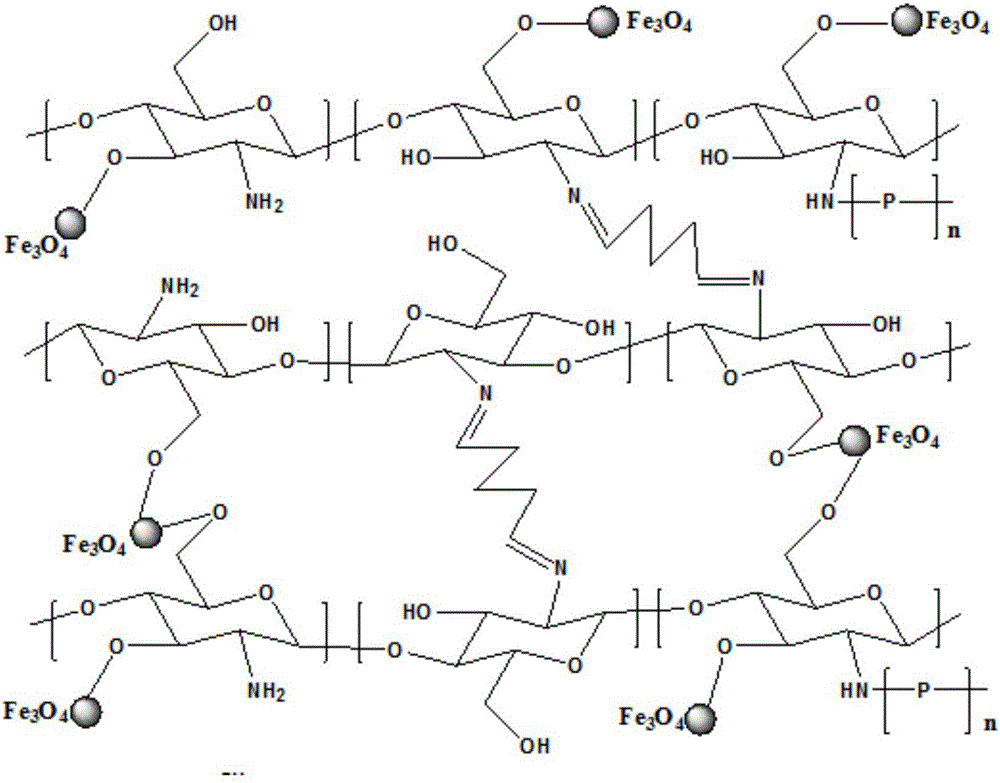

Chitosan magnetic composite spherule adsorbent with core-brush structure as well as preparation method and application thereof

A chitosan and adsorbent technology, which is applied in the field of chitosan magnetic composite pellet adsorbent and its preparation, can solve the problems of inability to biodegrade the adsorbent, poor adsorption effect, secondary pollution and the like, and achieves compact structure and high cost. , the effect of easy handling and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

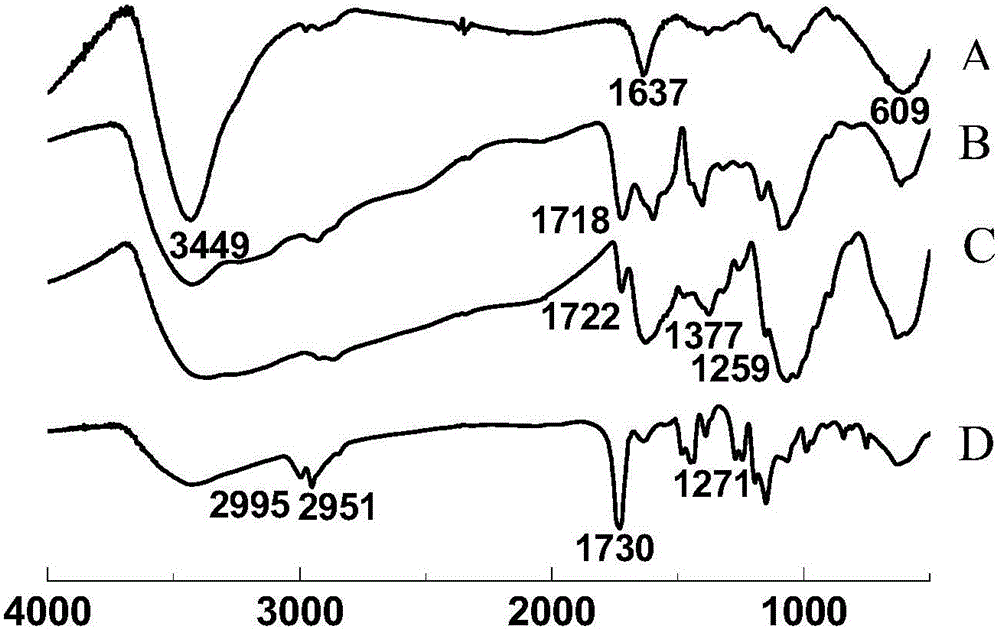

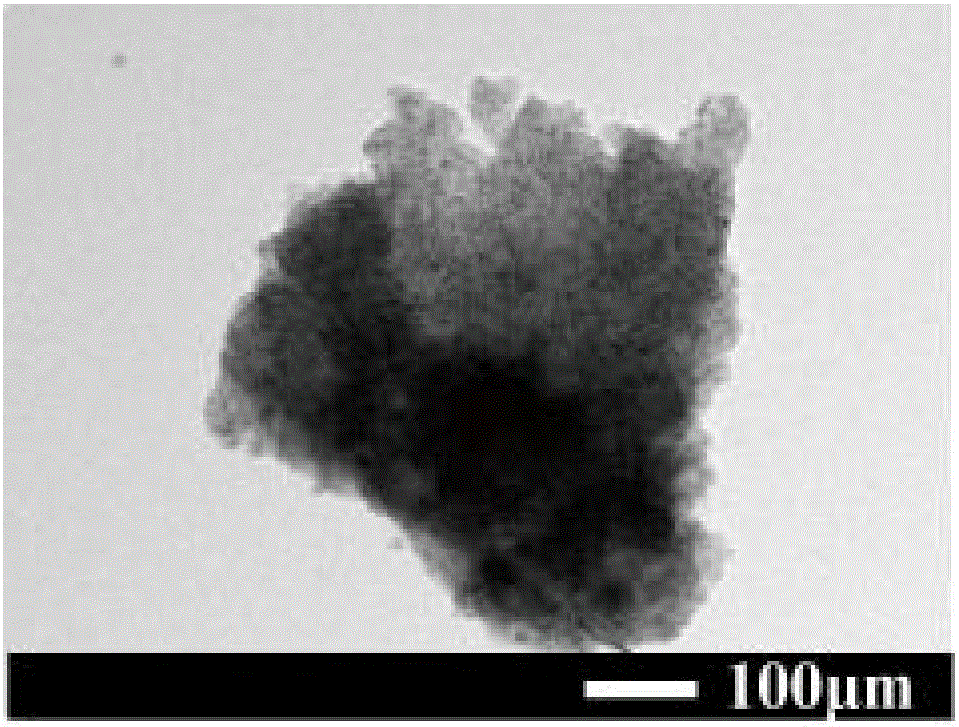

Method used

Image

Examples

Embodiment 1

[0048] Weigh chitosan (viscosity average molecular weight is 200,000), add deionized water, then directly add concentrated hydrochloric acid (chitosan is completely dissolved), then weigh FeCl 3 ·6H 2 O and FeCl 2 4H 2 O was directly added to the above solution (chitosan and FeCl 3 ·6H 2 O, FeCl 2 4H 2 O, water, and concentrated hydrochloric acid in a mass ratio of 1:2.32:0.85:60:1), dissolved, and ultrasonicated for 5 minutes to obtain a mixed solution. The mixed solution synthesized above was dripped into the sodium hydroxide-ethanol-water mixed solution at a flow rate of 1 mL / min via a peristaltic pump (the mass ratio of sodium hydroxide, ethanol, and water in the sodium hydroxide-ethanol-water mixed solution was 1 :3:6, the ratio of the quality of the above-mentioned mixed solution of synthesis to the mixed solution of sodium hydroxide-ethanol-water is 1:3; shaped pellets, and uncrosslinked chitosan magnetic composite pellets were obtained after filtration.

[0049...

Embodiment 2

[0055] Weigh chitosan (viscosity average molecular weight is 100,000), add deionized water, then directly add concentrated hydrochloric acid (chitosan is completely dissolved), then weigh FeCl 3 ·6H 2 O and FeCl 2 4H 2 O was directly added to the above solution (chitosan and FeCl 3 ·6H 2 O, FeCl 2 4H 2 O, water, and concentrated hydrochloric acid in a mass ratio of 1:3.48:1.28:50:2), dissolved, and ultrasonicated for 5 minutes to obtain a mixed solution. The mixed solution synthesized above was dripped into the sodium hydroxide-ethanol-water mixed solution at a flow rate of 1 mL / min via a peristaltic pump (the mass ratio of sodium hydroxide, ethanol, and water in the sodium hydroxide-ethanol-water mixed solution was 1 : 3:6, the ratio of the quality of the mixed solution of above-mentioned synthesis to the mixed solution of sodium hydroxide-ethanol-water is 1:5; shaped pellets, and uncrosslinked chitosan magnetic composite pellets were obtained after filtration.

[005...

Embodiment 3

[0062] Weigh chitosan (viscosity average molecular weight is 150,000), add deionized water, then directly add concentrated hydrochloric acid (chitosan is completely dissolved), then weigh FeCl 3 ·6H 2 O and FeCl 2 4H 2 O was directly added to the above solution (chitosan and FeCl 3 ·6H 2 O, FeCl 2 4H 2 O, water, concentrated hydrochloric acid in a mass ratio of 1:2.78:1.02:50:80:0.5), dissolved and ultrasonicated for 5 minutes to obtain a mixed solution. The mixed solution synthesized above was dripped into the sodium hydroxide-ethanol-water mixed solution at a flow rate of 1 mL / min via a peristaltic pump (the mass ratio of sodium hydroxide, ethanol, and water in the sodium hydroxide-ethanol-water mixed solution was 1 :3:6, the ratio of the quality of the mixed solution of above-mentioned synthesis to the mixed solution of sodium hydroxide-ethanol-water is 1:4; shaped pellets, and uncrosslinked chitosan magnetic composite pellets were obtained after filtration.

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com