Novel pug cut-off machine

A cutting machine and mud material technology, which is applied in the field of new mud material cutting machine, can solve the problems of cutting effect, knife surface residue, human resources consumption, etc., and achieve the effect of promoting health, easy operation, and simple and convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

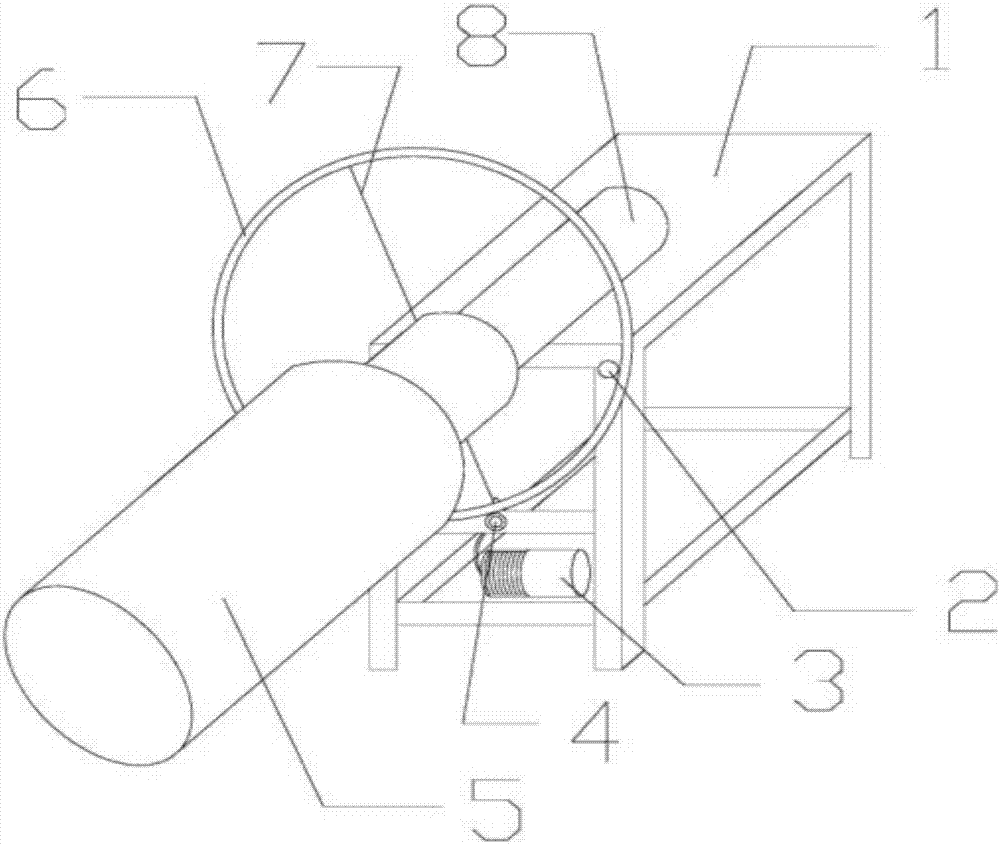

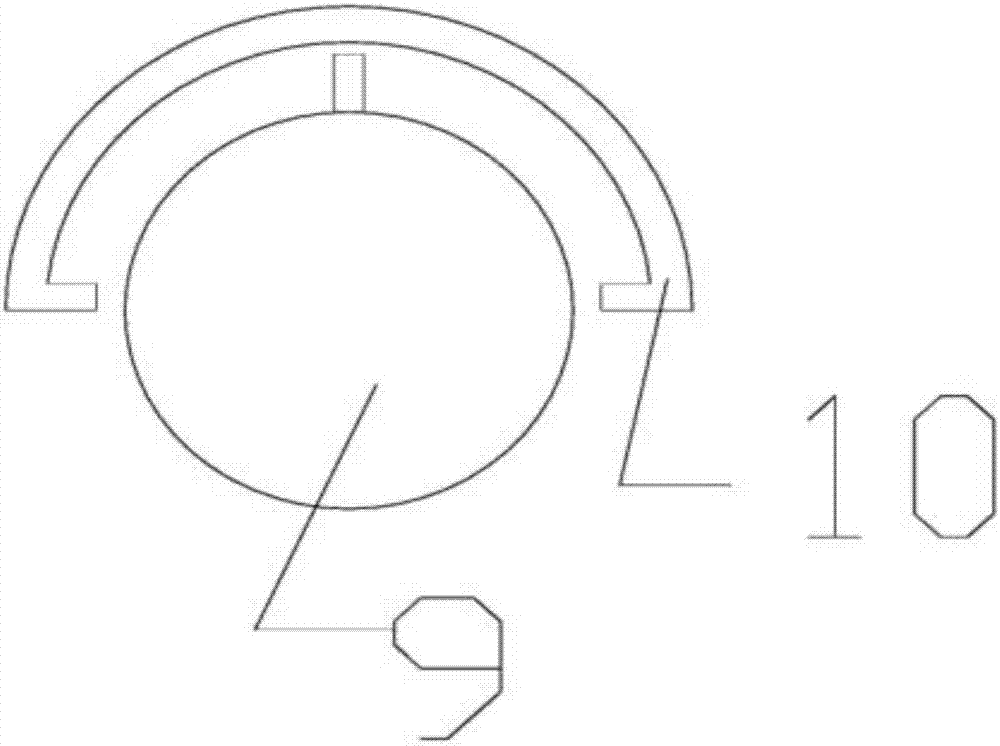

[0017] Such as Figure 1-2 As shown, a new type of mud cutting machine in this embodiment includes an underframe 1, the underframe 1 is close to the mud molding machine 5, and one end of the underframe 1 connected to the mud molding machine 5 is provided with a Cutting ring 6, described cutting ring 6 is fixed on the underframe 1 through movable steel pipe 4, described movable steel pipe 4 is connected with motor 3, controls movable steel pipe 4 to do circular swing left and right by motor 3, is provided with in described cutting ring 6 The steel wire 7, the bottom frame 1 is provided with a stopper 2, which is used to control the swing angle of the cutting ring, the movable steel pipe 4 is a double-layer steel pipe, the outer steel pipe 9 is a hollow semi-circular ring, and a stopper is respectively arranged at both ends. plate, the inner steel pipe 10 is tangent to the outer steel pipe 9, the upper end of the inner steel pipe is provided with a baffle, and the inner steel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com