Covering and repairing method for broken lining plate of shot blasting machine

A repair method and shot blasting machine technology, which is applied in the field of shot blasting machines, can solve problems such as troublesome repairs and affecting production, and achieve the effect of improving the overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0013] The specific method is:

[0014] The specific method is:

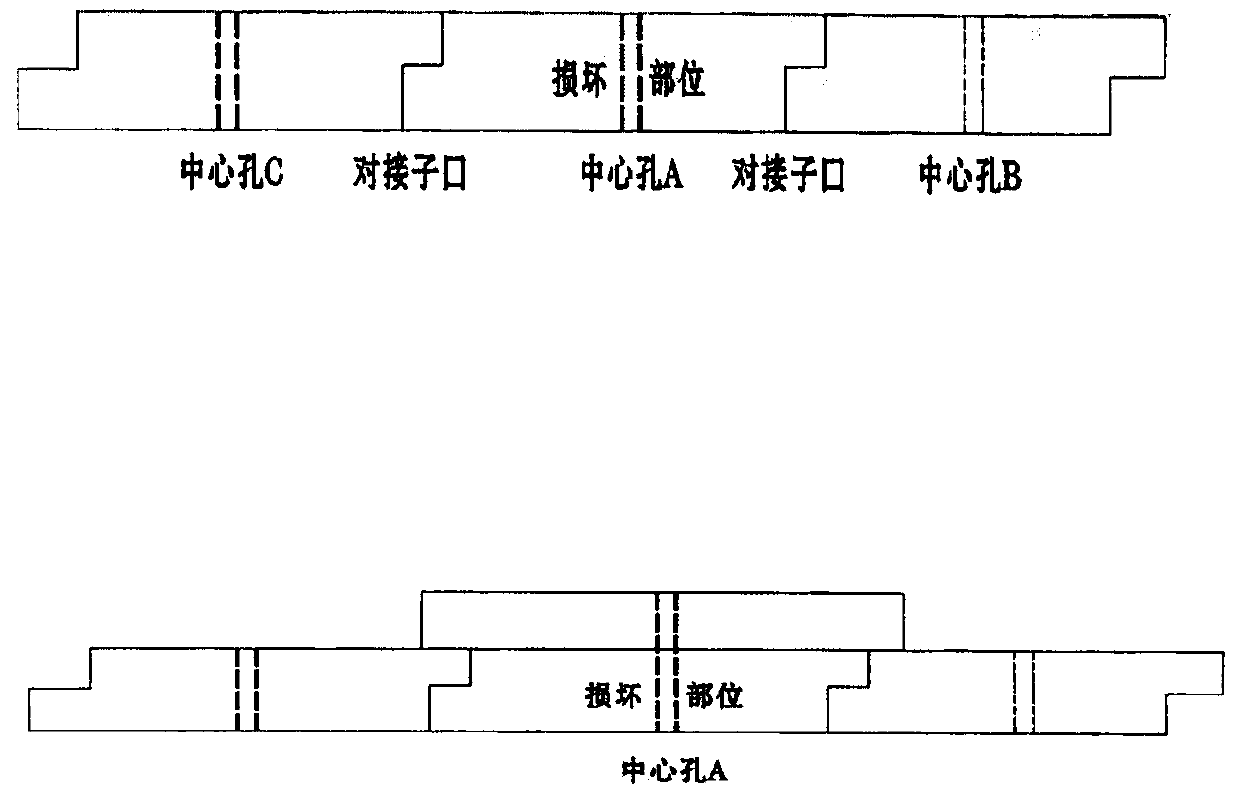

[0015] 1. After the liner is damaged, it is not necessary to remove the original old liner, but to cover the damaged part with a layer of high-carbon cast steel liner.

[0016] 2. When the liner is installed, the size requirements for the connection between the center hole and the spigot are very strict. High-chromium cast iron cannot be cut or polished. If the center hole is slightly deviated, the spigot cannot be connected. Although the hardness of high-carbon cast steel is above HRC60 , but it can be cut with plasma flame. Therefore, we do not cast slits to reduce the accuracy requirements for butt joints. Instead, we adopt the method of covering the joints around, see the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com