Energy-saving hydraulic system of electric forklift

A hydraulic system and electric forklift technology, applied in the field of hydraulic systems, can solve the problems affecting the reliability of hydraulic components, the work efficiency of the whole vehicle, the production constraints of large-tonnage battery forklifts, and the lack of energy recovery devices, and achieve simple, convenient and reliable electrical control. Simple, convenient and low-cost pipeline design and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

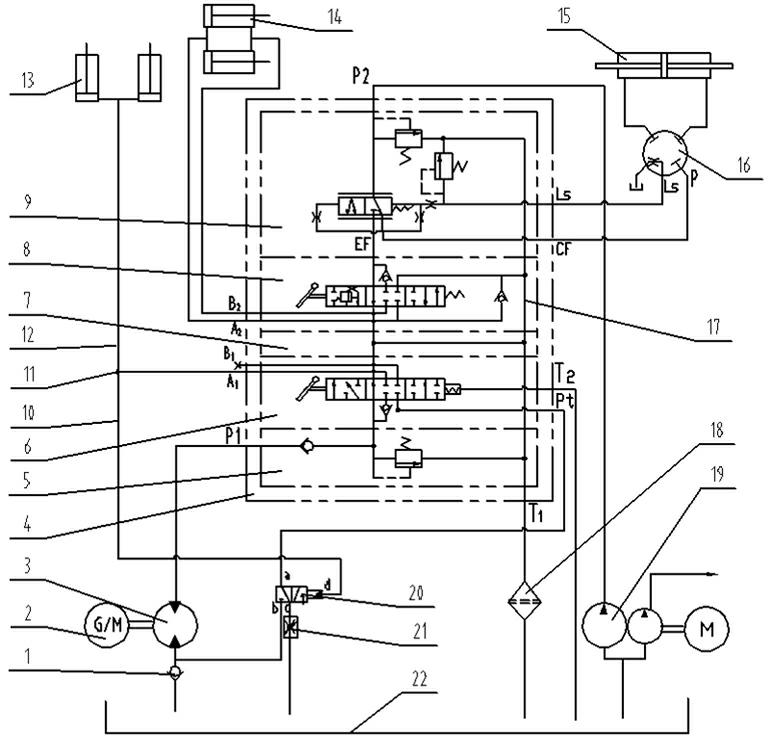

[0023] see figure 1 , an energy-saving hydraulic system for an electric forklift includes a check valve 1, a motor 2, an oil pump 3, a multi-way valve 4, a lifting cylinder 13, a tilting cylinder 14, a steering cylinder 15, a load sensing steering gear 16, and a double oil pump 19 , a hydraulic control sequence valve 20, a throttle valve 21, an oil filter 18, an oil tank 22, and pipelines connected to each other.

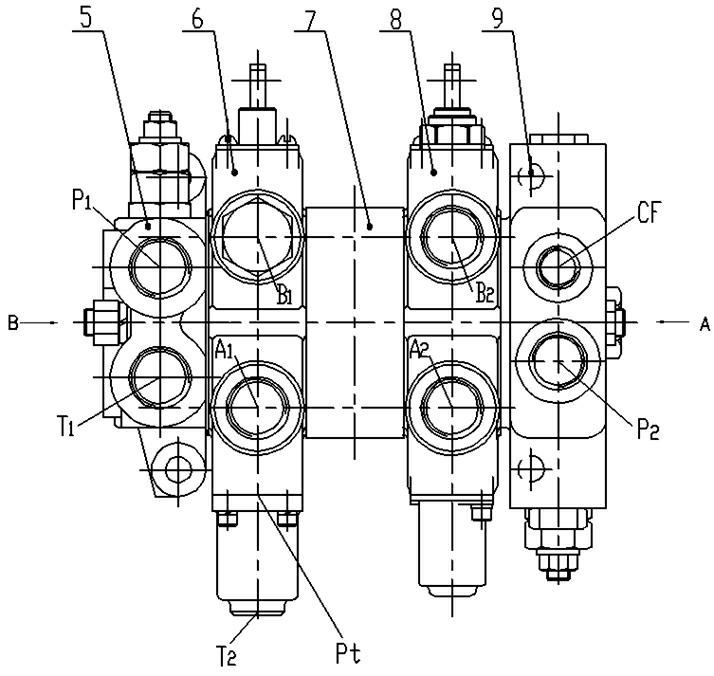

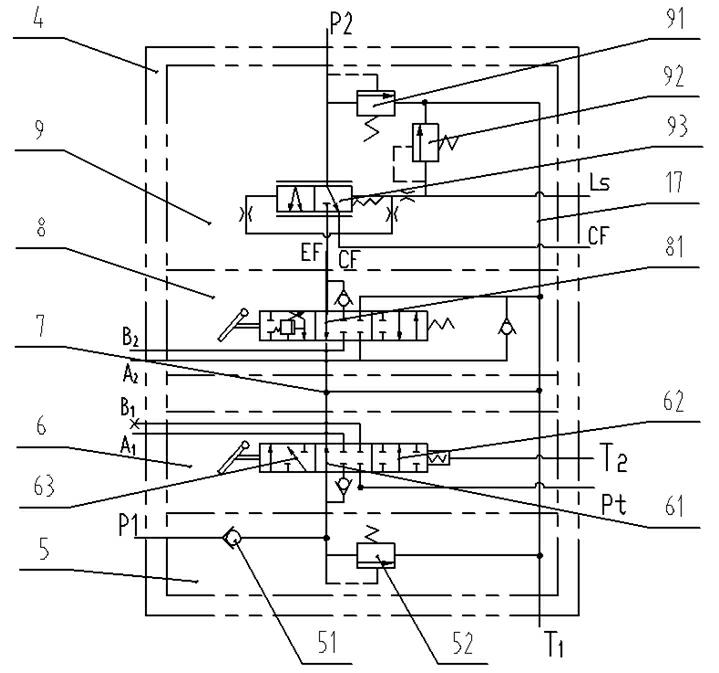

[0024] The multi-way valve 4 is a multi-way valve of the plate type, including an oil inlet and return valve plate 5, a lift reversing valve plate 6, an intermediate connection valve plate 7, an inclined reversing valve plate 8 and an oil inlet valve plate 9, and the The space is assembled together by bolt and nut connection;

[0025] The oil inlet and outlet valve plate 5 of the multi-way valve is provided with an oil inlet and outlet check valve 51 and a main safety valve 52, and the external oil port has P1 and oil return port T1; the lift reversing valve plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com