Continuous air blast type strong wind warm blast furnace

An air-supplying and warming technology, applied in the direction of brick blast furnace, can solve the problem of high investment cost, and achieve the effect of saving investment, multiple functions and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

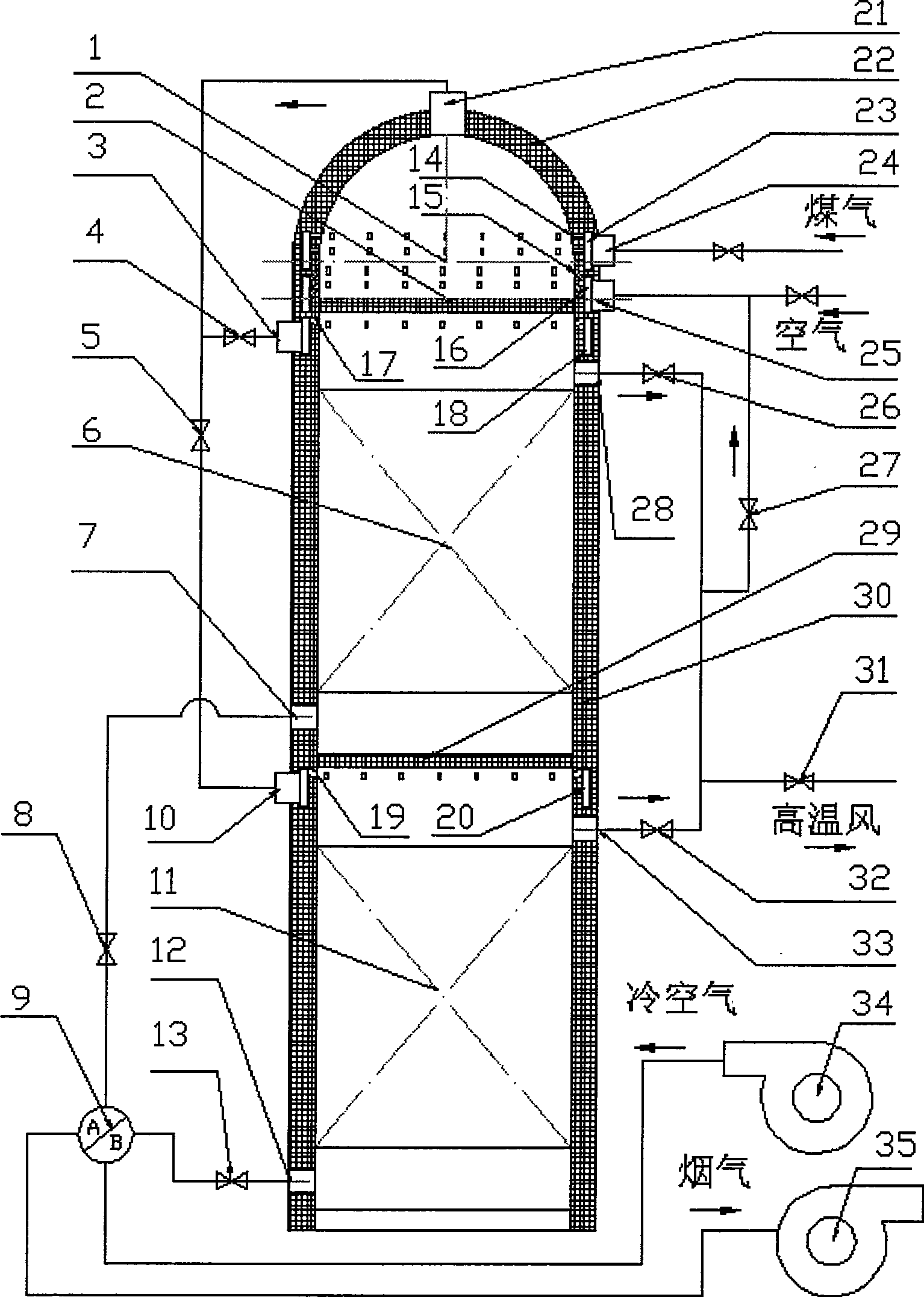

[0023] The specific embodiment of the present invention is as follows. The gas enters the combustion chamber through the gas inlet 24, the gas ring 23 and the gas nozzle 14, and 20-40% of the high-temperature wind passes through the pipeline of the valve 27 and mixes with cold air to be preheated to be hot air at 400-1200° C. and then passes through the air inlet 25, The air ring 16 and the air nozzle 15 enter the combustion chamber, and the two are mixed and burned in the combustion chamber. After combustion, the flue gas passes through the smoke exhaust port 21 on the furnace top, and the pipe is divided into two, one is connected with the valve 4 and the other is connected with the valve 5. The two valves are in the opposite state, one is open and the other is closed. When the upper checker brick 6 is in heat exchange with the flue gas, the pipe connected to the valve 8 passes through the flue gas, and the pipe connected to the valve 13 passes through the cold air. The valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com