Hardfacing electrode for shielded metal arc welding for repair of deep-sea trenching plough, and preparation method and use method thereof

A technology of surfacing electrodes and trenching ploughs, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as insufficient hardness of surfacing electrodes, and achieve low maintenance costs, extended overall service life, and excellent wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Table 1: Example 1 sampling mass fraction (Zt%)

[0047]

[0048] A deep-sea furrowing plow repair surfacing welding electrode, its preparation process comprises the following steps:

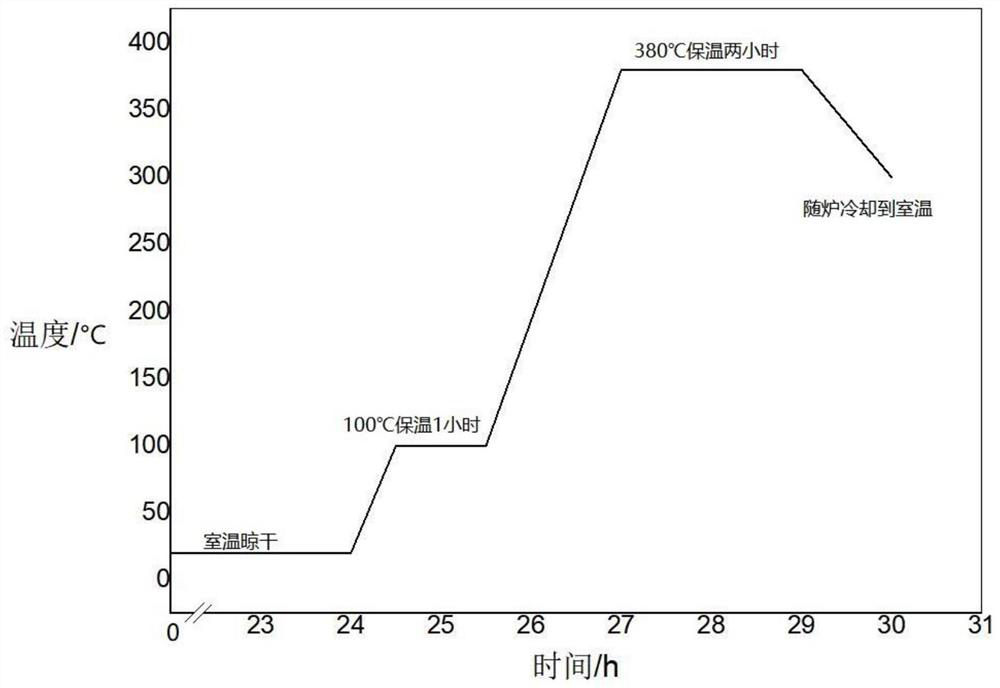

[0049] (1) Straighten the 1Cr13 martensitic stainless steel welding core with a diameter of 4mm, and use sandpaper to remove rust, clean and decontaminate; (2) Accurately weigh mineral and alloy powders with a balance according to Table 1, and pour them into a mortar at the same time Grinding and dry mixing until the powder has a uniform texture and consistent color; (3) Add water glass to the dry powder for wet mixing in small amounts and several times until the wet powder has a moderate viscosity and a uniform texture. Embodiment 1 preferred water glass modulus 2.9, Baume degree 47-48. (4) Spread the wet powder concentrically on the surface of the welding core, control the thickness to 2-3mm, and maintain good concentricity. (5) At room temperature, place the electrode vertically t...

Embodiment 2

[0055] Table 2: Example 2 sampling mass fraction (Zt%)

[0056]

[0057] A deep-sea furrowing plow repair surfacing welding electrode, its preparation process comprises the following steps:

[0058] (1) Straighten the 1Cr13 martensitic stainless steel welding core with a diameter of 4 mm, and use sandpaper to remove rust, clean and decontaminate; (2) Accurately weigh mineral and alloy powders with a balance according to Table 2, and pour them into a mortar at the same time Grinding and dry mixing until the powder has a uniform texture and consistent color; (3) Add water glass to the dry powder for wet mixing in small amounts and several times until the wet powder has a moderate viscosity and a uniform texture. Embodiment 1 preferred water glass modulus 2.9, Baume degree 47-48. (4) Spread the wet powder concentrically on the surface of the welding core, control the thickness to 2-3mm, and maintain good concentricity. (5) At room temperature, place the electrode vertically to...

Embodiment 3

[0064] Table 3: Example 3 sampling mass fraction (Zt%)

[0065]

[0066] A deep-sea furrowing plow repair surfacing welding electrode, its preparation process comprises the following steps:

[0067] (1) Straighten the 1Cr13 martensitic stainless steel welding core with a diameter of 4 mm, and use sandpaper to remove rust, clean and decontaminate; (2) Accurately weigh mineral and alloy powders with a balance according to Table 2, and pour them into a mortar at the same time Grinding and dry mixing until the powder has a uniform texture and consistent color; (3) Add water glass to the dry powder for wet mixing in small amounts and several times until the wet powder has a moderate viscosity and a uniform texture. Embodiment 1 preferred water glass modulus 3.0, Baume degree 47-48. (4) Spread the wet powder concentrically on the surface of the welding core, control the thickness to 2-3mm, and maintain good concentricity. (5) At room temperature, place the electrode vertically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com