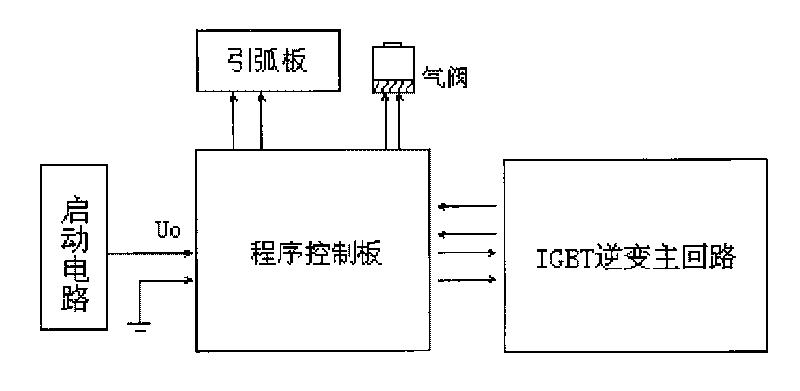

Welding staring circuit of IGBT inverted gas protective welder

A gas shielded welding and start-up circuit technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that the normal use time is not very long, and achieve the effect of improving service life and simple and optimized circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

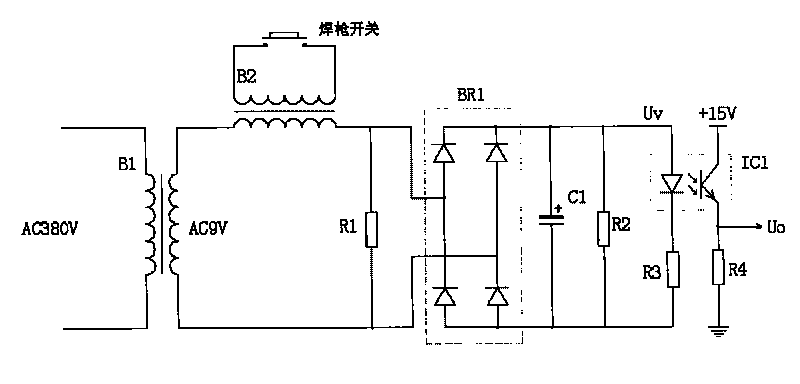

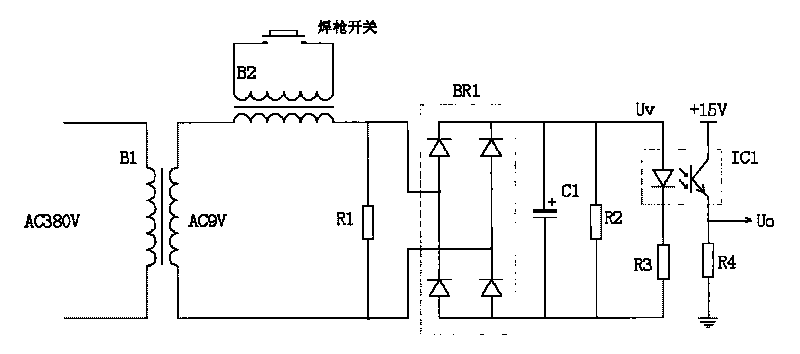

[0012] Such as figure 2 Shown: the primary of the control transformer B1 is connected to the industrial power supply AC 380V, the secondary is connected in series with the primary coil of the isolation transformer B2 and the first resistor R1 (2W / 51 ohms), the secondary of the isolation transformer B2 is connected in series with the welding torch switch, the The two ends of the first resistor R1 are connected to the two ends of the second resistor R2 (0.25W / 10K ohm) through the rectifier bridge BR1 and the filter capacitor C1 (25V / 470UF); the two ends of the second resistor R2 are connected to the input terminal of P521 optocoupler IC1 , the third resistor R3 (0.5W / 200 ohm) is connected in series between the second resistor R2 and the negative electrode of the optocoupler IC1 light-emitting tube, one end of the output end of the optocoupler IC1 is connected to the high level of the power supply +15V, and the other end is grounded through the fourth resistor R4. The voltage ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com