Advanced woody blend oil and production process thereof

A production process and technology for blending oil, applied in the field of edible oil, can solve the problems of insufficient nutritional value of herbal oil, short growth cycle of herbs, unfavorable human health, etc., to reduce blood cholesterol and cardiovascular and cerebrovascular diseases, reduce the occurrence probability, The effect of a long growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

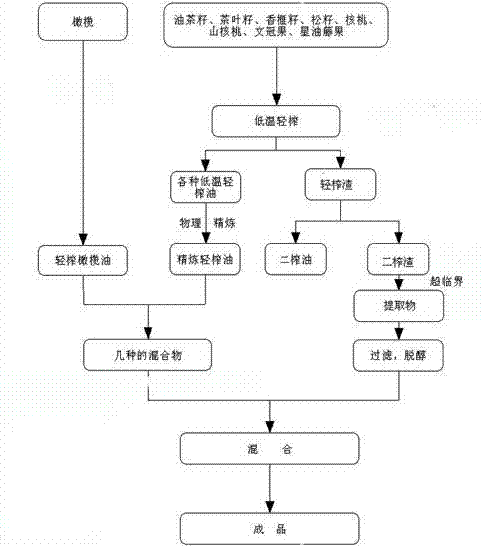

Image

Examples

Embodiment 1

[0032] The production process of the high-grade woody blend oil of this embodiment includes the following steps.

[0033] 1) Take mature, intact, mildew-free and insect-free camellia seeds, tea seeds, torreya seeds, pine nuts, walnuts, hickory nuts, sorbifolium and star oil vine fruits, clean them, shell them and dry them to a moisture content of 5 %the following.

[0034] 2) Lightly press camellia oleifera seeds, tea seeds, torreya seeds, pine nuts, walnuts, hickory nuts, sorbifoliums, and star oil vines at a light pressing temperature of 150°C and an oil output temperature of 90°C, and the oil is extracted The rate was 70%, and the corresponding lightly pressed oil and lightly pressed residue were obtained respectively. The lightly pressed oils include camellia seed lightly pressed oil, tea seed lightly pressed oil, Chinese torreya seed lightly pressed oil, pine nut lightly pressed oil, walnut lightly pressed oil, hickory nut lightly pressed oil, Xingguan fruit lightly pres...

Embodiment 2

[0040] The production process of the high-grade woody blend oil of this embodiment includes the following steps.

[0041] 1) Take mature, intact, mildew-free and insect-free camellia seeds, tea seeds, torreya seeds, pine nuts, walnuts, hickory nuts, sorbifolium and star oil vine fruits, clean them, shell them and dry them to a moisture content of 5 %the following.

[0042] 2) Lightly press camellia oleifera seeds, tea seeds, torreya seeds, pine nuts, walnuts, hickory nuts, sorbifoliums and star oil vines at a light pressing temperature of 120°C and an oil output temperature of 60°C respectively, and the oil is extracted The rate was 70%, and the corresponding lightly pressed oil and lightly pressed residue were obtained respectively. The lightly pressed oils include camellia seed lightly pressed oil, tea seed lightly pressed oil, Chinese torreya seed lightly pressed oil, pine nut lightly pressed oil, walnut lightly pressed oil, hickory nut lightly pressed oil, Xingguan fruit ...

Embodiment 3

[0047] The production process of the high-grade woody blend oil of this embodiment includes the following steps.

[0048] 1) Take mature, intact, mildew-free and insect-free camellia seeds, tea seeds, torreya seeds, pine nuts, walnuts, hickory nuts, sorbifolium and star oil vine fruits, clean them, shell them and dry them to a moisture content of 5 %the following.

[0049] 2) Lightly press camellia oleifera seeds, tea seeds, torreya seeds, pine nuts, walnuts, hickory nuts, sorbifoliums and star oil vines at a light pressing temperature of 130°C and an oil output temperature of 75°C, and the oil is extracted The rate was 70%, and the corresponding lightly pressed oil and lightly pressed residue were obtained respectively. The lightly pressed oils include camellia seed lightly pressed oil, tea seed lightly pressed oil, Chinese torreya seed lightly pressed oil, pine nut lightly pressed oil, walnut lightly pressed oil, hickory nut lightly pressed oil, Xingguan fruit lightly press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com