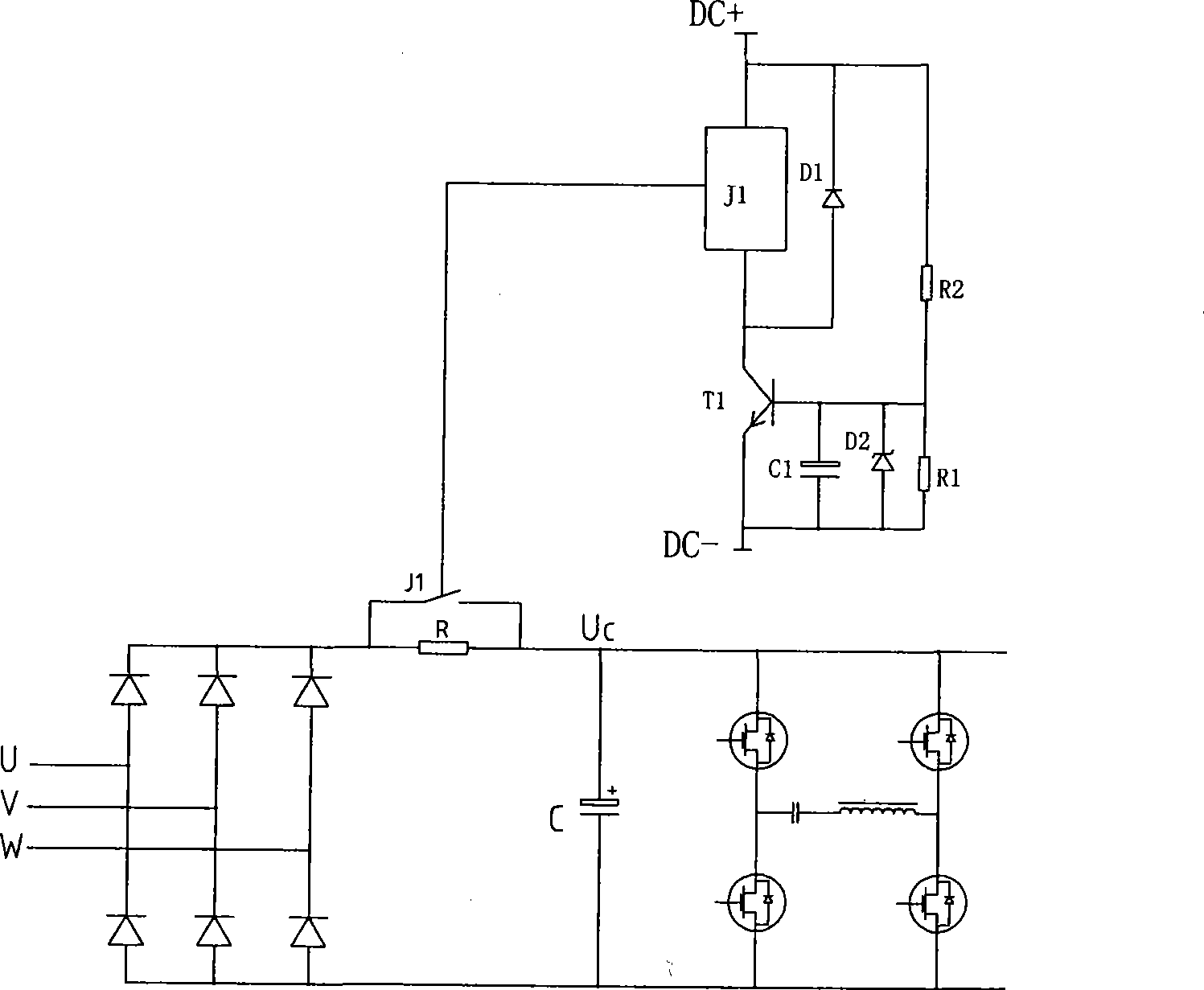

Soft starting plate for IGBT inverter manual metal-arc welding

An arc welding machine and inverter technology, applied in the field of IGBT inverter hand arc welding machine soft start board, can solve the problem of low safety of the main circuit, achieve the effect of simple optimization of circuit design and improve the overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

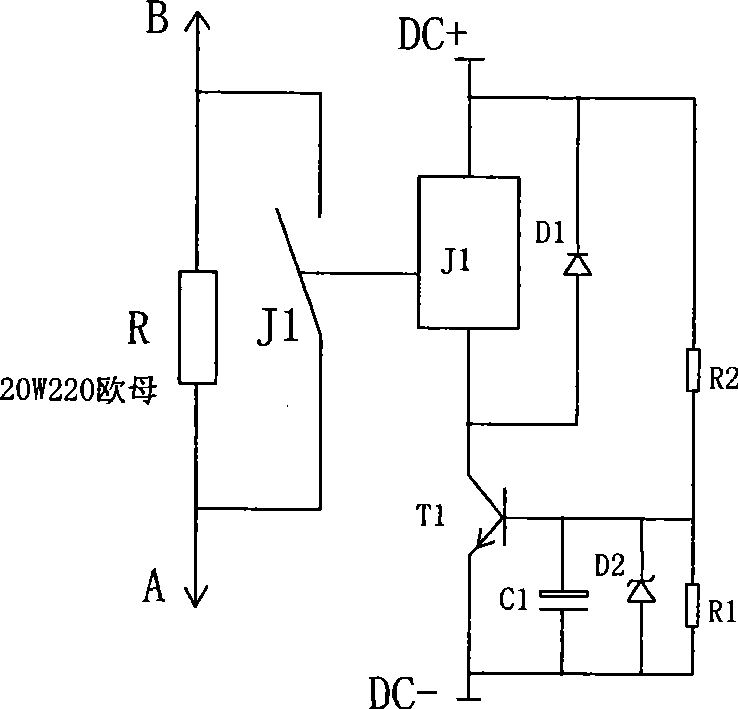

[0013] Further illustrate the concrete work process of the present invention below in conjunction with accompanying drawing:

[0014] Such as figure 2 As shown, the contact J-1 of the relay J1 is connected in parallel at both ends of the resistor R, one end of the relay J1 is connected to the collector of the transistor T1, the emitter of the transistor T1 is connected to the negative pole of the power supply, the capacitor C1, the diode D2 and the resistor R1 After being connected in parallel with each other, it is connected between the emitter and the base of the transistor T1; the other end of the relay J1 is connected to the positive pole of the power supply, and a resistor R2 is connected between this end of the relay J1 and the base of the transistor T1; Diode D1 is connected between both ends.

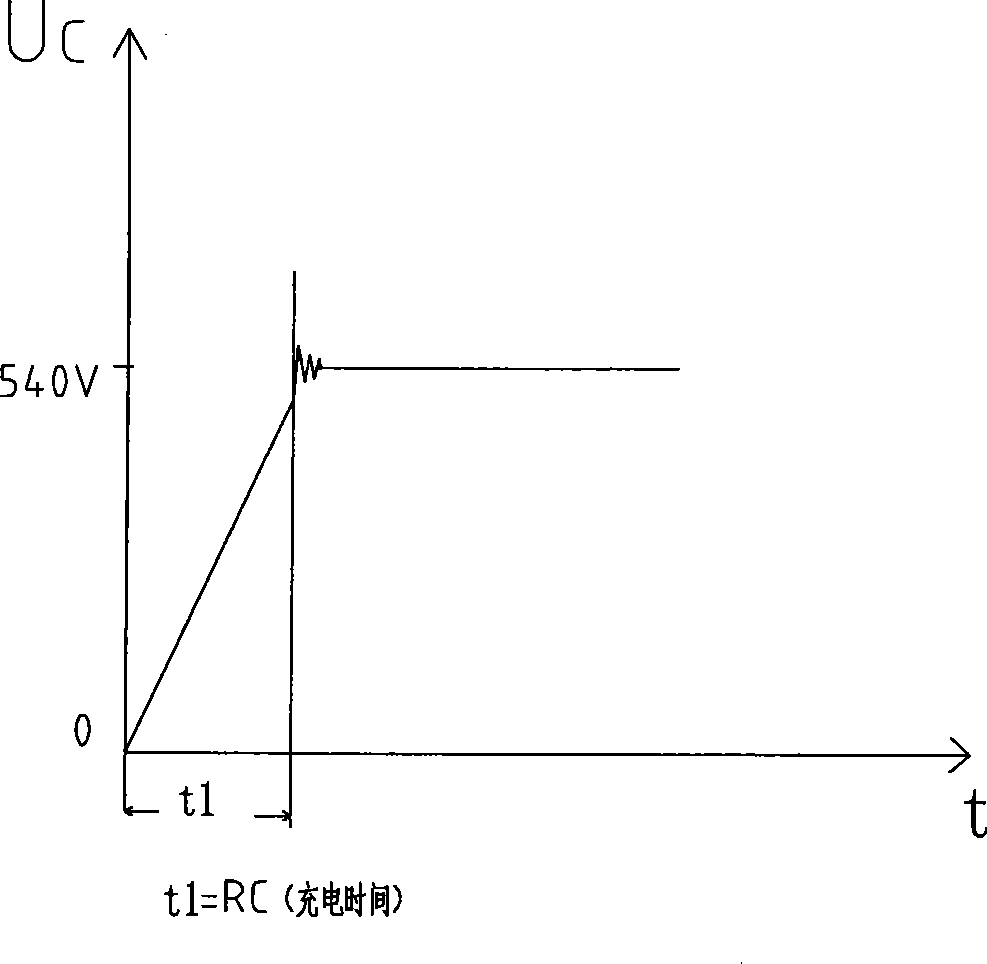

[0015] Its working process is: when the welding machine power is turned on, the main circuit and the control circuit are energized at the same time, and the A and B ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com