Method for positioning grooves between building wallboards

A positioning method and wall panel technology, applied in the field of construction, can solve the problems of low adaptability, complex mechanism design, high hardware cost, etc., and achieve the effect of reduced hardware cost, simple and convenient mechanism design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for locating grooves between building wall panels, which can directly and simply obtain the edge position of the grooves, which makes the equipment design simple and the hardware cost lower, and can adapt to the situation where the edge of the groove is incomplete or jagged, and the environment Light has a certain degree of anti-interference.

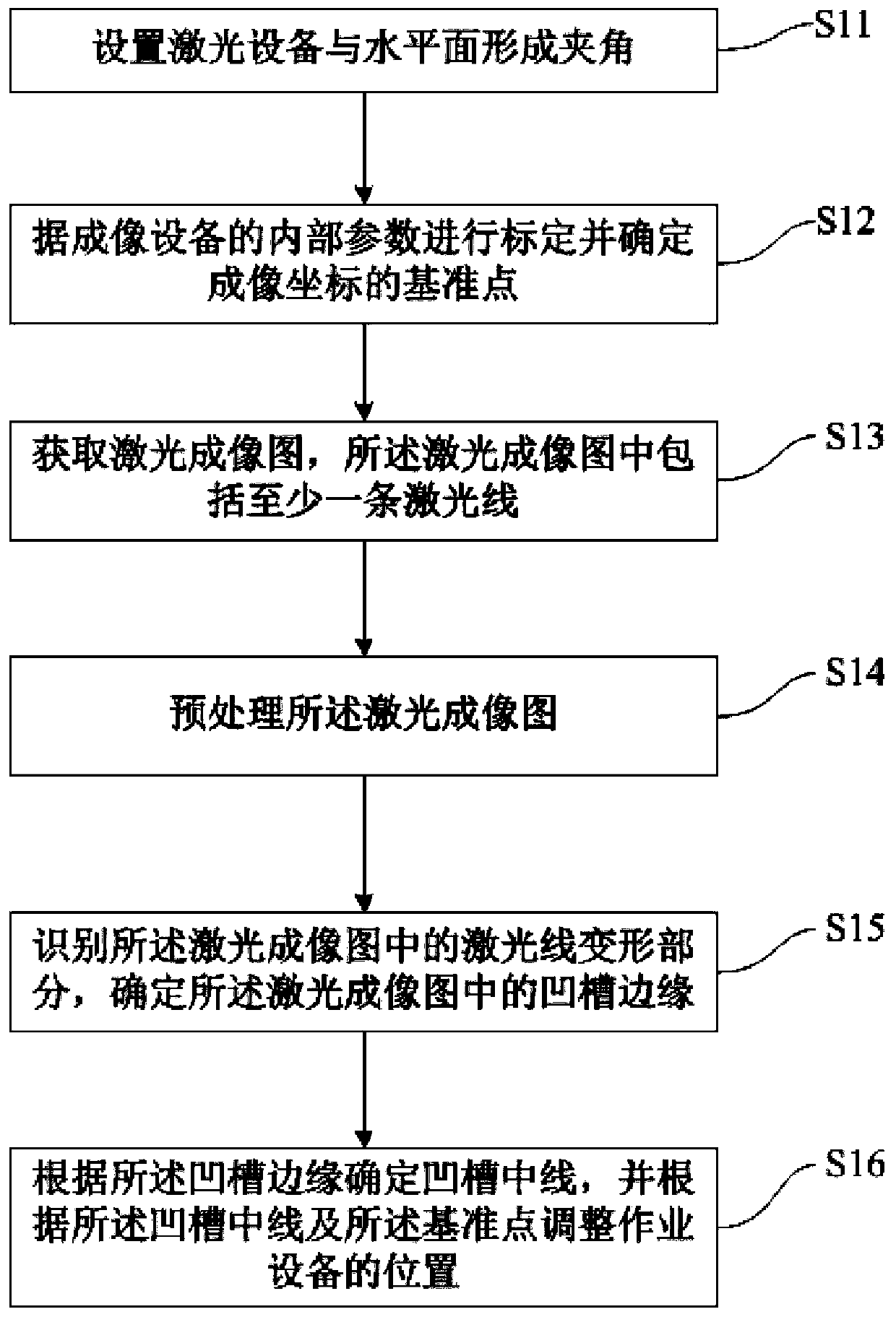

[0043] figure 1 It is a schematic flowchart of the method for positioning grooves between building wallboards provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the positioning method includes the following steps:

[0044] S11, setting the laser device to form an angle with the horizontal plane.

[0045] At the same time, the laser device also forms an included angle with the wallboard. The laser device hits the laser line from a certain angle to the wallboard, and after passing through the wallboard, the information is fed back to the imaging device through diffuse ...

Embodiment 2

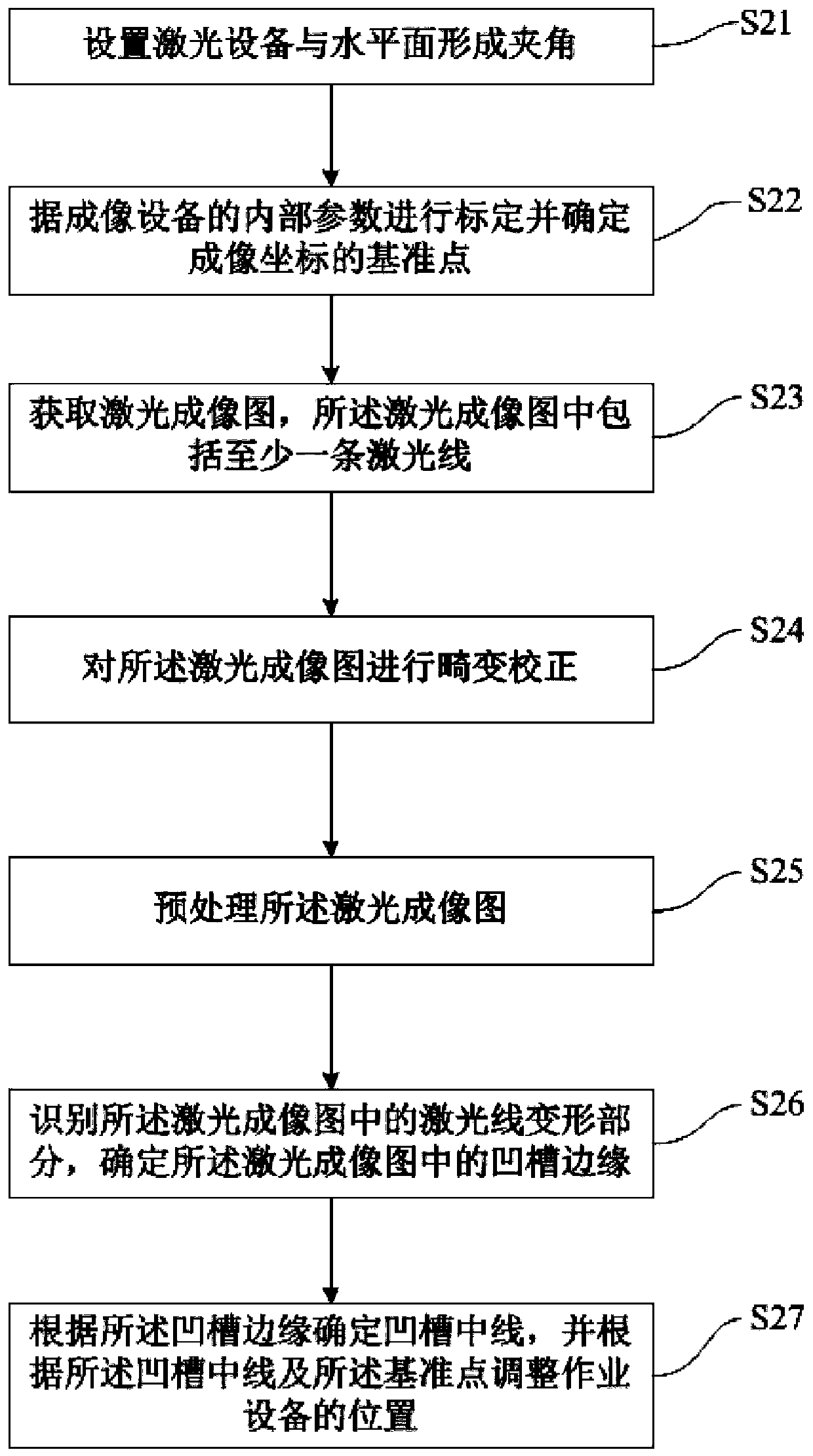

[0058] In this embodiment, on the basis of the foregoing embodiments, the methods for preprocessing and identifying deformation of laser lines are refined. figure 2 It is a schematic flowchart of a method for positioning grooves between building wall panels provided by Embodiment 2 of the present invention. Such as figure 2 As shown, the positioning method specifically includes the following steps:

[0059] S21, setting the laser device to form an angle with the horizontal plane.

[0060] S22, perform calibration according to internal parameters of the imaging device and determine a reference point of the imaging coordinates.

[0061] S23. Acquire a laser imaging image, where the laser imaging image includes at least one laser line.

[0062] S24. Perform distortion correction on the laser imaging image, so that the laser line becomes straight.

[0063] S25. Preprocessing the laser imaging image, so that the laser lines in the laser imaging image are easier to identify. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com