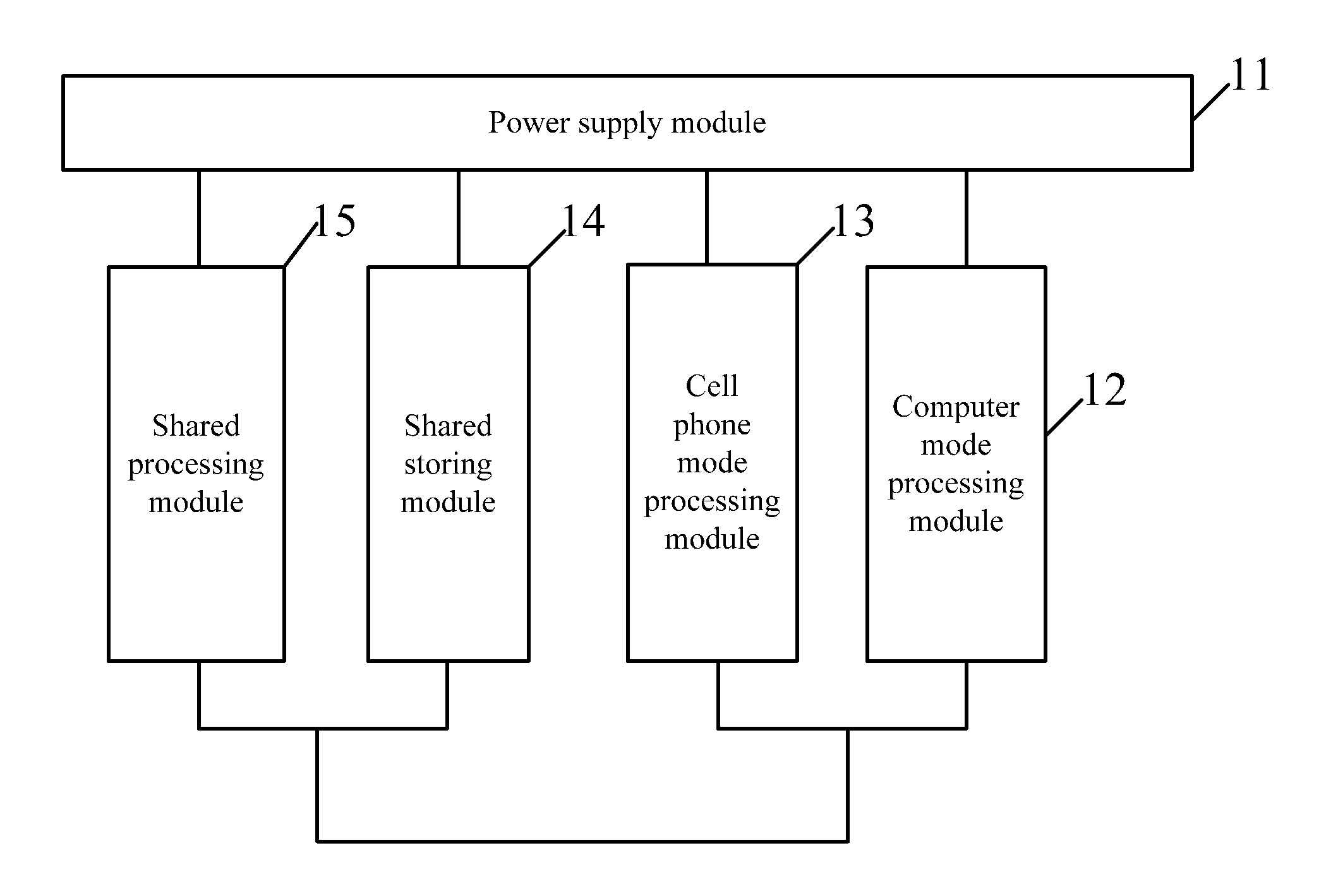

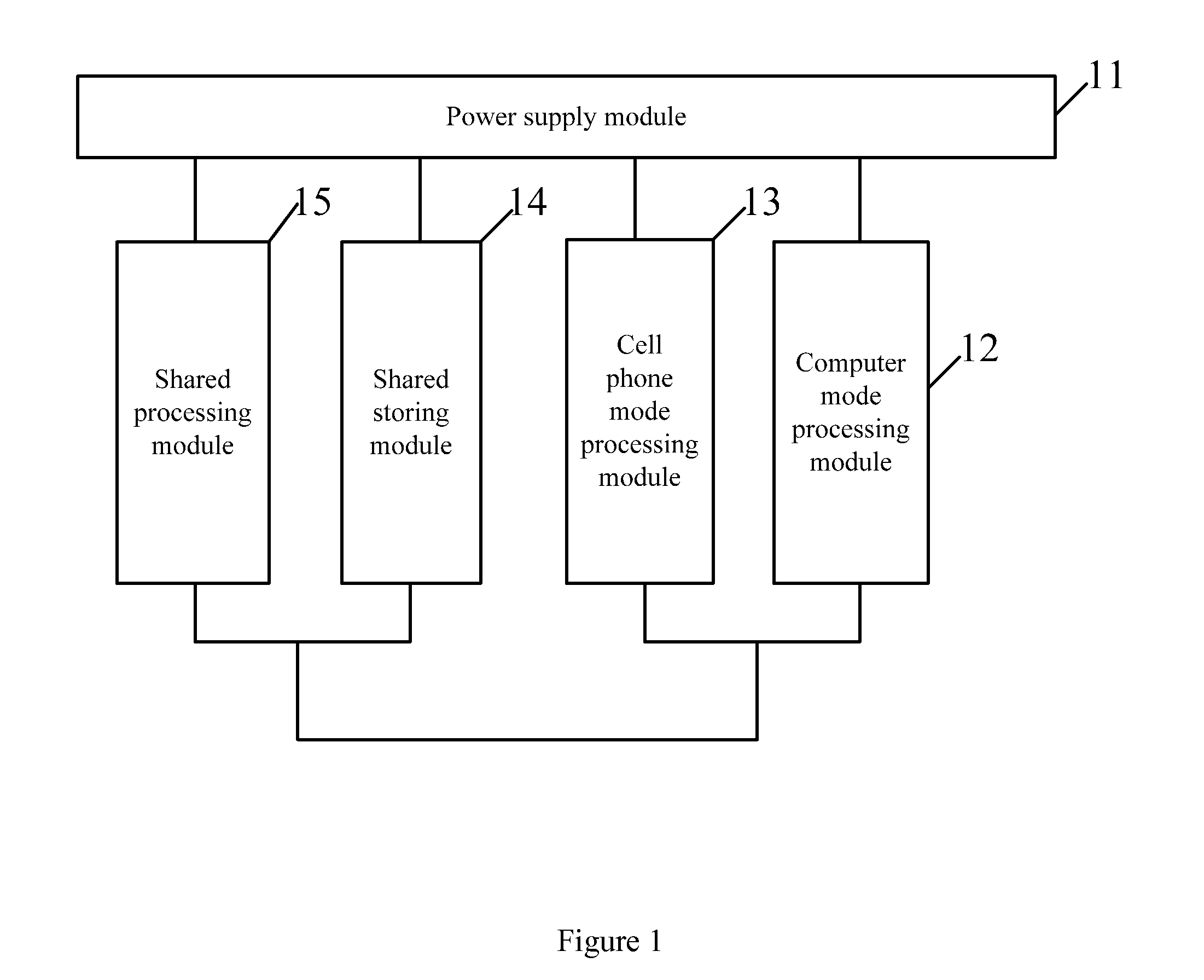

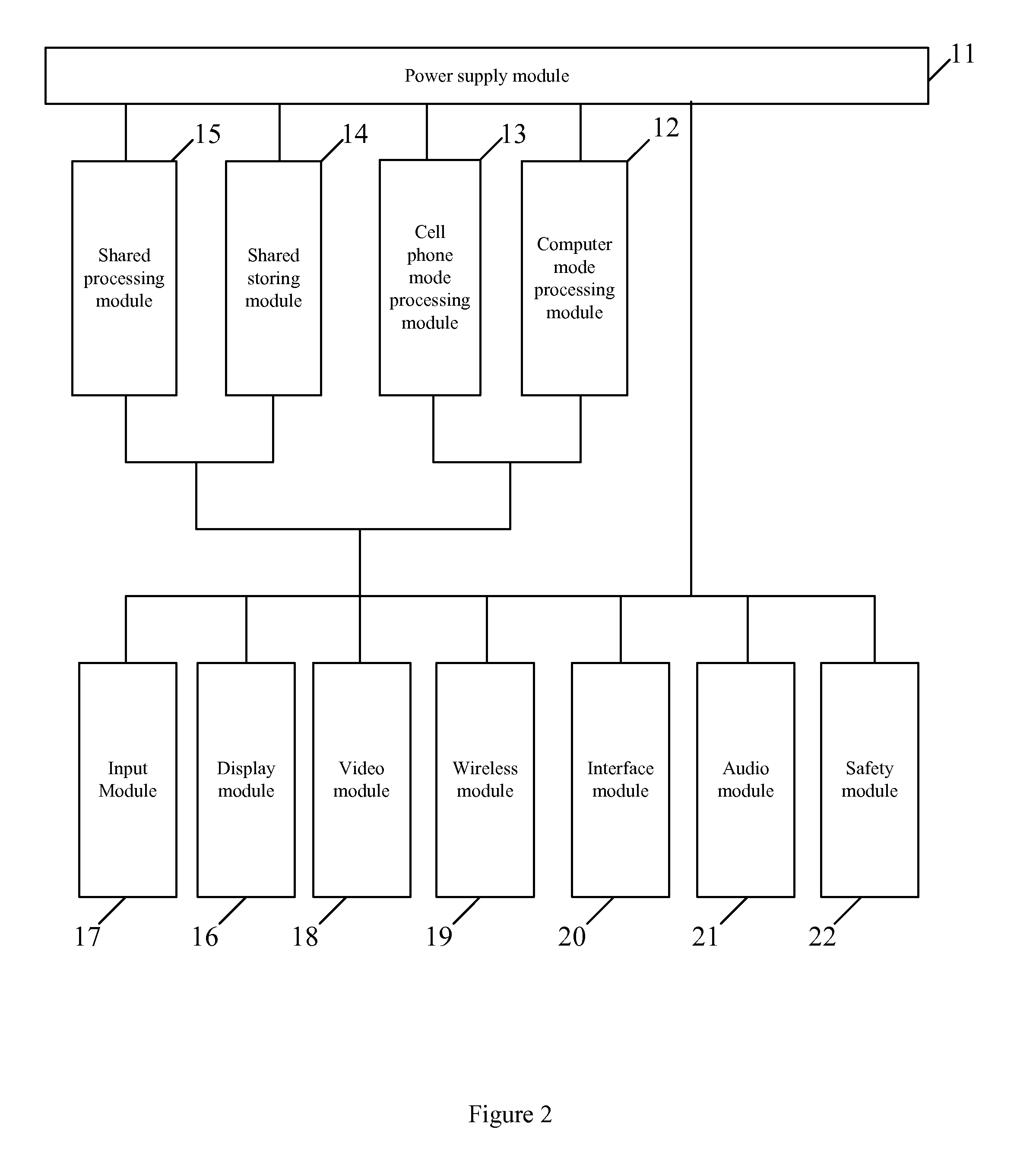

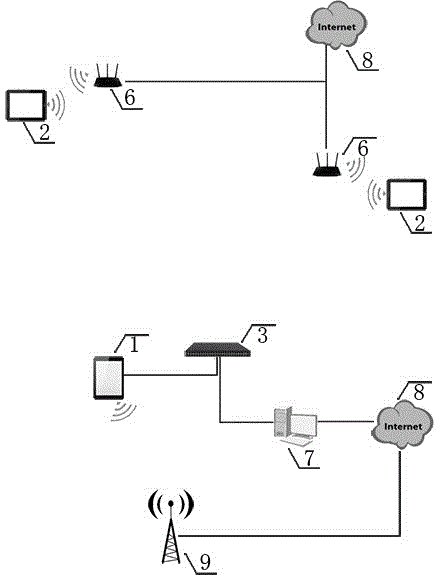

Hand-Held Device Integrating Computer and Cell Phone and Method for Realizing the Same

InactiveUS20120040714A1Easy to carryMeet demandConnection managementSubstation equipmentHand heldTerminal equipment

The hand-held device integrating computer and cell phone and a method for realizing the same. The hand-held device includes: a computer mode processing module; a cell phone mode processing module; a shared storing module connected both to the computer mode processing module and cell phone mode processing module; a shared processing module connected to all of the computer mode processing module, cell phone mode processing module and shared storing module for responding to the selection of the user and enabling the computer mode processing module or cell phone mode processing module; and a power supply module for supplying working power to the computer mode processing module, cell phone mode processing module, shared processing module or shared storing module. By this way, the computer and cell phone are combined together to form a hand-held terminal device capable of being received into a pocket.

Owner:WU WEI

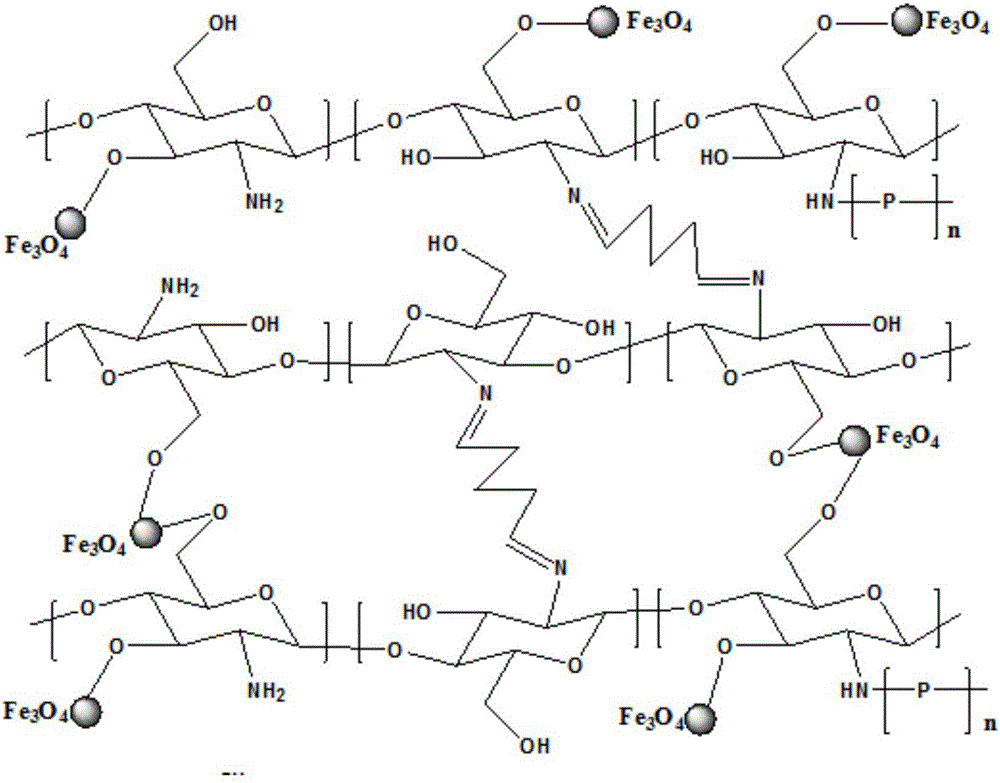

Chitosan magnetic composite spherule adsorbent with core-brush structure as well as preparation method and application thereof

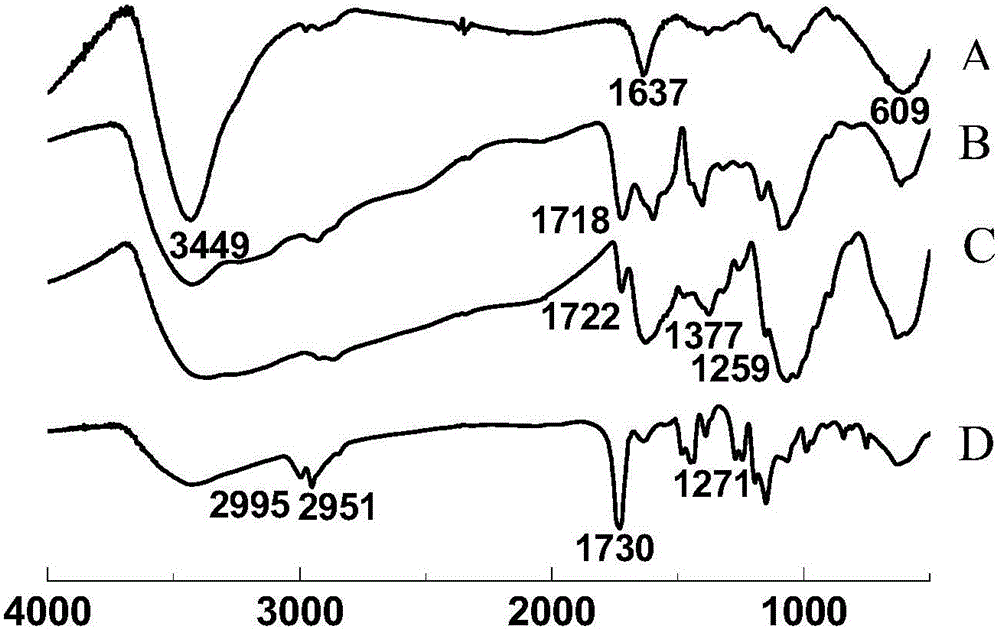

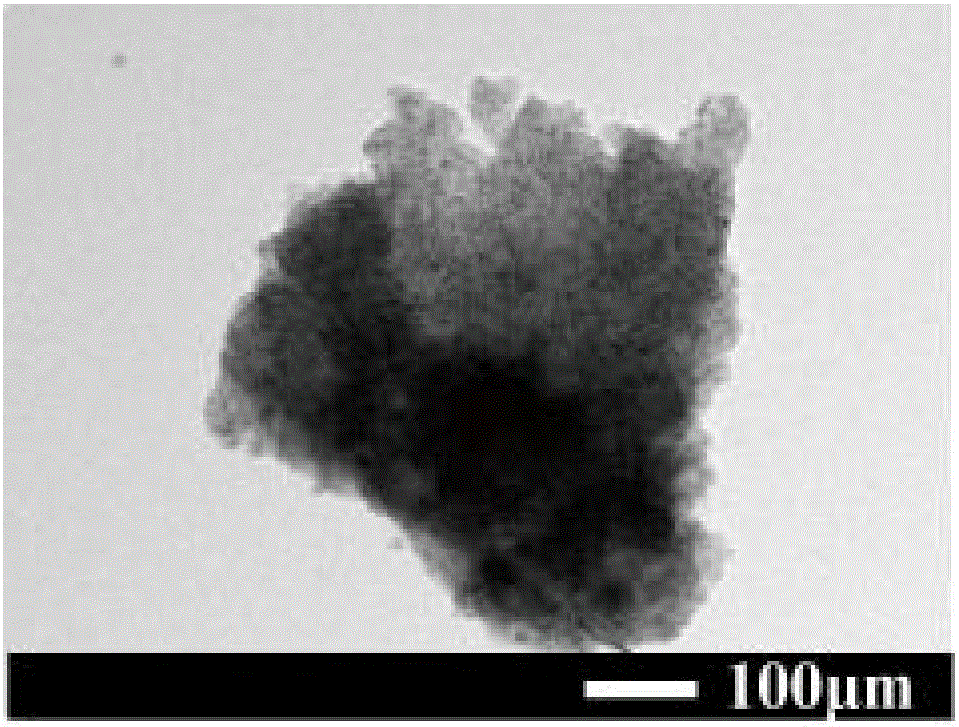

InactiveCN106040194ALow costImprove adsorption capacityOther chemical processesWater contaminantsCrosslinked chitosanSorbent

The invention discloses a chitosan magnetic composite spherule adsorbent with core-brush structure as well as a preparation method and application thereof and belongs to the technical field of adsorbents. The preparation method comprises the following steps of adding a mixed liquor containing ferric ions and ferrous ions into a solution containing chitosan by use of a magnetic carrier technology, so as to obtain non-crosslinked chitosan magnetic composite spherules; then adding a glutaraldehyde solution so as to obtain crosslinked chitosan magnetic composite spherules; weighing the crosslinked chitosan magnetic composite spherule, triggering with potassium peroxodisulfate, and then adding a monomer (poly-methylacryloyl MAETAC, polyacrylic acid or polymethyl methacrylate), thereby obtaining the modified chitosan magnetic composite spherule adsorbent with the core-brush structure. According to the adsorption experiments, the synthetized modified chitosan magnetic composite spherule adsorbent with the core-brush structure has the characteristics of biodegradable property, easiness for separation from water, reusability, favorable adsorption effect on chemical diclofenac sodium and the like.

Owner:NANJING NORMAL UNIVERSITY

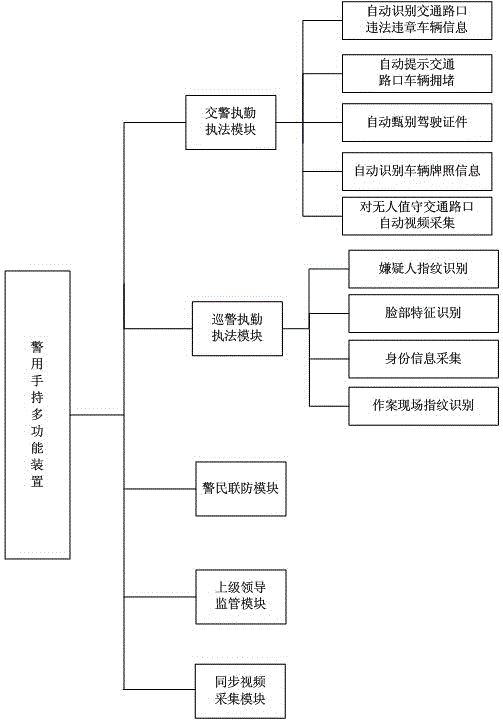

Police handheld multifunctional device

InactiveCN104616236AImprove Law Enforcement EfficiencyShort alarm timeData processing applicationsCo-operative working arrangementsGps navigationMultiple function

The invention provides a police handheld multifunctional device which comprises a CPU, a storage, a GPS navigation, a wireless network, a screen, an expansion slot, a shell and a police functional module. The police functional module comprises a traffic police duty and law-enforcement module, a patrolman duty and law-enforcement module, a police-people joint-defense module, a superior leadership supervision module and a synchronous video collection module. The police handheld multifunctional device not only can upload the field-collected information through a wireless network, but also can analyze the field data and feedback the information. Therefore, the police can make a judgment and take action timely, and leaders at different levels can conduct supervision conveniently.

Owner:刘俊江

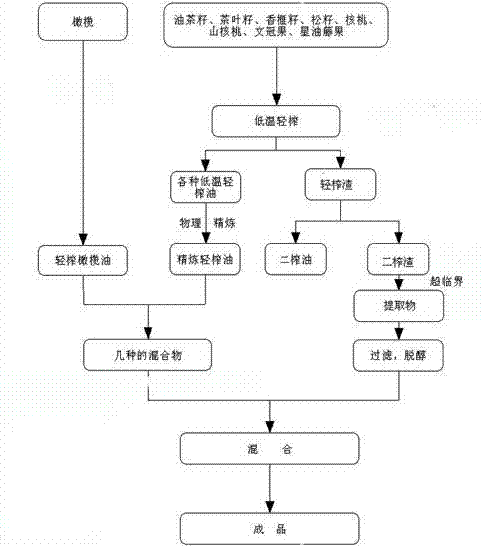

Advanced woody blend oil and production process thereof

ActiveCN103082027ALong growth cycleNutrient accumulationFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesRotary evaporator

The invention relates to a production process of advanced woody blend oil. The production process comprises the following steps of: respectively carrying out virgin expelling on camellia seeds, tea seeds, Chinese torreya seeds, pine nuts, walnuts, hickory nuts, brook feather and plukenetia volubilis fruits under the conditions that the virgin expelling temperature is lower than 150 DEG C, and the oil outlet temperature is lower than 90 DEG C to obtain corresponding virgin oils and virgin slags, wherein the oil yield is 60-70 percent; putting the obtained corresponding secondary expelled slags into a supercritical carbon dioxide kettle, and carrying out extraction to obtain an extract with edible ethanol as an entrainer, wherein the additive amount of the entrainer is 5 percent of the material weight, and extraction is carried out under the conditions that the pressure is 35 MPa and the temperature is 40 DEG C; after filtering the extract, secondarily filtering the extract and removing impurities of the extract by active carbon, and carrying out vacuum removing on ethanol in a rotary evaporimeter under the conditions of 40 DEG C, 8kPa and 25 turns / min to refine the extract; and mixing the virgin oils to obtain a finished product. According to the production process, the camellia seeds, the tea seeds, the Chinese torreya seeds, the pine nuts, the walnuts, the hickory nuts, the brook feather and the plukenetia volubilis fruits are all woody oil seeds and even advanced woody oil seeds, the growth period of the woody oil seeds is long, nutrition is more accumulated, and the woody oil seeds have more nutritive value and functions than herbal oil seeds.

Owner:温州瑞雪农业开发有限公司

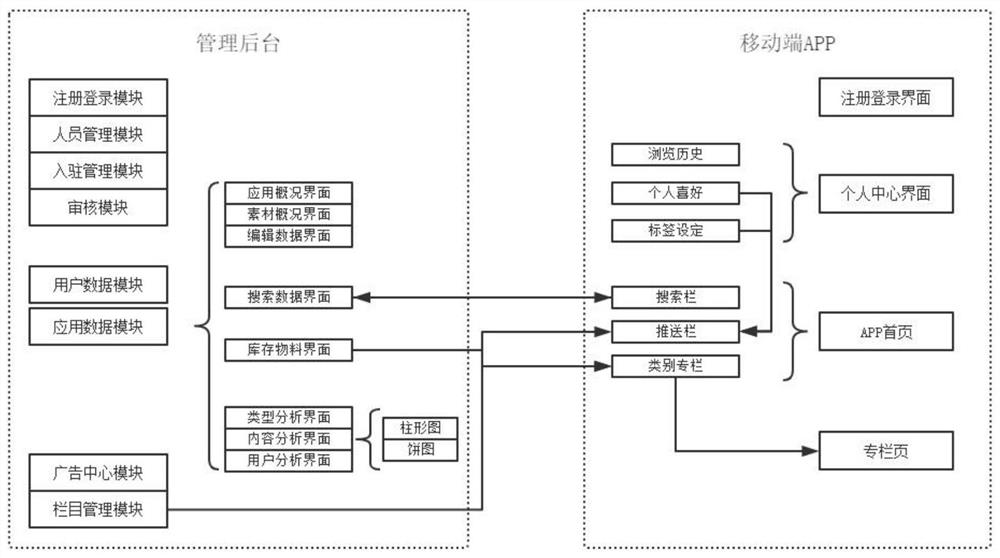

Universal multi-terminal applet system

PendingCN111625310AMeet individual configuration needsLighten the development burdenInterprogram communicationExecution for user interfacesPersonalizationMultiple platform

The invention discloses a universal multi-terminal applet system, and relates to the field of applet systems. In order to achieve the effects of one-time updating and multi-terminal maintenance, the system specifically comprises a management background, a mobile terminal APP, more than two scene templates and a compatible component, the universal multi-terminal applet system adopts a uni-app as adevelopment tool, the mobile terminal APP customizes an nvue scheme based on weex, a DSL framework is selected on the basis of JavaScript, and different codes are respectively compiled at each terminal by taking the DSL framework as a standard. As an intelligent applet aggregation platform, the intelligent applet aggregation platform has the function of generating multiple platform applets throughone key, multiple sets of scene templates and compatible components can meet the personalized configuration requirements of users, and the development burden of developers is reduced; the integratedbackground can achieve multi-terminal control, different platform characteristics do not need to be considered in the operation process, multi-terminal synchronous updating is achieved, and the working efficiency is greatly improved.

Owner:镇江纵陌阡横信息科技有限公司

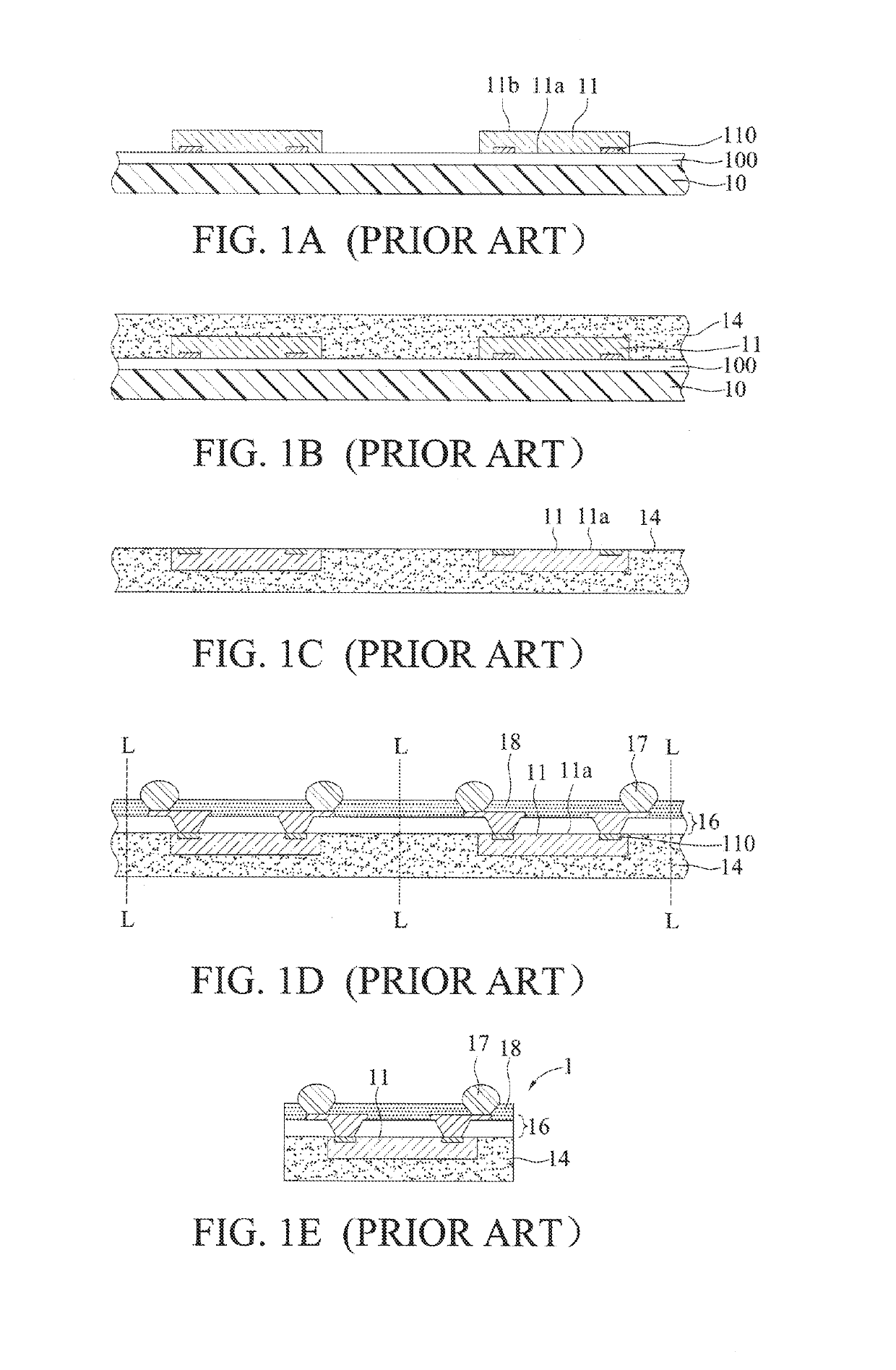

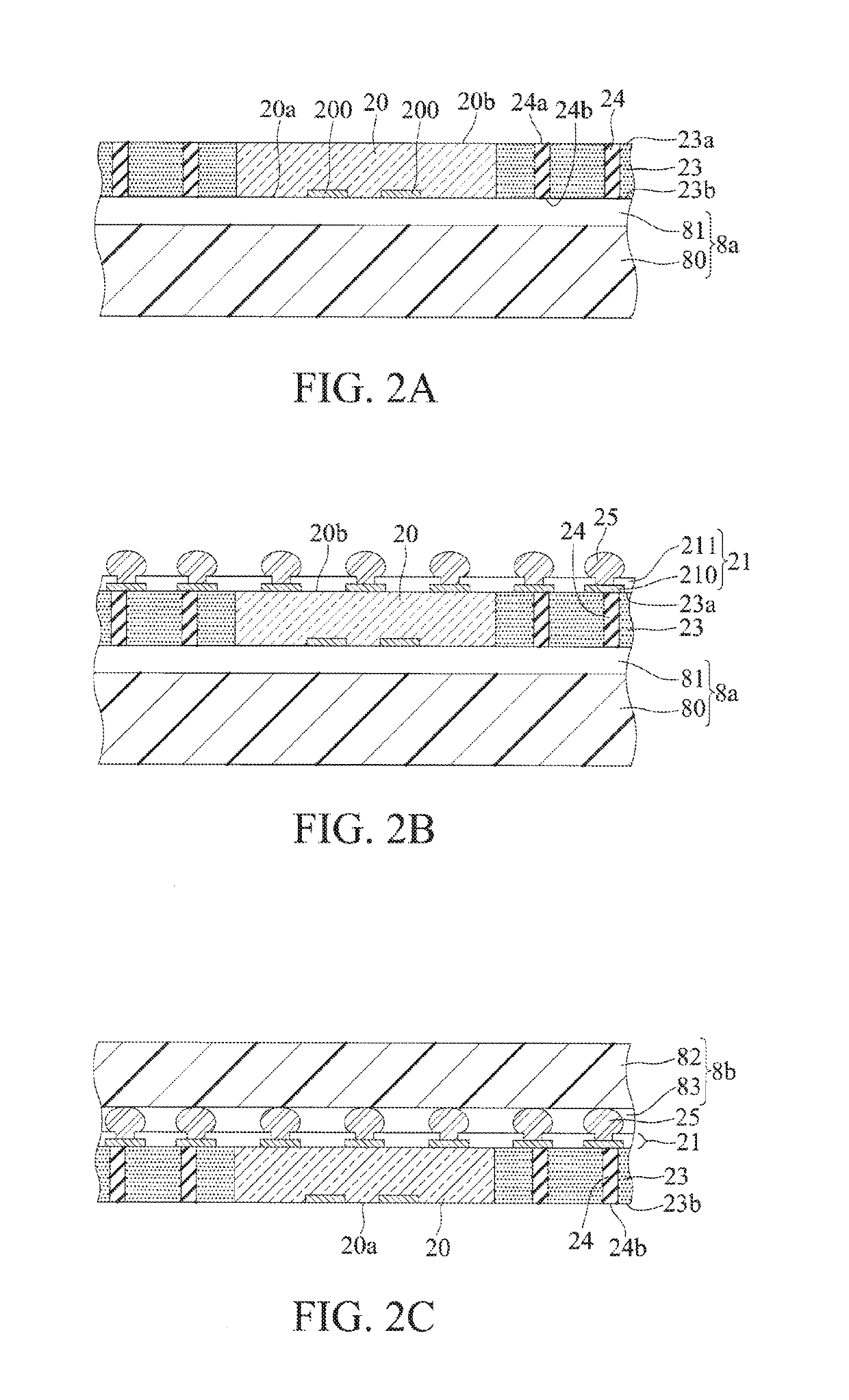

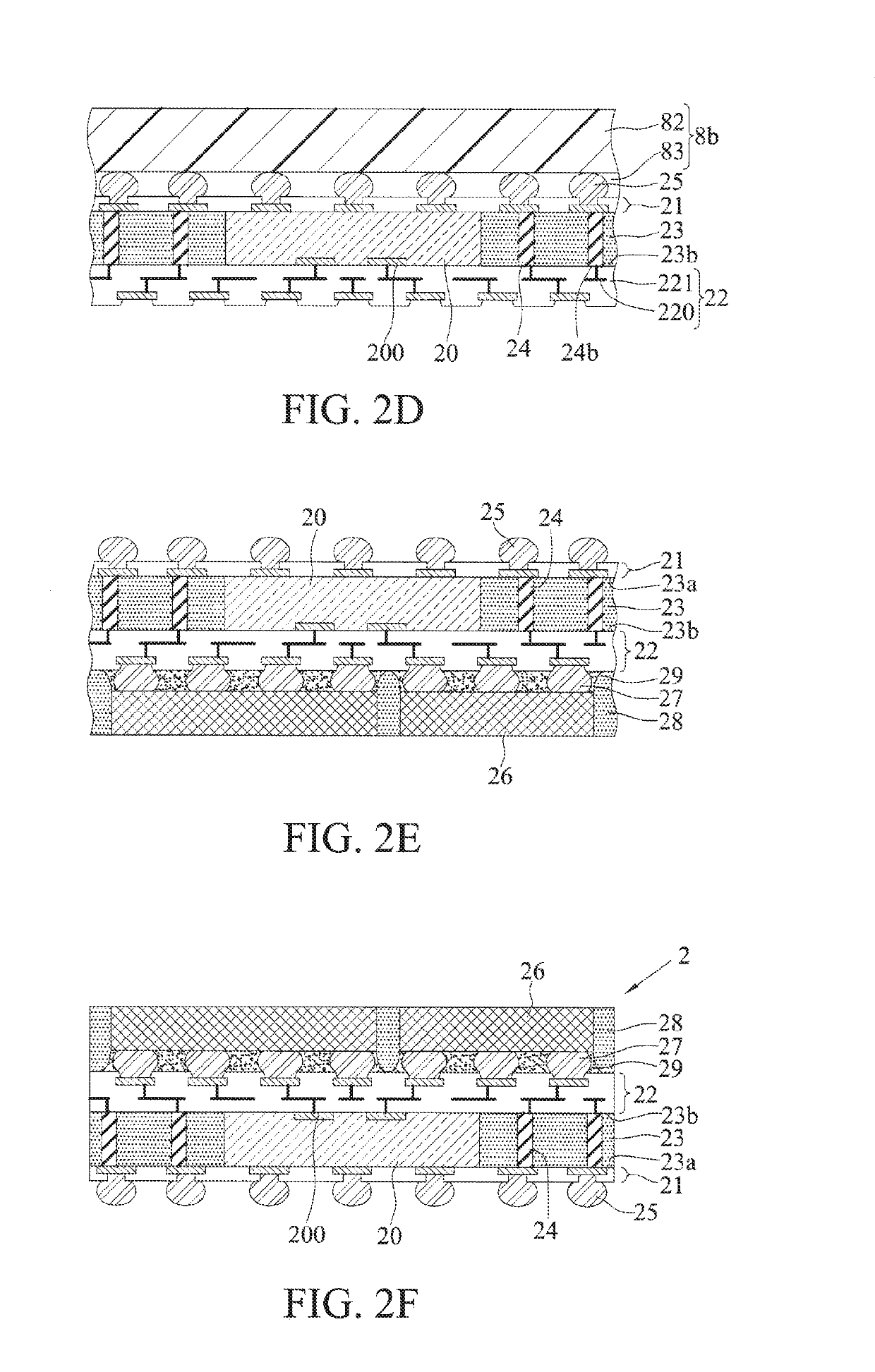

Electronic package and method for fabricating the same

ActiveUS20190237374A1Improve efficiencyComprehensive functionsSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

An electronic package and a method for fabricating the same are provided. The method includes: forming a circuit structure on an encapsulant; embedding a first electronic component and a plurality of conductive posts in the encapsulant; and disposing a second electronic component on the circuit structure. Since the first and second electronic components are arranged on opposite sides of the circuit structure, the electronic package can provide multi-function and high efficiency.

Owner:SILICONWARE PRECISION IND CO LTD

Internet intelligent building intercom system and device

InactiveCN105072511APrevent peepingReduce wearNetworks interconnectionStations for two-party-line systemsRemote controlThe Internet

The invention discloses an Internet intelligent building intercom system and device. Each of the system and the device mainly comprises an intelligent terminal, a lock control part, a client and a server side, wherein a networked indoor intelligent terminal is communicated with a networked gate intelligent terminal through the client in order to achieve voice and video telephone, and is connected to the lock control part through the gate intelligent terminal in order to achieve the purpose of carrying out remote control on a cell gate through the indoor intelligent terminal. When a visitor calls one owner through the client on the gate intelligent terminal, the gate intelligent terminal sends the obtained visitor information to the client on the indoor intelligent terminal of the owner, and the owner makes a further operation according to the information displayed on the client.

Owner:ANHUI WEIWEI NETWORK TECH

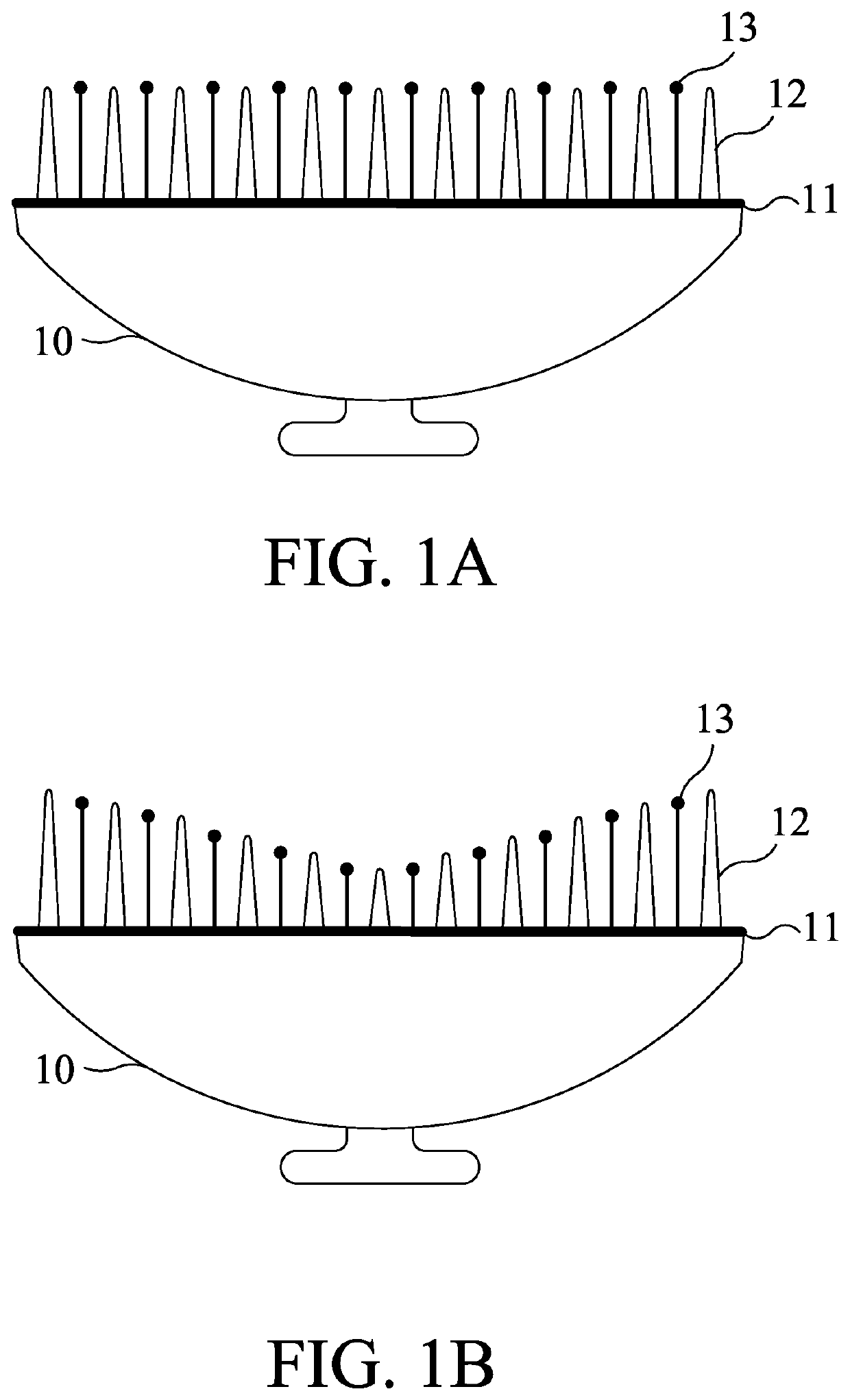

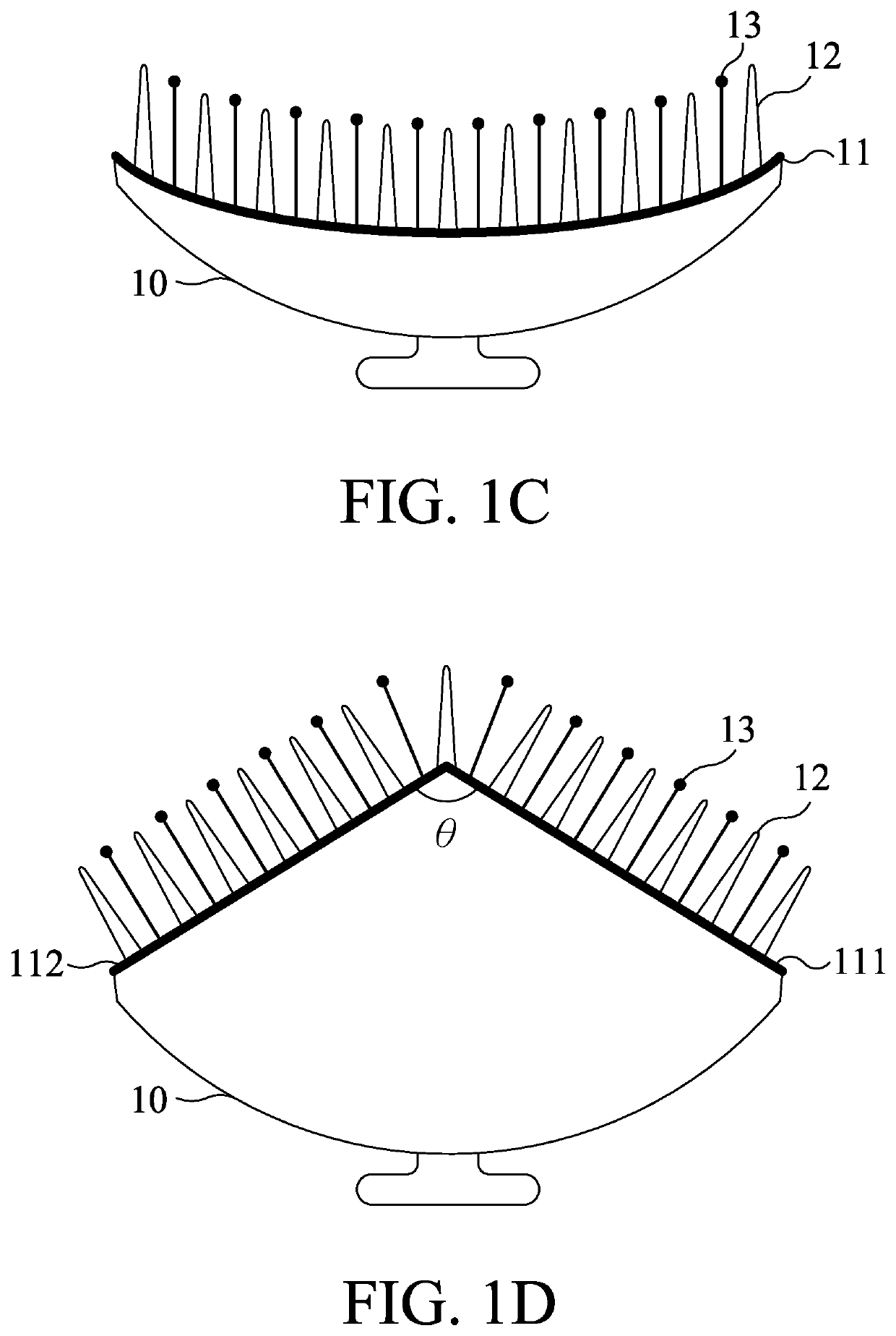

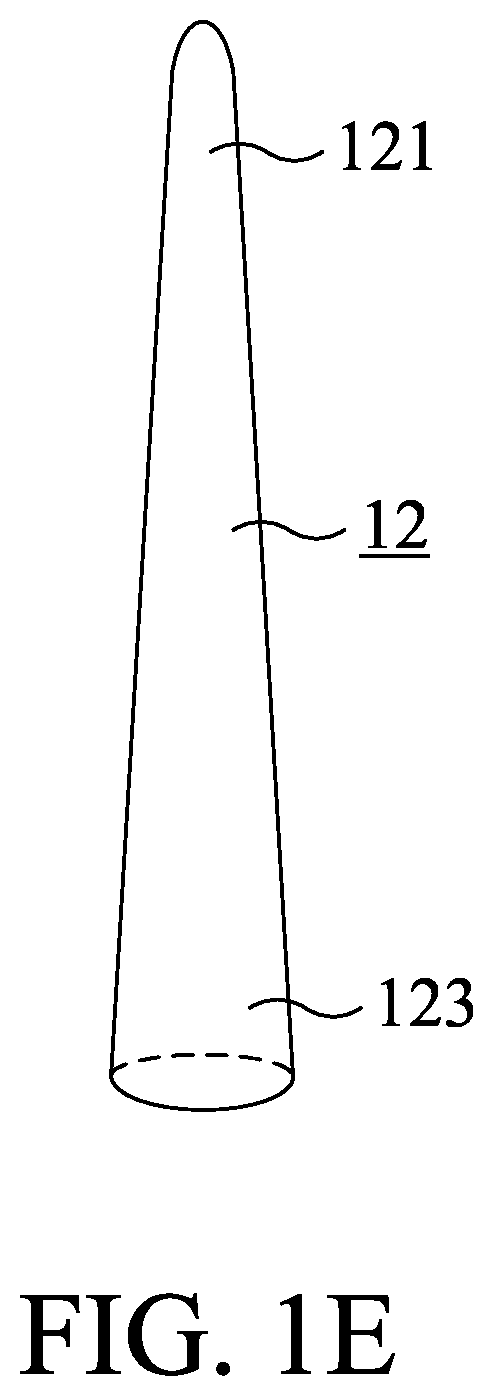

Detangling massage brush

A massage brush includes a bristle base; a plurality of massage bristles formed on the bristle base for massaging scalp; and a plurality of detangling bristles formed on the bristle base for detangling hair. The detangling bristles are thinner than the massage bristles at the bristle base, and having a diameter ranged between 0.4 mm and 1.8 mm. For example, the detangling bristles include a first group of detangling bristles having a diameter ranged between 0.8 mm and 1.8 mm and / or a second group of detangling bristles having a diameter ranged between 0.4 mm and 1 mm.

Owner:CHANG STEPHANIE +1

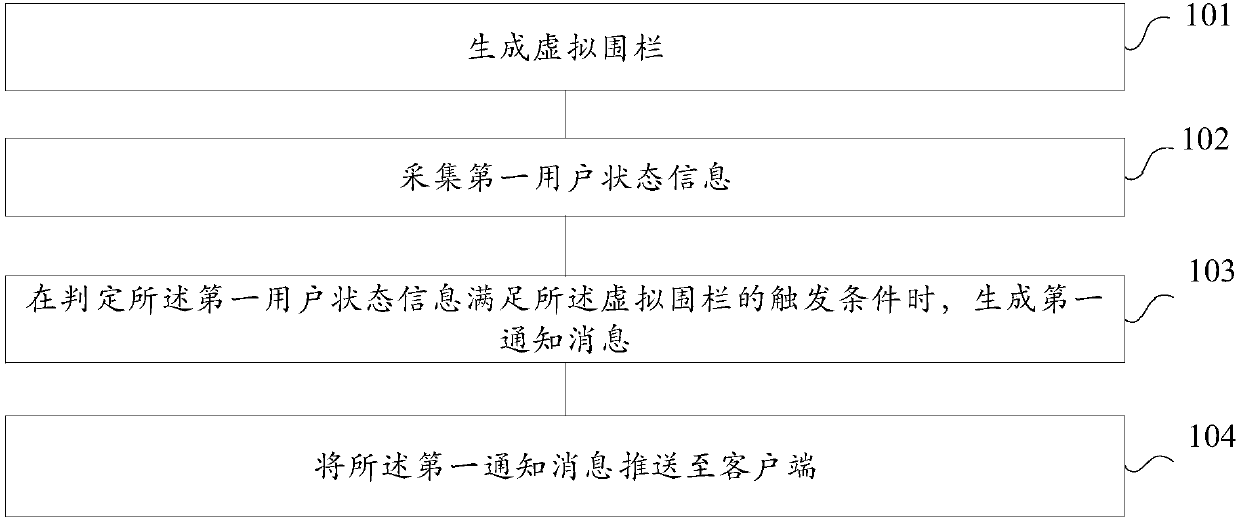

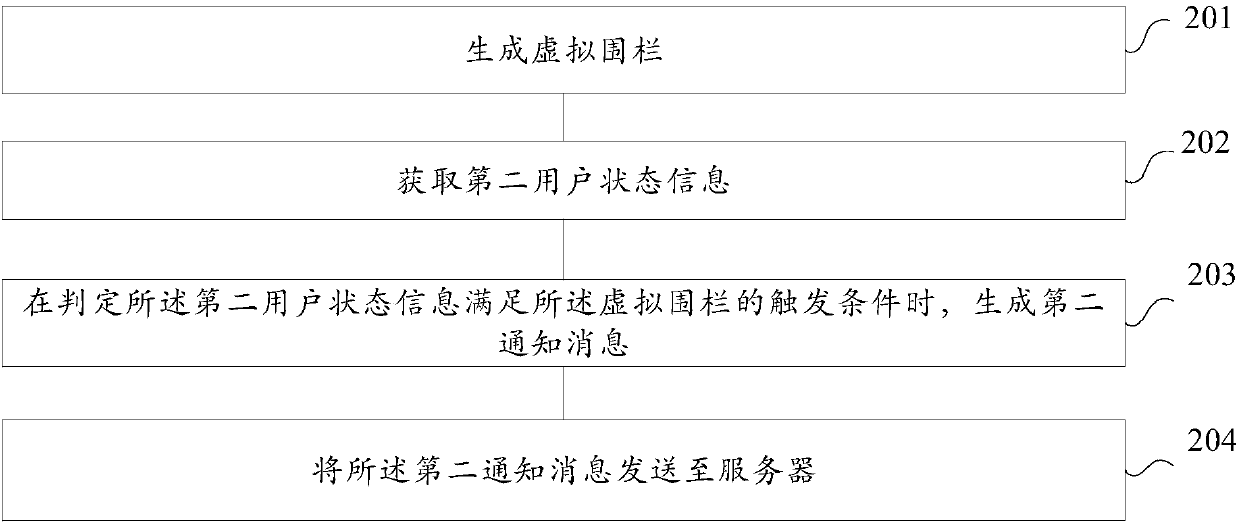

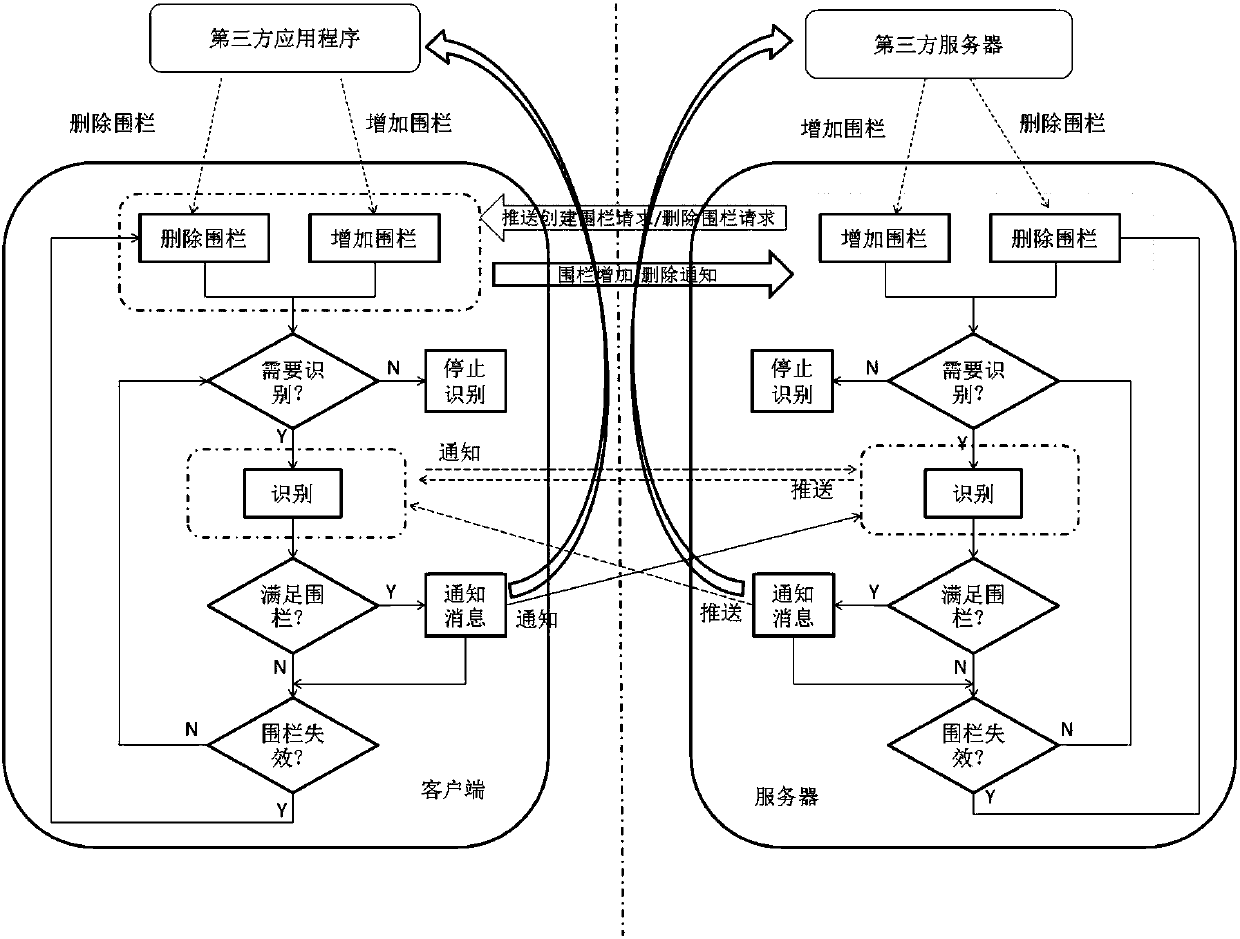

Information processing method, client and server based on geo-fencing

ActiveCN107948923AComprehensive functionsReduce energy consumptionMessaging/mailboxes/announcementsTransmissionInformation processingClient-side

The embodiments of the application provide an information processing method, a client and a server based on geo-fencing. The method includes the following steps: generating a geo-fence, wherein the geo-fence is generated according to input trigger conditions, and the trigger conditions include point-of-interest information and / or area-of-interest information; collecting first user status information; when judging that the first user status information meets the trigger conditions, generating a first notification message; and pushing the first notification message to a client. According to theembodiments of the invention, the recognition result can be exchanged, and the recognition accuracy is greatly improved.

Owner:BANMA ZHIXING NETWORK HONGKONG CO LTD

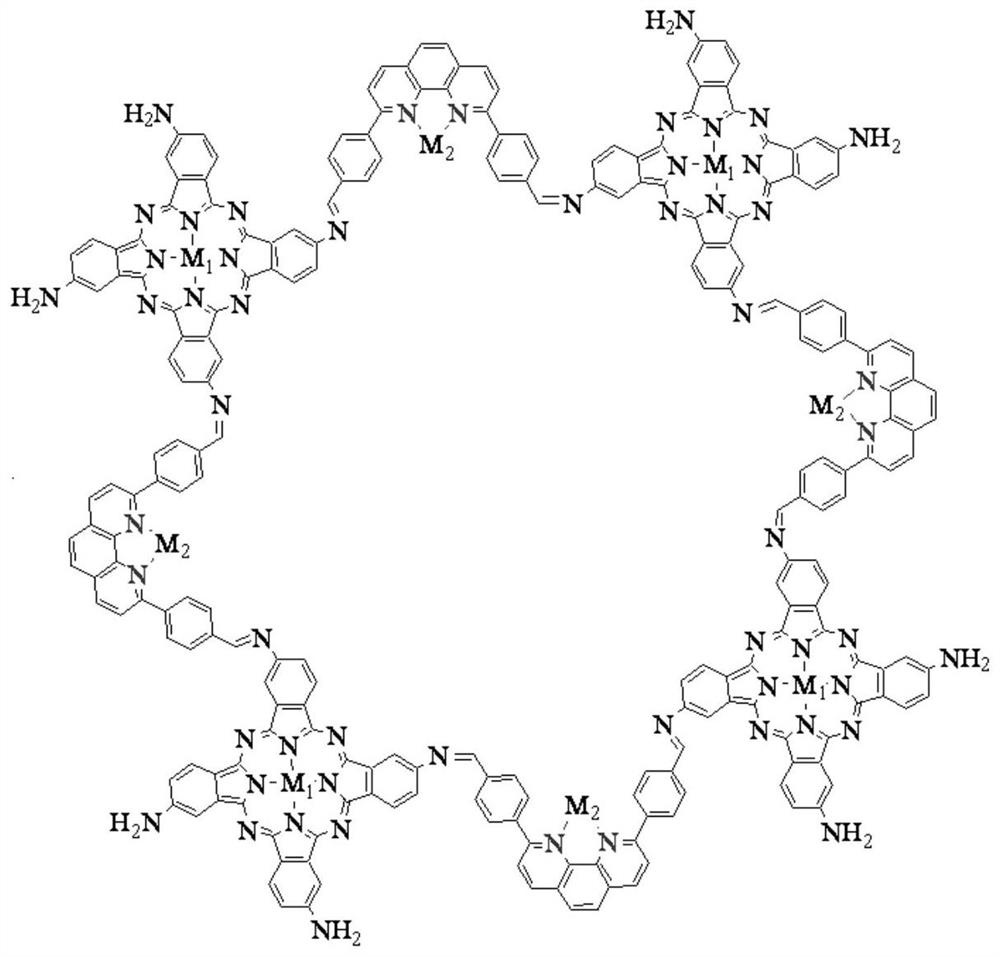

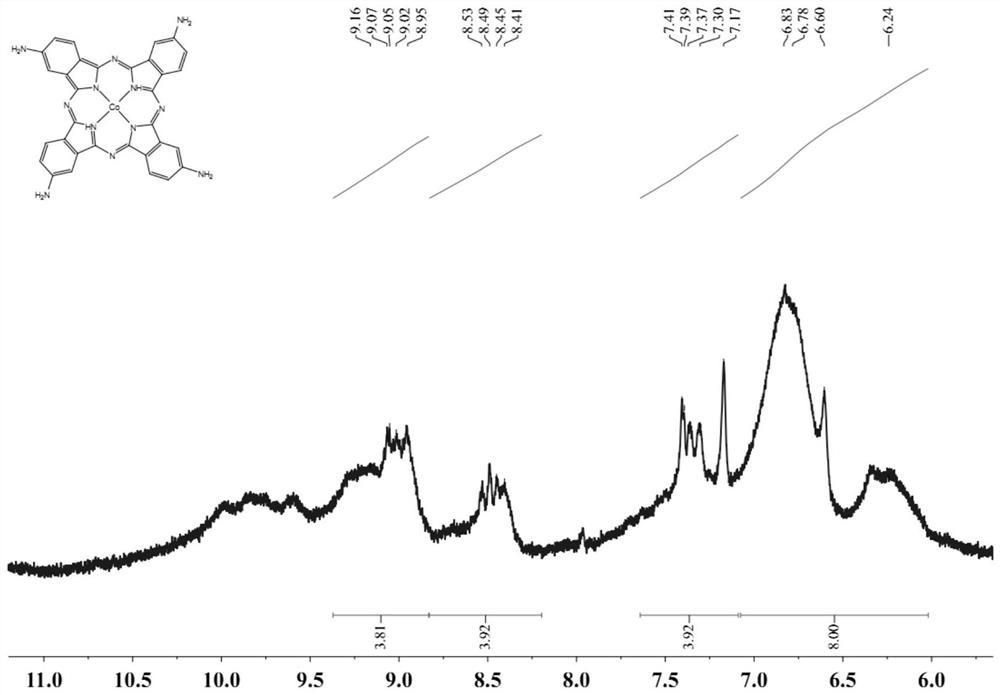

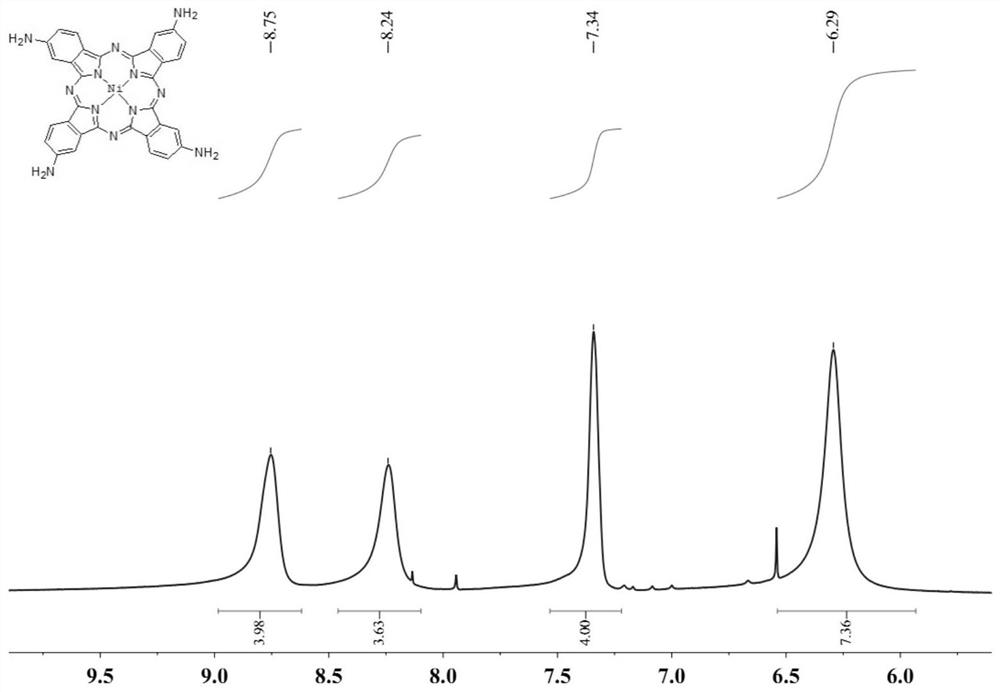

Bimetal covalent organic framework material and preparation method thereof and aptamer sensor

ActiveCN112321839AEvenly dispersedLarge specific surface areaMaterial analysis by electric/magnetic meansBiological testingCompound organicPhthalocyanine

The invention belongs to the technical field of composite functional materials, and particularly relates to a bimetal covalent organic framework material and a preparation method thereof and an aptamer sensor. The bimetal covalent organic framework material is a metal-covalent composite organic framework material, and comprises a covalent organic framework main body formed by carrying out a Schiffbase condensation reaction on tetraamino metal phthalocyanine and PTD, and metal ions compounded with a PTD unit on the covalent organic framework main body in a metal-organic coordination form, wherein the metal in the tetraamino metal phthalocyanine is selected from cobalt or nickel. The metal ions are introduced into porous COFs in a targeted manner to form metal covalent organic frameworks (MCOFs). The MCOFs can build a bridge between the MOFs and the COFs, so that the porosity, the stability, the crystallinity and the adjustability of the MOFs and the COFs can be balanced, and complementary characteristics are formed between the MOFs and the COFs.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

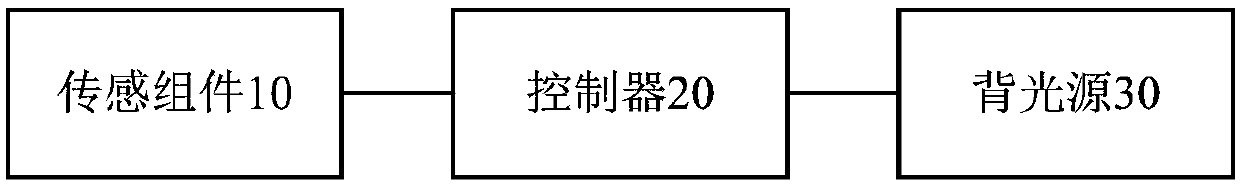

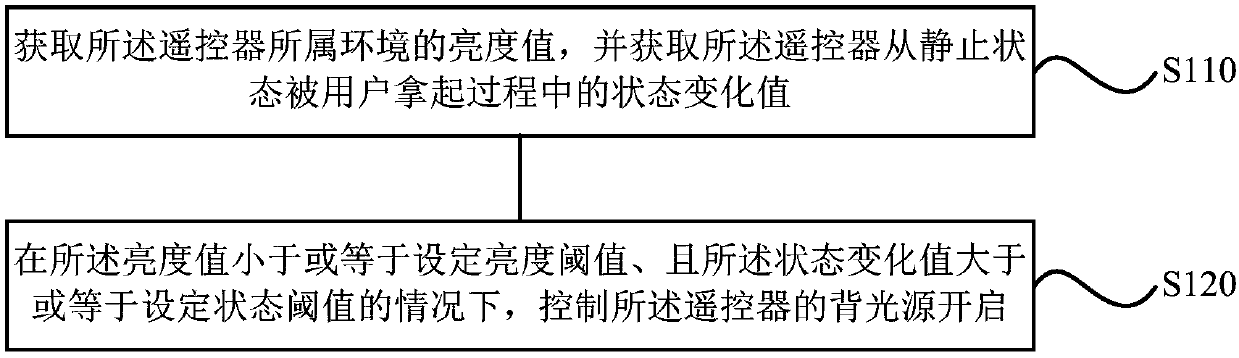

Control device and method of remote controller, storage medium, remote controller and device

PendingCN107911919ARealize intelligent backlight controlSolve the problem that button operation is easy to cause misoperationElectrical apparatusElectric light circuit arrangementState variationEngineering

The invention discloses a control device and method of a remote controller, a storage medium, the remote controller and a device. The control device includes a sensor assembly (10) and a controller (20), wherein the sensor assembly (10) is used for acquiring the luminance value of an environment with the remote controller and acquiring a state change value of the remote controller in a process from a static state to a state of being taken up by a user; the controller (20) controls a back light source (30) of the remote controller to switch on when the luminance value is smaller than equal to apreset luminance threshold value and the state change value is greater than or equal to a preset state threshold value. By adopting the scheme provided by the invention, defects of high error operation rate, use inconvenience and inadequate functions and the like can be overcome and beneficial effects of low error operation rate, use convenience and adequate functions can be realized.

Owner:GREE ELECTRIC APPLIANCES INC

Anode and secondary battery

ActiveUS9012066B2Improve performanceExcellent cycle characteristicsAlkaline accumulatorsFinal product manufactureElectrical batteryPore diameter

Owner:MURATA MFG CO LTD

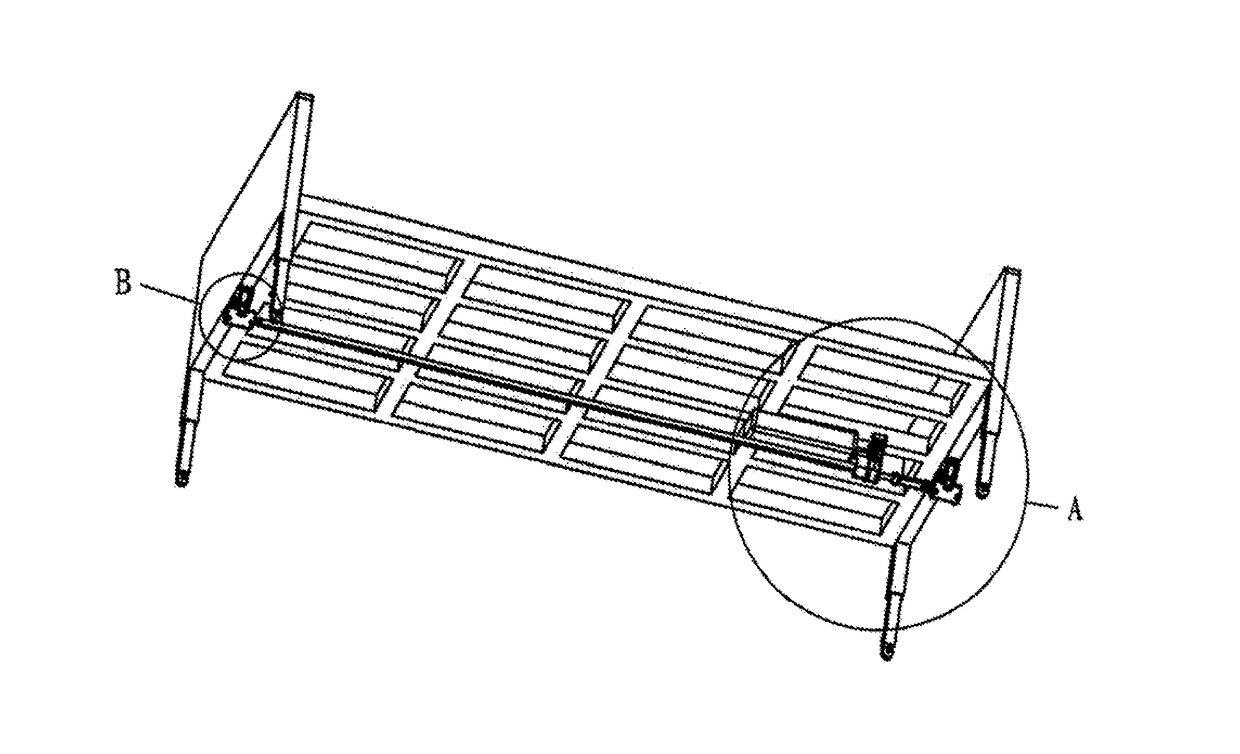

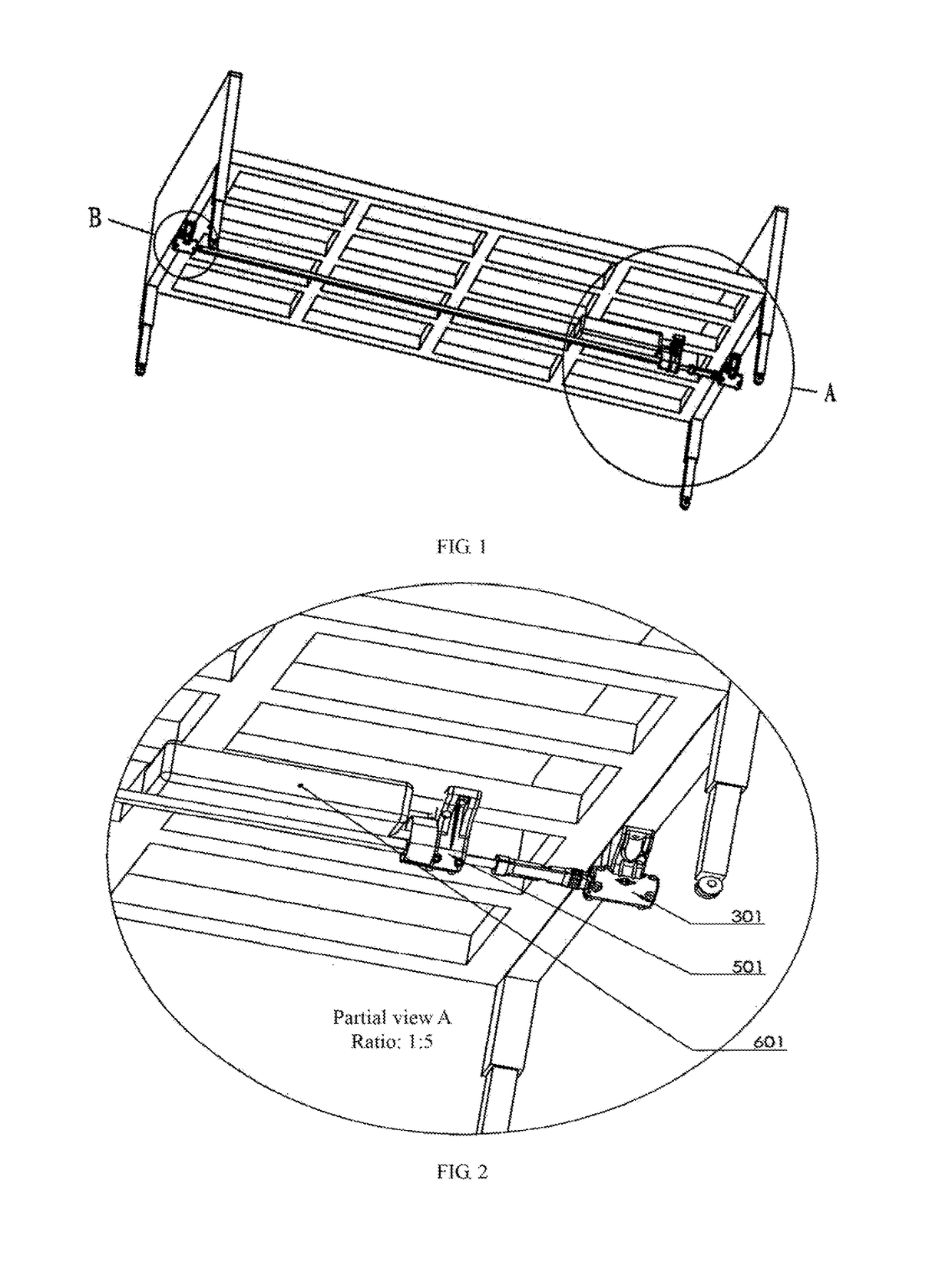

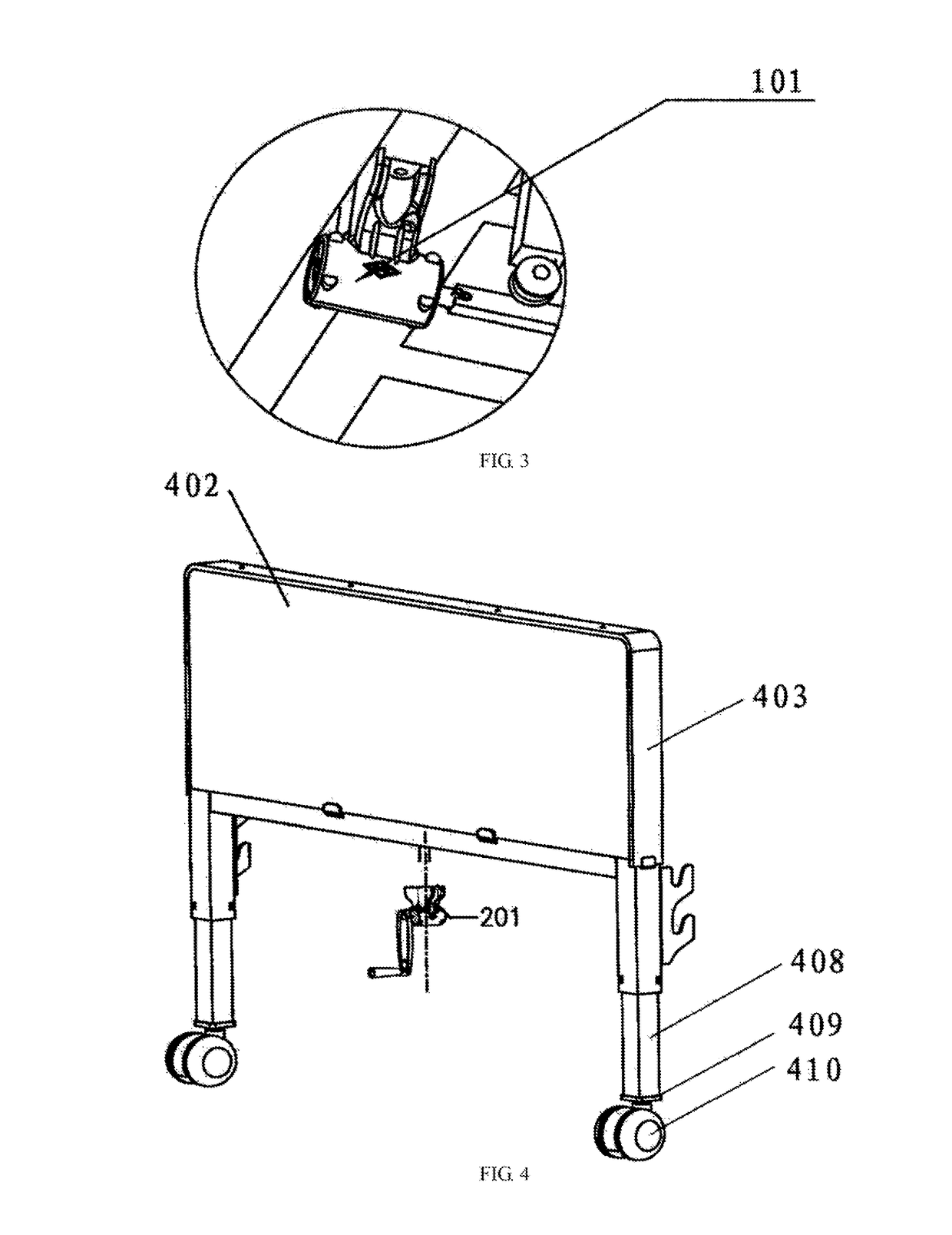

Medical rehabilitation bed

ActiveUS20170156955A1Compact structureComprehensive functionsNursing bedsTransmission systemBed boards

A medical rehabilitation bed is disclosed, relating to the technical field of self-help rehabilitation bed structures in medical instrument products. The medical rehabilitation bed comprises a bed head, a bed tail and a bed board. A pull rod is arranged at the bottom of the bed board; one end of the pull rod is mechanically connected to a bed head gearbox arranged at the bed head, and the other end of the pull rod is mechanically connected to a bed tail gear device arranged at the bed tail. Transmission systems having the same structure and capable of controlling the bed head and the bed tail to ascend and descend are arranged in the bed head and the bed tail, respectively. The transmission systems are mechanically connected to the bed head gearbox and the bed tail gear device, respectively. The medical rehabilitation bed has a compact structure and comprehensive functions.

Owner:YANG WEIZHONG

Method for preparing polyethylene wax containing phenoxy group at chain end by thermal degradation

The invention discloses a method for preparing polyethylene wax containing phenoxy group at the chain end by thermal degradation, which comprises the following steps: evenly mixing hydroquinone and polyethylene granules in a mass ratio of (1-4):100 into a high-pressure reaction kettle, introducing nitrogen to raise the pressure in the kettle to 0.4-0.6MPa, raising the temperature in the kettle to200-210 DEG C, and controlling the stirring rate at 50-80rpm; continuing heating to 330-380 DEG C, reacting at the constant temperature to react for 0.5-5 hours while keeping the pressure in the kettle below 1 MPa, and stopping heating; and stopping stirring when the temperature in the kettle drops to 190-200 DEG C, taking out the melt when the temperature in the kettle drops to 160-180 DEG C, and pulverizing the melt after the temperature in the kettle drops to room temperature, thereby obtaining the product. Since the oxygen-free thermal degradation technique of hydroquinone and polyethylene is utilized, long-chain free radicals generated by gradual chain ruptures in the hydroquinone free radical and polyethylene degradation process is coupled and terminated in time by loss of hydrogen to obtain a low-molecular-weight polyethylene wax with a phenoxy group at one end or phenoxy groups at two ends, thereby providing a new optional species for the application field of polyethylene wax.

Owner:SICHUAN UNIV

Manufacturing process for printed circuit board

InactiveCN102497736AImprove performanceMeet miniaturizationPrinted circuit assemblingCapacitanceProcess engineering

The invention discloses a manufacturing process for a printed circuit board, particularly the manufacturing process for a buried type capacitive printed circuit board. The manufacturing process comprises the following steps of: 1, preparation of a substrate and a bottom plate; 2, lamination; 3, drilling, desmearing and hole metallization; and 4, production of capacitance graphics, wherein the specific operation of the lamination in the step 2 comprises pre-pressing in a die, total pressure application, heat and pressure preservation, cold pressing and aftertreatment. By the process, the lamination step is optimized in the manufacture of the printed circuit board, so that the thermal stress of the circuit board is increased, and a finished product still can stay the same after being thermally shocked for many times. The performance of the product is improved, production steps are optimized, and a development basis is further provided for the development of the printed circuit board.

Owner:苏州日月明微电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com