Reinforcing sheet designing and reinforcing method for thermoplastic fiber composite material tapping component

A technology of composite materials and reinforcement sheets, which is applied in the field of reinforcement of perforated parts and the production of reinforcement sheets for perforated parts, which can solve the problems of low reliability, poor quality, and low work efficiency of the reinforcement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

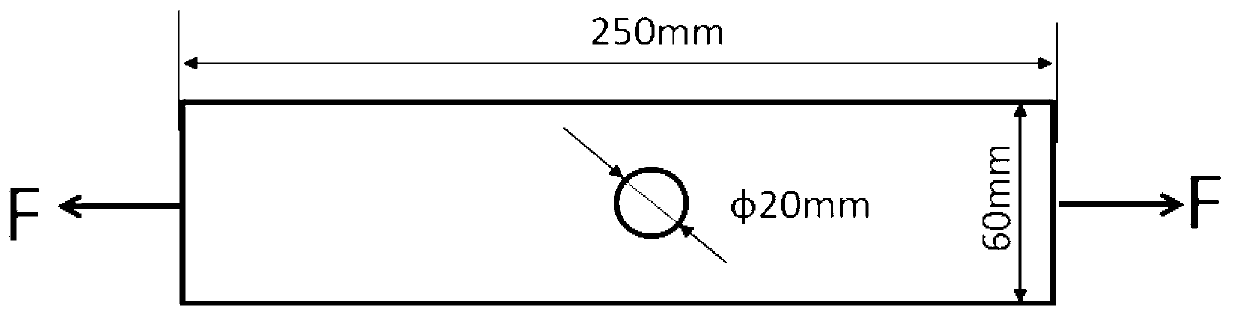

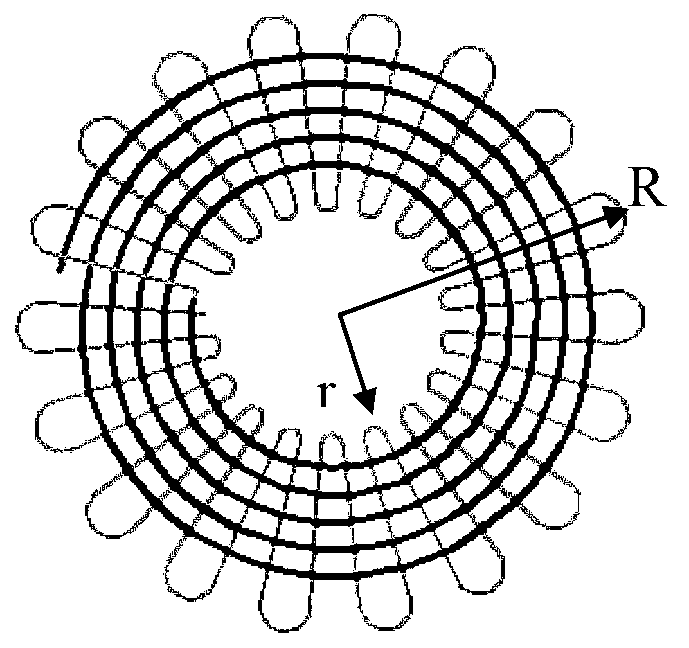

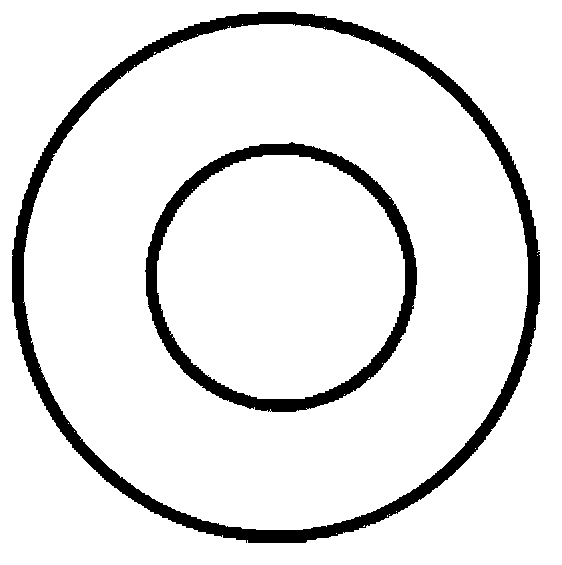

[0107] In this embodiment, the open-hole thermoplastic composite material is a carbon fiber / polyphenylene sulfide composite open-hole laminate prepared by four layers of polyphenylene sulfide film and four layers of CF300 3K carbon fiber twill fabric. Uniaxial tensile load, its structure and the direction of the tensile load are as follows figure 1 As shown; the hole diameter of the opening part is 20mm; the reinforcing sheet 4 is made of a mixed fiber tow of polyphenylene sulfide fiber and CF300 3K carbon fiber, and the reinforcing sheet 4 is opened with the carbon fiber / polyphenylene sulfide composite material Laminate preforms 3 warp Figure 4 The integrated curing molding process shown in the figure obtains a carbon fiber / polyphenylene sulfide composite laminate reinforced with openings. The specific method includes the following steps:

[0108] Step 1. According to the shape and size of the opening part of the carbon fiber / polyphenylene sulfide composite laminate, desig...

Embodiment 2

[0115] In this embodiment, the solidified thermoplastic composite material opening 1' is a glass fiber / polypropylene composite opening laminate made of four layers of polypropylene / glass fiber plain cloth, and the composite laminate bears Uniaxial tensile load, its structure and the direction of the tensile load are as follows figure 1 As shown; the hole diameter Φ of the opening part is 20mm; the reinforcing sheet 4 is made of a mixed fiber tow of polypropylene fiber and glass fiber, and the reinforcing sheet 4 passes through Figure 5 The secondary curing compression molding process shown is solidified on the opening parts of the glass fiber / polypropylene composite open-hole laminate to obtain the open-hole reinforced glass fiber / polypropylene composite open-hole laminate. The specific method includes the following steps:

[0116] Step 1, according to the shape and size of the opening part of the glass fiber / polypropylene composite material open-hole laminate, design a matc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com