Patents

Literature

54results about How to "Simple and convenient design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

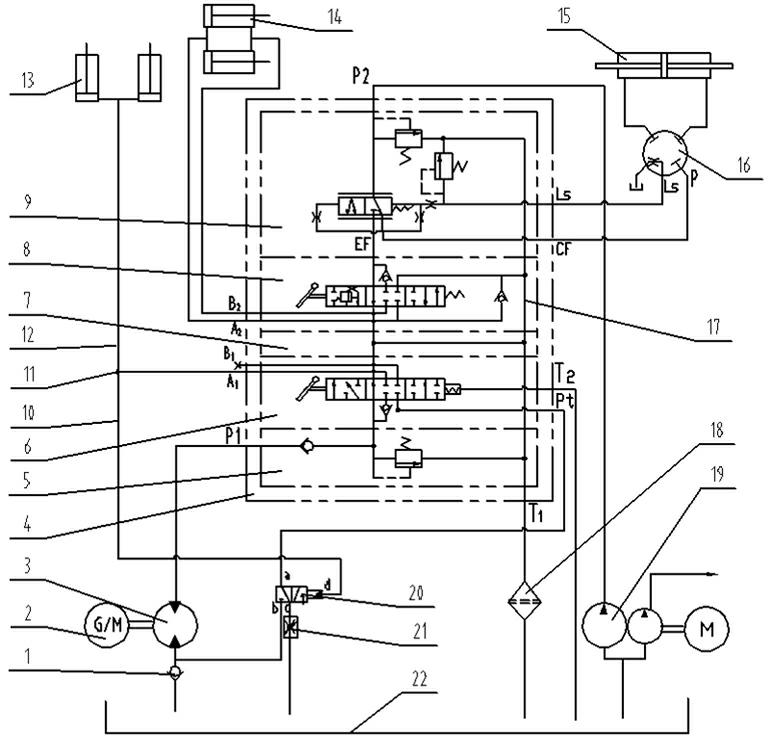

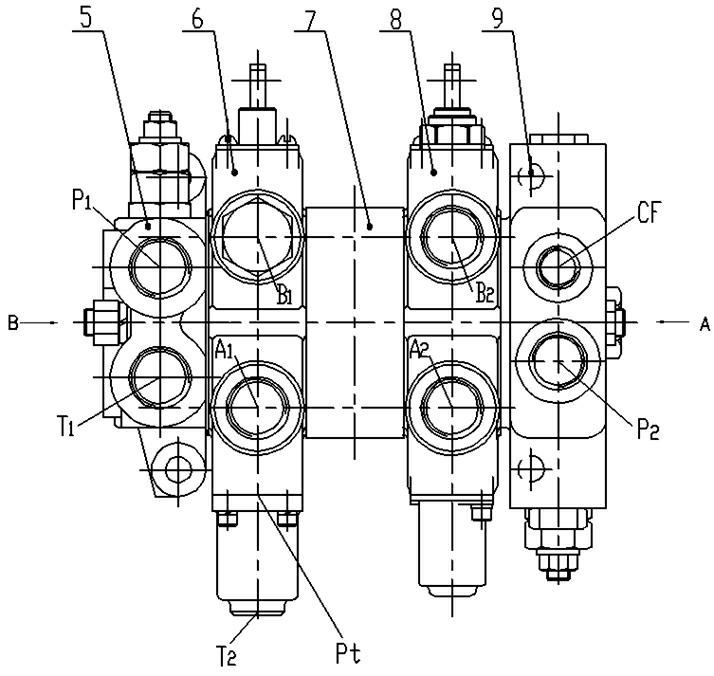

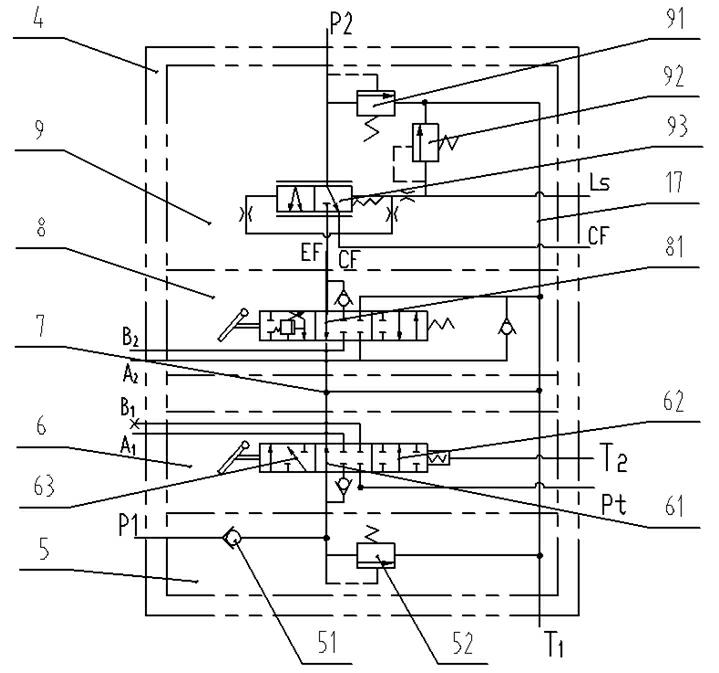

Energy-saving hydraulic system of electric forklift

ActiveCN102134047ASimple, convenient and reliable electrical controlEasy to operateLifting devicesPotential energySafety valve

The invention relates to an energy-saving hydraulic system of an electric forklift. The system comprises a one-way valve, a motor, a multi-way valve and the like, wherein the multi-way valve is a plate valve and comprises an oil inlet / return valve sheet, a lifting reversing valve sheet, a middle connection valve sheet, an oblique reversing valve sheet and an oil inlet valve sheet; the one-way valve and a main safety valve are arranged in the oil inlet / return valve sheet which is externally connected with an oil port P1 and an oil return port T1; the lifting reversing valve sheet is a three-position six-way reversing valve sheet, a middle-position channel, a right-position oil channel and a left-position oil channel are arranged in the lifting reversing valve sheet, and the lifting reversing valve sheet is externally connected with oil ports A1, Pt and T2; the middle connection valve sheet is a transitional connection valve sheet, and a three-way pipe is arranged in the middle connection valve sheet; the oblique reversing valve sheet is a three-position six-way reversing valve sheet, a middle-position oil channel is arranged in the oblique reversing valve sheet, and the oblique reversing valve sheet is externally connected with oil ports A2 and B2; and an oblique overflow valve, a reversing overflow valve and a priority valve are arranged in the oil inlet valve sheet, and the oil inlet valve sheet is externally connected with oil ports P2, CF and Ls. Through the invention, after the electric forklift is charged once, the recovery efficiency of potential energy can reach 59.7%, the total recovery efficiency of the system can reach 31.3%, and the working time of the electric forklift can be prolonged by 1 / 5.

Owner:ANHUI HELI CO LTD

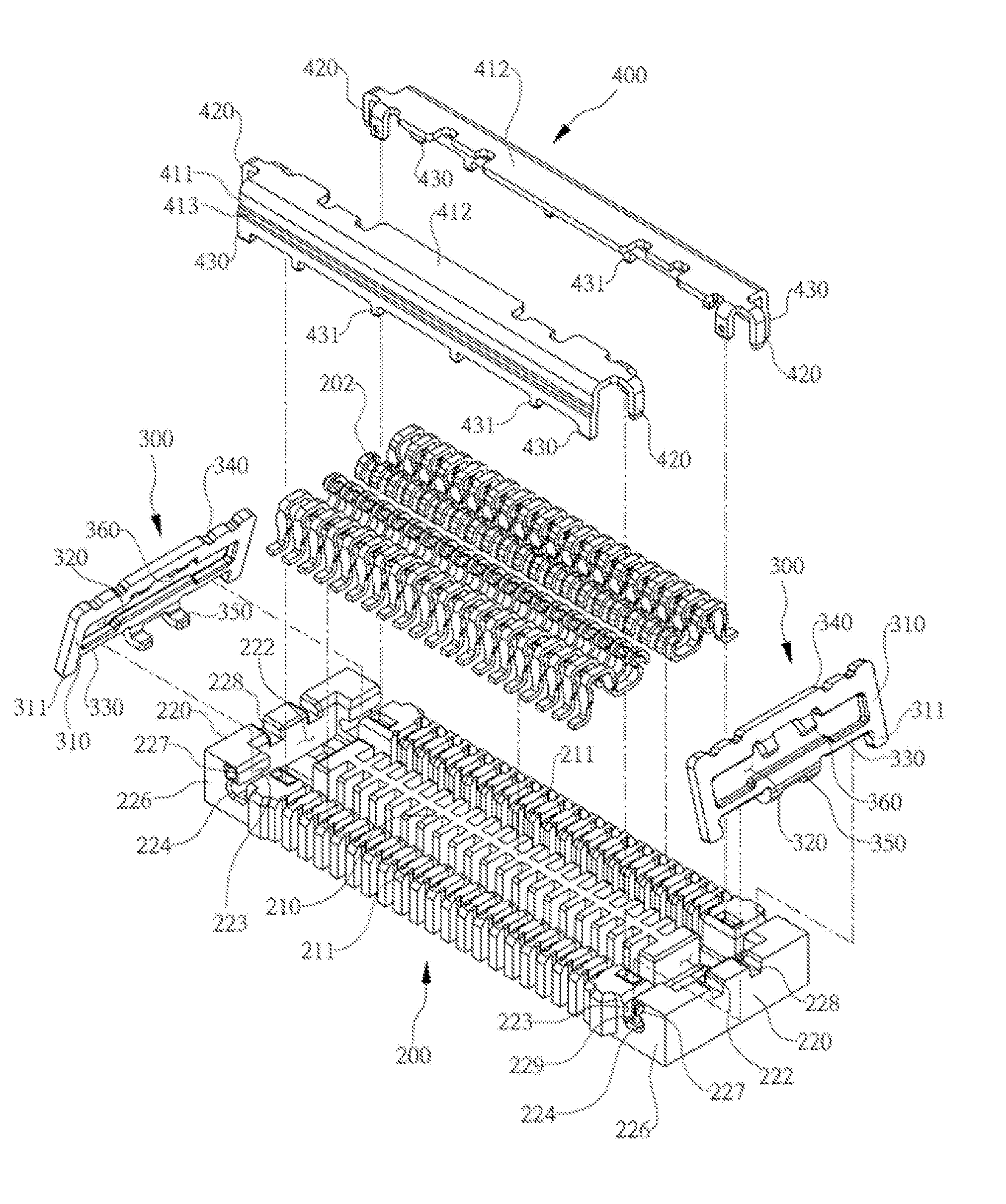

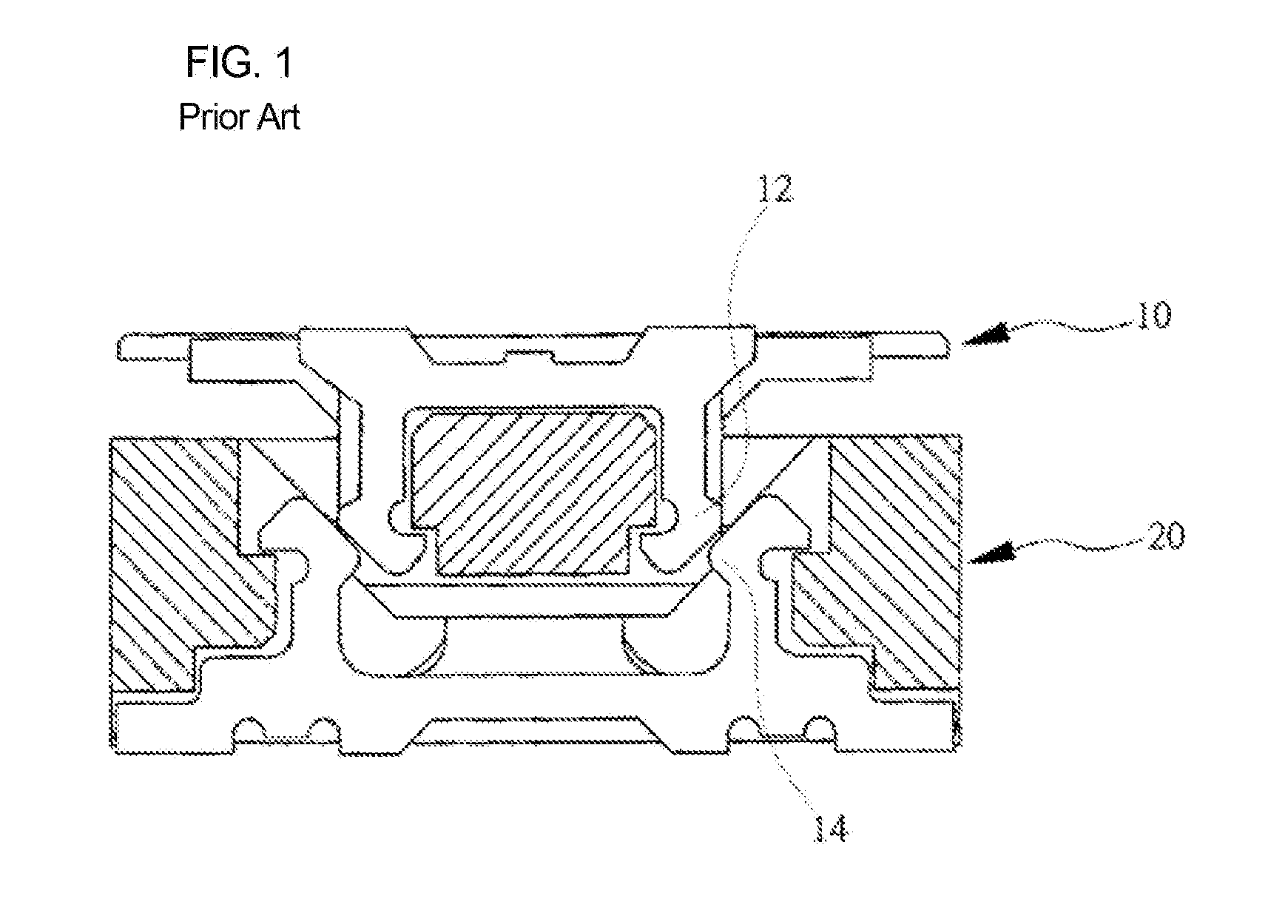

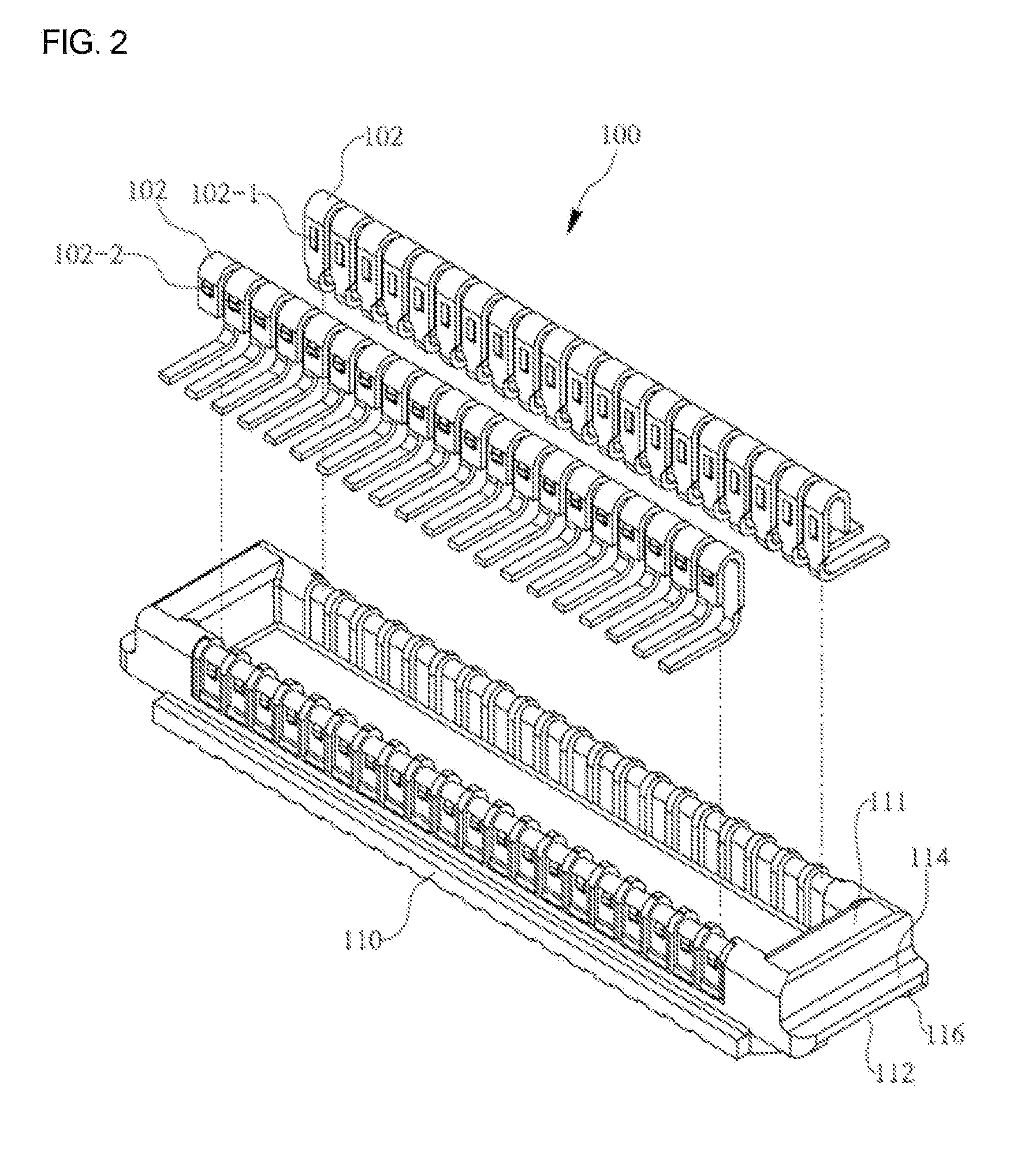

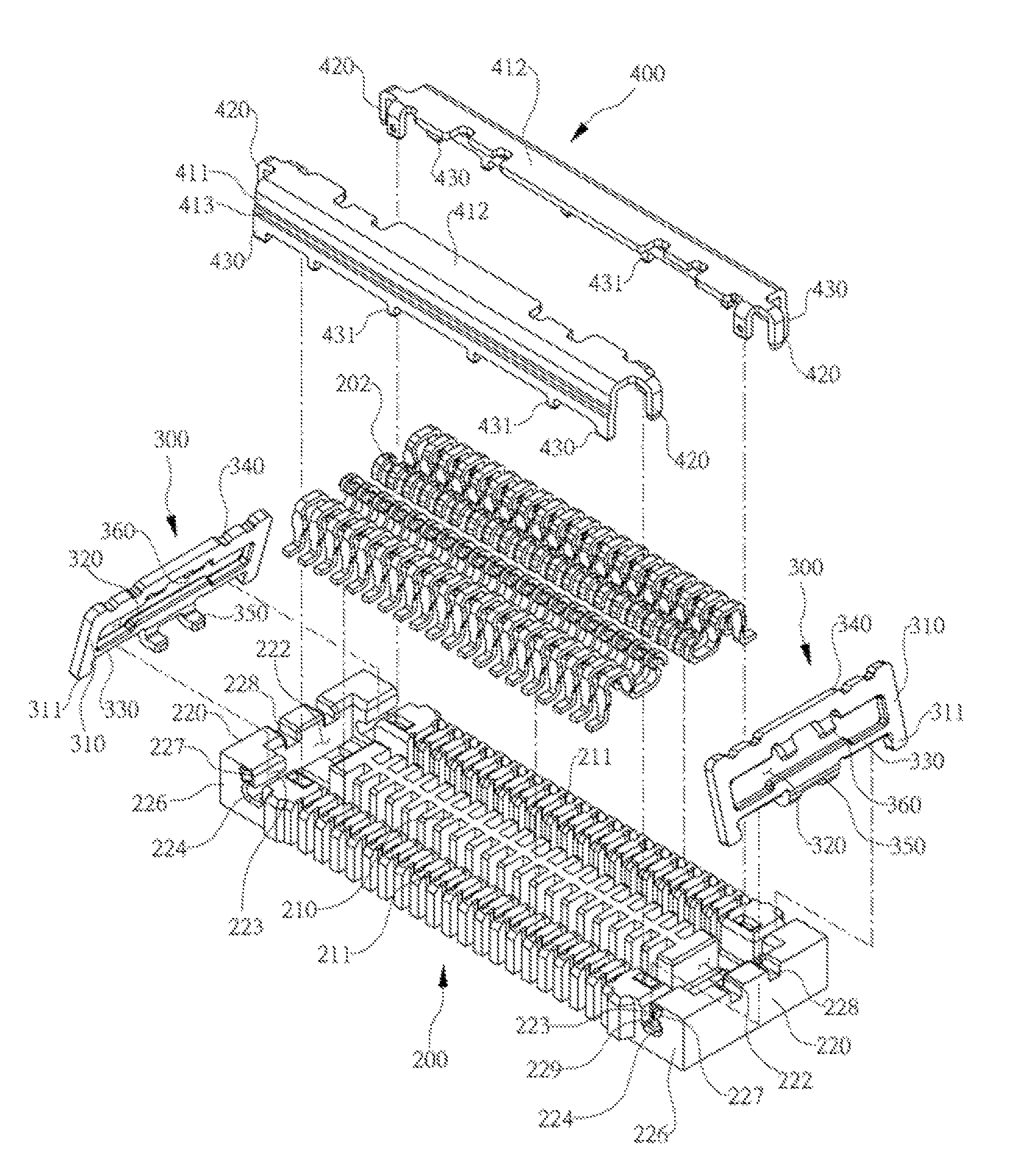

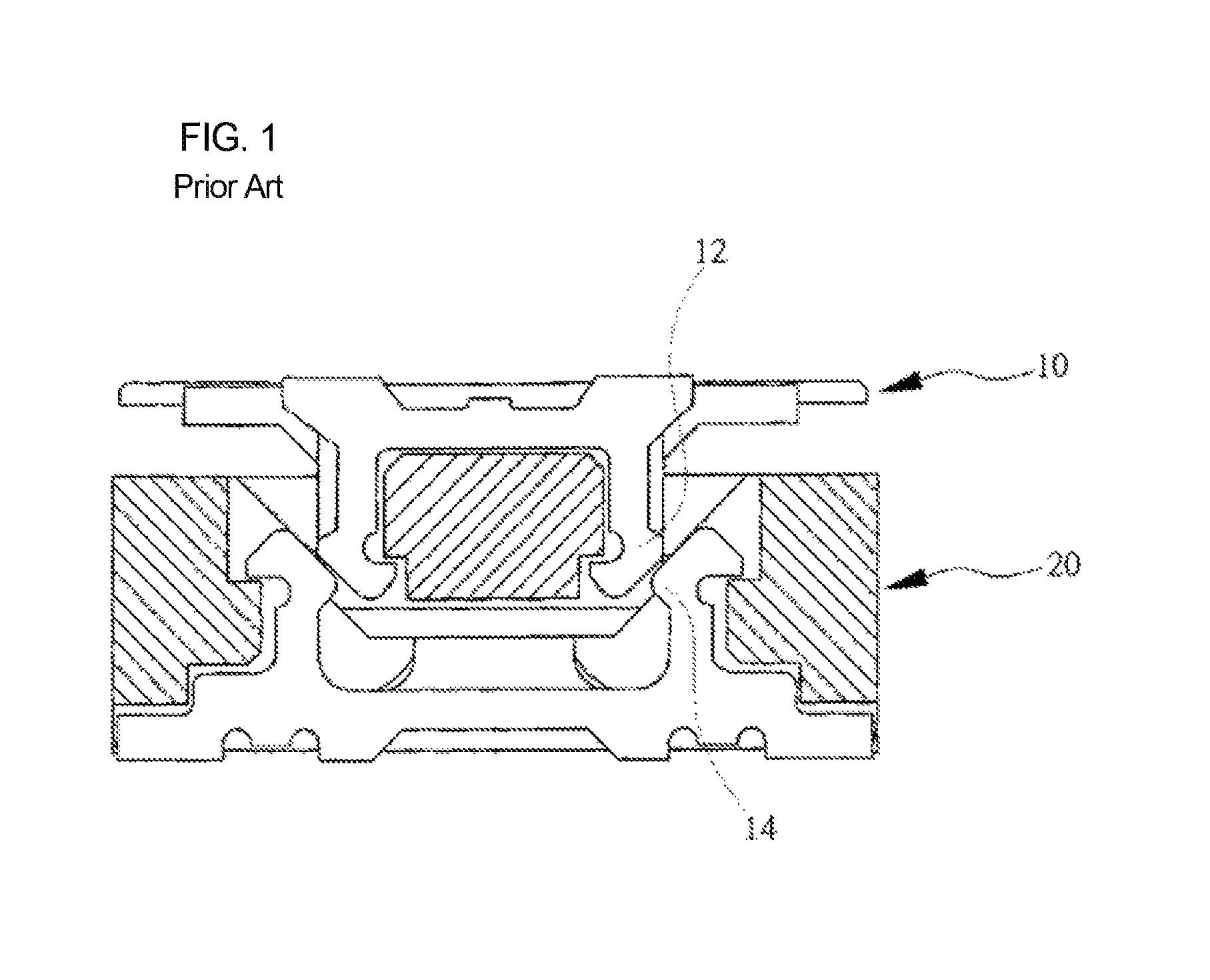

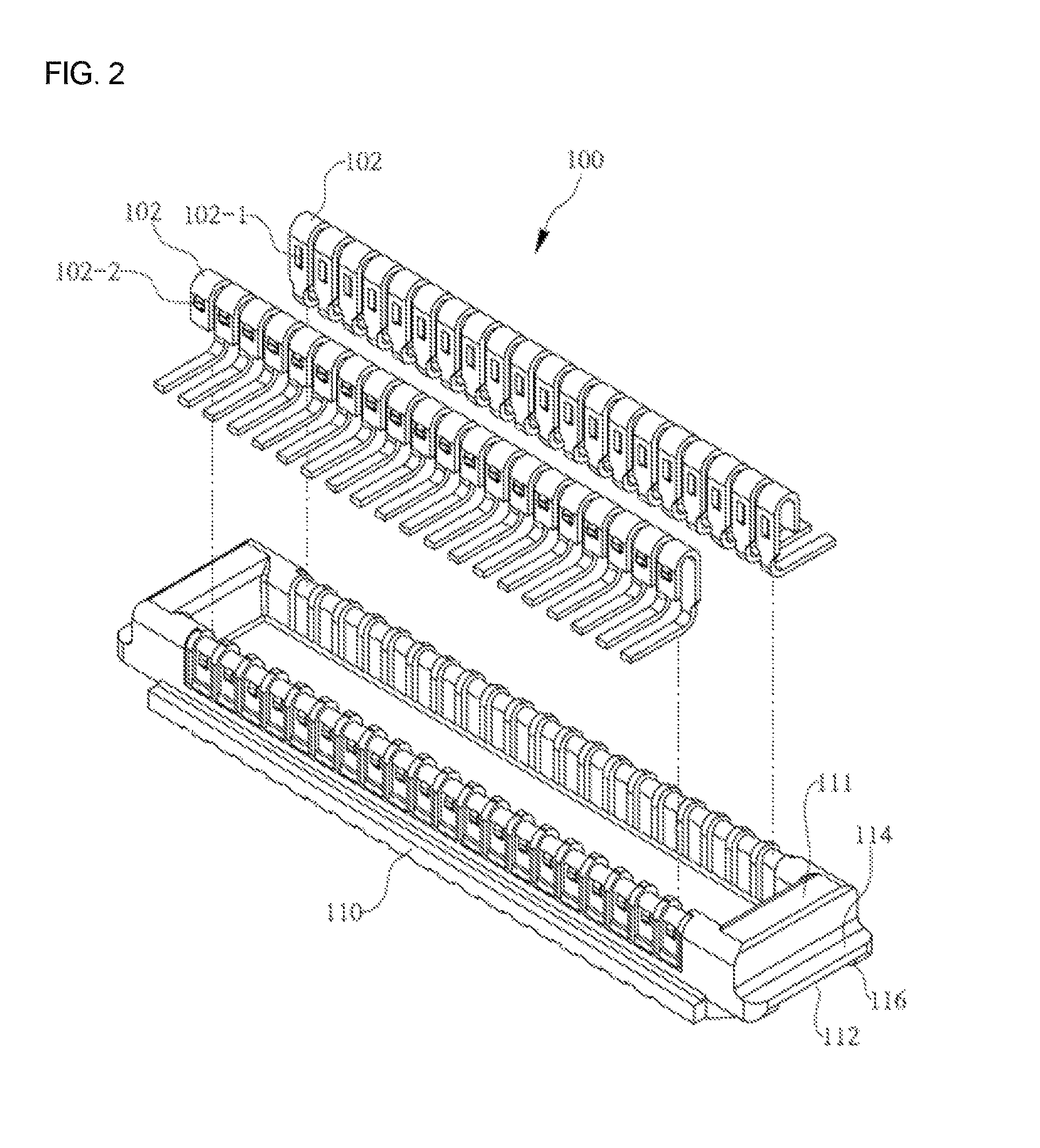

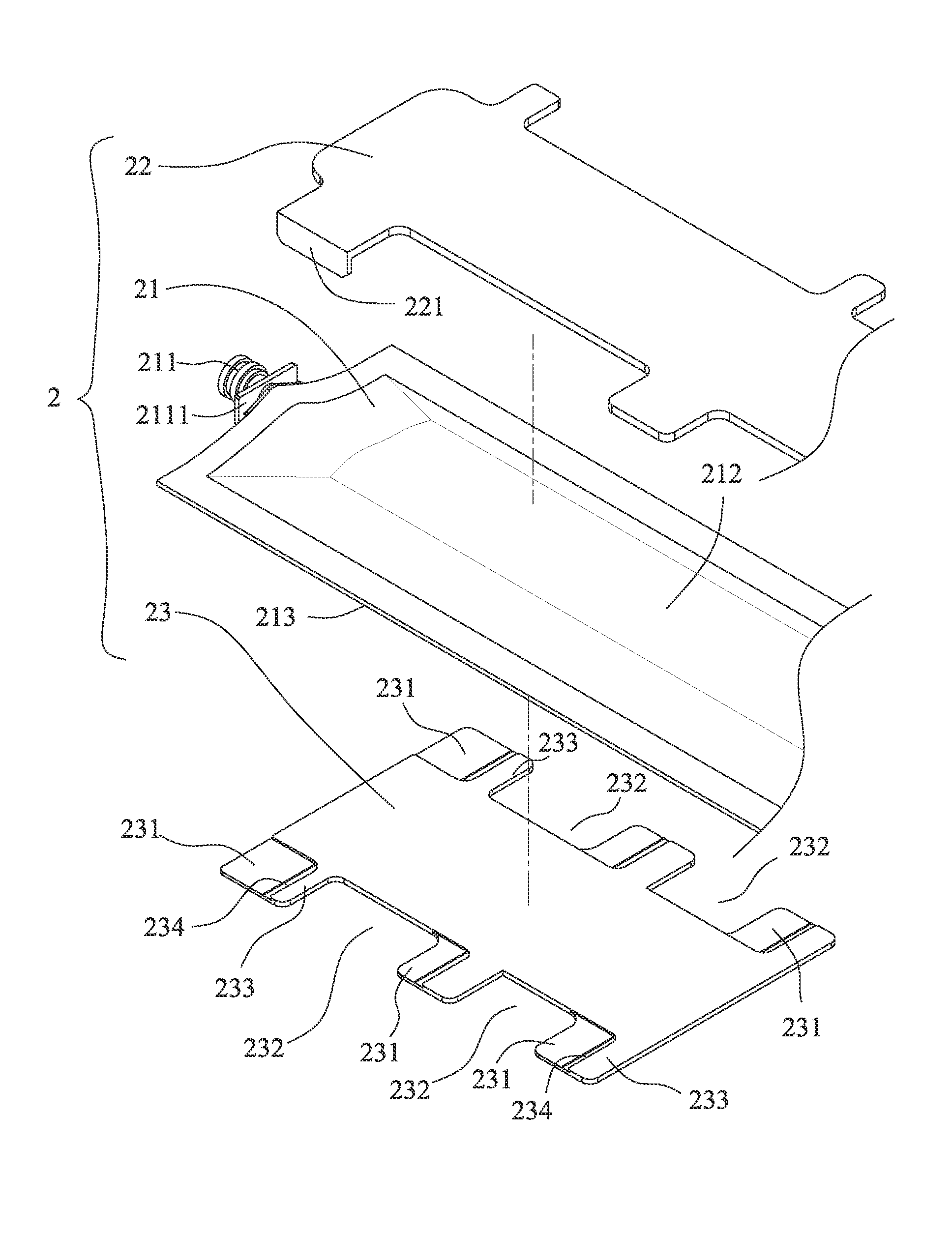

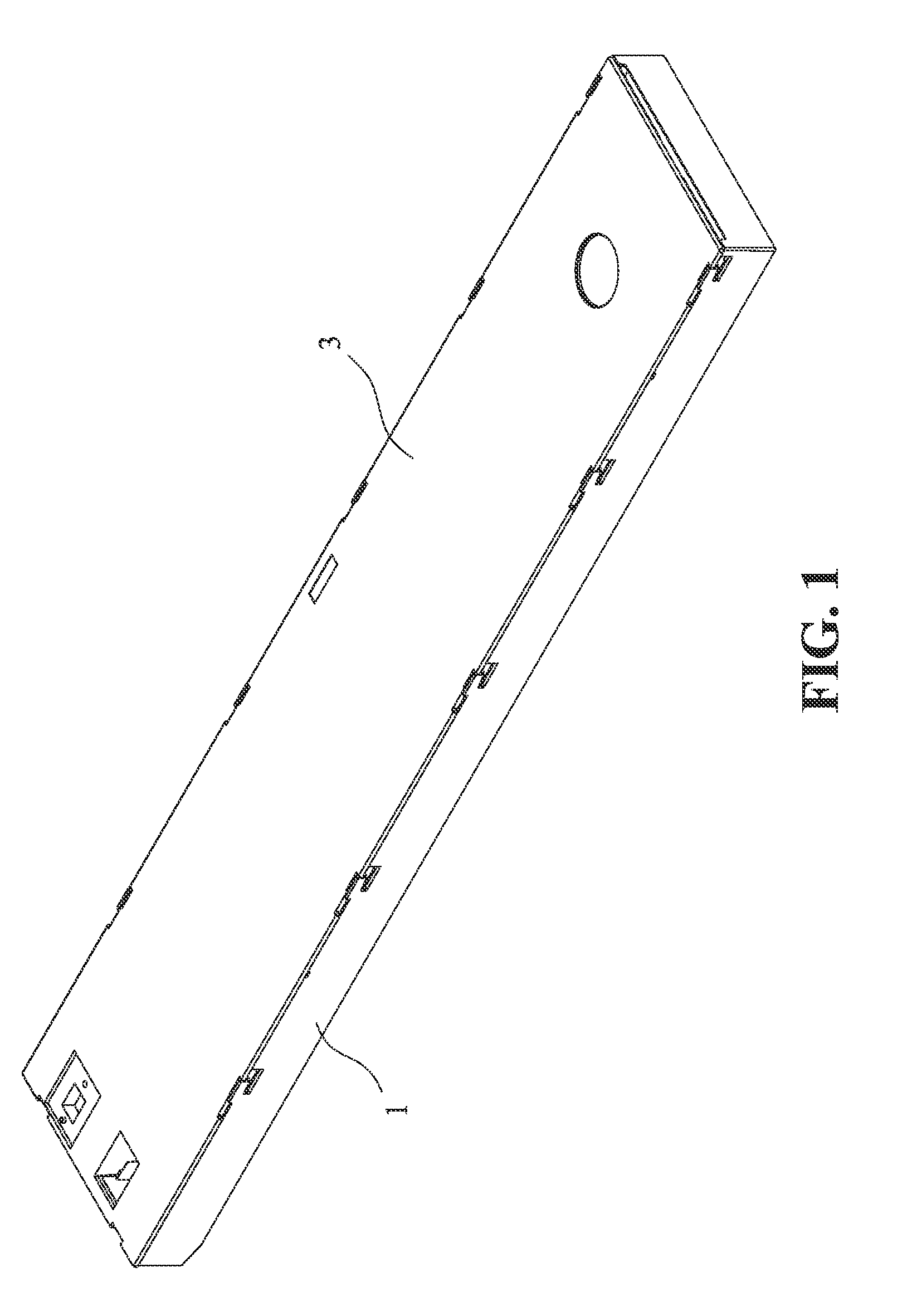

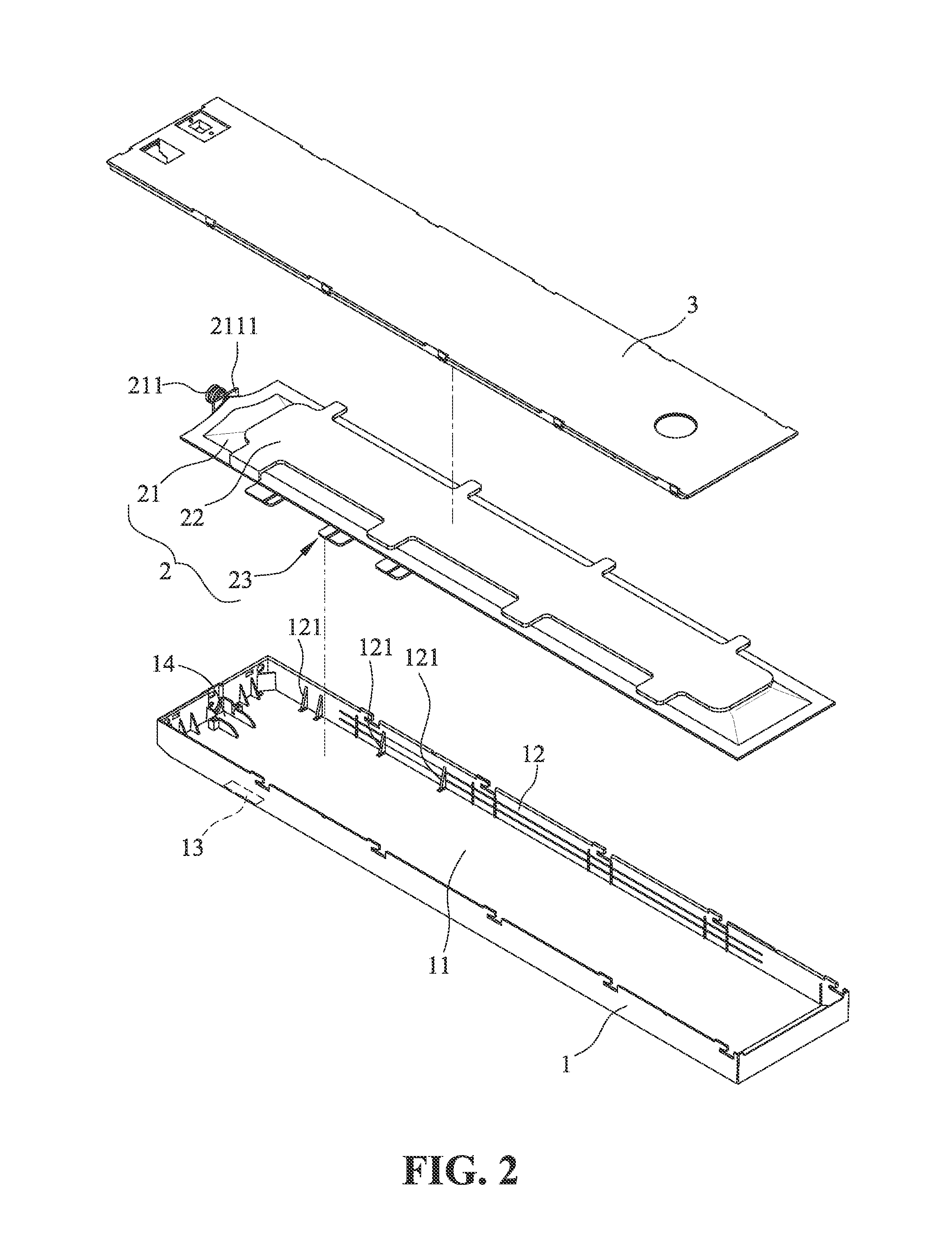

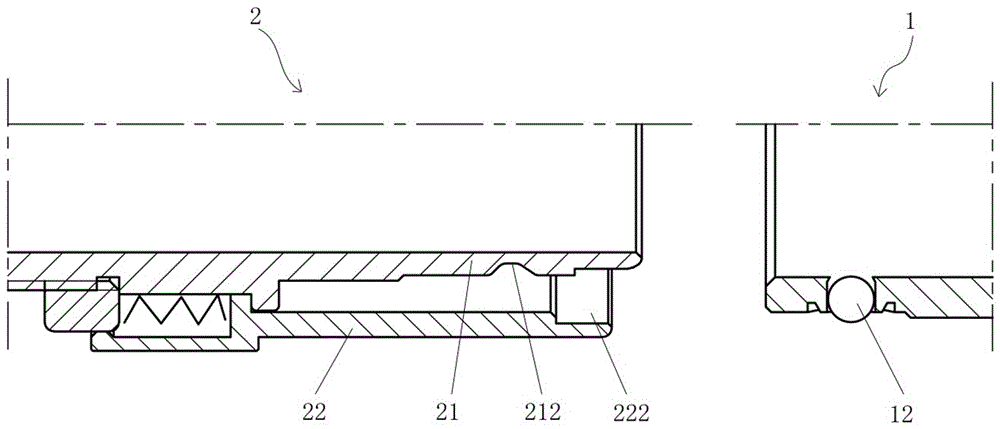

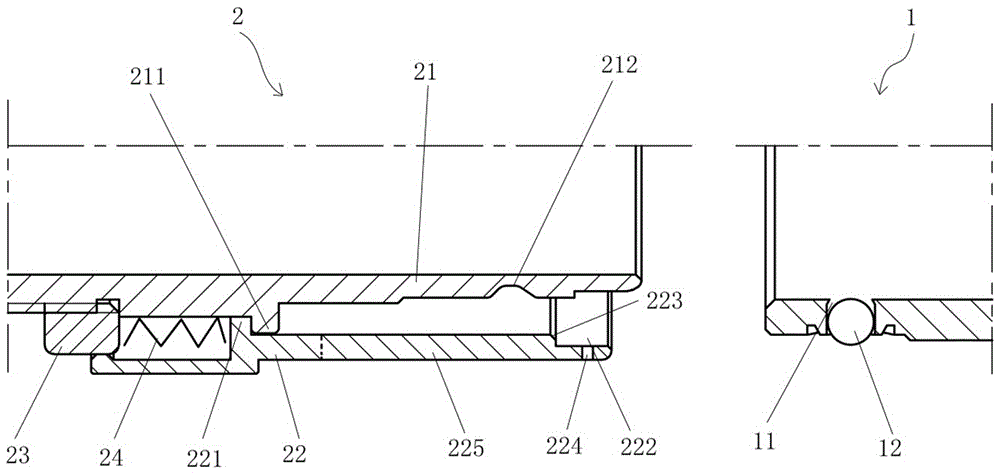

Shield and locking type board to board connector

ActiveUS20150132985A1High mechanical strengthSimple and convenient designCoupling contact membersClamped/spring connectionsOn boardElectromagnetic interference

A shield and locking type board to board connector functioning to connect a first board and a second board to each other, the connector including: a first connector unit having both a first base and a first terminal; a second connector unit having a second base and a second terminal; two shield members each having a shell shape, the shield members respectively provided on front and rear bases facing the second base such that the shield members arrest EMI (electromagnetic interference) noise; and a locking member provided in the second connector unit so as to prevent the first connector unit from being removed outward by an outward movement thereof after the first connector unit is combined with the second connector unit in a close contact state.

Owner:UJU ELECTRONICS

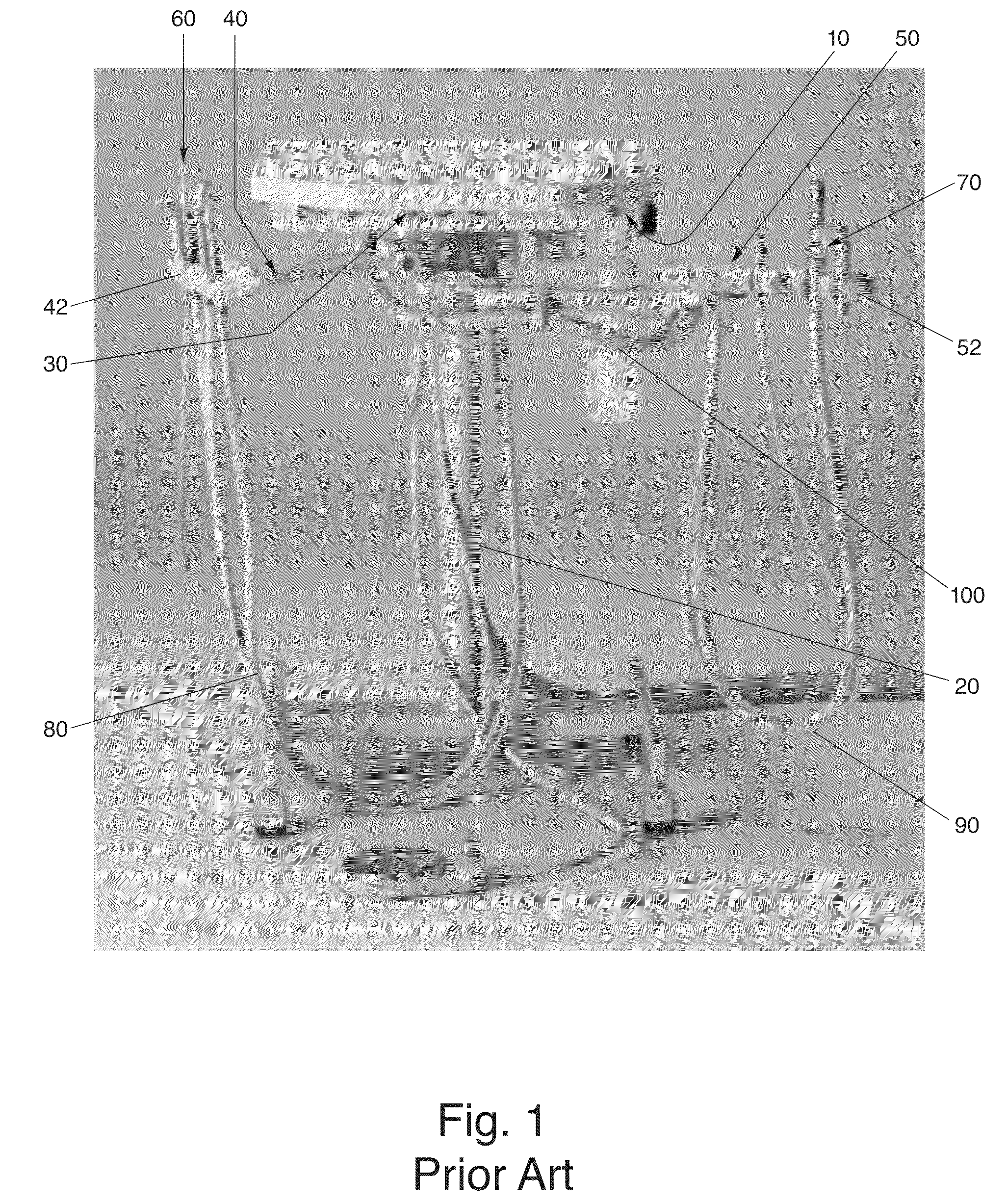

Delivery channel

InactiveUS20090166306A1Overcome disadvantagesSimple and convenient designOperating chairsDental chairsEngineeringContact mechanism

Owner:AHEARN DAVID J

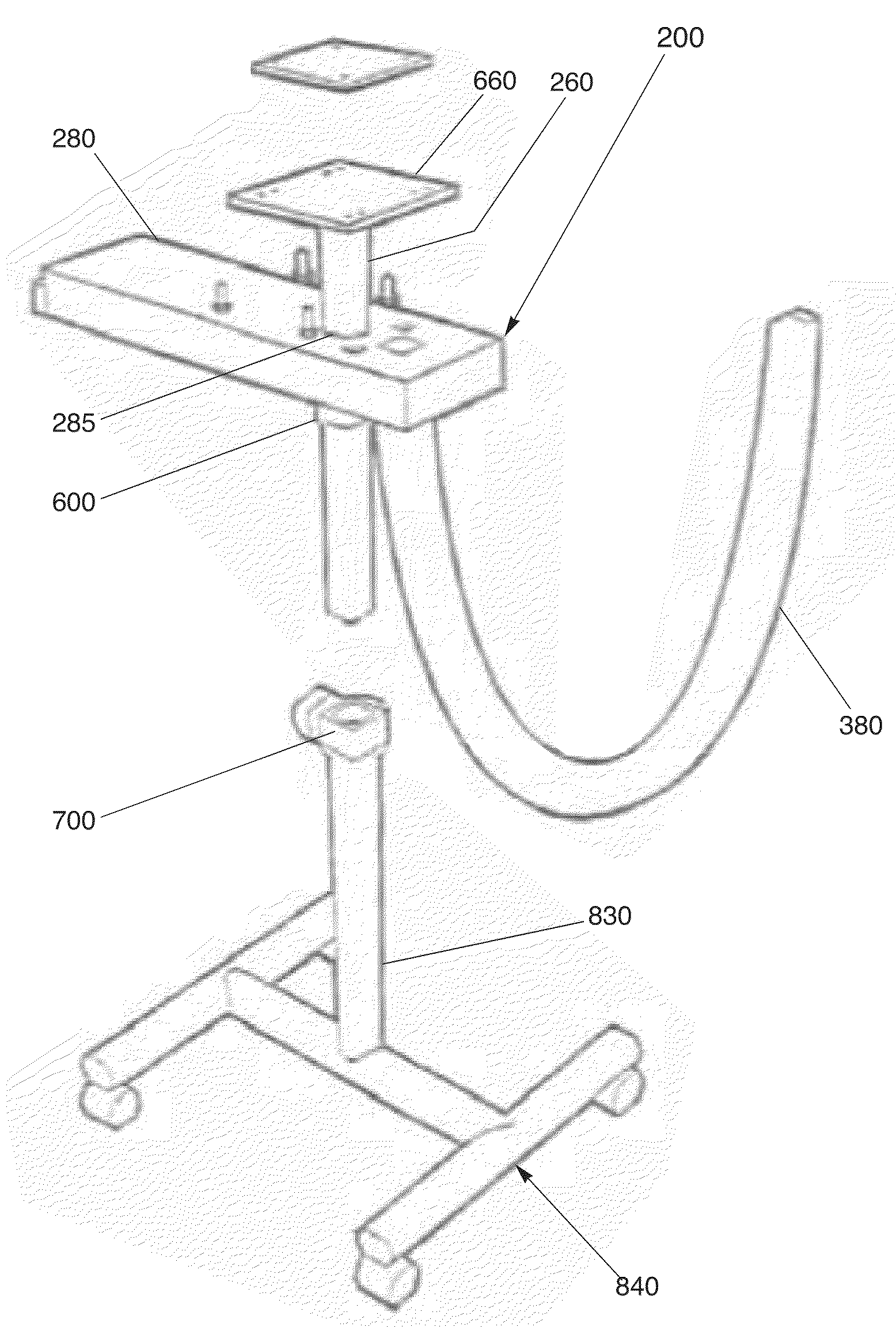

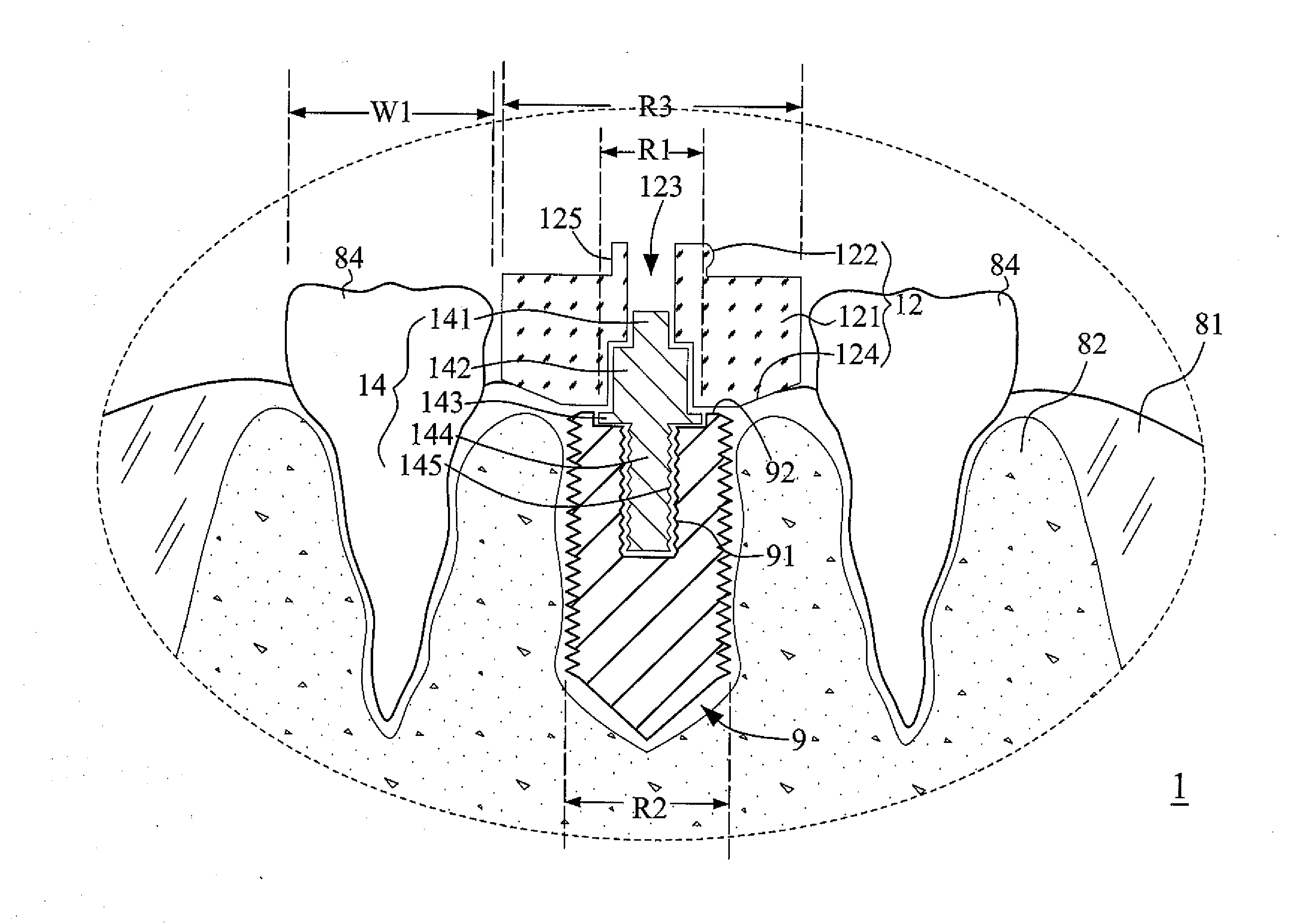

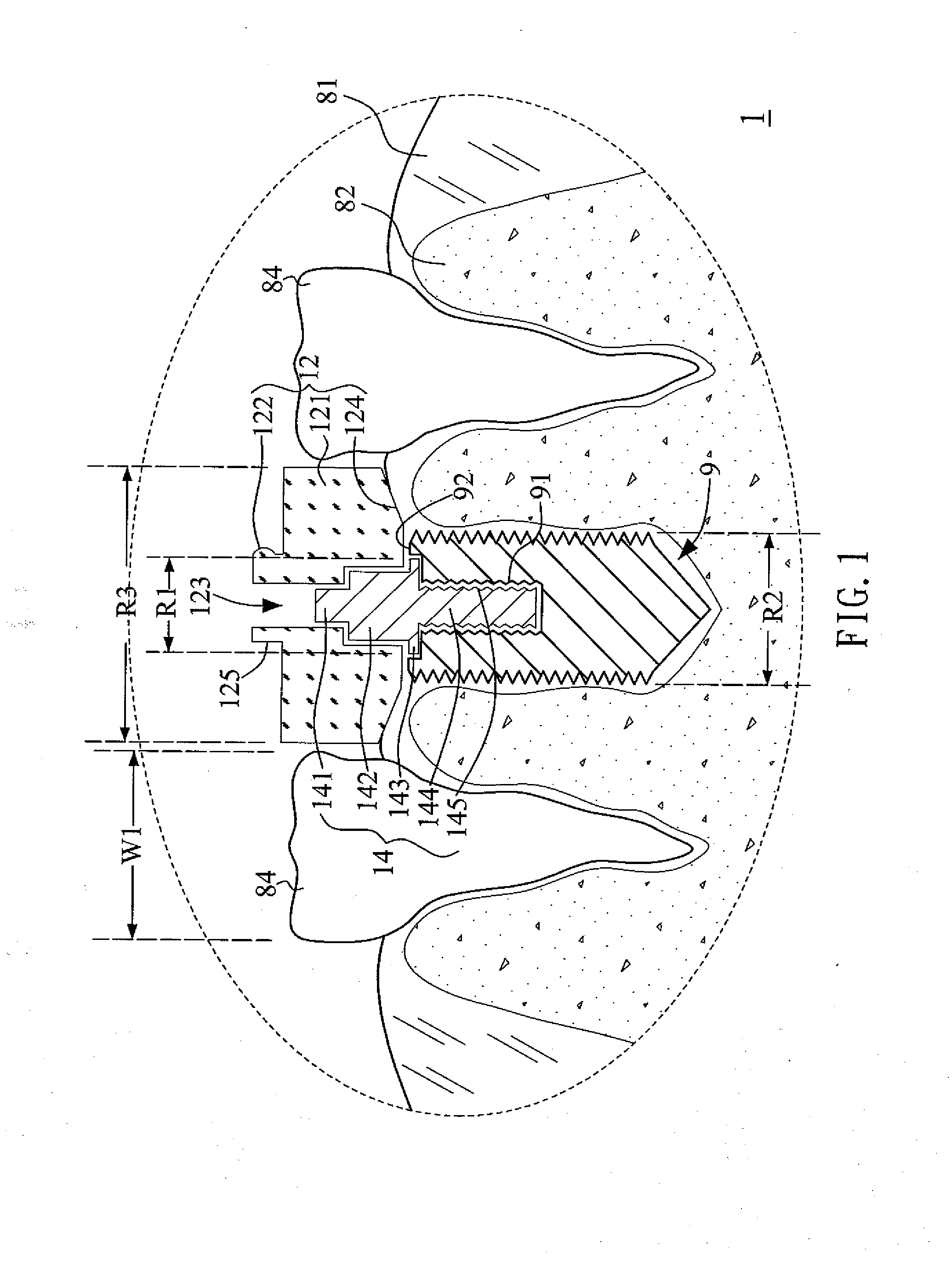

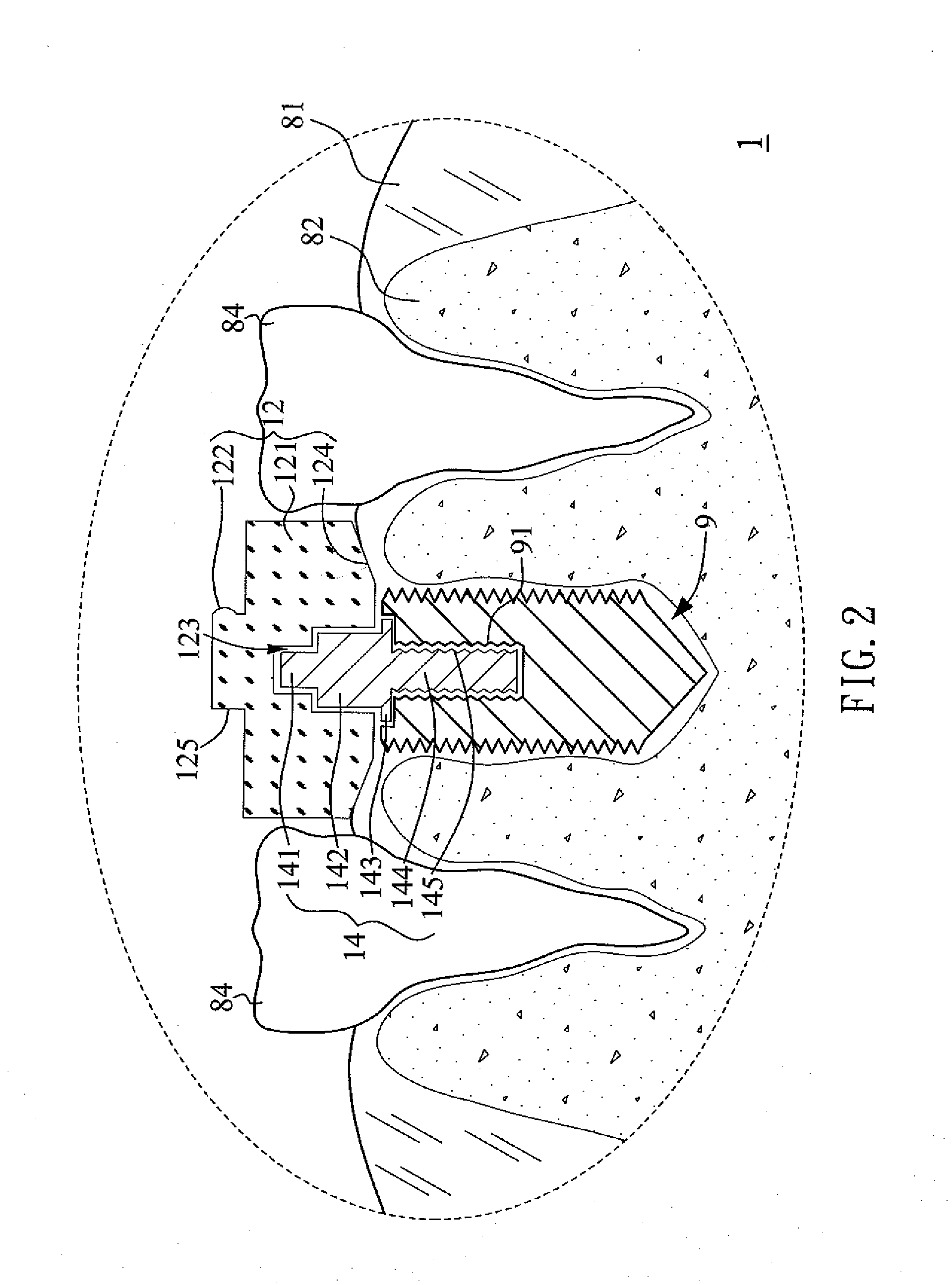

Multi Functional Implanting Suite and Implanting Method Thereof

InactiveUS20140178835A1Comprehensive functionsSimple and convenient designDental implantsImpression capsAbutmentDental clinic

A multi functional implanting suite for an implant utilized in tooth reconstruction, artificial tooth implanting or dental restoration is disclosed. The implanting suite comprises a cap and a fastening member, in which it may be equipped with multi functions including healing abutment, scan jig, mold taking suite, temporary crown or UCLA abutment, so that the dental clinics may merely purchase one dental tool and then solve may tooth reconstruction, artificial tooth implanting or dental restoration situations.

Owner:LIN CHEN YI

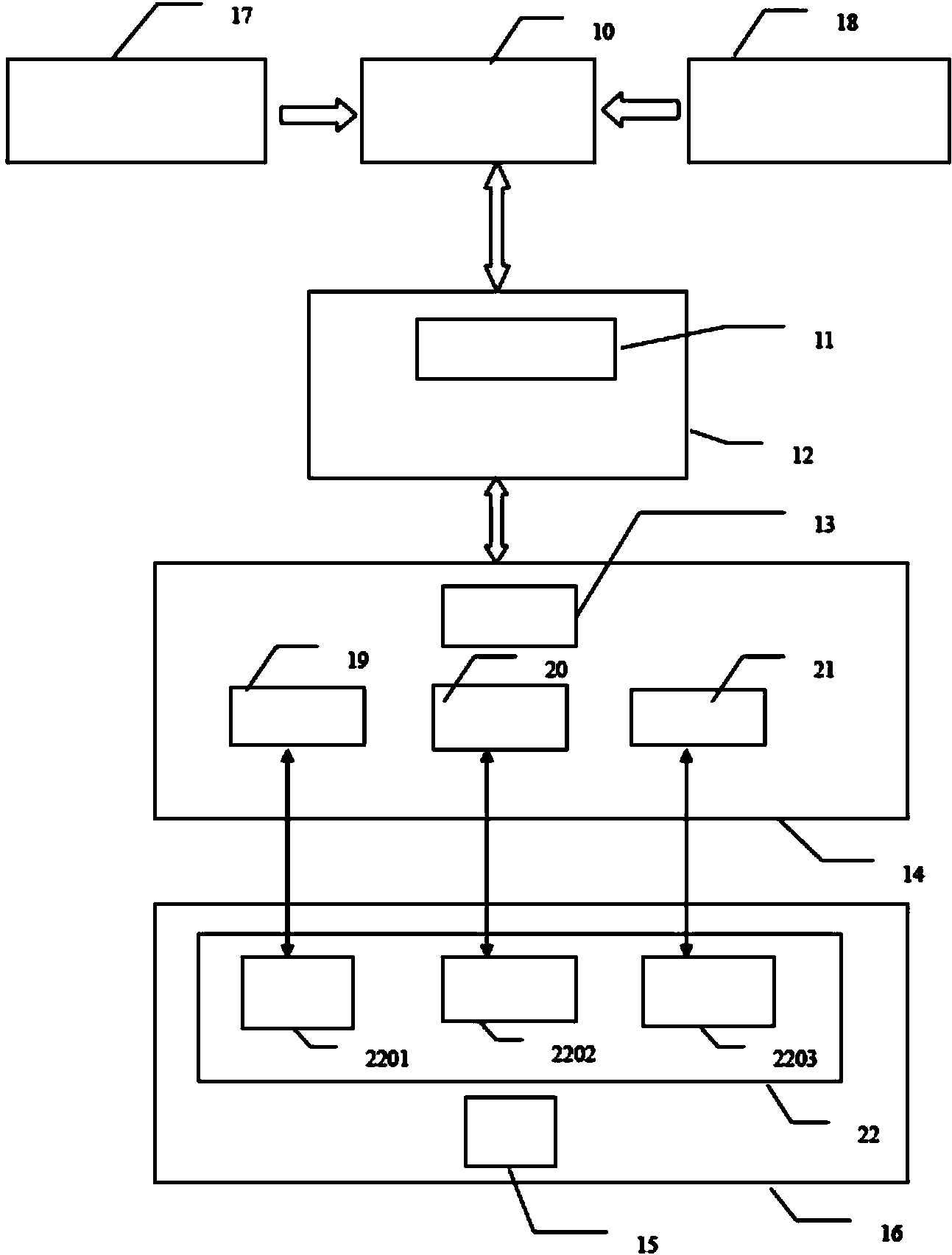

Automobile ventilation control device and control method of automobile ventilation control device

InactiveCN104236031AKeep clean and healthyFree from pollutionSpace heating and ventilation safety systemsLighting and heating apparatusBroadbandAir change

The invention relates to an automobile ventilation control device and a control method of the automobile ventilation control device. The automobile ventilation control device comprises an air conditioner, wherein the air conditioner is arranged in an automobile, an air conditioner control panel used for controlling the air conditioner is arranged on the air conditioner, a filter element is arranged in the air conditioner, the automobile ventilation control device also comprises an on-line particle monitor, a server, an intelligent communication device and a ventilation controller in mutual connection, wherein the on-line particle monitor is connected with the server through a wireless network, the server and the intelligent communication device are in interactive connection through a wireless broadband network, the intelligent communication device is connected with the ventilation controller in a wireless mode, and the ventilation controller is connected with the air conditioner control panel through a cable wire. The automobile ventilation control device and the control method of the automobile ventilation control device have the advantages that ventilation equipment such as the air conditioner in an automobile can be timely and automatically switched according to the air quality inside and outside the automobile, the efficient ventilation and air change are realized, and the effect of preventing outside severe air from polluting the inside of the automobile is fully guaranteed, so that fresh air enters a cab, the air in the automobile keeps clean and healthy, the real-time guarantee on the breathing health of people is realized, and the automobile ventilation control device and the control method are suitable to be popularized and used in relevant transportation equipment.

Owner:北京每日互联科技有限公司

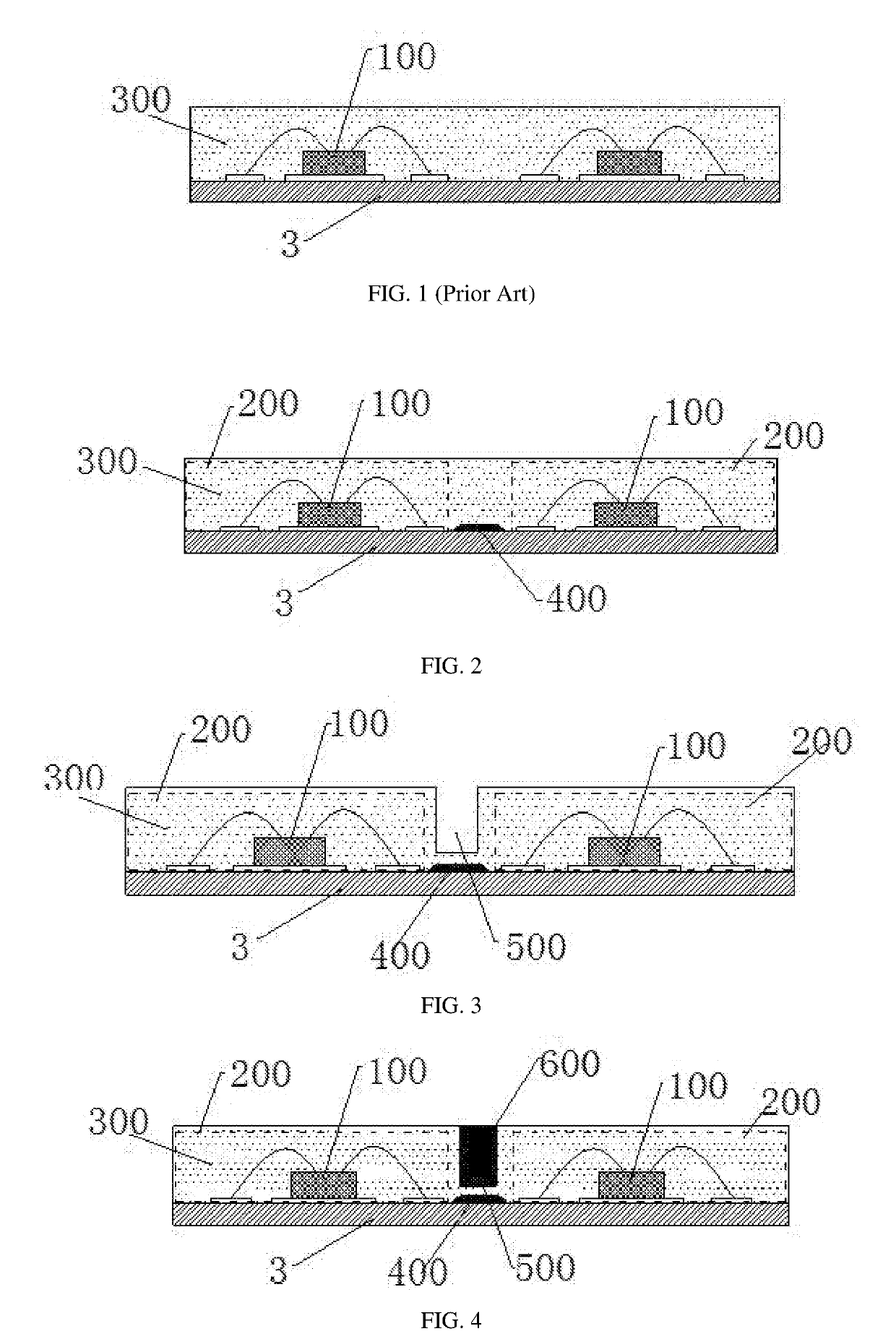

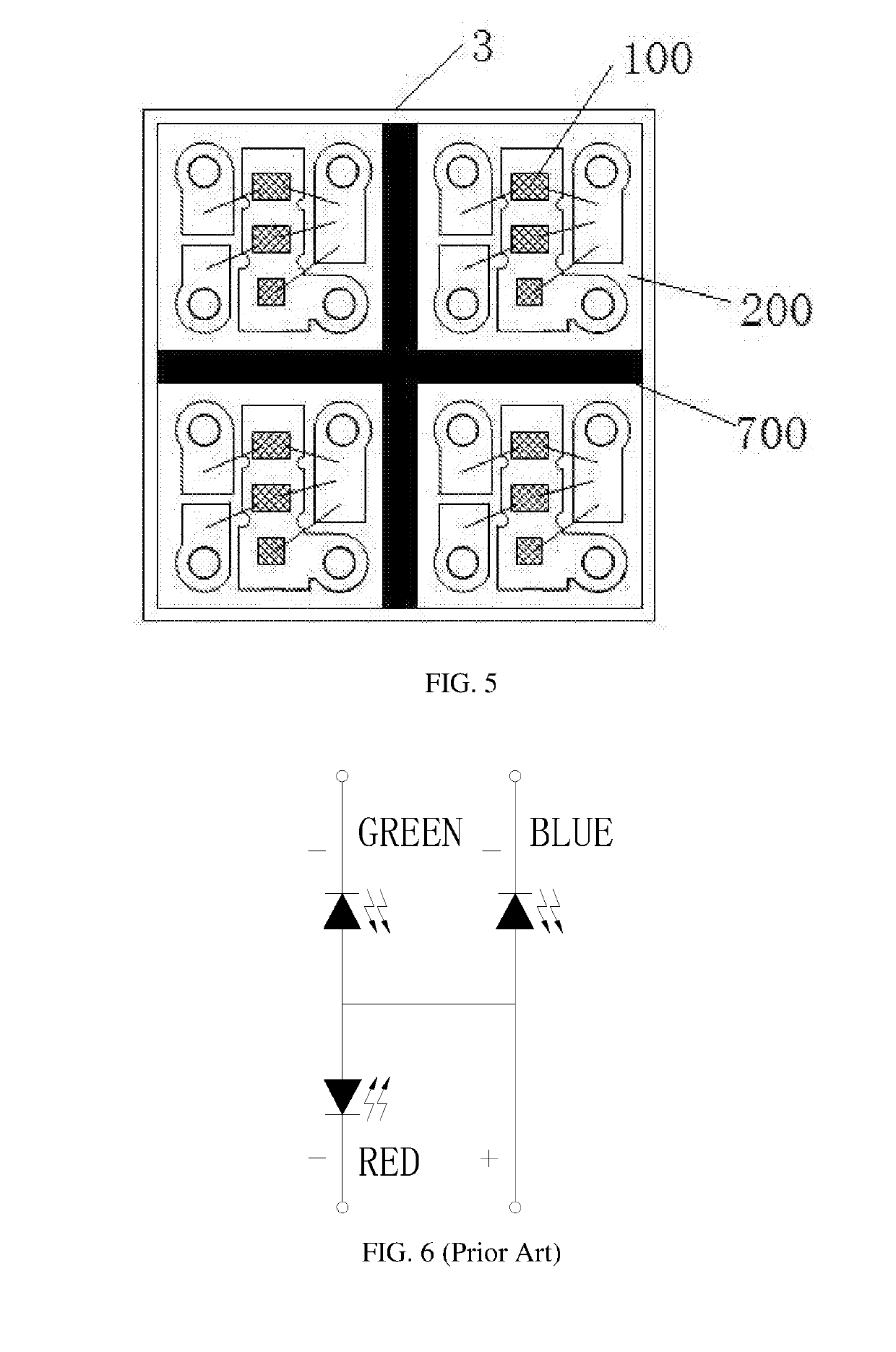

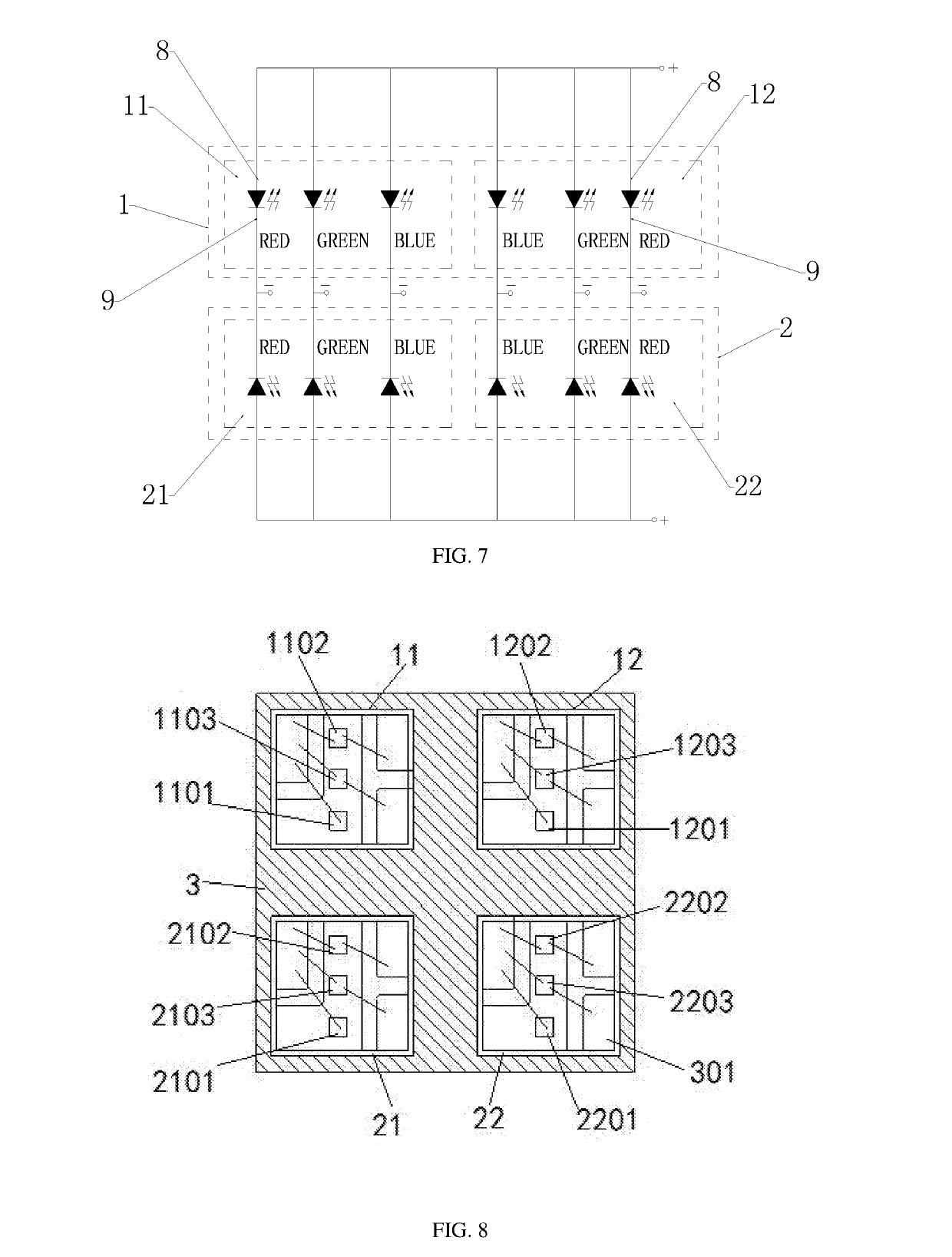

Rgb-led packaging modules and display screen formed thereof

ActiveUS20190280163A1Solve the real problemReduce impactElectroluminescent light sourcesSolid-state devicesComputer moduleRefractive index

The present disclosure provides RGB-LED packaging modules and a display screen including a substrate; a plurality of light-emitting units disposed on the substrate, each light-emitting unit including a set of RGB-LED chips; a plastic layer provided on the light-emitting units; and a virtual isolating region provided between the light-emitting units, the virtual isolating region including a black light-absorbing layer provided on the substrate. The present disclosure makes use of the black light-absorbing layer to absorb light which may cause interference among the light-emitting units. By providing the virtual isolating region and an isolating trough, and utilizing the difference of refractive index of packaging plastic and refractive index of air, light emitted by the light-emitting units can be reflected to reduce the influence of adjacent light-emitting units. A black isolating-frame is filled in the isolating trough to minimize the interference among the light-emitting units.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

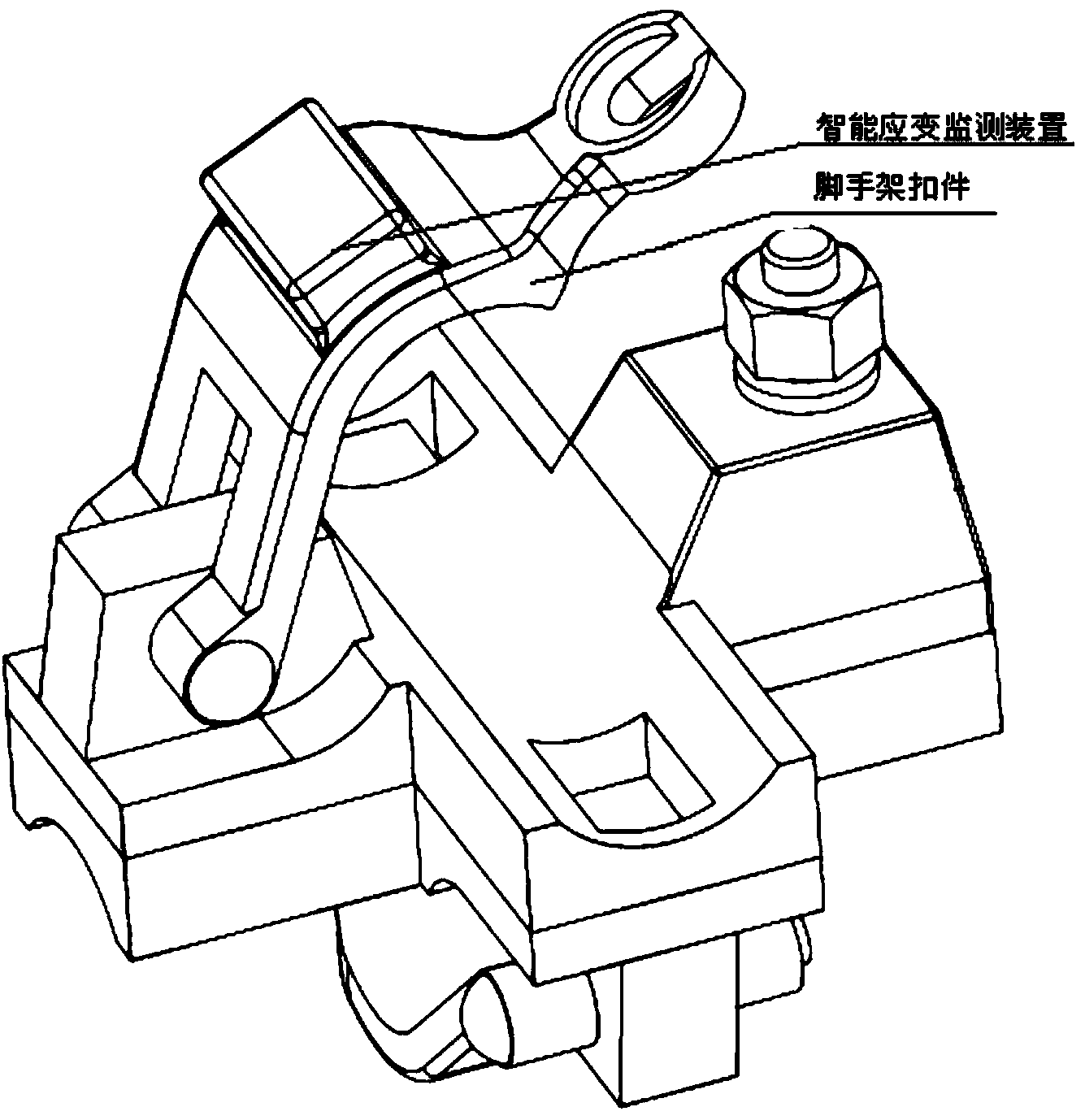

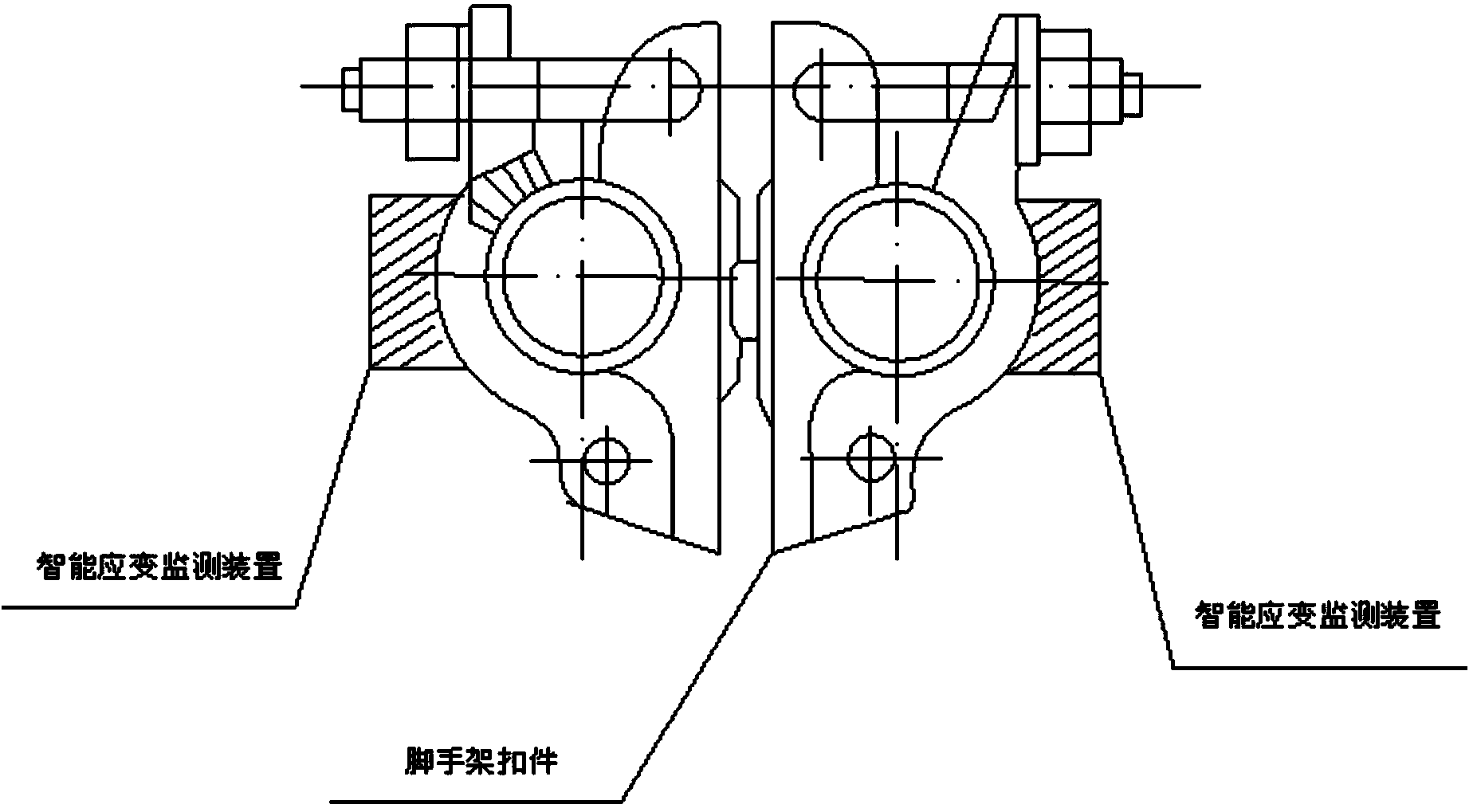

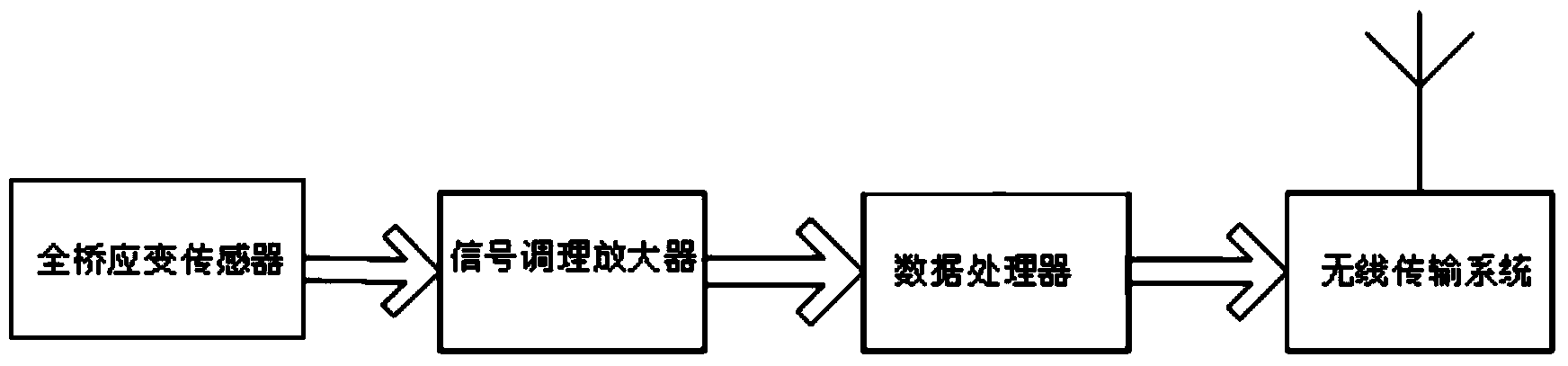

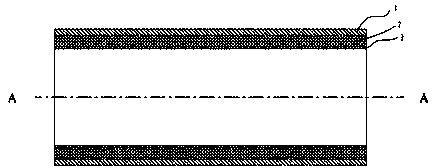

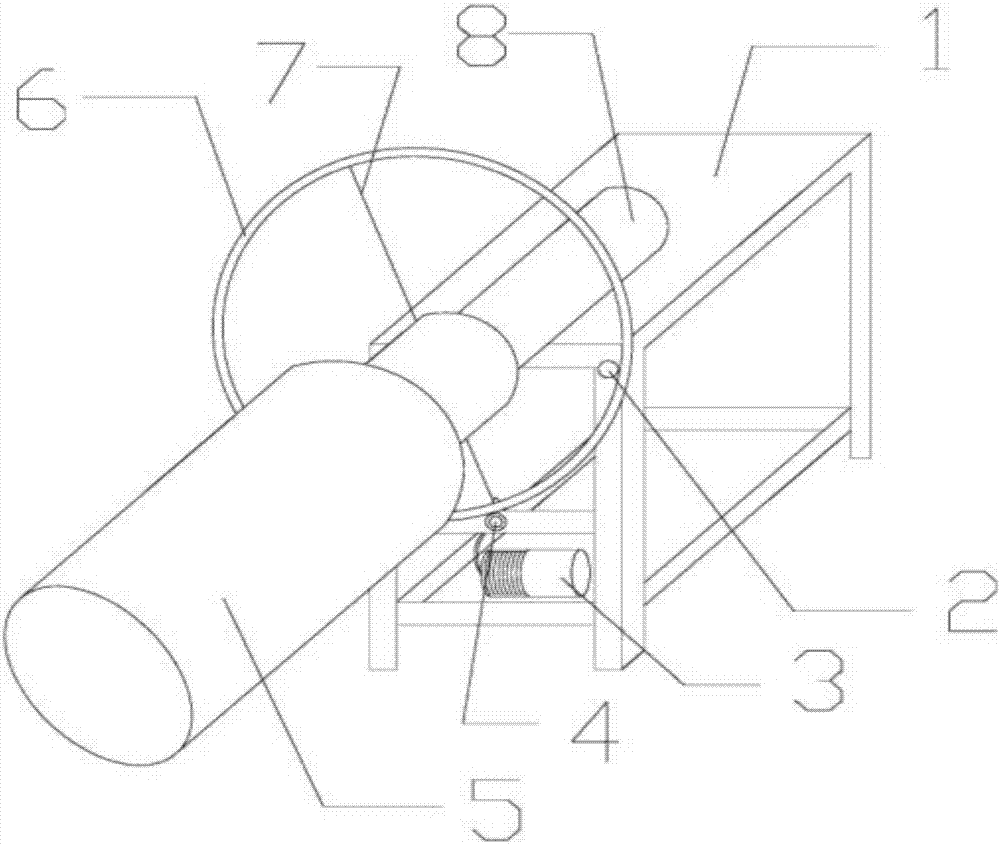

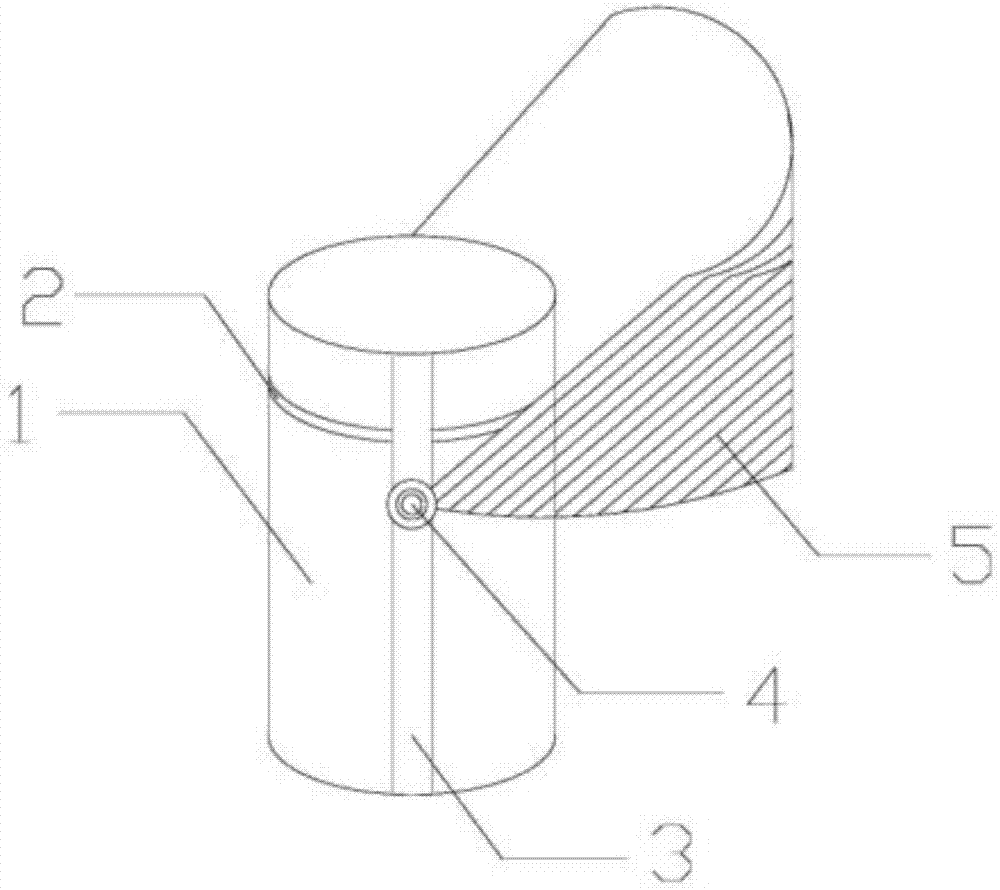

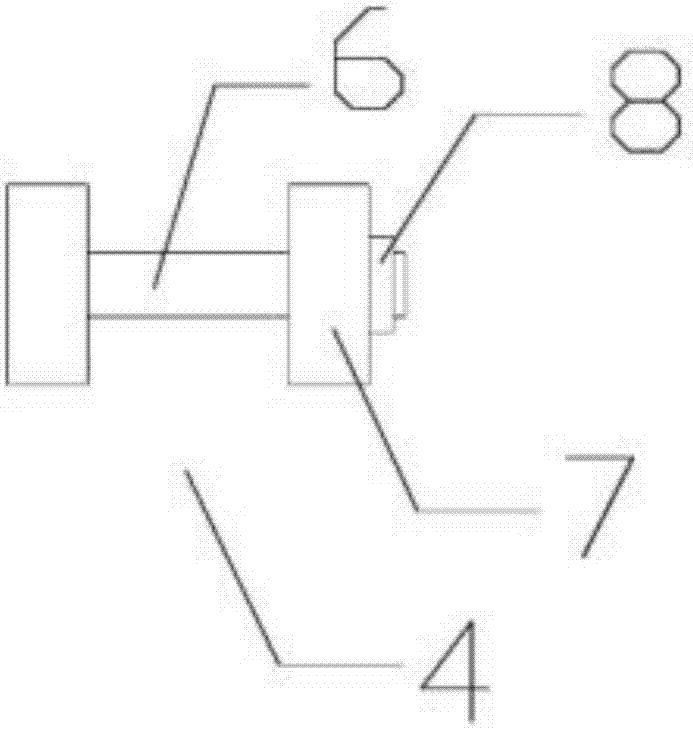

Intelligent scaffold fastener with function of measuring stress change

InactiveCN103912114ASensing stress changes in real timeReal-time monitoring of stress changesScaffold connectionsForce measurementElectromagnetic interferenceEngineering structures

The invention relates to the technical field of scaffolding, in particular to an intelligent scaffold fastener with a function of measuring stress change. The intelligent scaffold fastener comprises a fastener body and an intelligent stress change monitor attached to the fastener body. Compared with the prior art, the intelligent scaffold fastener is simple and better in design and convenient to carry and is capable of sensing stress change in real time; the stress change of the fastener can be monitored in real time; the defects caused by large-scale wiring of the traditional stress chain monitoring equipment are avoided effectively; wiring-free monitoring is achieved, monitoring period is short, and efficiency is high; the intelligent scaffold fastener is high in electromagnetic interference resistance, good in stability, directly applicable to practical engineering, and suitable for stress monitoring for industrial production and various engineering structure scaffold fasteners.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Ablation-proof structure of solid rocket engine

Disclosed is an ablation-proof structure of a solid rocket engine. The ablation-proof structure of the solid rocket engine comprises a pressure-bearing structure casing, a thermal insulating layer and an anti-scouring low-residue protective layer, wherein the thermal insulating layer is located in the pressure-bearing structure casing, and the anti-scouring low-residue protective layer is embedded into the inner surface of the thermal insulating layer. By means of the technical scheme, solid residues generated during ablation of the thermal insulating layer can be reduced, and moving parts are prevented from being blocked.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

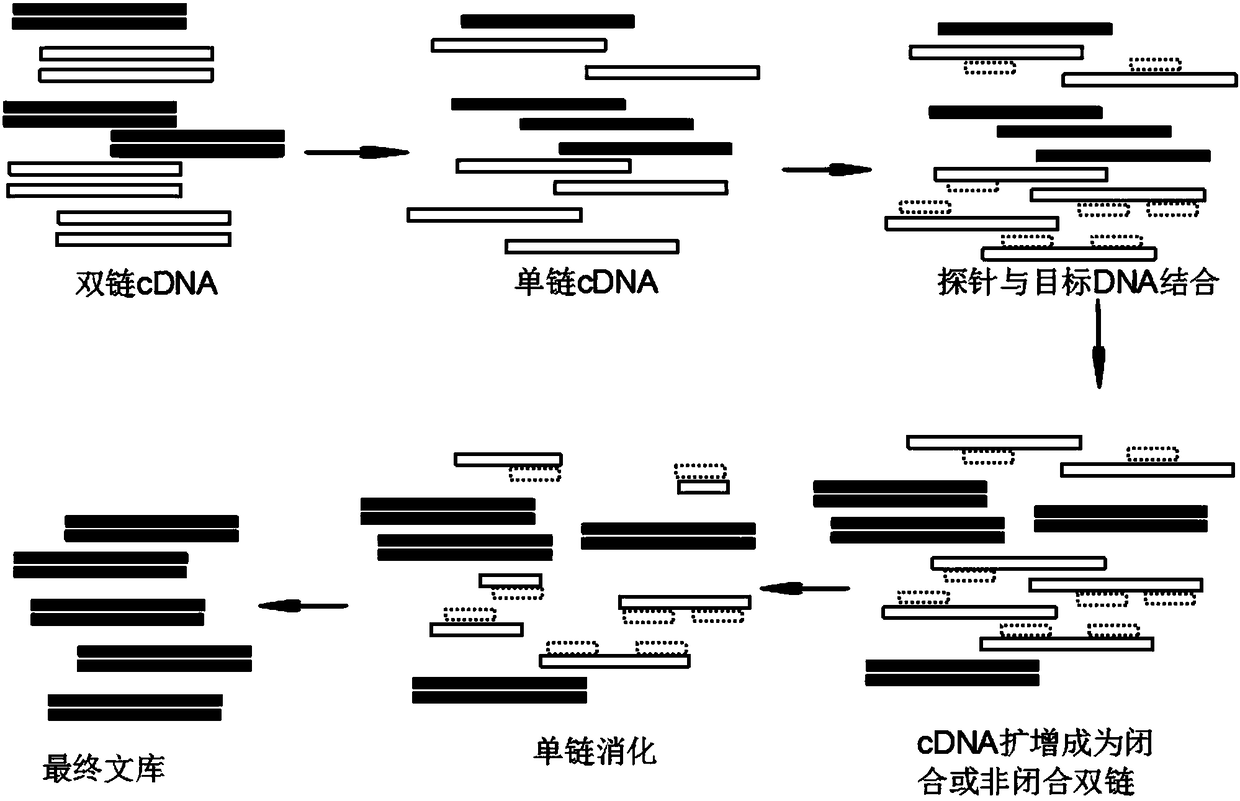

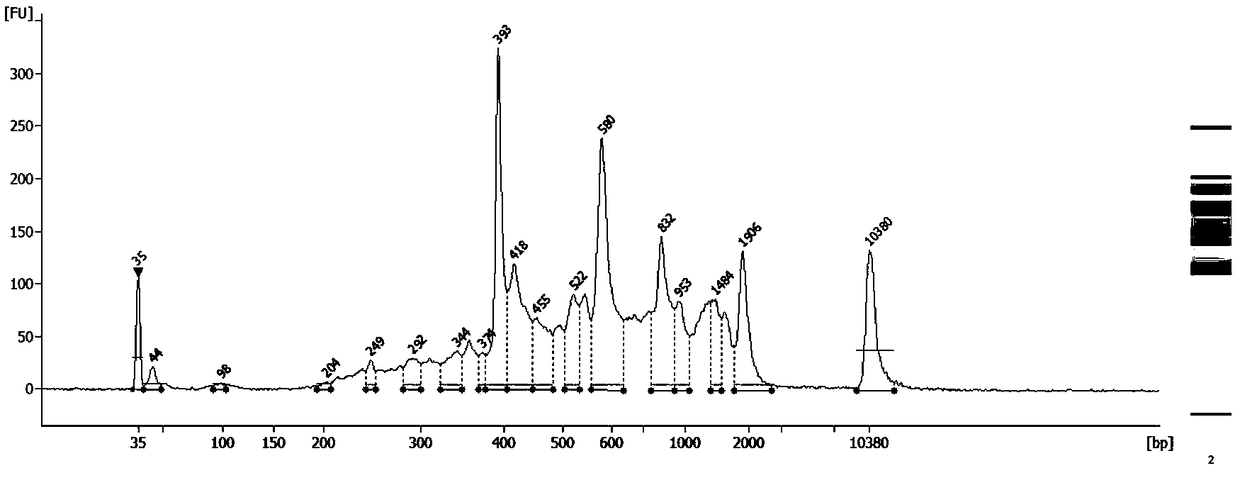

Single-cell transcriptome library establishment method and application thereof

InactiveCN108193283AIncrease profitIncrease coverageMicrobiological testing/measurementLibrary creationLysisSingle cell transcriptome

The invention provides an optimized single-cell transcriptome library establishment method. The method comprises the following steps: (1) obtaining a sample RNA through cell lysis or extraction; (2) performing reverse transcription operation on the sample to make the RNA form cDNA through reverse transcription; and (3) constructing a transcriptome library by using a separated cDNA, wherein the step (3) of constructing the transcriptome library by using the separated cDNA comprises the following steps: (3-1) performing a tail adding reaction or adopting a single-chain connection manner to add an adaptor; (3-2) performing two-chain synthesis on the cDNA and performing an amplification reaction; (3-3) performing exponential amplification; and (3-4) after transcriptome library construction isperformed on the cDNA amplification product subjected to step (3-3) treatment, removing ''useless DNA''; or after the ''useless DNA'' in the cDNA amplification product subjected to step (3-3) treatment, constructing a transcriptome library. Compared with the prior art, the method provided by the invention is more high-efficiency, simpler, more practical and more accurate, has less pollution, lessloss, low costs and good method repeatability, expands the application range of the sample and improves the precision degree of detection.

Owner:SHANGHAI MAJORBIO BIO PHARM TECH

Shield and locking type board to board connector

ActiveUS9331429B2High mechanical strengthSimple and convenient designCoupling contact membersOn boardBoard-to-board connector

Owner:UJU ELECTRONICS

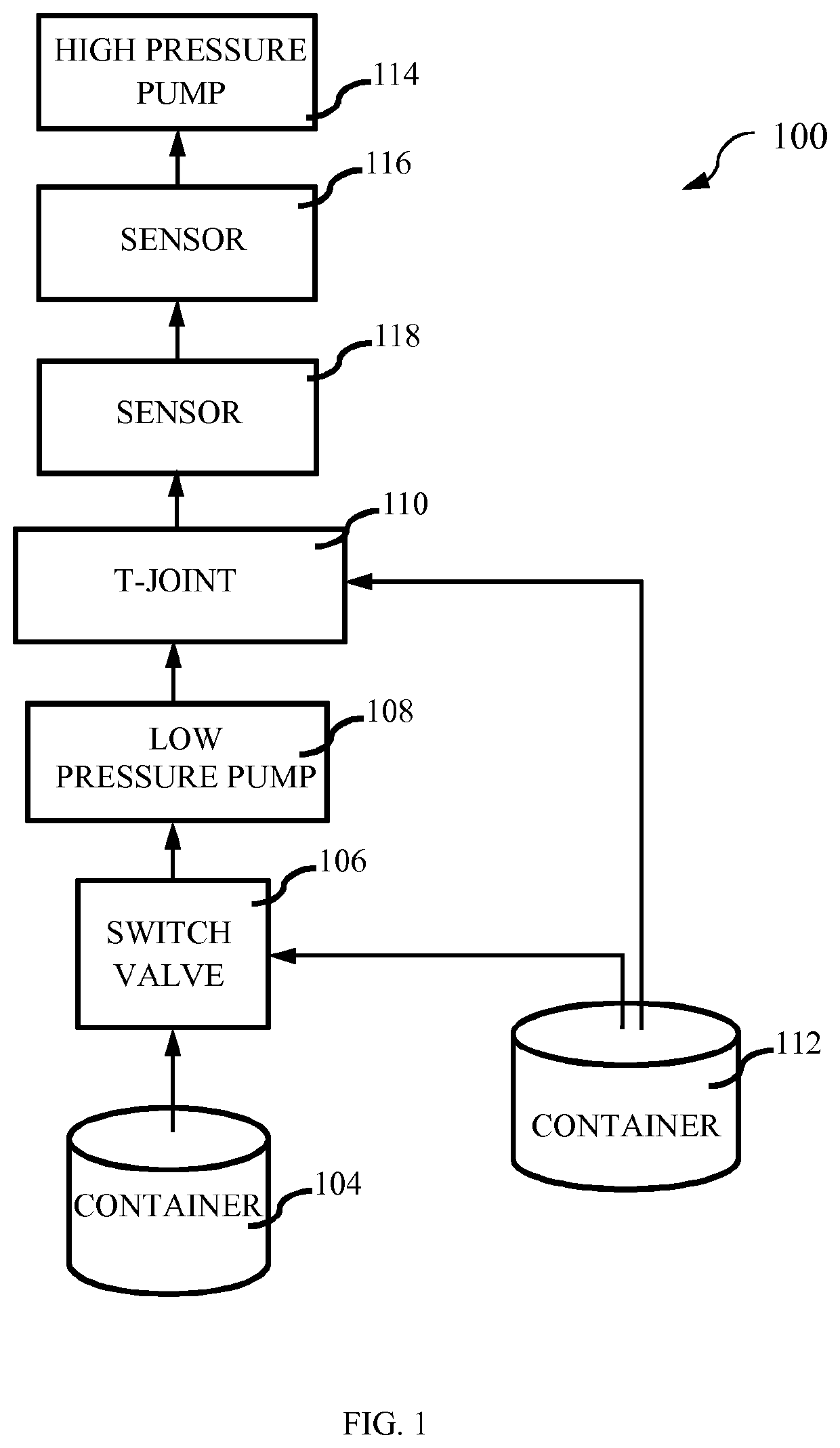

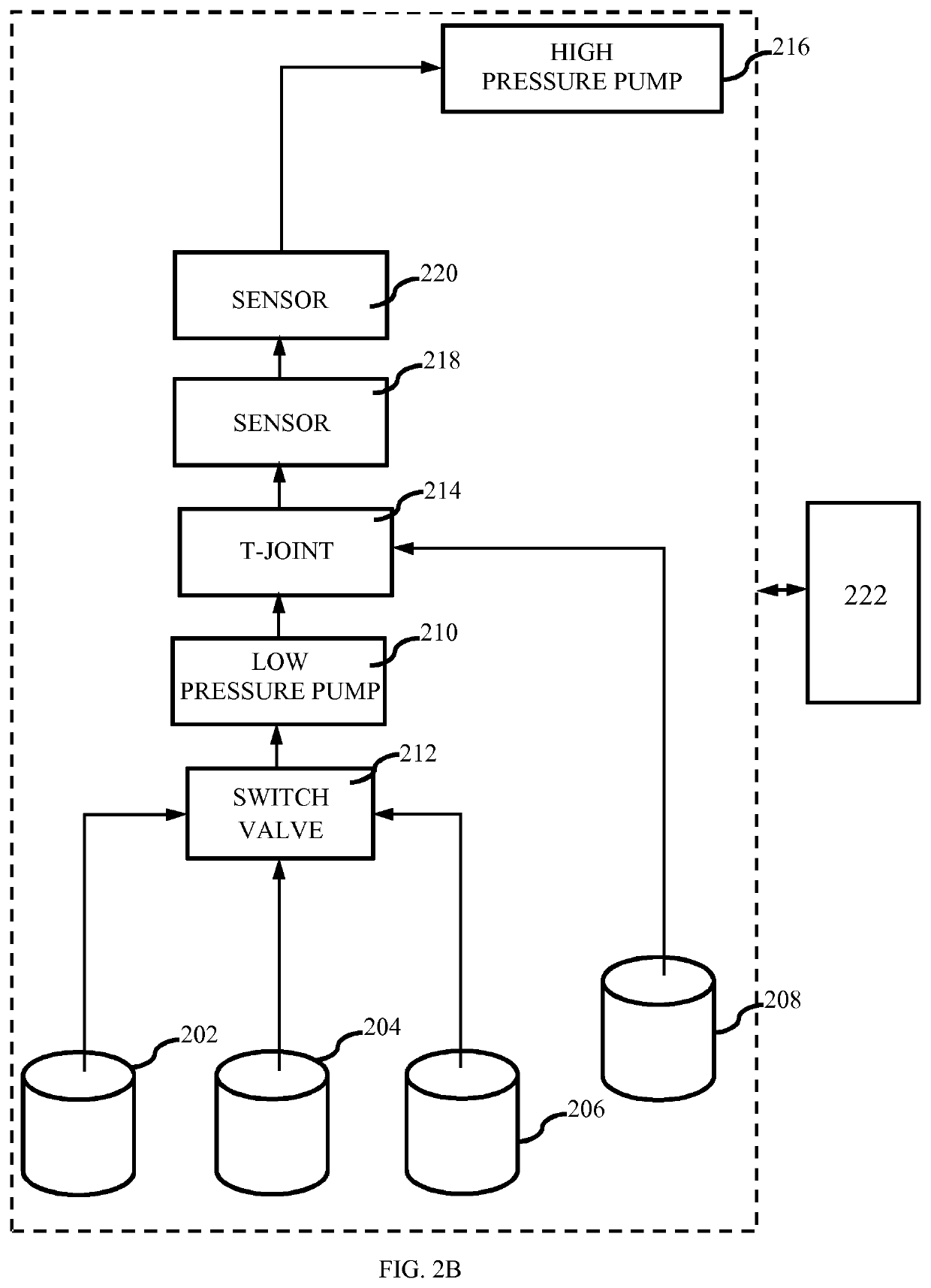

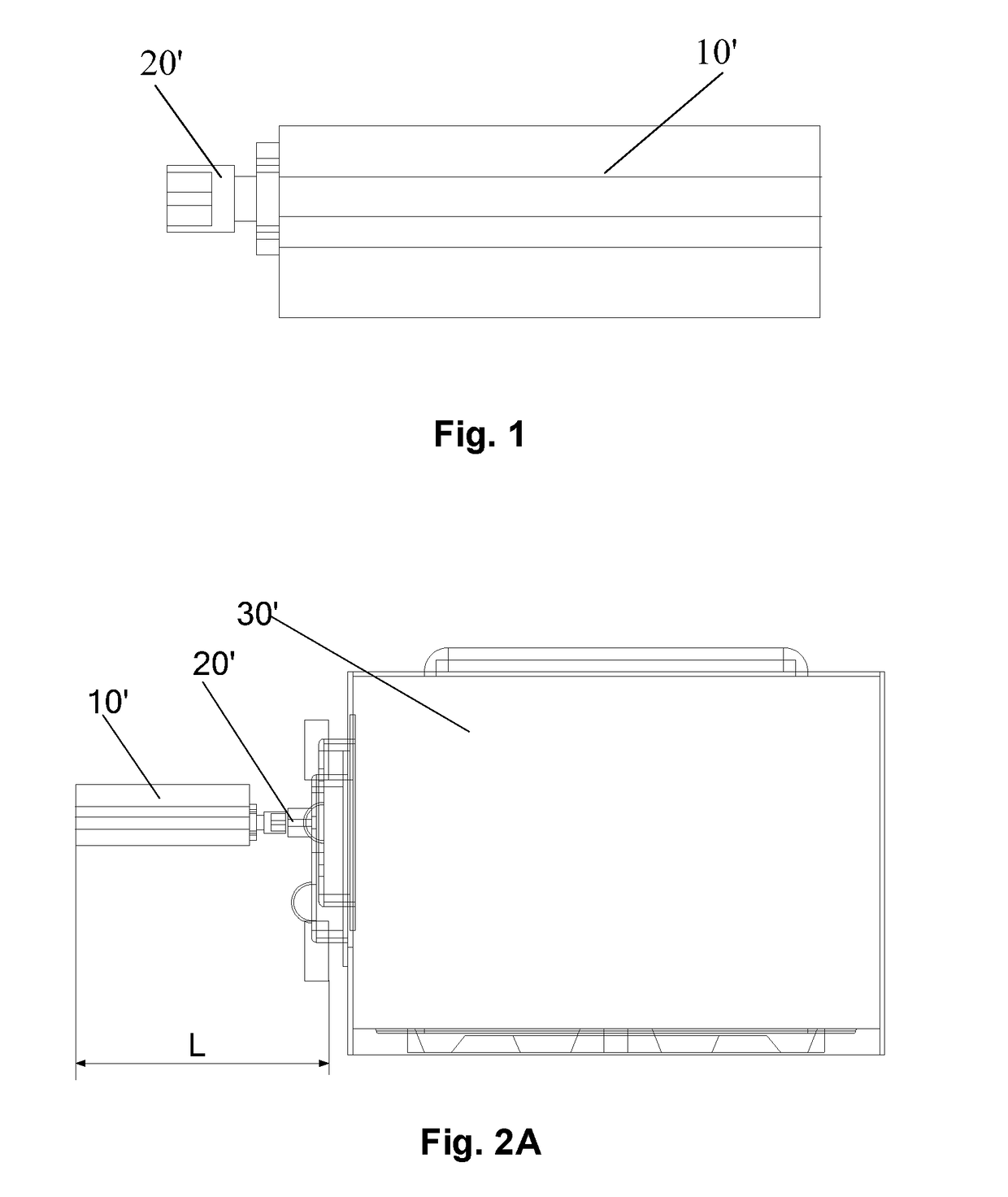

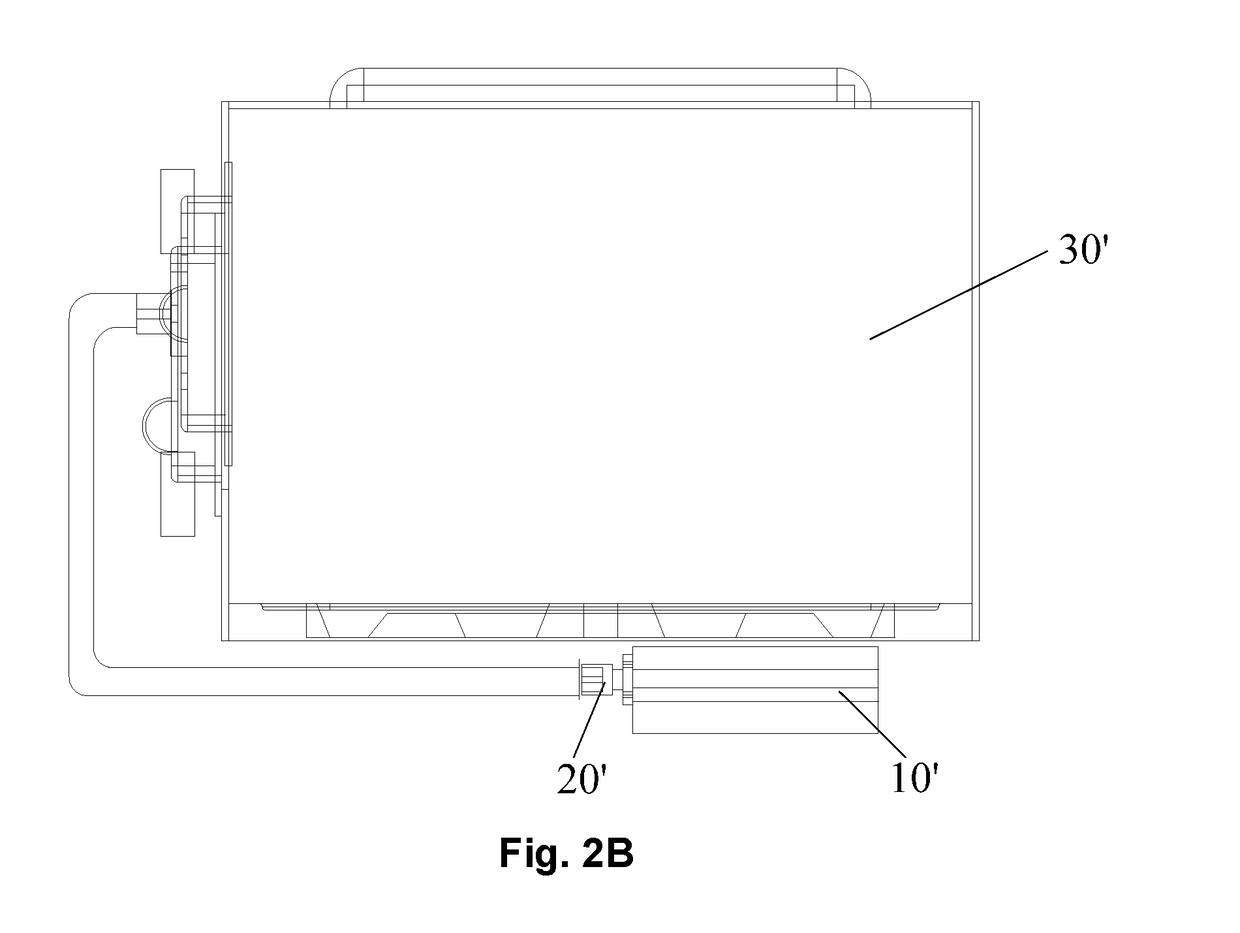

System for blending solutions

ActiveUS10773185B2Simple and convenient designWay of increaseComponent separationMixing methodsEngineeringBuffer solution

A system for blending solutions and a buffer solution is disclosed. In this system a switch valve is present capable of flowing one or more solutions, a low pressure pump for pumping the one or more solutions through the switch valve and a T-joint capable of receiving the one or more solutions through the low pressure pump and blending the one or more solutions with a buffer solution. A high pressure pump is present for collecting a blended solution.

Owner:CYTIVA SWEDEN AB

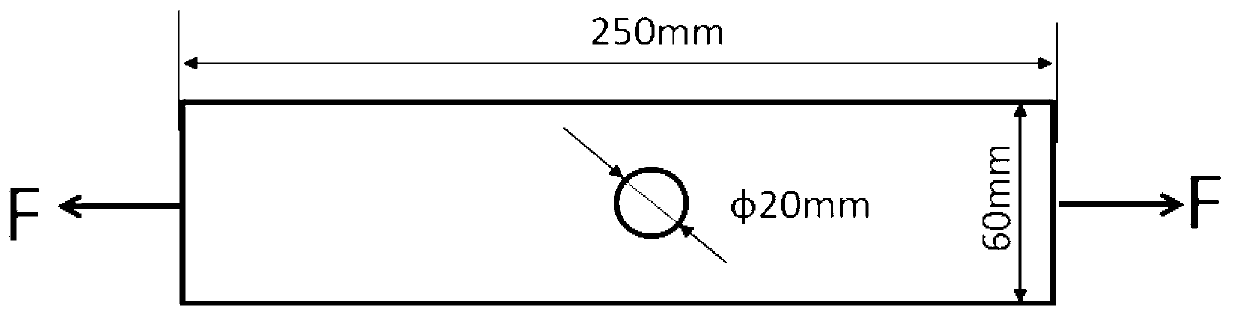

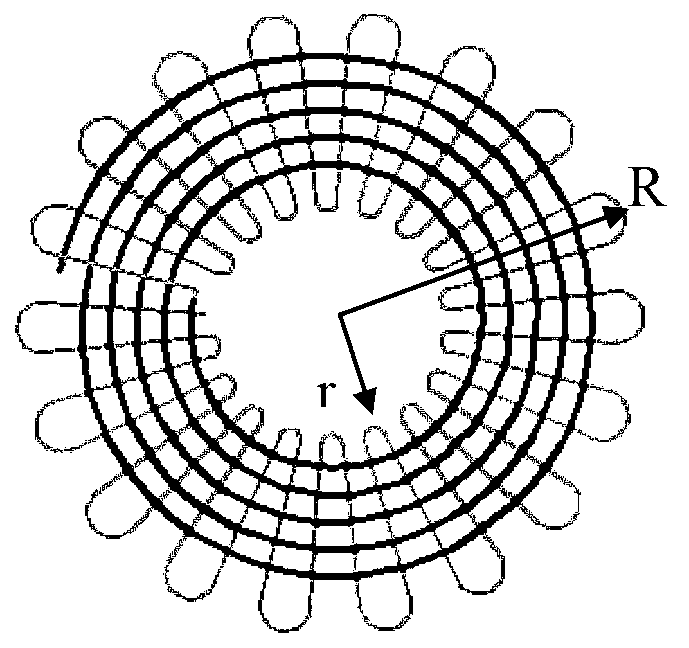

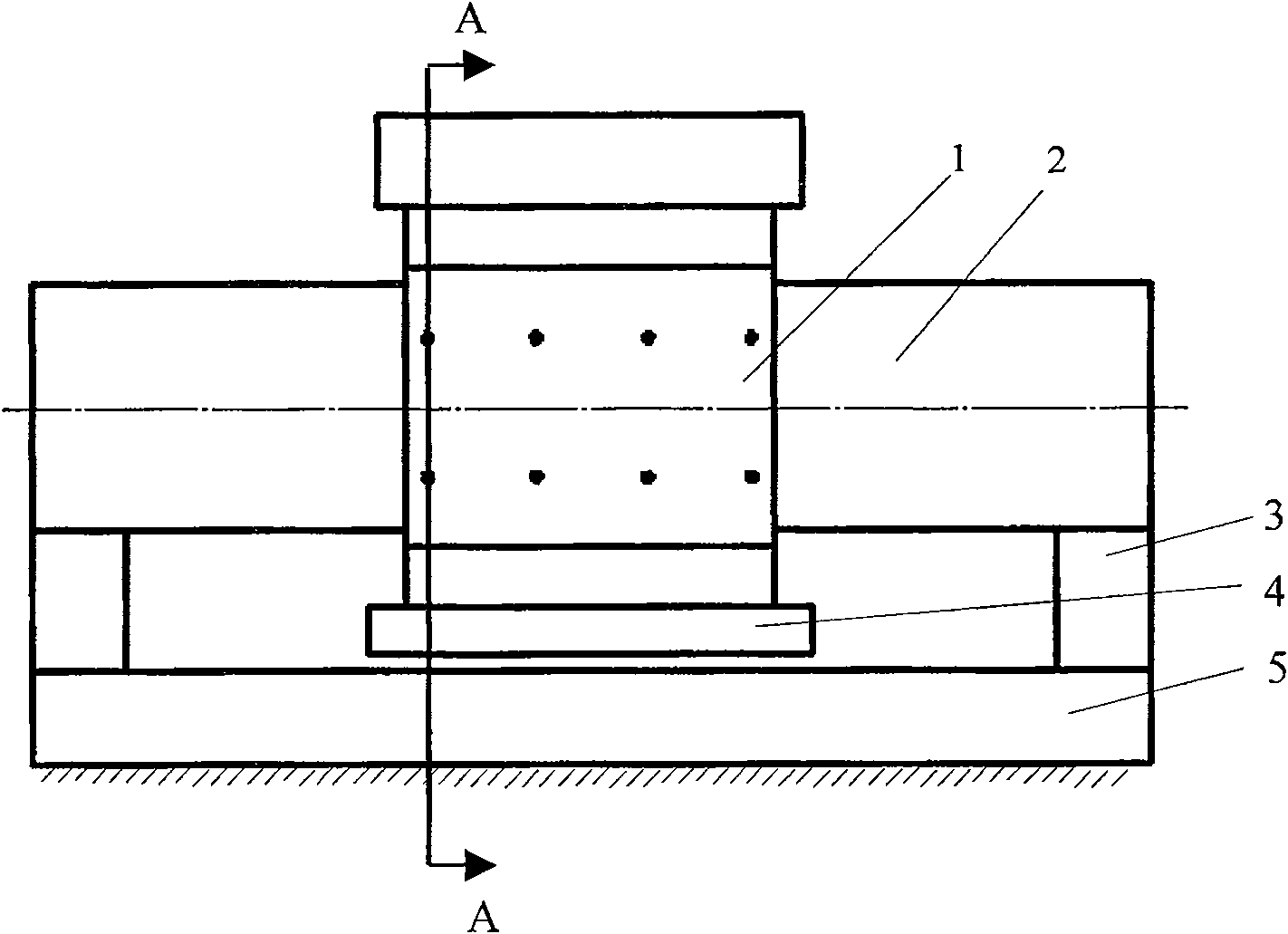

Reinforcing sheet designing and reinforcing method for thermoplastic fiber composite material tapping component

ActiveCN102922834ASimple and convenient designEasy to makeSynthetic resin layered productsThermoplastic composites

The invention discloses a reinforcing sheet designing and a reinforcing method for a thermoplastic fiber composite material tapping component. Specifically, a matched reinforcing sheet with a radial fiber track layer and an annular fiber track layer is designed according to the shape and the size of the tapping component; and then the reinforcing sheet is used for reinforcing the thermoplastic fiber composite material tapping component. The reinforcing sheet has the advantages of simplicity and convenience in design, excellent reinforcing effect, no cutting, mass production and the like. When the reinforcing sheet performs a reinforcing action, the molding process is simple and flexible, and the reinforcing efficiency is greatly improved, so that the reinforcing sheet has a very wide application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Ink cartridge with replaceable ink bag

An ink cartridge with replaceable ink bag is provided, including a cartridge body, an ink bag and a lid body. The lid body is removably engaged to the cartridge body to house the ink bag. The wall on long side of the cartridge includes at least a retention block. The ink bag includes a trigger based on amount of remaining ink, a bag body and a positioning element. The bag body is partially glued to the positioning element. The surroundings of the positioning element are disposed with at least a retention element. The retention element can be inserted between the retention block and the bottom of the cartridge body for fixing the ink bag inside the cartridge. As such, the cartridge body and the lid body of the present invention can be reused to save the cost as well as resources to reduce the environmental waste.

Owner:JETBEST CORP

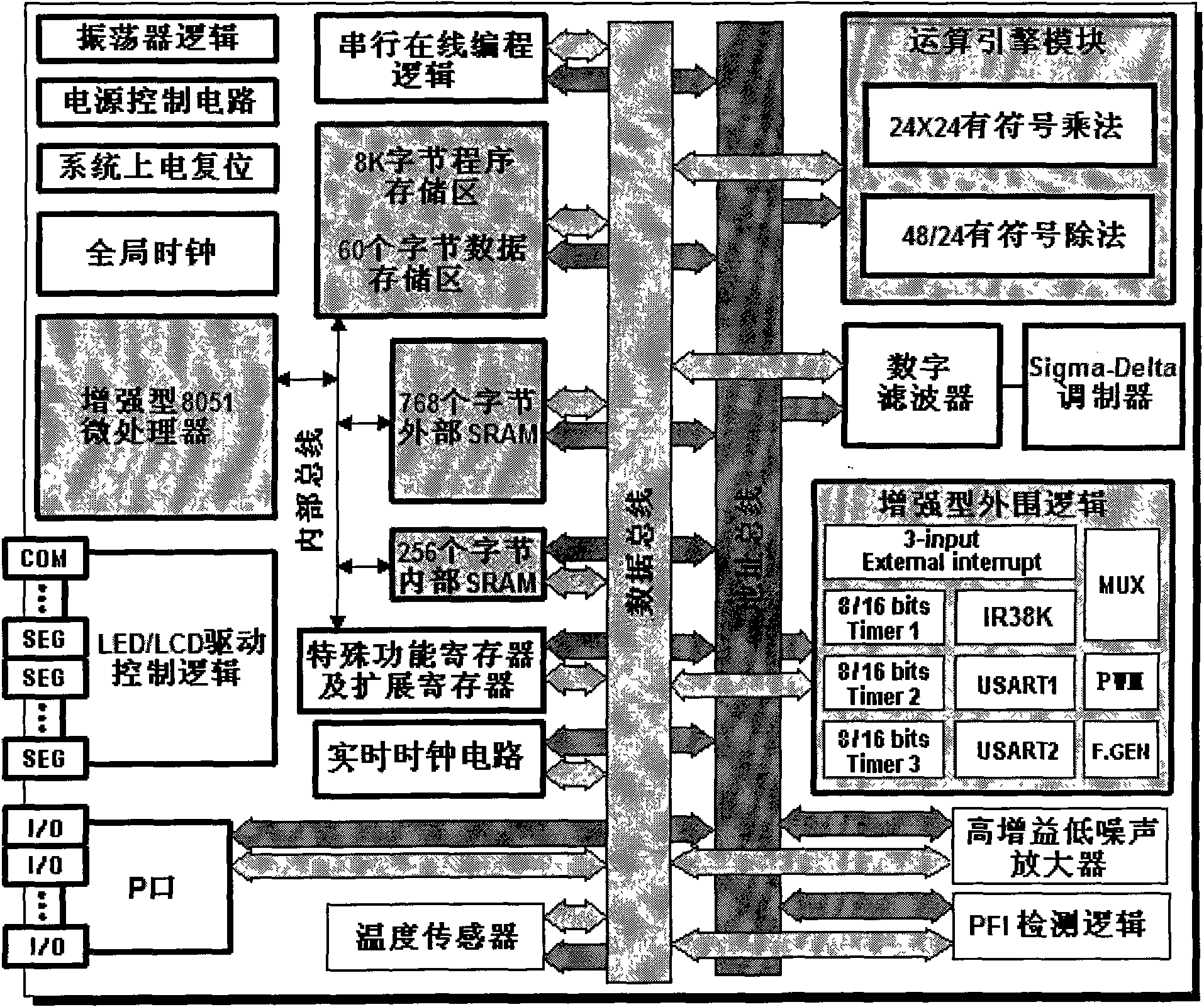

Special integrated circuit for electronic scale

InactiveCN101603853AImprove performanceImprove performance indicatorsProgramme controlComputer controlAnti jamming24-bit

The invention discloses a special integrated circuit for an electronic scale. In the same chip, not only a reinforced type 8051 microprocessor is integrated, but also the following parts are embedded: a real-time clock circuit used for recording and printing real-time weighing time and dates, an LED / LCD drive control logic used for displaying data related to the electronic scale, a high-precision analog to digital conversion circuit used for converting an analog weight signal outputted by a strain sensor into a digital signal, a calculating engine module used for quickly realizing the 24-bit signed multiplication-division by arithmetical operation of hardware, a reinforced type peripheral control logic which comprises two UART ports supporting infrared communication and RS232 communication and is used for communication of the electronic scale, and a temperature sensor used for realizing the comprehensive real-time temperature compensation for measuring precision. The special integrated circuit has the advantages of high measuring precision, good reliability, strong anti-jamming capability, low production cost and power consumption, miniaturization and the like.

Owner:KAIFENG GROUP

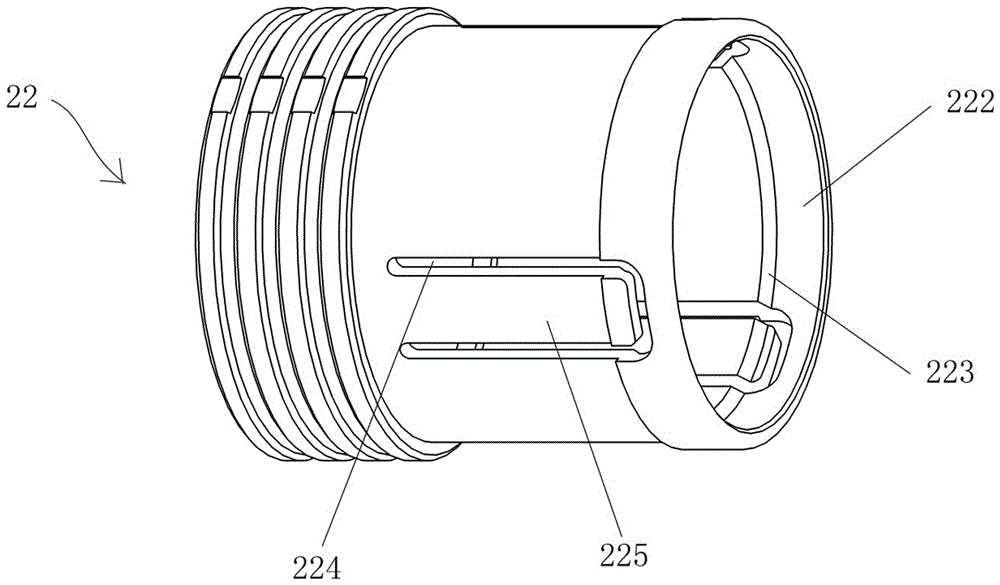

Connector and locking sleeve thereof

InactiveCN106848740AIncrease radial distanceStable separationCoupling device detailsPull forceEngineering

The invention relates to a connector and a locking sleeve thereof. The connector comprises an inner shell and the locking sleeve arranged in the inner shell in a sleeved mode. A locking groove is formed in the outer wall surface of the inner shell, and a locking steel ball of an adapter can enter the locking groove and be locked. The locking sleeve is provided with a sleeve body, the sleeve body is provided with a steel ball stopping part used for stopping the locking steel ball on the adapter in the locking groove in the radial direction, the steel ball stopping part can elastically deform in the radial direction when the adapter bears forcible pulling force, and then an elastic structure capable of giving a way to the locking steel ball in the radial direction to achieve unlocking is formed. In the actual use process, when abnormal situations appear, a cable or a cable clip bears separation force and the locking sleeve does not bear separation force, the steel ball locking between the connector and the adapter can be eliminated due to the arrangement of the elastic structure on the locking sleeve so that the connector and the adapter can be smoothly and forcibly separated.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

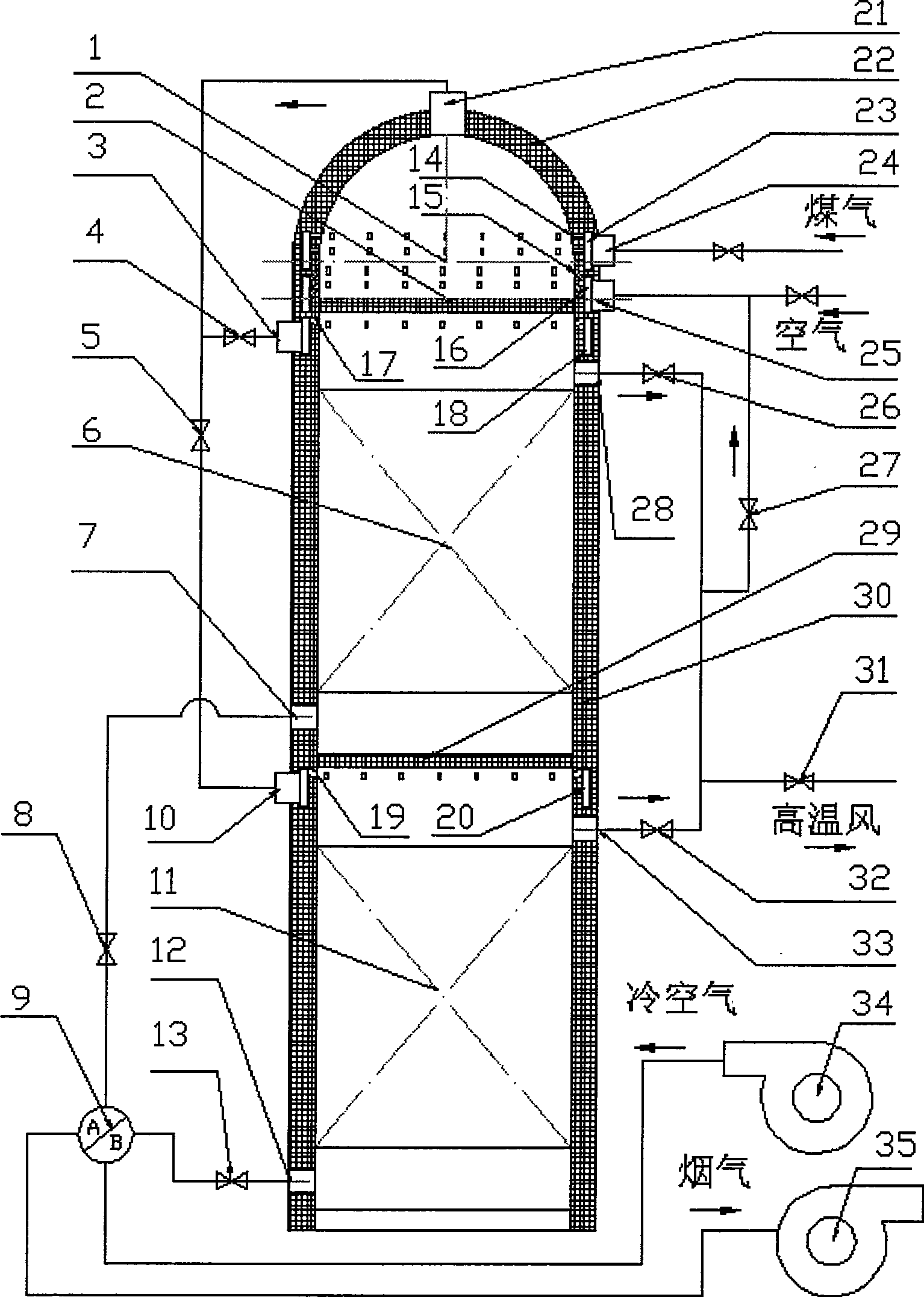

Continuous air blast type strong wind warm blast furnace

The invention discloses a high air temperature hot air furance for continuously supplying hot air, and belongs to the technical field of auxiliary equipment of hot air furnace of an ironmaking blast furance in the iron and steel industry. The hot air furnace comprises a furnace top, a combustion chamber, checker bricks, a connecting pipe and the like. The hot air furnace is characterized in that the checker bricks in the furnace are separated into an upper group and a lower group which are arranged at intervals, one group of checker bricks are used for heat storage, the other group of checker bricks are used for air supply, a combustor is arranged on the furnace top, and after combustion, flue gas passes through the furnace top, the connecting pipe, a ring channel and a nozzle and enters the checker bricks for combustion and heat storage in the mode of small flow; at the same time, cold air enters the other group of checker bricks and is preheated to be high temperature air and subjected to reversing control by a reversing valve; the working conditions in the two groups of checker bricks are opposite, and the cycle is repeated again and again, and the high temperature air is continuously supplied. The hot air furnace has the advantages of realizing the supply of the high temperature air at a temperature of between 1250 and 1600 DEG C by completely burning low-heat value coal gas and meeting the needs of blast furnace ironmaking, along with simple structural design, self pre-heating and continuous hot air supply.

Owner:SHOUGANG CORPORATION

Horizontal gas/gas two-phase composite straight line reference method and apparatus based on gravity force balance

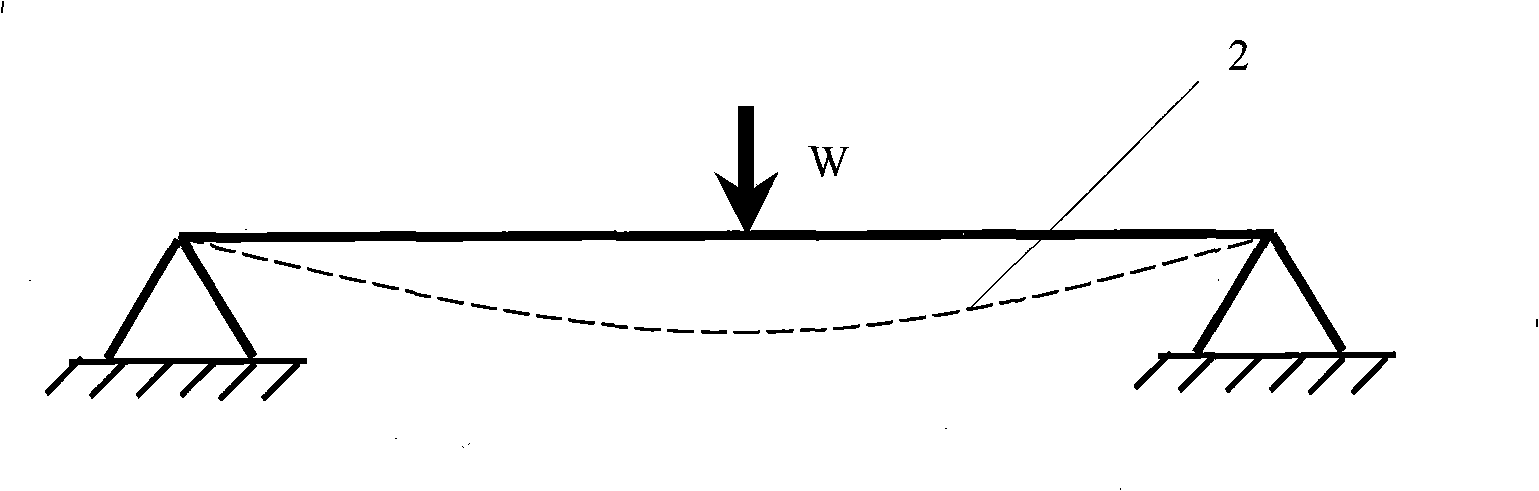

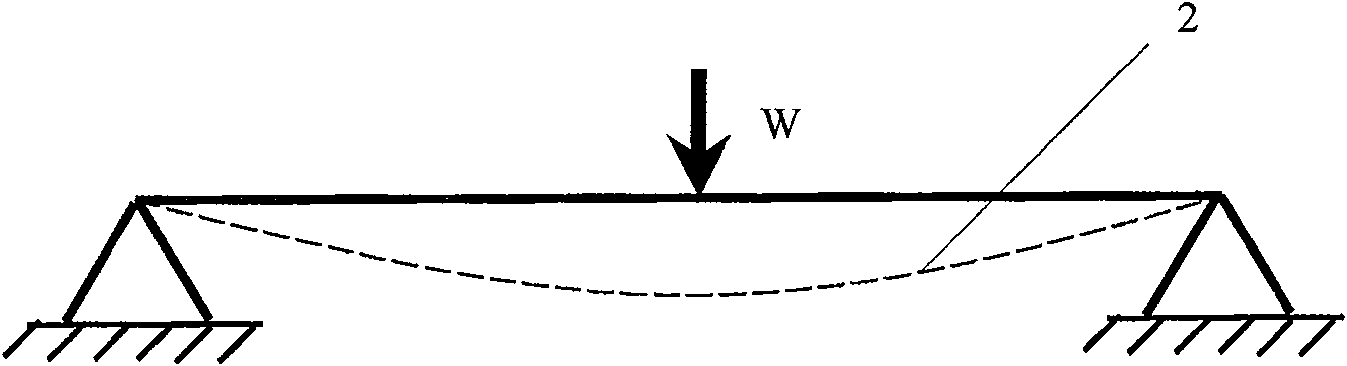

ActiveCN101403628AImprove support rigidityImprove stabilityMeasurement apparatus componentsGravitational forceEngineering

A horizontal gas-gas two phase composite beeline benchmark method and a device based on the gravity balance belong to the technical field of precision instruments and measurement. The method comprises the steps: a balance slideway is constructed below of an orientation slideway, which forms an open external gas support and acts on an anti-thrust plate in the lower part of a flotation guide cover, the gravity balance of the orientation slideway and the balance slideway is designed aiming at the load gravity, under the conditions of satisfying the load gravity of the balance slideway, and the gas film supporting stiffness arrives the maximum or is in the confirmed range of the gas film supporting stiffness; the device comprises the anti-thrust plate fixedly connected with lower part of the flotation guide cover, an anti-thrust flotation dual surface is formed between the anti-thrust plate and the balance slideway, the anti-thrust plate is provided with a throttle structure facing to the balance slideway which is parallel to the orientation slideway. The invention leads the flotation guide cover to have excellent stability, the slideway load capability and the supporting stiffness are greatly improved, the high linear accuracy of the slideway under big load and big stroke is ensured, the structure is simple, and the application scope is wide.

Owner:NANTONG MINGGUANG ELECTRIC WIRE

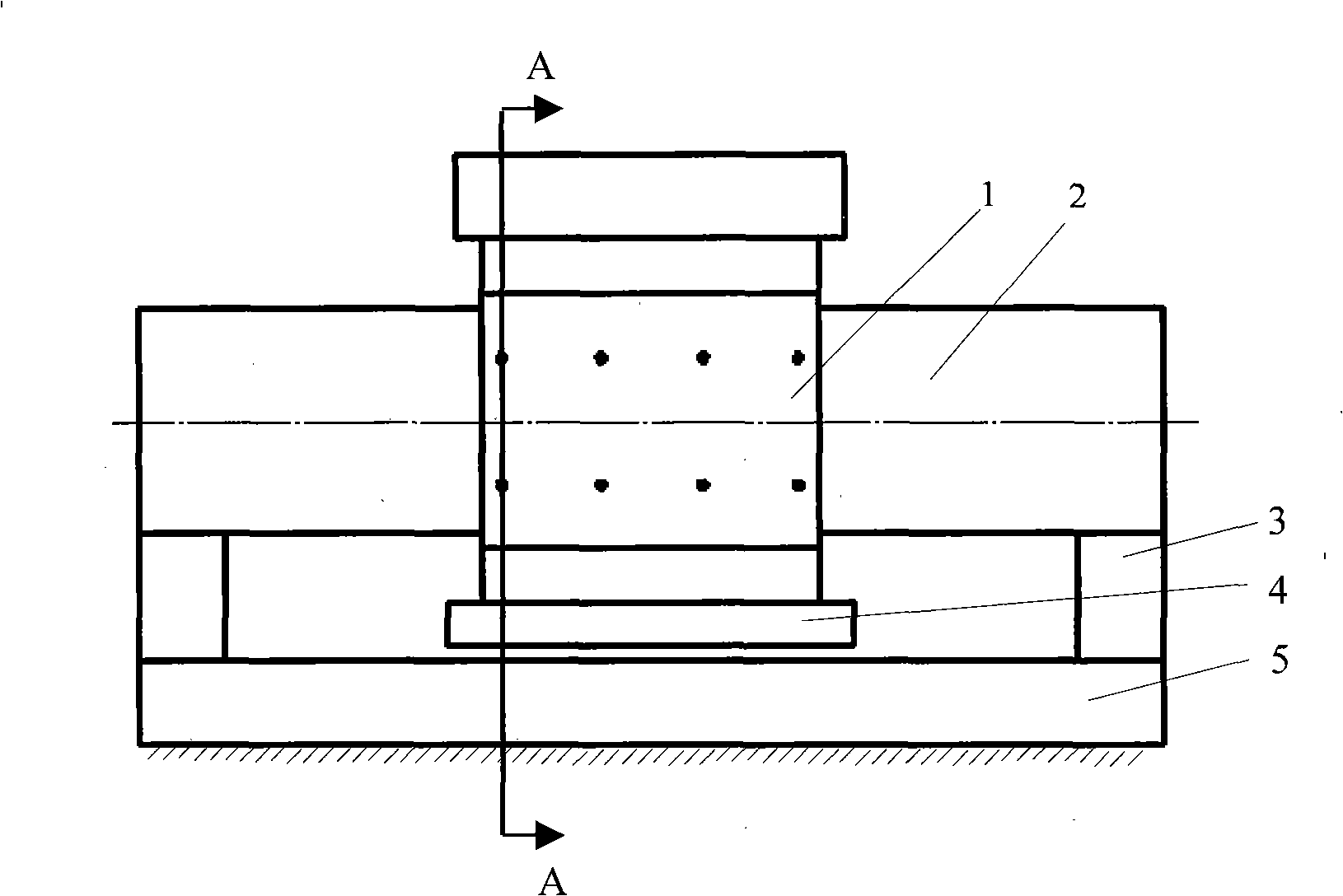

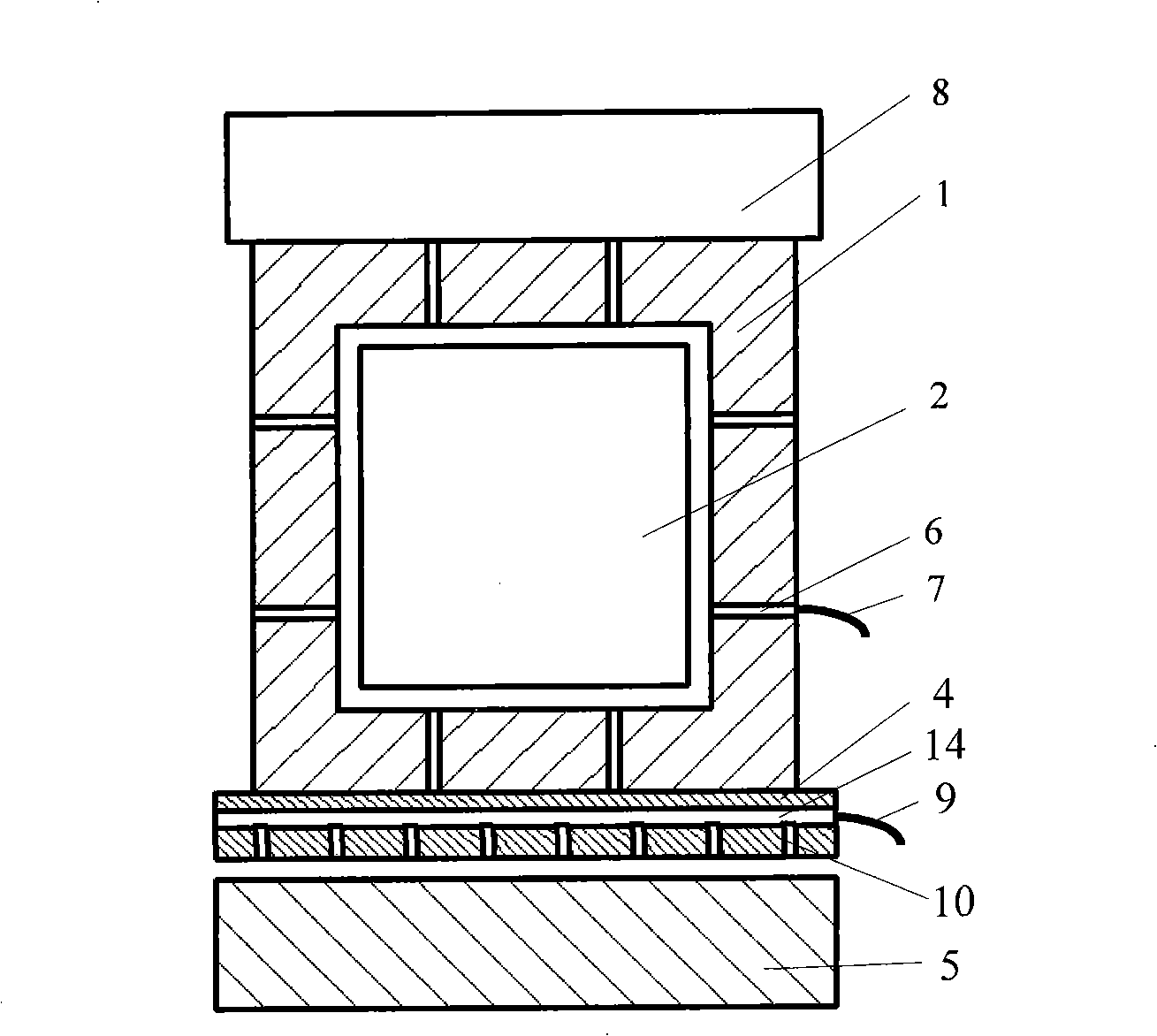

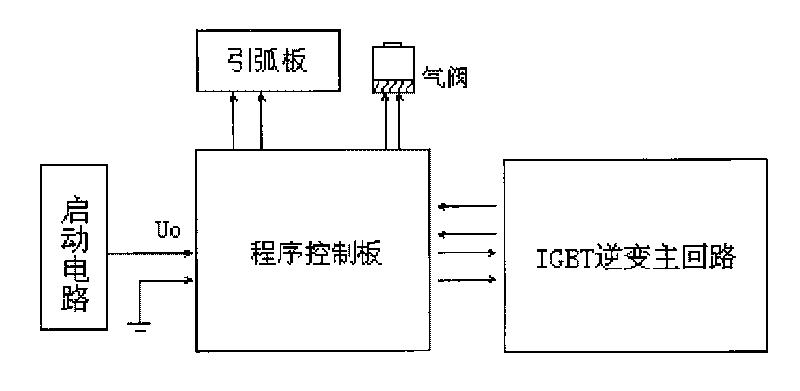

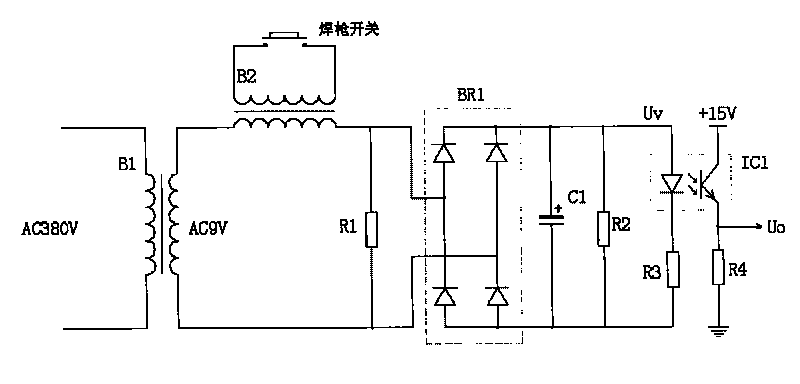

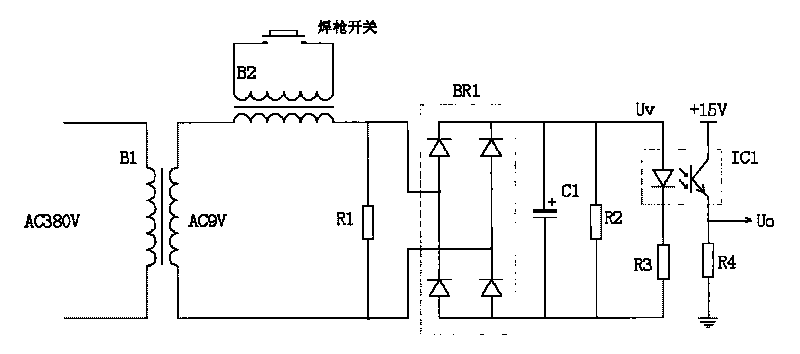

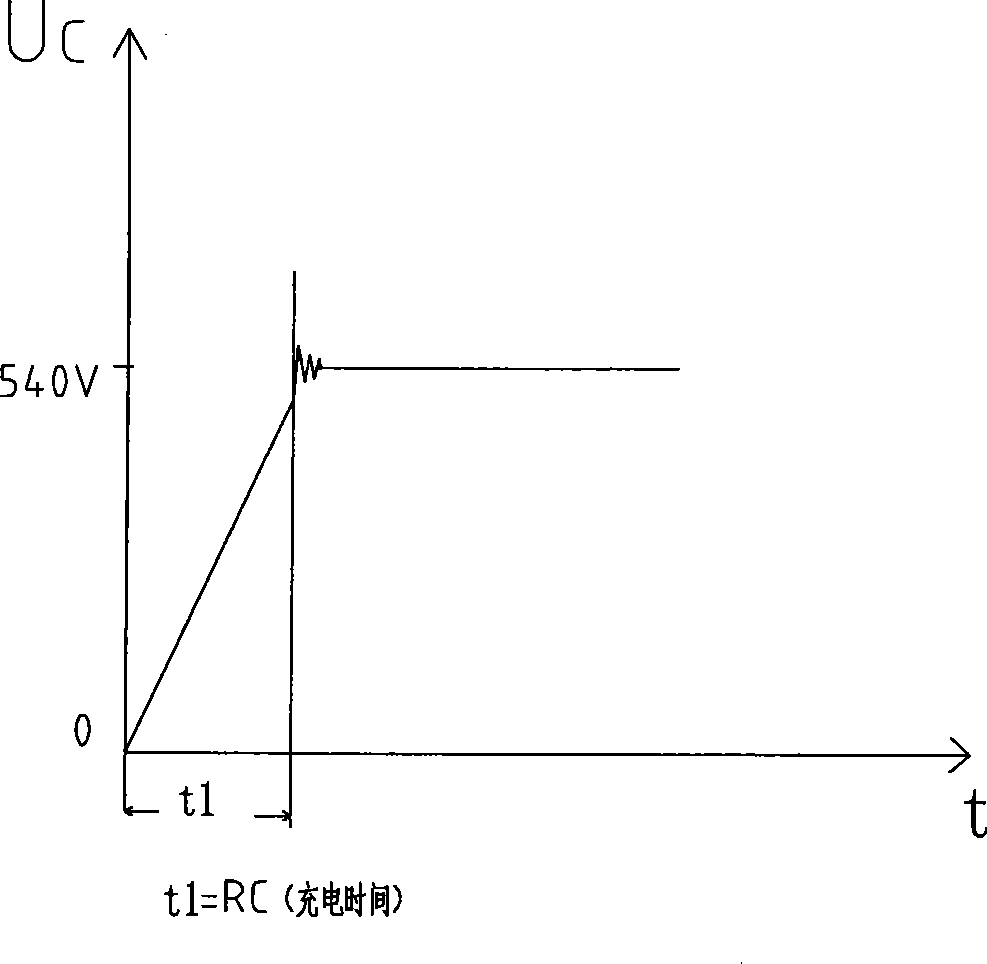

Welding staring circuit of IGBT inverted gas protective welder

ActiveCN101695782ASimple and convenient designAvoid direct accessArc welding apparatusCapacitanceOptical coupler

The invention relates to a welding staring circuit of an IGBT inverted gas protective welder, which has a structure that a primary coil of a control transformer is connected with an industrial power supply, a secondary coil of the control transformer is serially connected with a primary coil and a first resistor of an isolation transformer, a secondary coil of the isolation transformer is serially connected with a welding gun switch, and two ends of the first resistor are connected with two ends of a second resistor through a rectifier bridge and a filter capacitor; two ends of the second resistor are connected with the input ends of an optical coupler, one of the output ends of the optical coupler is connected with a high level of a power supply, the other output end is grounded through a fourth resistor, and voltage obtained at two ends of the fourth resistor serves as a switching signal of a post-control circuit. The invention has the advantages that the design of the circuit is simple, optimized, safe and reliable; the isolation transformer ensures that the welding gun switch is isolated from the control circuit, thereby preventing high-frequency signal from directly entering into the control circuit; 9V of AC controls the primary side of the optical coupler after rectified and filtered, thereby ensuring that a fore-circuit is isolated from a post-circuit again; and finally the whole service life of the welder is prolonged.

Owner:无锡聚合科创发展有限公司

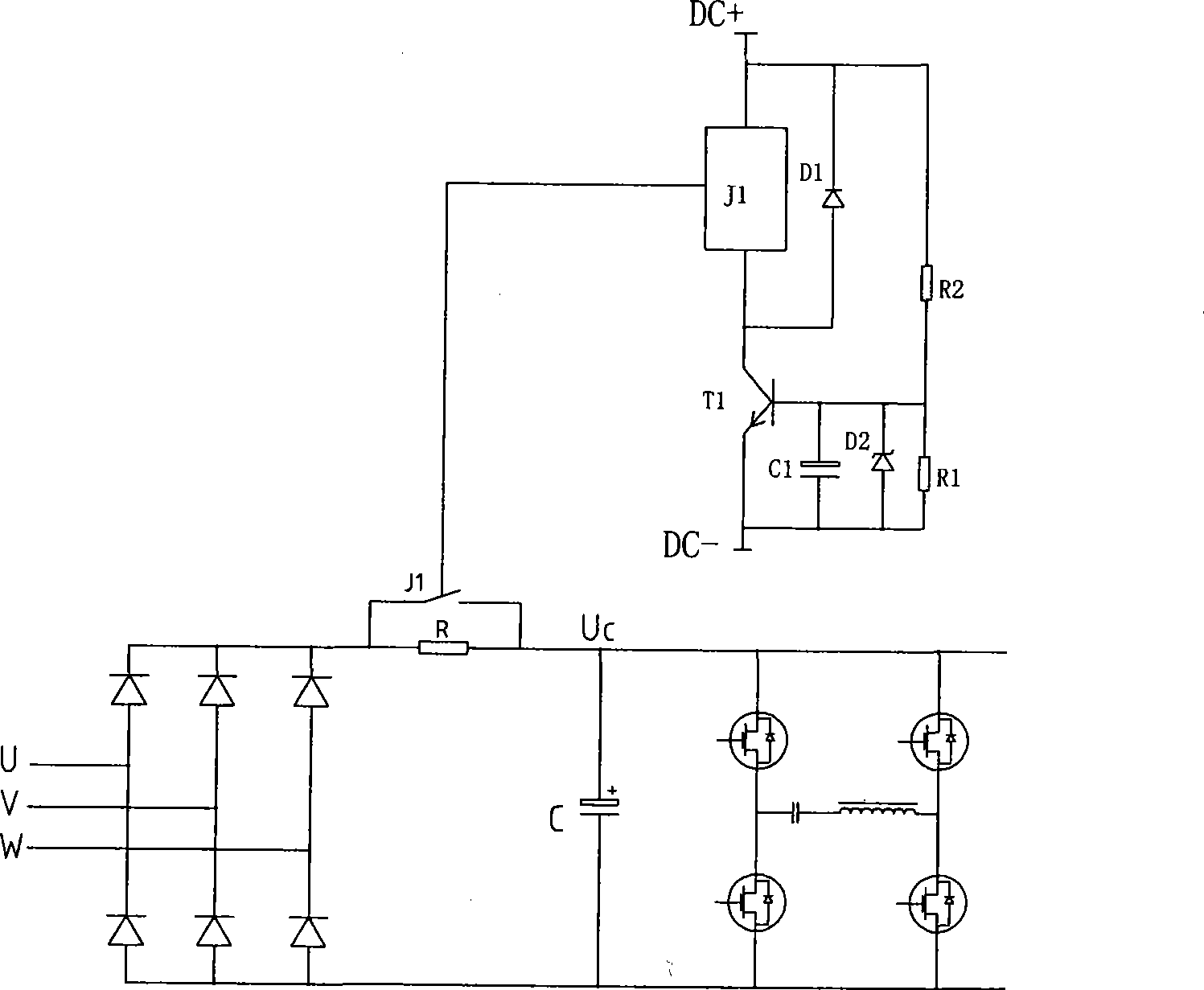

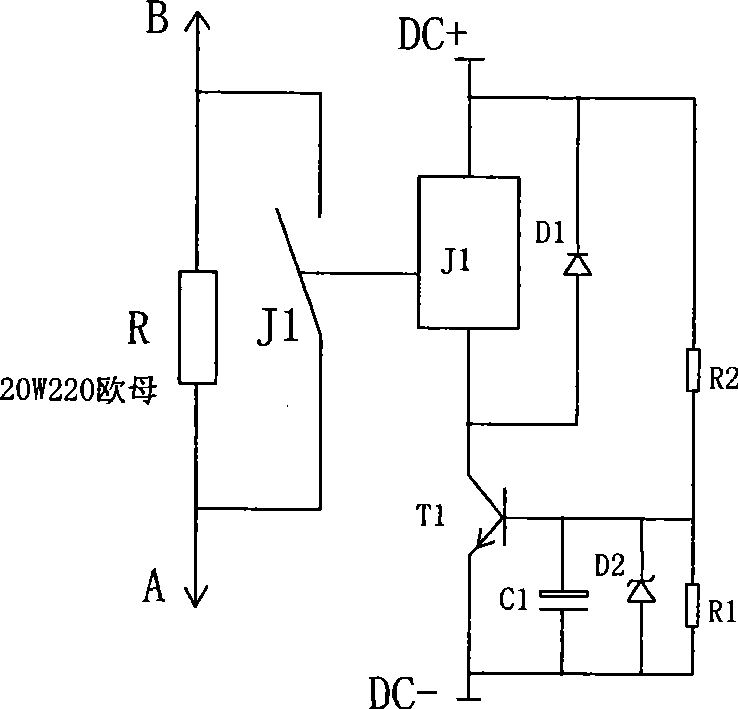

Soft starting plate for IGBT inverter manual metal-arc welding

InactiveCN101367150ASimple and optimized circuit designImprove overall service lifeArc welding apparatusArc weldingResistor

The invention relates to an IGBT inverter arc welding machine, in particular to a soft starting board for an IGBT inverter manual arc welding machine, wherein the soft starting board is one of function boards of the inverter arc welding machine. The technical proposal of the invention comprises that both ends of a resistor R are parallelly connected with contacts J-1 of a relay J1, one end of the relay J1 is connected wit a collector of a dynatron T1, an emitter of the dynatron T1 is connected with a negative electrode of a power supply, and a capacitor C1, a diode D2 and a resistor R1 are connected with each other in parallel and then are connected between the emitter and a base of the dynatron T1; the other end of the relay J1 is connected with a positive electrode of the power supply, and a resistor R2 is connected between the end of the relay J1 and the base of the dynatron T1; and a diode D1 is connected between both ends of the relay J1. The soft starting board can ensure that the whole circuit is safer and more reliable, and prolong the service life of the welding machine.

Owner:无锡市南方电器制造有限公司

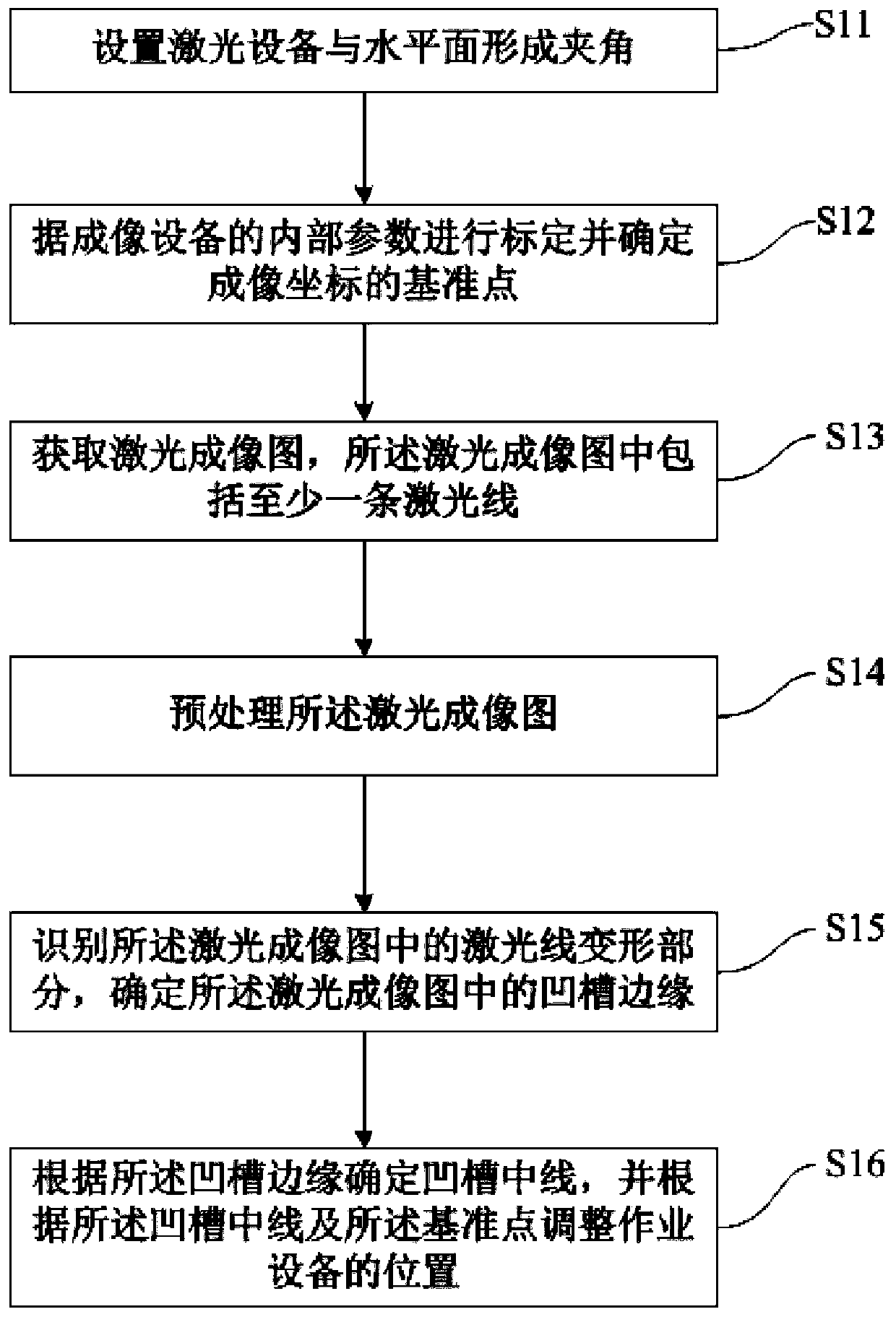

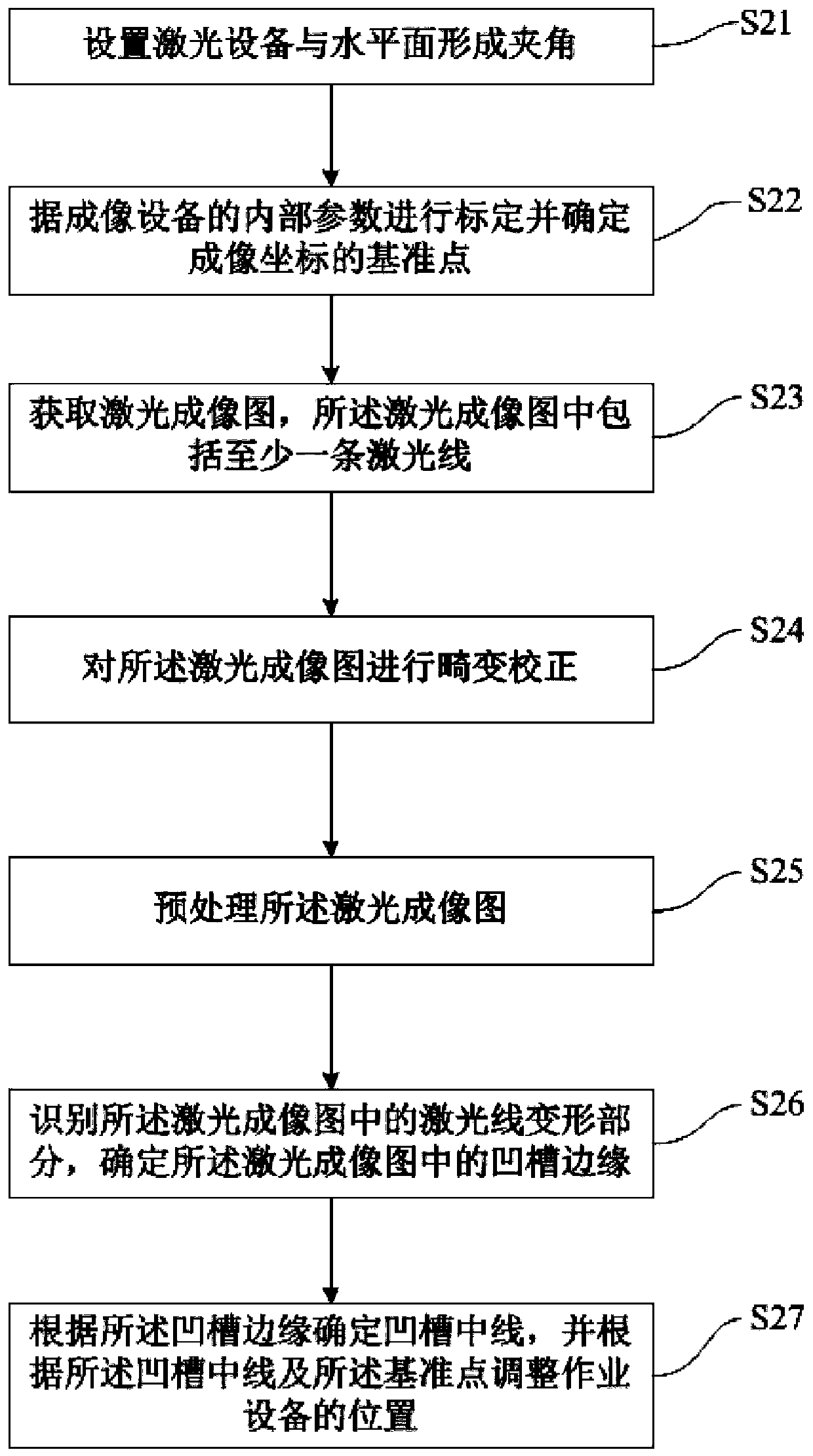

Method for positioning grooves between building wallboards

ActiveCN110443260ASimple and convenient designLow costCharacter and pattern recognitionElectromagnetic wave reradiationPhysicsImaging equipment

The invention provides a method for positioning a groove between building wallboards. The method comprises the steps of arranging laser equipment to form an included angle with the horizontal plane; calibrating according to the internal parameters of the imaging equipment and determining a reference point of an imaging coordinate; obtaining a laser imaging graph, wherein the laser imaging graph comprises at least one laser line; preprocessing the laser image; identifying a laser line deformation part in the laser imaging graph, and determining a groove edge in the laser imaging graph; and determining a groove center line according to the groove edge, and adjusting the position of the operation equipment according to the groove center line and the reference point. According to the method for positioning the groove between the building wallboards, the groove can be simply positioned, the hardware cost is reduced, and the adaptability is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

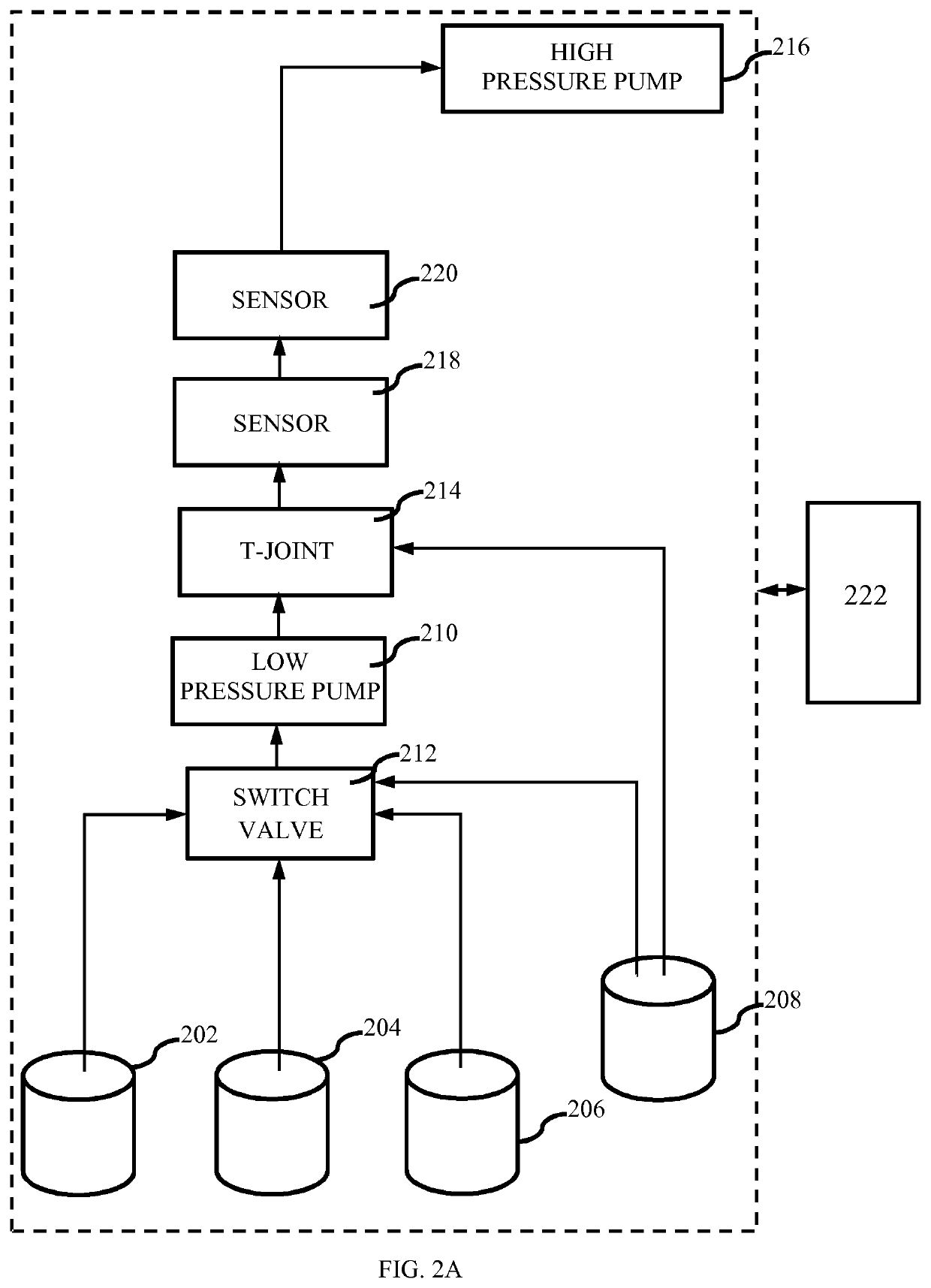

System for preparing solutions for chromatography

ActiveUS10926191B2Simple and convenient designWay of increaseComponent separationFlow mixersBuffer solutionAnalytical chemistry

A system for preparing solutions for chromatography application is disclosed. The system comprises a T-joint for preparing a buffer solution by mixing at least one first solution and a second solution. The T-joint receives the second solution from a solution supply unit connected to the T-joint. Further one or more low pressure pumps supply the one or more first solutions into the T-joint. The high pressure pump collects the buffer solution and delivers it to a chromatography apparatus.

Owner:CYTIVA SWEDEN AB

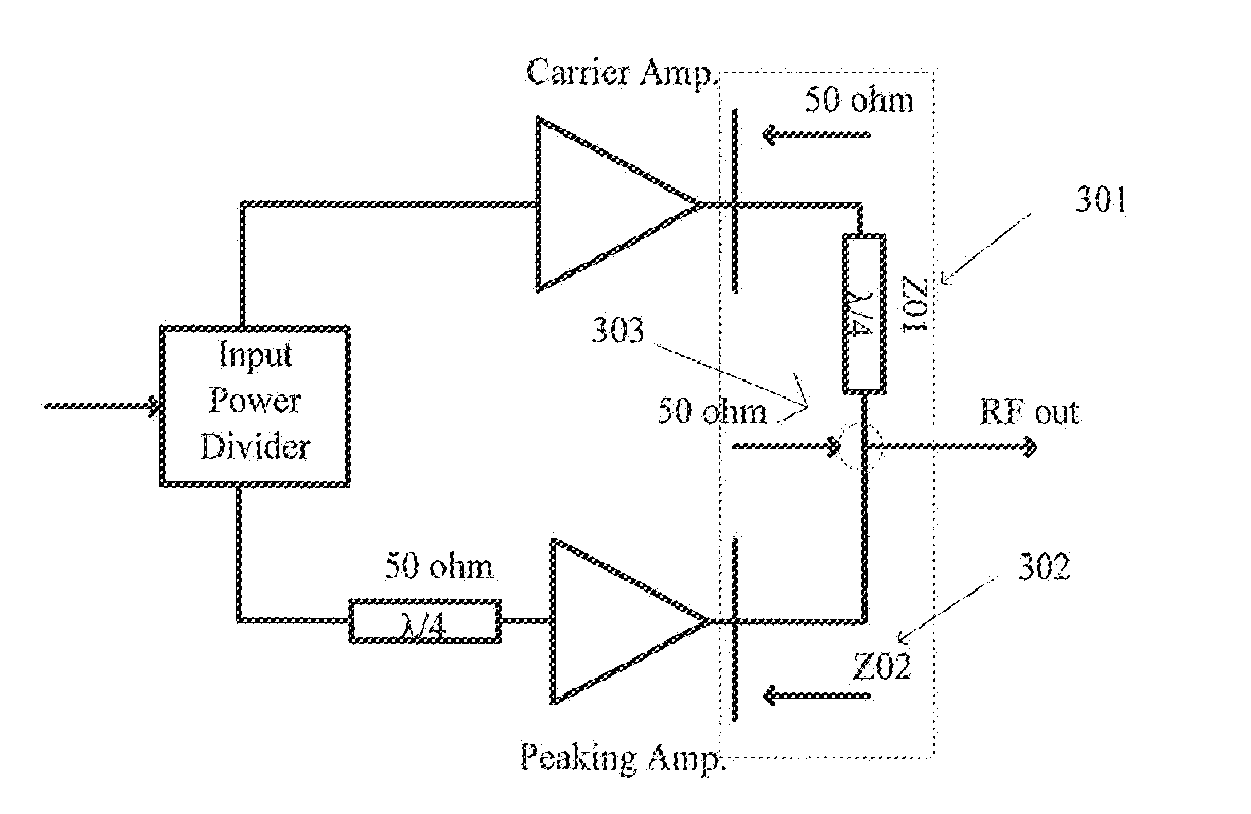

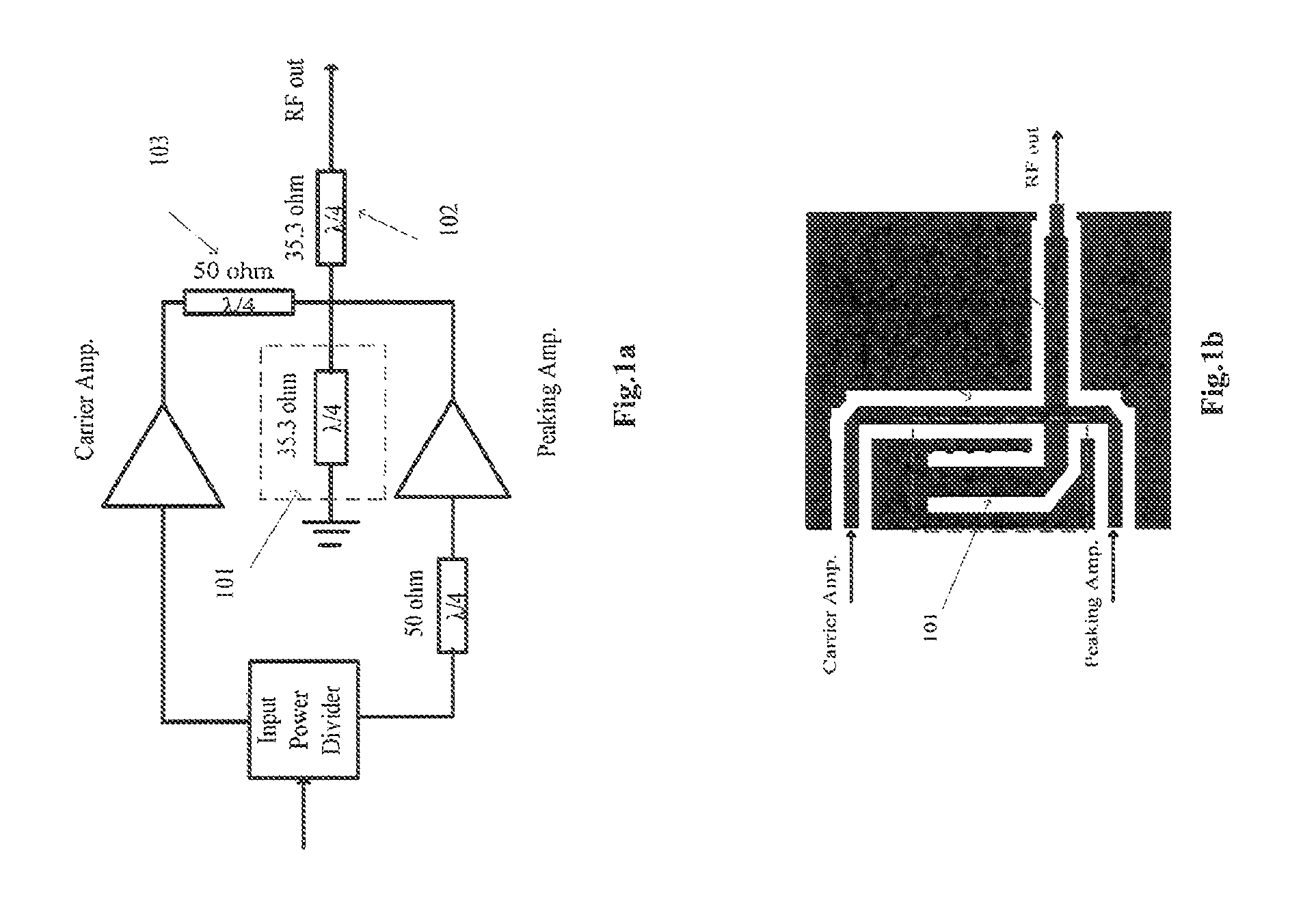

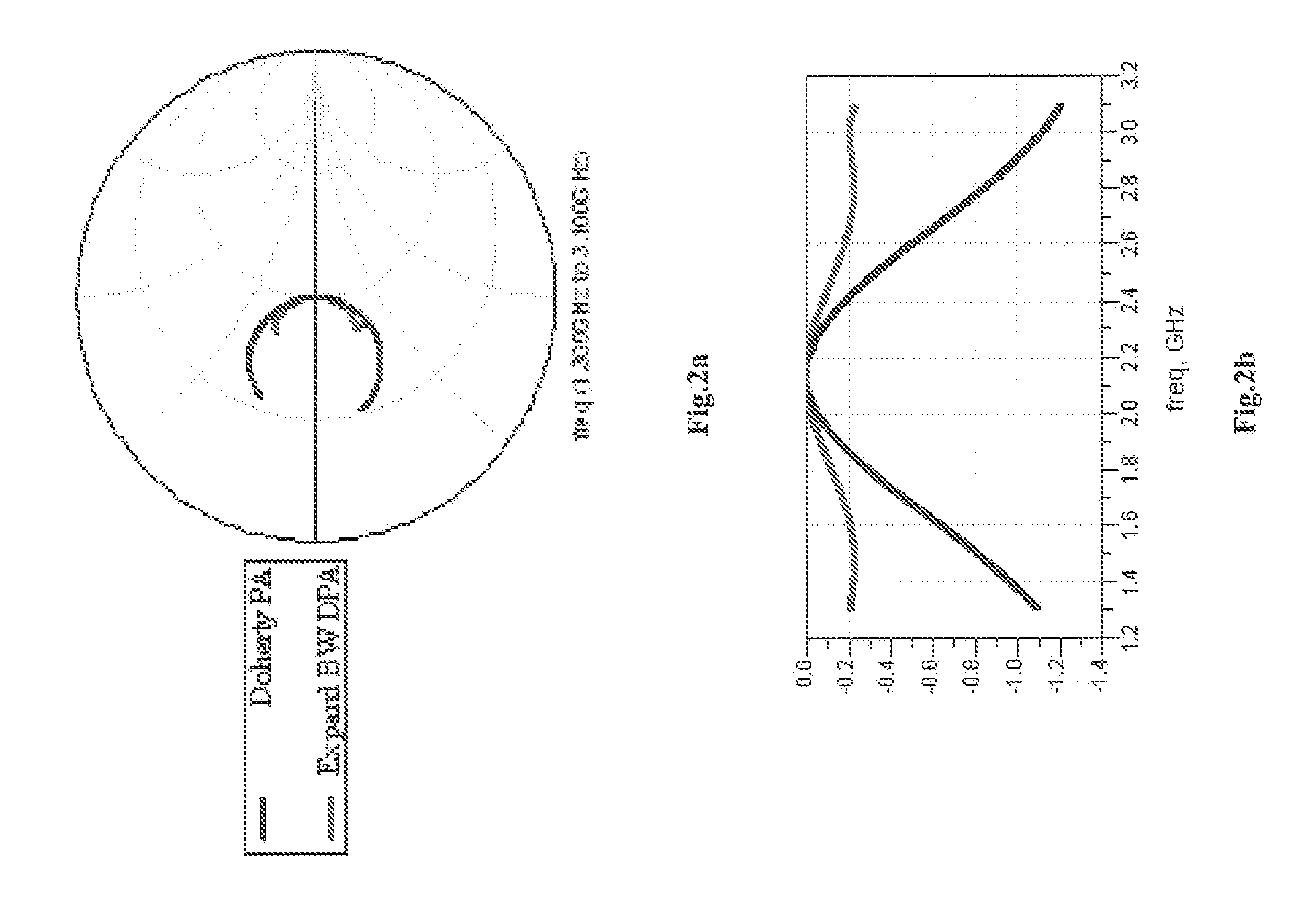

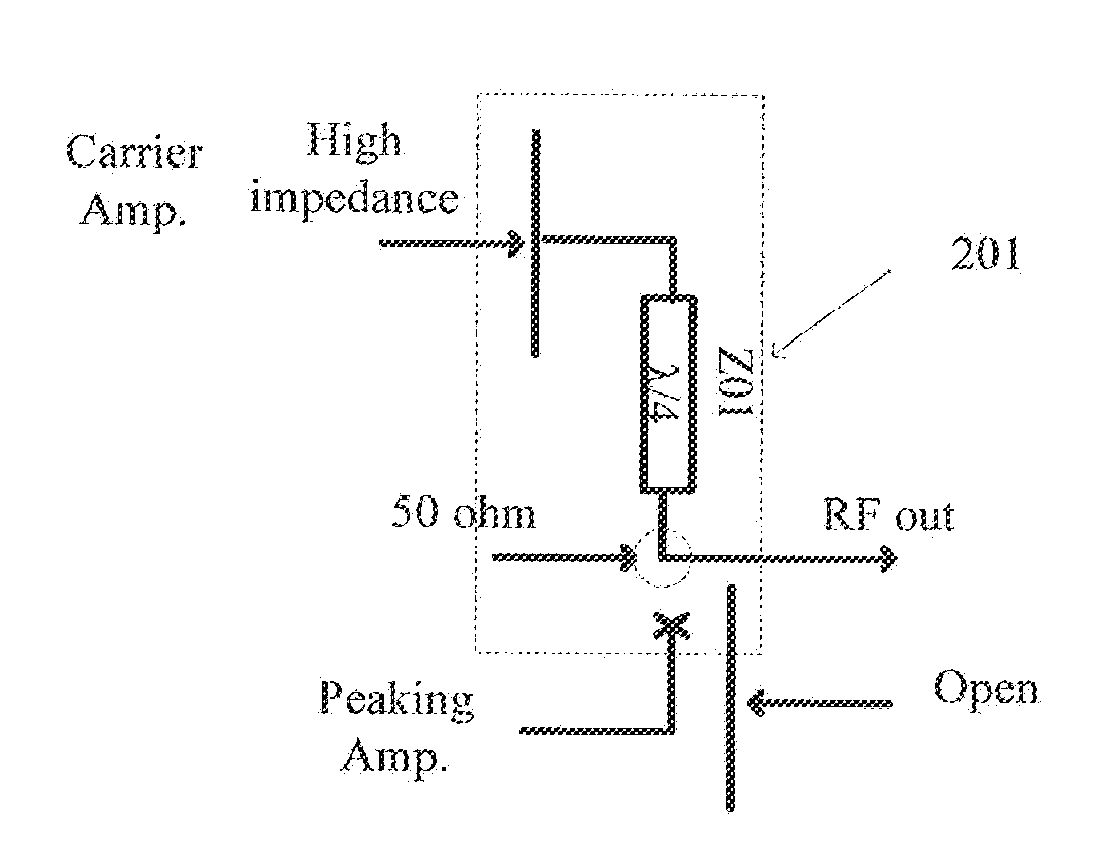

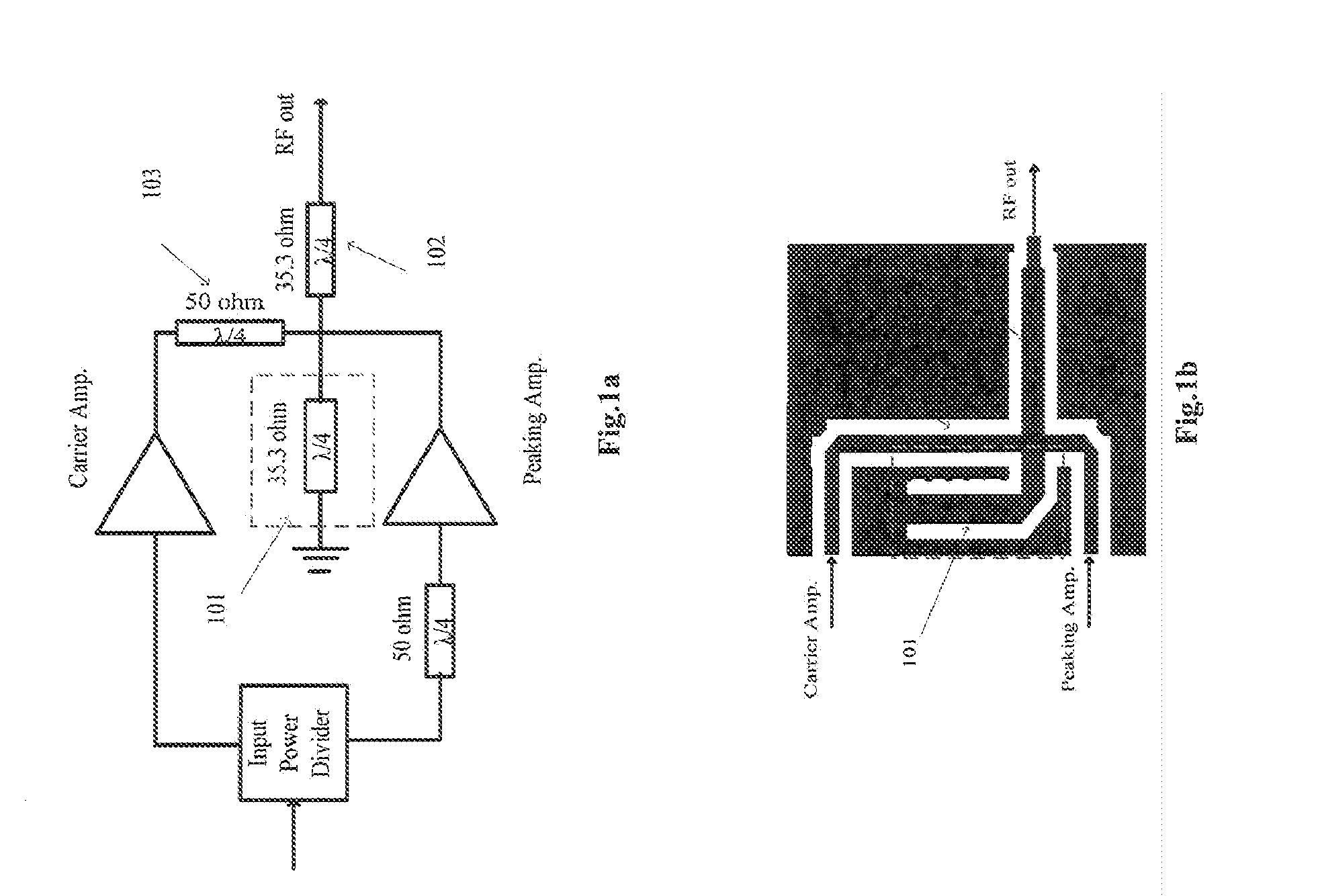

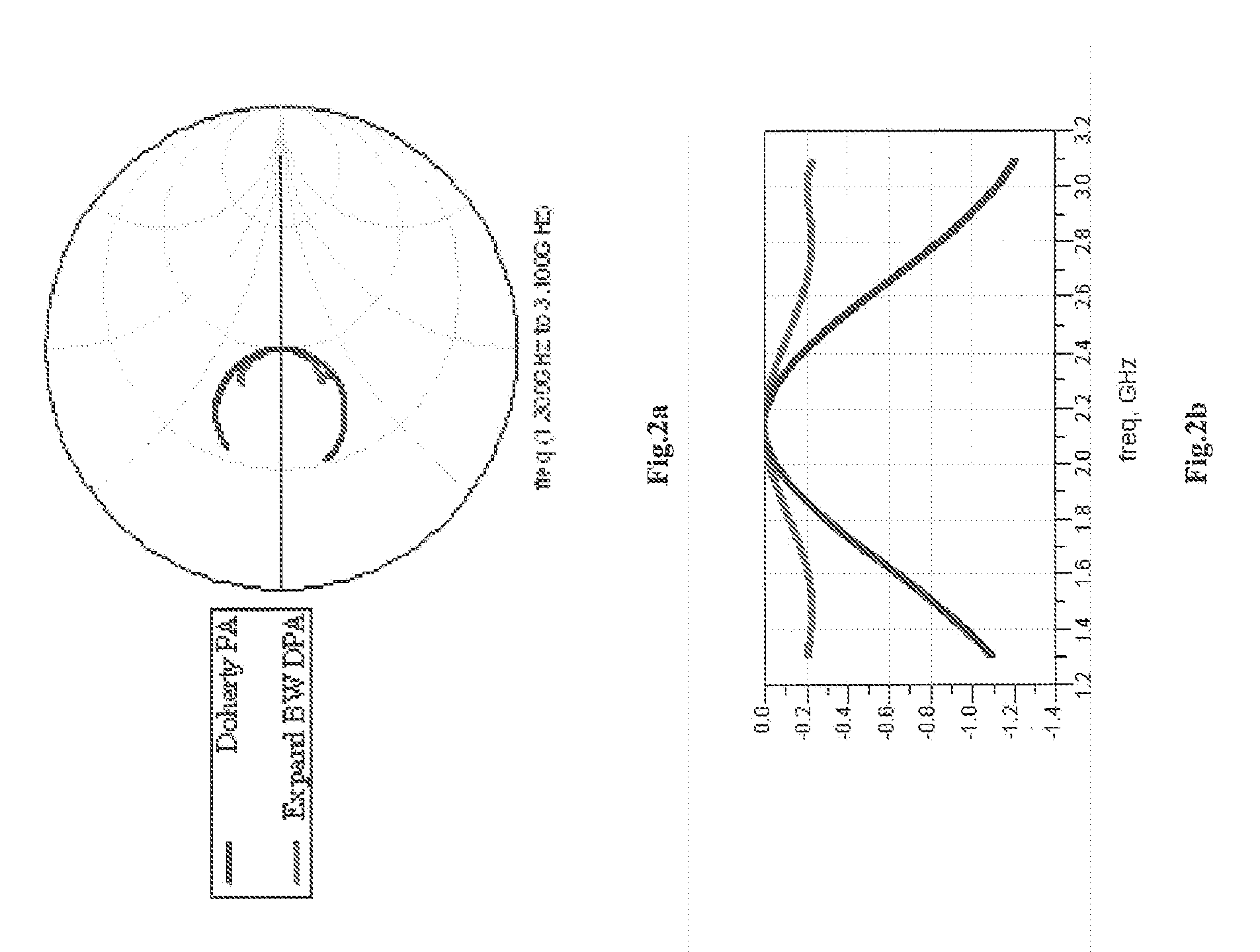

Bandwidth-extended Doherty power amplifier

ActiveUS9450543B2Facilitates design of narrowedLow pour pointHigh frequency amplifiersPower amplifiersPresent methodEngineering

The present invention provides a new structure of Doherty power amplifier. The present invention reduces use of ¼ wavelength lines and lowers the Q point of the Doherty power amplifier. The present method extends the DPA bandwidth with a simpler and more convenient design and facilitates the design of a narrowed size.

Owner:ALCATEL LUCENT SAS

Horizontal gas/gas two phase composite linear primary method and device based on gravity balance

InactiveCN100575887CImprove support rigidityImprove stabilityMeasurement apparatus componentsEngineeringTwo phase composite

Owner:NANTONG MINGGUANG ELECTRIC WIRE

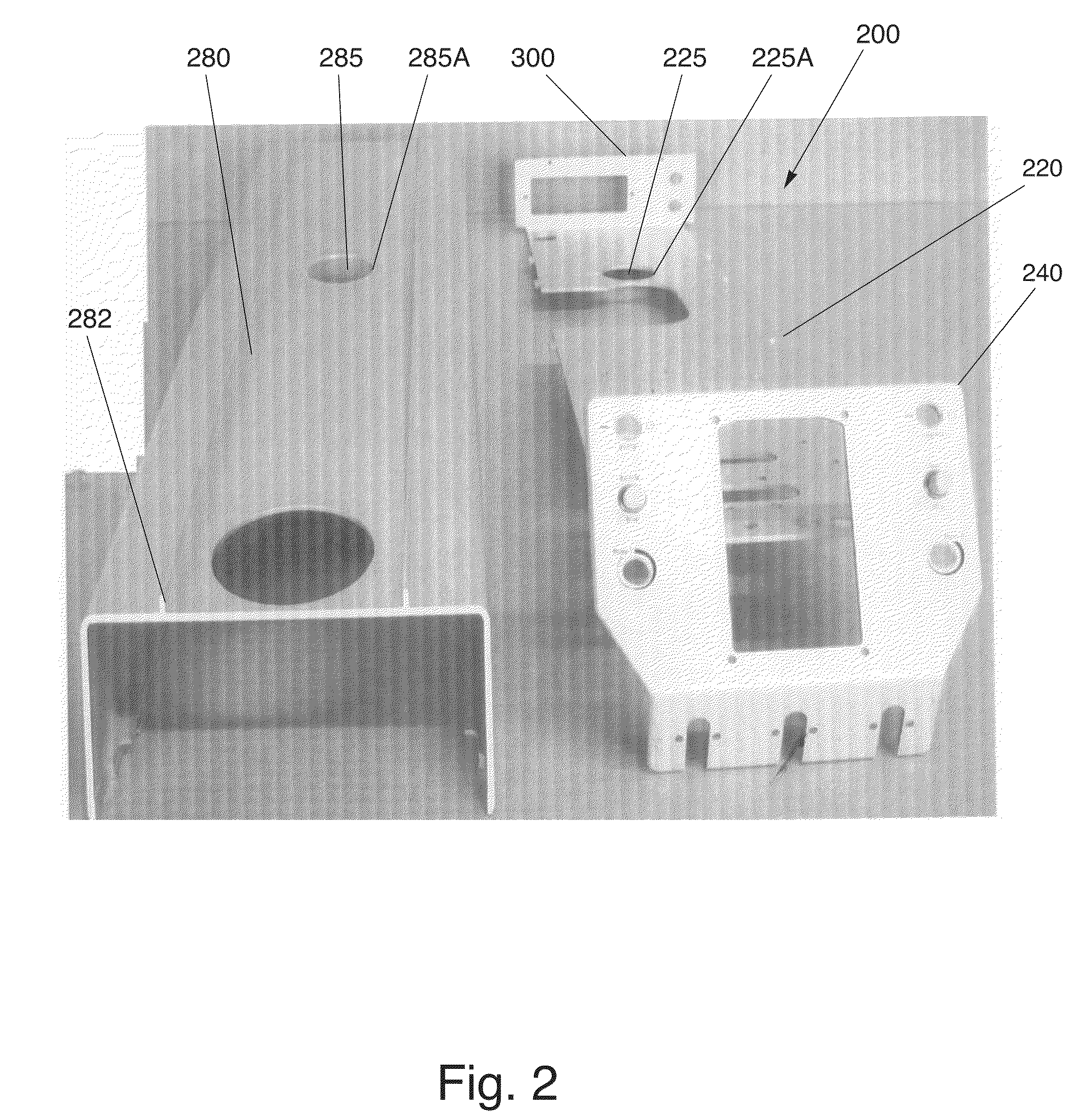

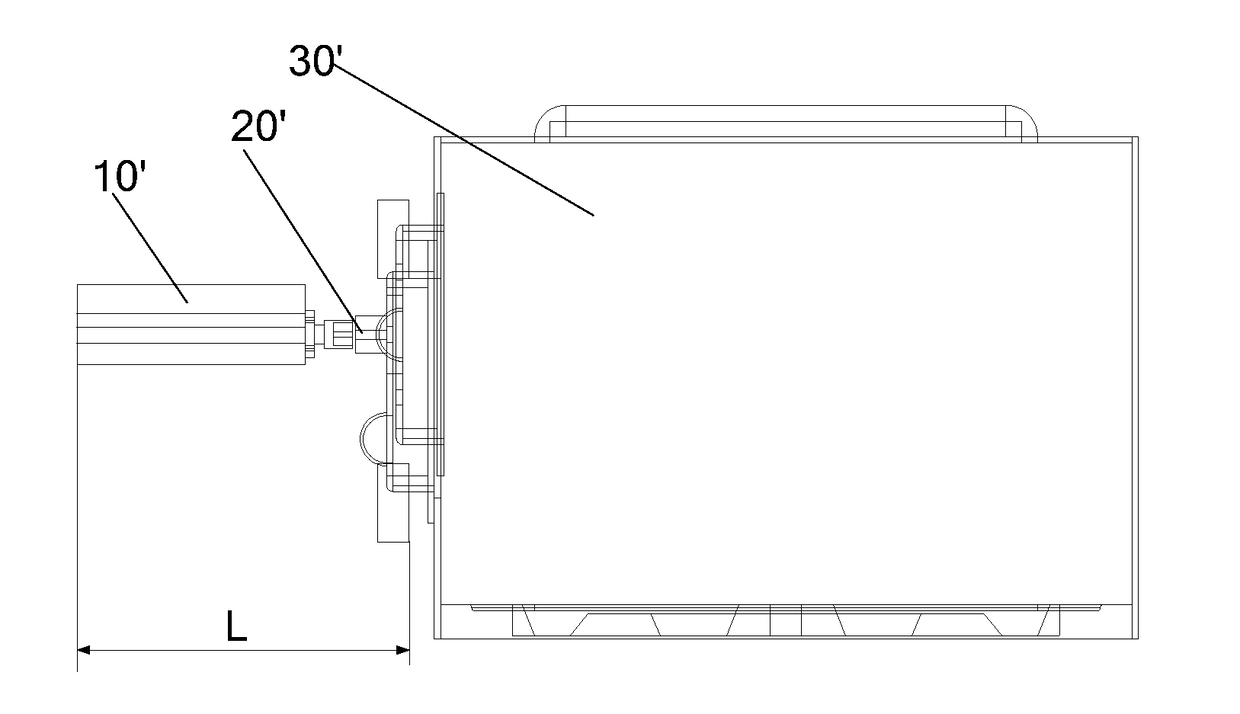

Connection structure and input/output connection structure of semiconductor microwave generator for microwave oven, and microwave oven

ActiveUS20170094731A1High efficiencyImprove efficiencyMicrowave heatingHome appliance efficiency improvementMicrowave ovenEngineering

The invention provides a connection structure and input / output connection structure of a semiconductor microwave generator for a microwave oven, and a microwave oven. The connection structure of the semiconductor microwave generator for the microwave oven comprises: a semiconductor microwave generator and a microwave output device; a microwave signal output port is provided on a front face or a back face of the semiconductor microwave generator; a first end of the microwave output device is connected to the microwave signal output port, and a second end of the microwave output device communicates with a cooking cavity of the microwave oven.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Novel pug cut-off machine

InactiveCN107116672ASimple and convenient designEasy to operateAuxillary shaping apparatusElectric machinerySteel tube

The invention discloses a novel pug cut-off machine and belongs to the field of cut-off equipment. The novel pug cut-off machine comprises a bottom frame and is characterized in that the bottom frame abuts against a pug shaping machine body, a cutting ring is arranged at the end, connected with the pug shaping machine body, of the bottom frame and fixed onto the bottom frame through a movable steel pipe, the movable steel pipe is connected with a motor, and the movable steel pipe is controlled to circularly swing in the left-right direction through the motor; a steel wire is arranged in the cutting ring, a check block is arranged on the bottom frame and used for controlling the swing angle of the cutting ring, and the movable steel pipe is a double-layer steel pipe; an outer-layer steel pipe body is in a hollow semi-ring shape, the two ends of the outer-layer steel pipe body are each inwards provided with a baffle, and an inner steel pipe body is tangent to the outer steel pipe body; and the upper end of the inner steel pipe body is provided with a baffle, and the inner steel pipe body is connected with the motor. According to the novel pug cut-off machine, design is simple and convenient, effective innovation is achieved, the cutting ring makes circularly-reciprocating movement through the motor, and by adjusting the movement speed of the cutting ring, pug after shaping is cut into fixed sizes; and the design is simpler and more convenient, and operation is easy.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

Novel splash-proof barrel with foldable covers

InactiveCN107298238ASimple and convenient designPromote good healthShock-sensitive articlesExternal fittingsSteel tubeEngineering

The invention discloses a novel splash-proof barrel with a foldable cover, which belongs to the field of storage barrels. The invention includes a bucket body, a filter cloth is arranged inside the bucket body to further filter the mud, two sunken tracks are arranged on the side of the bucket body, a splash guard is arranged on the track, and the splash guard is fixed in the track by a slider, so that The above-mentioned splash guard is a folded waterproof cloth, and the frames at both ends are fixed by steel pipes. The slider is in the shape of a "worker" and is embedded in the track. A nut is arranged on the block, and the position of the slide block can be moved and fixed by the tightness of the nut. The track is "concave" shape, that is, the opening is narrower than the internal channel. The design of the present invention is simple and convenient, effective and innovative. The setting of the track and the slider can better control the height of the splash guard, which is flexible and changeable. Can further filter mud.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

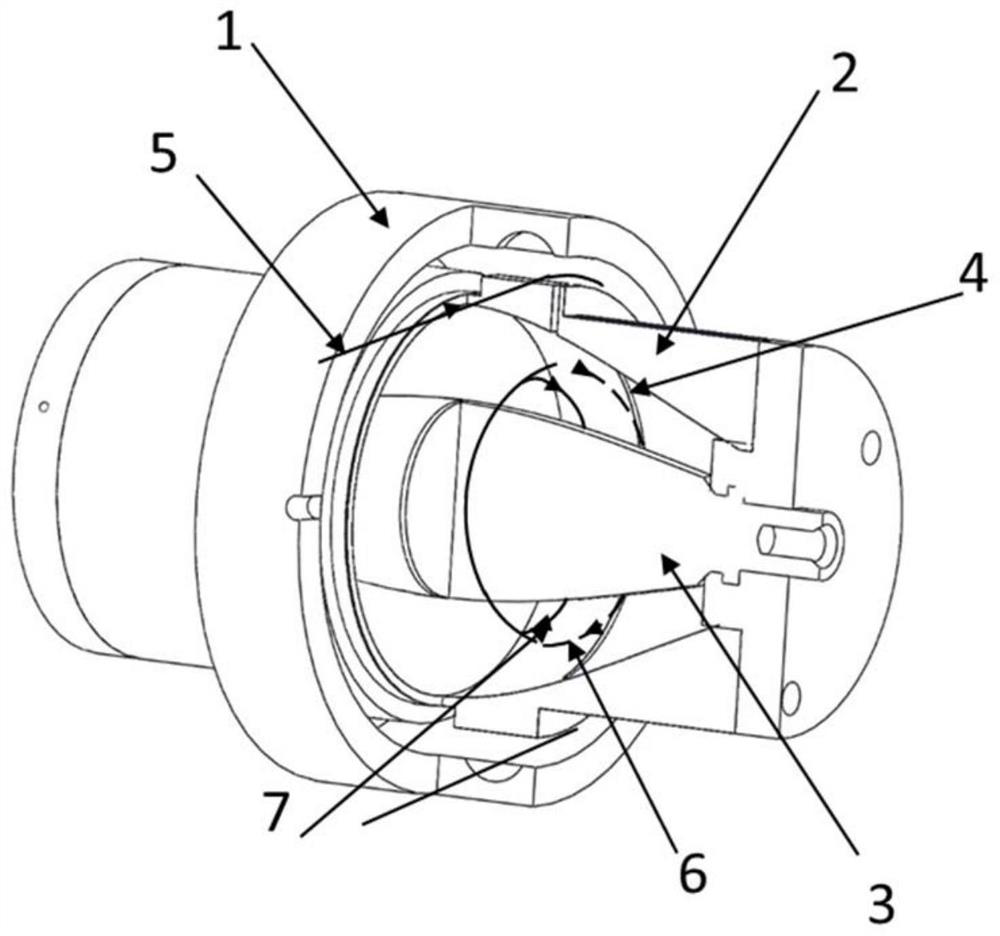

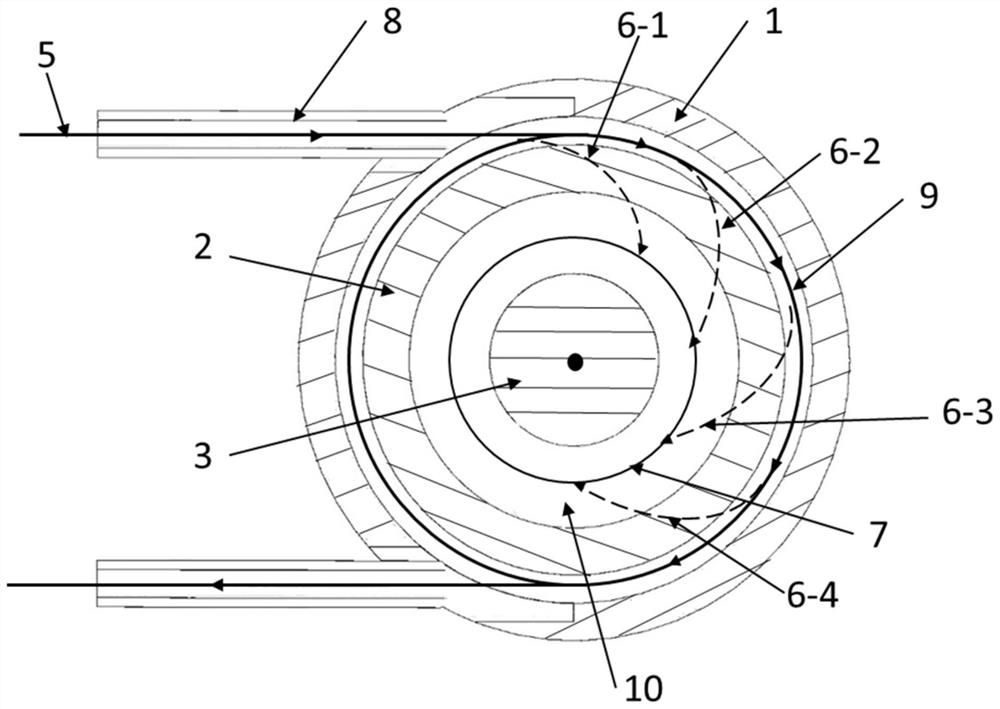

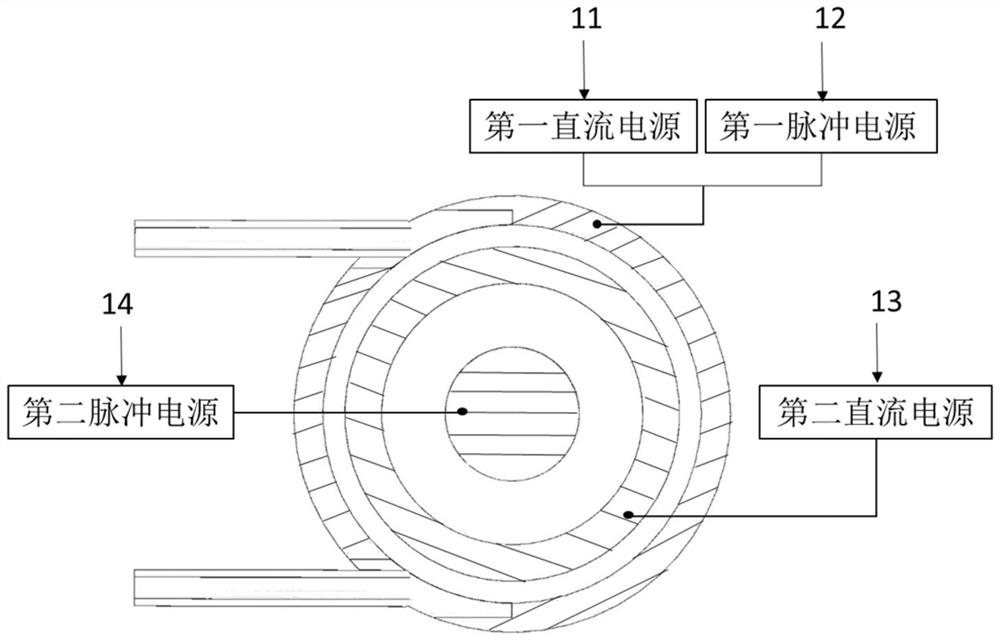

Novel electrostatic ion trap ion tangential introduction orbit deflection device

InactiveCN112185798AAvoid loss phenomenonReduce lossesStability-of-path spectrometersElectron/ion optical arrangementsIon trap mass spectrometryIon beam

The invention relates to a novel electrostatic ion trap ion tangential introduction track deflection device which comprises a deflection outer track and a deflection inner track which form a concentric cylinder, the potential of the deflection outer track is higher than that of the deflection inner track, and the deflection outer track and the deflection inner track form an ion high potential storage deflection cavity O-trap. An ion introduction track used for tangentially introducing ion beams is arranged at the outer end of the high-potential storage deflection cavity O-trap, an electrostatic ion trap inner electrode is arranged in the center of the deflection inner track, and the deflection inner track and the electrostatic ion trap inner electrode form an electrostatic ion trap analysis cavity. The deflection inner rail is provided with an ion orbital transfer introduction channel for introducing ions into the electrostatic ion trap analysis cavity. Compared with the prior art, thedevice has the advantages of reducing ion loss, improving signal intensity, being simple to control and the like.

Owner:FUDAN UNIV

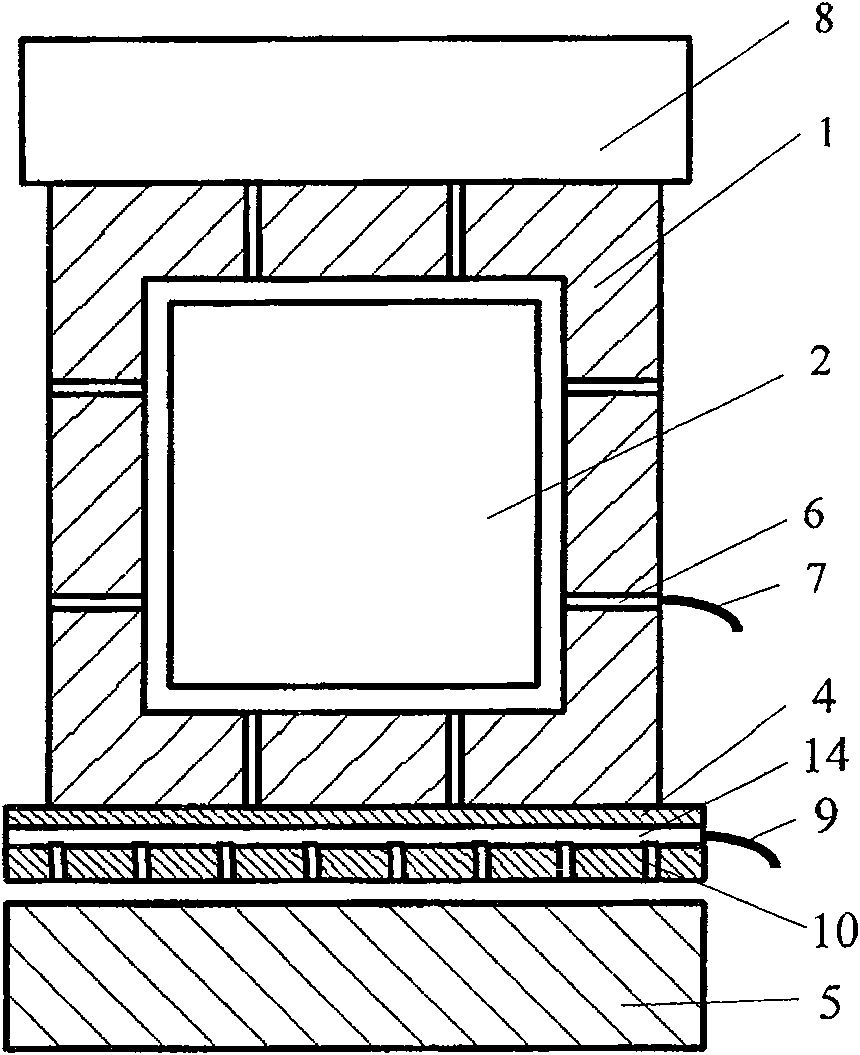

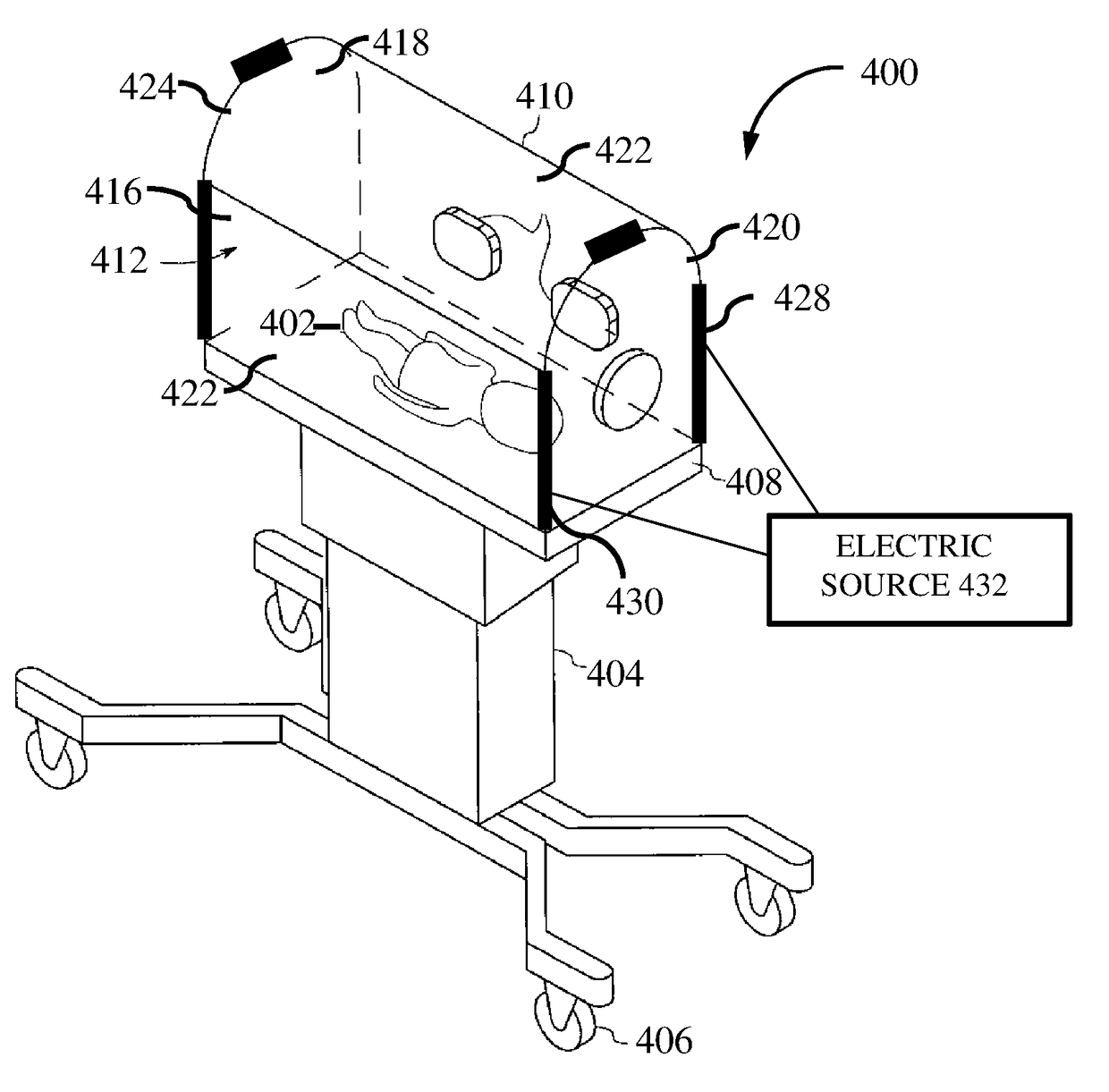

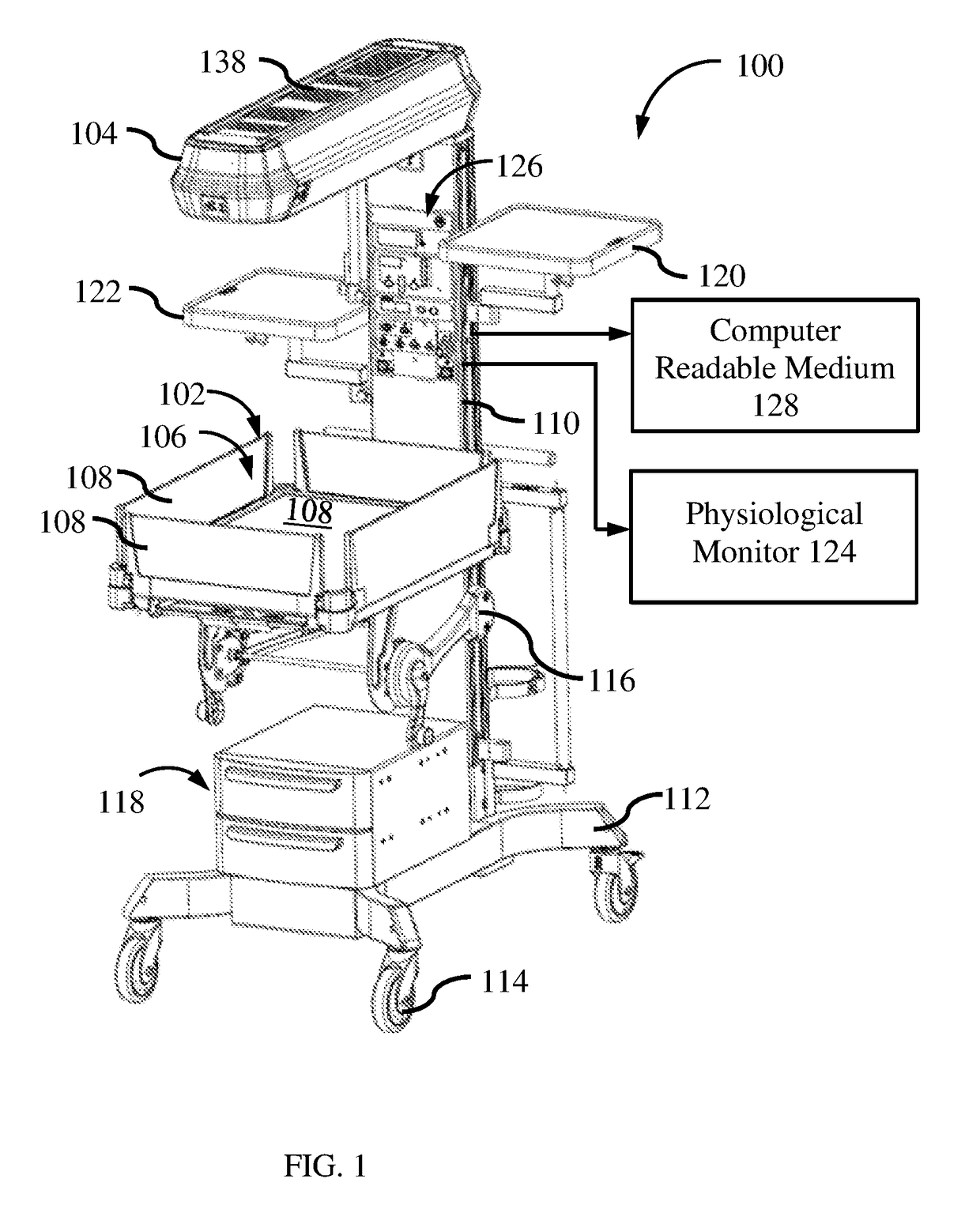

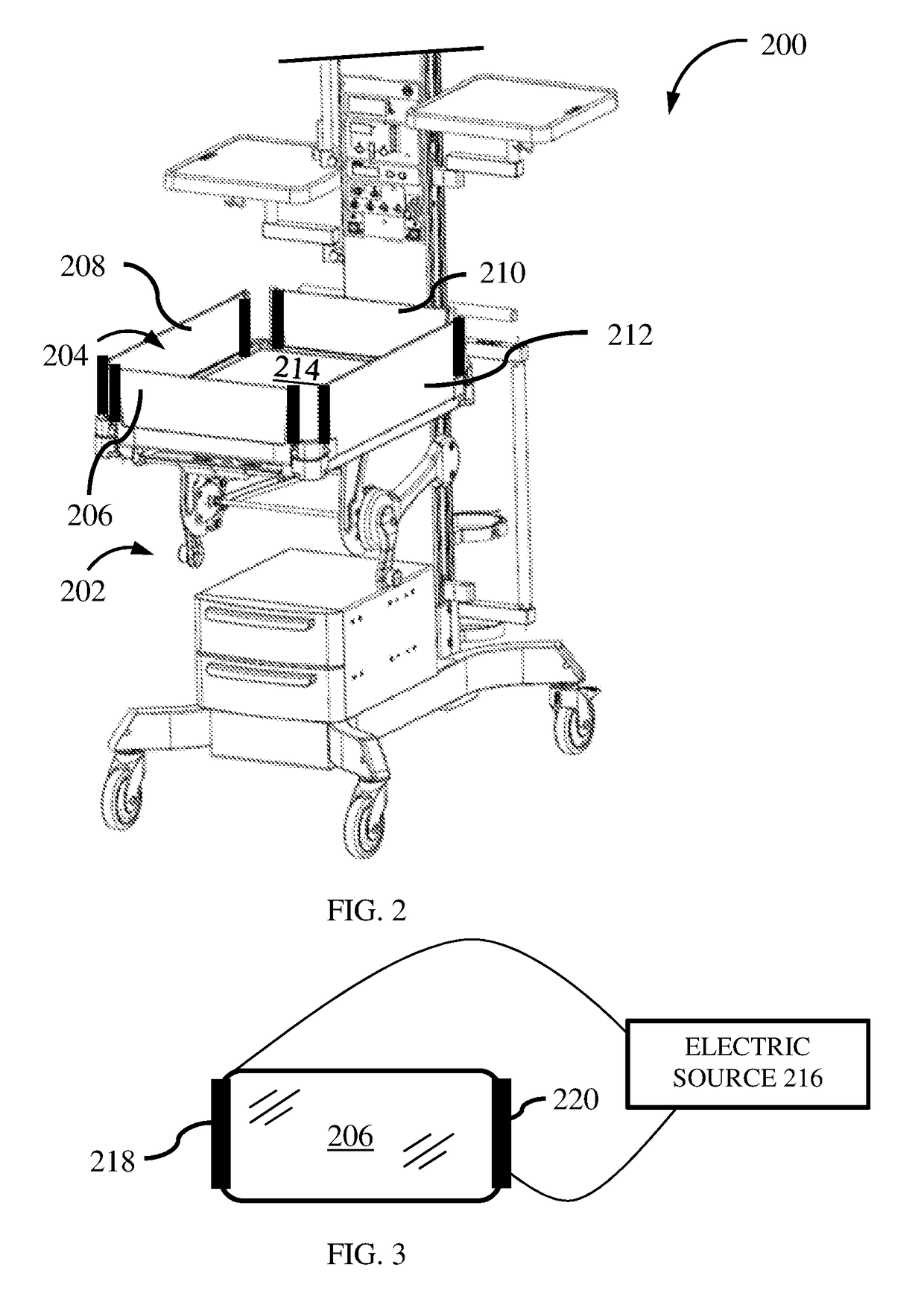

Infant care system

InactiveUS20170128300A1Simple and convenient designOvercomes drawbackBaby-incubatorsDiagnosticsElectricityEngineering

An infant care system for warming infants is disclosed. The infant care system comprises a supporting structure and an infant enclosure. The infant enclosure is assembled onto the supporting structure and capable of holding an infant. The infant enclosure includes a plurality of walls for forming the enclosure. The plurality of walls is capable of providing heat energy into the infant enclosure for the infant. An electric source is electrically connected to the plurality of walls for providing power to these walls for generating the heat energy for warming the infant.

Owner:GENERAL ELECTRIC CO

Bandwidth-extended doherty power amplifier

ActiveUS20140347134A1Facilitates design of narrowedLow pour pointHigh frequency amplifiersPower amplifiersPresent methodEngineering

The present invention provides a new structure of Doherty power amplifier. The present invention reduces use of ¼ wavelength lines and lowers the Q point of the Doherty power amplifier. The present method extends the DPA bandwidth with a simpler and more convenient design and facilitates the design of a narrowed size.

Owner:ALCATEL LUCENT SAS

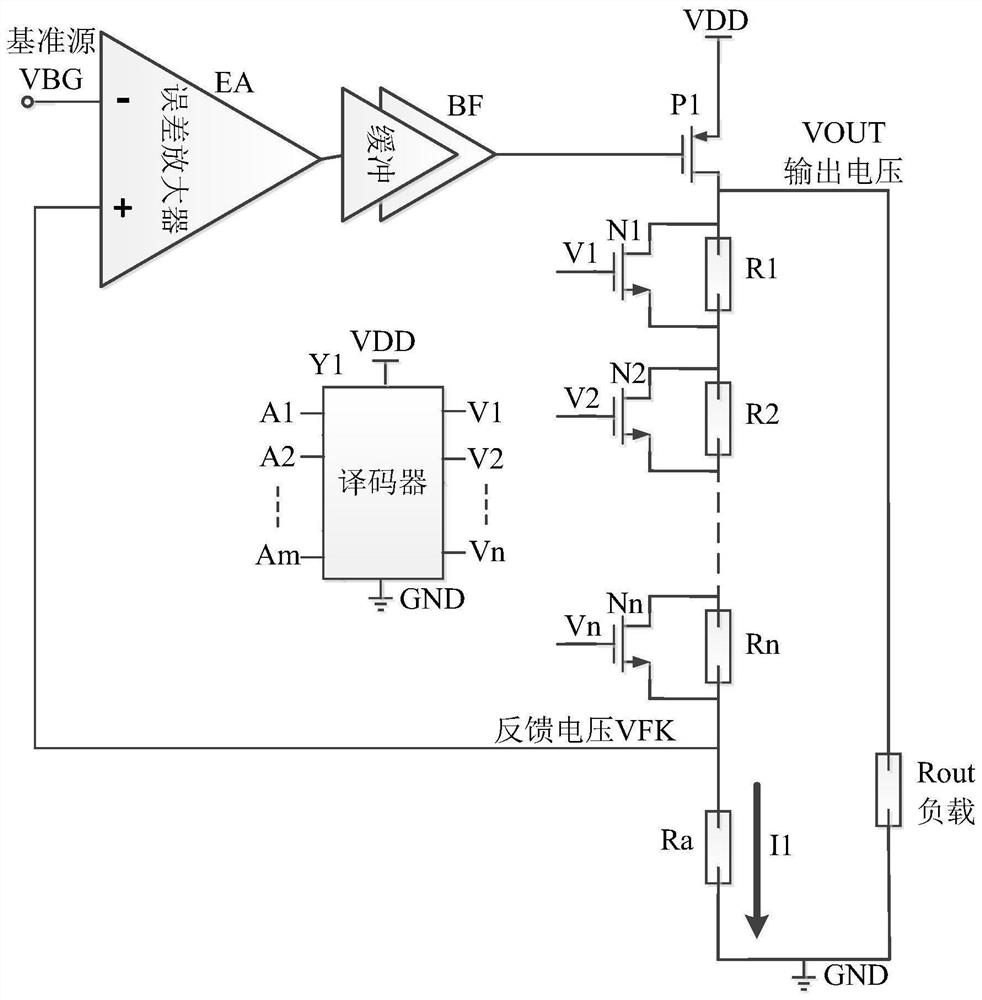

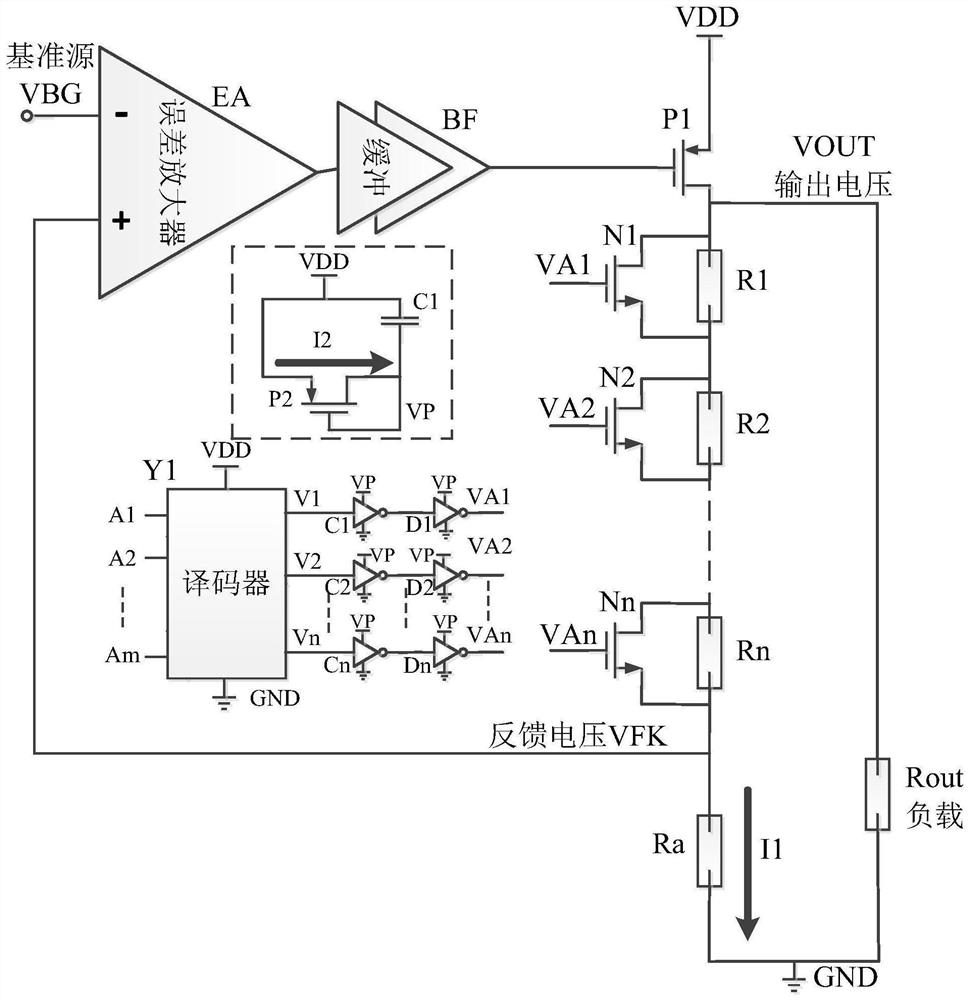

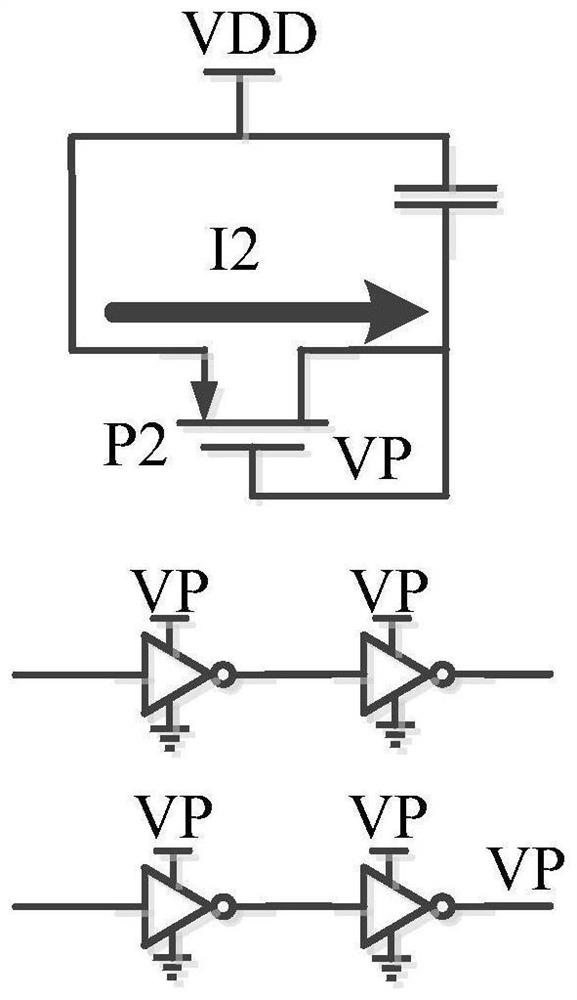

Self-adaptive filtering control circuit applied to multi-voltage output LDO chip

ActiveCN112148055ASimple and convenient designTo prevent excessive resistance from cutting off the circuitAdaptive networkElectric variable regulationIntegrated circuitControl switch

The invention discloses a self-adaptive filtering control circuit applied to a multi-voltage output LDO chip, and belongs to the field of integrated circuit design. The self-adaptive filtering controlcircuit comprises an error amplifier, a buffer circuit, a resistance feedback network, a control circuit and a self-adaptive filtering circuit; the error amplifier and the buffer circuit are used forgenerating and amplifying a negative feedback signal; the resistance feedback network is used for controlling the output voltage; the control circuit is used for generating a control voltage; and theself-adaptive filtering circuit is used for filtering power supply voltage noise. When the control signal generated by the control circuit is used for controlling a MOS switch, filtering is carried out by the self-adaptive filtering circuit, so that the PSRR index of the LDO is prevented from being influenced by power supply noise. The self-adaptive filtering control circuit has the following technical advantages that firstly, the structure of the self-adaptive filtering control circuit not only can reserve the advantages of a traditional resistance feedback network, but also can avoid the existing problems; and secondly, a large resistor required by the filtering circuit can be integrated in a low-cost on-chip manner and is self-adaptive, so that the possibility that the circuit is cut off due to overlarge resistance can be prevented.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com