Traction mechanism

A technology of racks and traction parts, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

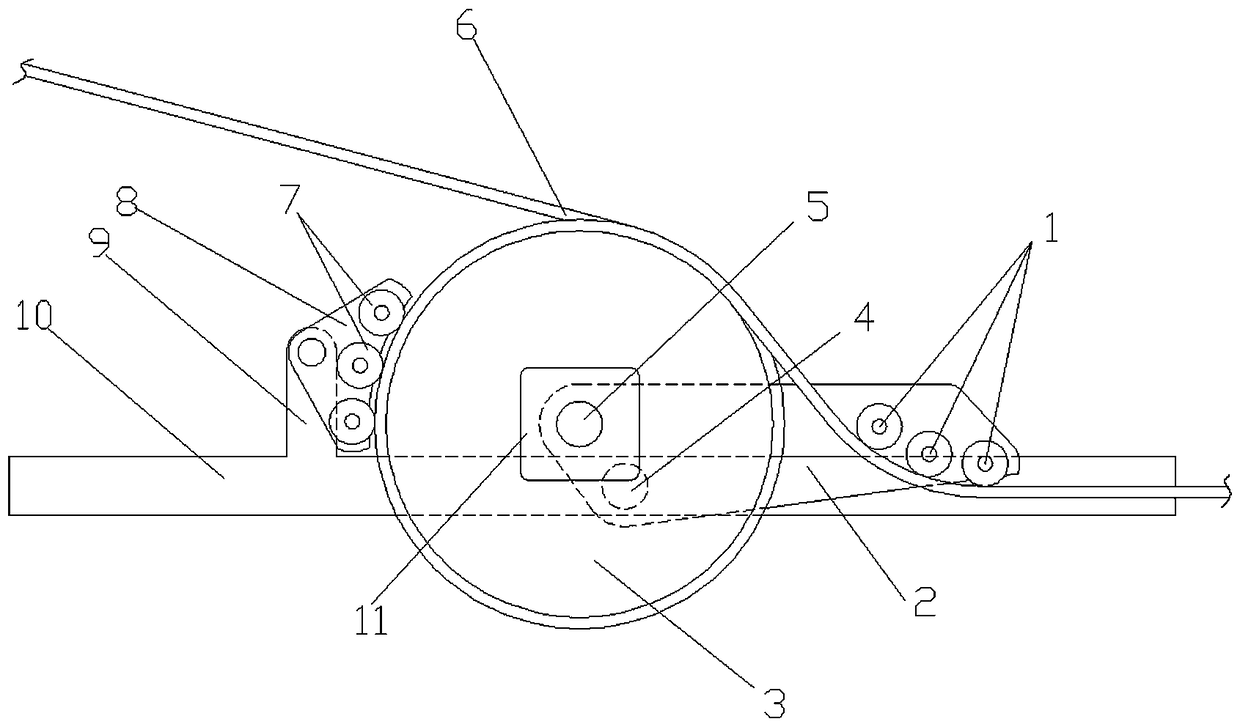

[0016] An example of a stretch mechanism figure 1 Shown: the frame 10 is included. In this embodiment, the frame is a beam structure with a length extending in the left and right direction. The frame is rotatably equipped with a rocker arm 2 with a rotation axis extending in the front and rear direction. Item 4 in the figure represents the rocker arm 2 Rotating shaft, the rocker arm is rotatably equipped with a winding pressure roller 3 for winding in one end of the corresponding traction member 6 and winding out at the other end. Item 5 in the figure represents the rotation shaft of the winding pressure roller 3, and the rotation axis of the winding pressure wheel The rotation axis of the arm is arranged in parallel, and the rotation axis of the winding pressure wheel is on the left side of the rotation axis of the rocker arm. In this embodiment, the winding pressure wheel is provided with a winding wheel groove, and the radius of the winding pressure wheel is four times the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com