Interface layer reinforced aluminum alloy-silicon carbide double-base fiber composite material and preparation method therefor

A fiber composite material and silicon carbide-based technology, which is applied in the field of interface layer reinforced aluminum alloy-silicon carbide double-matrix fiber composite material and its preparation, can solve the problem of effectively reducing the porosity of ceramic matrix composite materials and reducing defects, which cannot be truly Give full play to the properties of ceramic matrix composites and alloy materials, without improving the interfacial compatibility of ceramic and metal dissimilar materials, and achieve the effect of improving interfacial compatibility, high stiffness and good fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

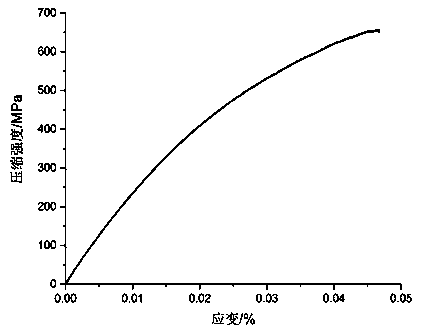

[0023] An interface layer reinforced aluminum alloy-silicon carbide double matrix fiber composite material with a density of 2.2g / cm 3 , composed of fiber preform, silicon carbide, interface layer and aluminum alloy, characterized in that the silicon carbide matrix is filled in the fiber preform to form a silicon carbide-based fiber composite material, and the interface layer is wrapped in silicon carbide-based fiber composite material. On the surface of the matrix and the fibers, the aluminum alloy is finally filled inside and on the surface of the silicon carbide-based fiber composite material; the fiber type of the fiber preform is carbon fiber, and the carbon fiber volume fraction is 40%; the interface layer is SiC; the The silicon carbide-based fiber composite material has a density of 1.5g / cm 3 , The open porosity is 30%.

[0024] A method for preparing an interface layer reinforced aluminum alloy-silicon carbide double-base fiber composite material, characterized in ...

Embodiment 2

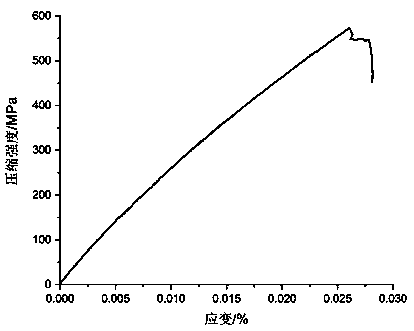

[0032] An interface layer reinforced aluminum alloy-silicon carbide double-matrix fiber composite material with a density of 2.45g / cm 3, composed of fiber prefabricated body, silicon carbide, interface layer and aluminum alloy, characterized in that the silicon carbide matrix is filled in the carbon fiber prefabricated body to form a silicon carbide-based fiber composite material, and the interface layer is wrapped in silicon carbide-based fiber composite material. On the surface of the matrix and fibers, the aluminum alloy is finally filled inside and on the surface of the silicon carbide-based fiber composite material; the fiber type of the fiber preform is silicon carbide fiber, and the volume fraction of silicon carbide fiber is 45%; the interface layer is Ni; the density of the silicon carbide-based fiber composite material is 1.6g / cm 3 , The open porosity is 30%.

[0033] A method for preparing an interface layer reinforced aluminum alloy-silicon carbide double-base f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com